Autogrow IntelliDose User manual

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 1

IntelliDose

Installation and User Guide

•Doses up to 9 part Nutrients, additives and pH

•Measures Conductivity, pH, Temperature

•Displays EC, CF, TDS, oC, oF, pH

•Connect to the via Internet Cloud Environment (subscription required)

•Variable ratios for nutrient part (change from vegetative to generative)

•Auto schedule of nutrient ratios and EC’s

•Proportional Dosing (for rapid dosing between irrigations)

•Direct drive dosing pumps (keeps costs down)

•Irrigation with day/night control –precision timer

•Day/Night EC levels

•Water level control –to lower EC

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 2

Contents

Quick-start page with helpful hints

Section A

IntelliDose® Hydroponic Doser

Section B

Settings via IntelliGrow

Section B2

Settings via IntelliDose keypad

Section C

Calibration Instructions

Section D

Dosing Settings

Section E

Proportional dosing (default OFF)

Section F

Sequential dosing (default ON)

Section G

Installation

Section H

Maintenance

Section I

Fault finding

Section J

Specification

Section K

Advanced Irrigation Features

Section J

Compliance Declaration

Important notice:

When using automatic dosing equipment, all chemicals must be in a form diluted

state, especially acids and alkalis.

Acids and alkalis should be diluted to a maximum strength of 2% or less.

We recommend diluting your nutrients 1-part nutrient to 4 parts water while

dialling in your dosing settings.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 3

Quick start

This is not a substitute to reading the relevant sections of the manual but is included to

emphasise some important and useful points.

Install the controller to one side of the mixing tank where it will not be exposed to splashes and

vapours. Remember, the sensor leads must be able to reach the sample pot which should be

mounted just above the top of the mixing tank. See section G for detailed installation notes.

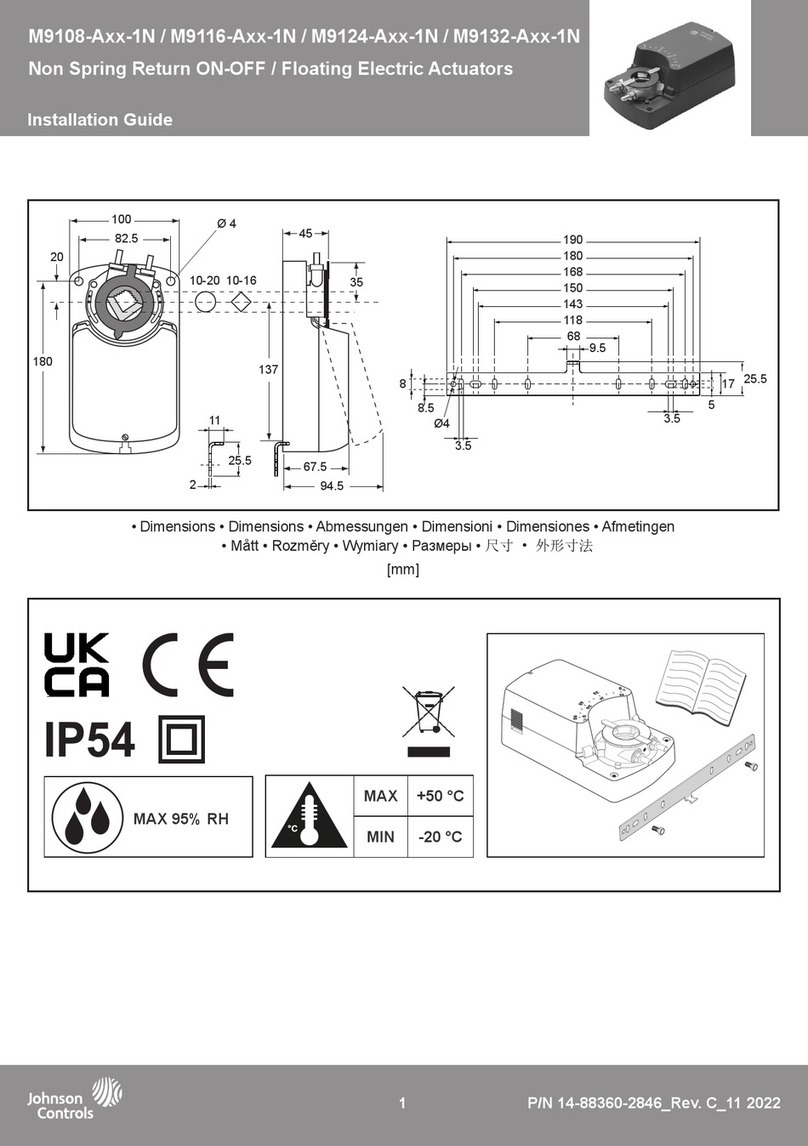

Typical installation using peristaltic pumps

HINTS:

•Mount sample pot just above top of tank as many small pumps have low head

pressure capability

•Mount IntelliDose away from spray and humidity from tank and stock solution,

preferably just outside grow room

•Adjust the valve on inlet pipe to the sample pot to achieve a steady flow without

excessive turbulence or air bubbles in the sample pot

Clean the EC sensor and calibrate all sensors before use –See section C for details

Fill stock tanks and mix tank with plain water and run for a day to check for leaks and observe

operation is correct.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 4

IMPORTANT:

When using an automatic doser, the stock solutions and acid/alkali must be diluted. This

is particularly important if a small mixing tank (e.g. under 1,000L/250gal) is used.

The acid or alkali for pH adjustment must be diluted to no more than 2%

You may need to experiment with the dilution rate of the nutrients so that a 3 to 8 second dose

results in a TDS change of 50ppm (0.1EC or 1CF) and for pH a 3 to 8 second dose results in a pH

change of about 0.1pH. In any event, the acid should be diluted to below 2% strength to ensure

that it does not react adversely with your nutrient and this will also increase the life of the

peristaltic tubing.

It is also important that the tank is continually stirred while dosing and there is a continuous

gentle flow through the sample pot. If the sample pot is mounted too high there is a danger of

the flow ceasing if the pump loses pressure (head) for any reason such as wear or partially

clogged input filter.

IntelliGrow

With IntelliGrow, your Intelli devices are accessible via your web browser so you can control

your growing operation remotely from your phone, tablet, or computer. IntelliGrow gives you

complete visibility 24 hours a day and enables you to manage multiple locations from the

comfort of your office, using a single sign on.

Automatically manage your nutrient and pH levels, set remote alarms and data log your

progress with this one simple machine.

Please visit https://autogrow.com/our-products-solutions/intelligrow for more information.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 5

Section A - IntelliDose® Hydroponic Doser

The IntelliDose hydroponic doser is the most advanced and user friendly doser on the

market. It has a wide range of possible applications which we discuss briefly in this section.

To keep the user interface as simple as possible, only the readings and settings relevant to

the selected features are displayed on the controller’s LCD. For more advanced options, log

in to https://intelligrow.autogrow.com/

Selection of units

You may select either EC, CF or TDS (ppm) units for the nutrient strength and either degrees

C or degrees F for temperature. The acidity or alkalinity is always measured in pH. In this

manual, we use EC (electrical conductivity) to denote either EC, CF or TDS. The date format

is selectable between mm/dd/yy and dd/mm/yy formats.

(The TDS standard used for this controller is EC x 500 but it is also possible to select EC x 640

and EC x 700)

Mixing nutrients - IMPORTANT - PLEASE READ THIS CAREFULLY!

When using any automatic doser, it is important that the nutrients and acid/alkali are diluted

to 2%. The instructions on many dry powdered nutrients, tell you to prepare the stock

solutions to quite a concentrated level (100:1 or more). Liquid nutrients are also very

concentrated. For a small mixing tank, this will be too strong and even if very short doses are

given the system will overshoot. If using powdered nutrient, mix them into water so that for

each 1Kg/2.24lbs of powder you obtain at least 20L/5gal of solution. Liquid nutrients should

be diluted with water to make up at least 5 times their original volume. Acids and alkalis

should be diluted to be less than 2% strength. If using strong acids, always wear goggles,

gloves and add the acid to the water then stir well.

When you have the dilution right, you should get a 0.1 mS/cm change in EC with a 5 second

dose time of A and B solutions. In a similar way, the pH should change by about 0.1pH with a

5 second dose time of pH adjuster solution. If it changes by less, that is fine, but if it changes

by more, you will need to dilute the solution further.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 6

One part or two-part dosing

For 1-part dosing, only one dosing pump is used to add nutrient to the mixing tank. When 2-

part dosing is selected then two dosing pumps will be used to add part A and part B stock

solutions. In this case it is sometimes found the part A and part B do not dose at exactly the

same rate (one tank empties quicker than the other). There are a number of reasons why this

may occur including different pipe arrangements, filters partly blocked, tanks or dosing valves

mounted at different heights and even the difference in specific densities of the stock

solutions. To compensate for this, you may adjust the two dose rates electronically by

reducing either A or B dose rates below 100%. For example, if you set A at 100% and B at 95%

then B will dose a little less than A each time that a dose is added to the tank. This is set by

trial -and-error starting with both A and B at 100%. (Always leave one at 100% and reduce the

other)

Multi-part dosing

With 3 to 9-part dosing, the ratios may be varied to suit a feeding schedule as recommended

by the nutrient supplier. In this case the ratios between all the nutrient parts can be

individually varied. A schedule may be added with IntelliGrow which will automatically vary

the nutrient ratios and EC as required. This can be used to gradually and automatically

change the mix from vegetative to generative whilst at the same time gradually changing

the EC. Note: On each date specified, the settings change to the new values and then stay

at these settings until the next date schedule is reached. Once the last entry is reached the

settings just stay at those values permanently. It is important to note, that when using

variable ratios for various nutrient parts, the dose time must be set to be long enough that

the part with smallest ratio still gets a dose of one second.

Sequential dosing (default ON)

This causes the dosing pumps or valves to activate in sequence, one after the other and

allows high current valves or pumps to be connected to the unit without fear of

overloading the controller or its power adapter. If in doubt about the current required to

drive the pumps, always select sequential dosing. If 3 or more nutrient parts are selected

sequential dosing is enforced to avoid damage to the controller.

Proportional dosing (default OFF)

This causes the dose size to automatically vary in proportion to the error, it is useful when

you want the tank to dose up quickly. If this is selected, then the dose size is specified as both

a maximum and minimum dose time. The controller then looks at the size of the error and if

large, will give large doses, as the EC or pH setpoint is approached, the controller will give

smaller doses. This is useful in irrigating (drip) systems that do not re-circulate as it allows

rapid dosing after each irrigation occurs. This feature is not available with more than a 2 part

mix.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 7

Different EC for day and night

This feature is useful for crops needing a weaker solution during the heat of the day and a

stronger mix when it cools at night time. (e.g. to help prevent tip burn in lettuce) The user

can define when “day” starts and ends and this does not have to align in with actual day

time i.e. you can set day to start at 11am and end at 3:30pm if you wish. Note: The controller

has capability of strengthening the mixture by dosing and weakening the mixture by adding

water.

Automatic addition of water

By installing a mixing tank with two water level ball valves, one at a low level and other at a

high level it is possible for the controller to dilute the nutrient tank by adding water. This is

done by operating a solenoid valve in line with the high-level valve. See diagram on page 19.

This function is mainly of interest to lettuce growers.

Irrigation

This allows a pump to switch on periodically for a set time to irrigate plants in pots or bags.

The irrigation can be specified to operate in “day only” mode or it can have a different

interval set for day and night. For example, you could set it to irrigate for 4 minutes every

1 hour 35 minutes during the day and for 4 minutes every 5 hours at night (or not at all

during the night). Alternatively, it can be set to come on once every day at the same time.

This could be used to operate lighting (instead of irrigation) for indoor crops. For more

advanced irrigation settings, See section K.

The IntelliDose sends a 24VDC signal to activate the irrigation pump. If you are in North

America and have a 120V irrigation pump, you can utilize an Autogrow Twin Relay Box to

run your pump from the IntelliDose. For all other regions, you can simply purchase an

Autogrow Twin Relay Box to run your irrigation pump, please ask your local distributor.

If your pump is powered by 220V mains power, you will need to use an interface relay to

connect to the IntelliDose (please call your distributor for more information).

Fail safe dosing

Dosing may be inhibited if any of the following conditions are detected.

•EC is measured less than 0.1 or greater than 6

•pH is measured less than 4.5 or greater than 8

Alarms

The alarms can be enabled on the controller buzzer or to text/email you when using

IntelliGrow. Each of these can be silenced or enabled. Any enabled alarm will sound when a

relevant reading deviates outside set limits.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 8

Outputs

The outputs voltages for dosing and irrigation control are all dependent on the power supply

adapter used. The IntelliDose is supplied with a 24VDC power supply.

Power supply

The controller requires a power supply of 24V DC. Note: The outputs are limited to a current

of 1.2A inductive load and 3A resistive load. The power supply should be sized according to

the maximum load that can be applied at any one time. The maximum total draw at any one

time should not exceed 4A.

Getting Started

Follow the installation instructions in section G and when everything is installed and

connected do the following.

Switch on the power. Check that the power light on the front panel is on and that the LCD

display has some information on it.

For more information on the IntelliLink:

https://autogrow.com/products/intellilink

Alternatively, if you want to use a dedicated computer as a gateway at the grow site, you

can connect the IntelliDose directly via a USB cable.

Windows:

Windows 32-bit

Download il-finder 32-bit

Windows 64-bit

Download il-finder 64-bit

We recommend using a 24VDC solenoid for irrigation.

We recommend you use the Autogrow IntelliLink gateway device to connect

your controller directly to your network.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 9

Here are the instructions to activate your IntelliGrow Subscription

•You will need to first register for a new account

here https://intelligrow.autogrow.com/

•Login using your account details and connect your devices as per the picture below

•Click your profile in the top right of the page and select “Payments” from the menu.

•Click on IG Starter/Standard Annual “Buy Now” button.

•Fill in your details in the Order Summary and click subscribe

User Email Address

User Email Address

or

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 10

Section B –Settings using IntelliGrow website

ORDER OF SETTING UP A NEW CONTROLLER

1) Visit https://intelligrow.autogrow.com/ to create account

2) Connect your IntelliDose to your gateway (computer or IntelliLink)

3) Ensure your IntelliDose shows as connected to your IntelliGrow account

4) Set the configuration of the controller to match the physical equipment. Print the wiring

diagram and connect the dosing pumps accordingly.

5) At the controller, connect both the EC (TDS) and pH probes

6) Calibrate both EC (TDS) and pH probes

7) Enable all functions that you wish to use

8) Check the time/date on the controller

Configuration

First, under the General tab, select your temperature units, date format, EC preference and name

your device.

Next, under the Functions tab, select the number of nutrient parts you wish to automatically dose.

You have a total of 9 outputs, the more you use for nutrients, the less will be available for pH dosing

and irrigation. Having selected the number of nutrients to be dosed, continue by selecting the pH

dosing required, then whether irrigation output is required.

The wiring diagram is dynamic and will change according to your output configuration. Every time

an output designation changes, you must check your wiring diagram to confirm your wiring is

correct. This is available via IntelliGrow, under Functions.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 11

If you wish to have a different EC (TDS) for day and night, this can also be selected. If selected, you

can also choose to add water automatically to reduce EC.

As soon as you have used all the 9 available outputs, the options will appear greyed out and will be

un-selectable. The only way to select them is to go back and deselect some previous choices.

You can select “Use Scheduled Settings” if desired, see page 12. This gives you the opportunity to set

up a complete growing schedule by specifying the nutrient ratios and EC for each stage of growth.

This schedule is easy to modify if the plant growth is slower or faster than expected, you can make

alterations at any time. It is possible to save the schedule to disk so that it can be used for future

crop cycles.

In the Advanced section, you can select proportional dosing if required. This will only work

satisfactorily on systems that irrigate large quantities of water from the tank and therefore need very

rapid dosing to get the EC and pH back to correct levels. If this is not the case, then deselect this

option. It should only be used with 1 or 2 part mixes, and where you intend setting the dose interval

to zero to achieve continuous dosing. This is sometimes used on very large irrigated systems so that

continuous dosing occurs while irrigation takes place and fresh make-up water is entering on a

continuous basis.

Sequential dosing should always be selected unless there is a good reason not to. This will allow you

to dose different nutrients and additives at different rates.

The fail-safe disable for dosing should always be enabled for safety. These prevent dosing if the

controller suspects that a probe has become faulty or if the EC/pH are too far from your set points.

The “Save current settings to disk” and “Restore settings from disk” do exactly that. They fetch all

settings from the controller and store them in a file on your computer's hard drive. This allows you

to quickly reset the controller to a previously saved setup that was known to work well, for a

particular season.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 12

Dose Times & Intervals

Dose times and interval are set by trial and error. The smaller the reservoir, the smaller the dose times

need to be. The strength or concentration of your stock solutions will also affect the dose time setting.

The stronger the stock solution, the shorter the time the pump runs. If you are using a small reservoir

tank you must ensure that your stock solutions are very dilute.

Ideally, you are trying to achieve a dose time such that the EC(TDS) goes up by about 0.1EC (50 ppm)

for each dose. If you need to set the dose time to a very small number to achieve this, then you need

to dilute the stock solution. The minimum time that any pump should run for is 1 second. If at any

stage you have a ratio for one of the nutrient parts set for 20%, then the minimum dose time has got

to be at least 100/20 = 5 seconds. This is because 5 seconds corresponds to a 100% dose and 20% is

only 1/5th of this so the pump for this nutrient part will only run for 1 second. The process is similar

for pH dosing where you are trying to achieve a change of 0.1pH for each dose.

The dose interval is set to allow time for a dose to fully mix in before the controller makes the

decision as to whether another dose is required. Normally set to 1 minute for a small tank and up

to 10 minutes for very large systems.

Every system is unique and will have its own requirements. If you would like help to determine the

pH Raise or Lower

For most growers, pH lower is the most common requirement. Depending on water source,

nutrients and plant growth, you may find you need to use pH Raise at certain growth stages. The

IntelliDose can be configured to run no pH adjuster, pH raise, pH lower or both. If you choose to run

both, you will be able to wire up a peristaltic pump to each raise and lower, but the system will only

be able to dose in one direction at a time. When you need to change direction, you simply login to

your IntelliGrow account and switch pH from raise to lower or vice versa. On the controller keypad

navigate to Menu > Configure > Advanced > pH Output Setup.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 13

Scheduling

To set up the scheduling function, scroll down the page to Functions and tick the "Use scheduled

settings".

After saving the settings, you will use the drop-down menu to access your Set Points. Please note, if

scheduling has been selected, then settings like the nutrient set points and nutrient dose ratios will

appear “greyed out” on the home page as they are derived from the entries on the schedule tab and

cannot be altered here.

If you need any help with setting Schedules, please contact Autogrow at support@autogrow.com

and one of our experts will help you to build your perfect feed schedule.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 14

History

This history screen allows you to graphically view all data logged from the controller.

This is very useful for diagnosing problems.

The pop-up calendar allows you to easily view records from previous days, months or years. The

Options tab allows you to customize your history screen to show only attributes and functions

required for your system. Once you have customized your history screen, you can save the settings

to disk to be able to pull it up quickly in the future.

Export the data

You have the option to export the data as a .csv file if desired.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 15

Section B2 –Settings using IntelliDose Keypad

Though you can set most everything on the controller itself via the keypad, the Scheduling, Wiring

Diagram and History features are only available on IntelliGrow. The calibration of probes can only be

completed via the keypad.

The two keys at the bottom of the display are “soft keys”. This means their function at any time, is

shown on the screen above them. After switching on, you will see the right-hand key has the label

“menu” on the LCD above it and the left-hand key is unused at this point. To the right of the LCD

screen are two arrow keys. Used for moving up or down through the menus, and when in a screen

which allows you to edit a numeric value, they are used for increasing or decreasing the values. They

are also used to select between different options.

On first pressing the “menu” button, you will see yourself in the main menu. Use the down arrow

to move down and you see the following items

DOSING

CALIBRATION

OVERRIDES

IRRIGATION

ALARMS

CLOCK

CONFIGURE

If you wish to make a change to, e.g. irrigation timings, move down to irrigation and then press

“enter” to enter the Irrigation sub-menu. Now by pressing the down and/or up arrows move

through this sub-menu to see the item that you wish to change, press enter to access this item.

After making any changes the soft keys will allow you to either save the new setting or to cancel

and exit out of that screen.

The setting order is the same as when using IntelliGrow and the settings that you will access are also

the same, we suggest you use the previous pages on IntelliGrow settings, to guide you through the

setting procedure.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 16

Section C –Calibration Instructions

Calibrate EC sensor

•Clean the face of the probe. Remove the shroud from the end of the probe and use a little

kitchen liquid scouring cleaner such as “Jif" or "SoftScrub” on a clean “Scotchbrite” nylon

scouring pad. Alternatively, use 600 grit wet-and-dry paper with the cleanser. Use a circular

motion to scour the face of the probe and then rinse well in running water. Do not touch the

face of the probe with your fingers, shake off any residual water.

•Replace the shroud and then place in the calibrating solution. The solution supplied has an

EC of 2.77mS/cm. To ensure the IntelliDose calibrates properly, you will need to use

2.77mS/cm solution to calibrate. Allow about 5 minutes for the temperature compensation

to fully stabilize, press the menu button to reach the Calibration screen, press “Enter” to get

to the Calibrate sub-menu, press menu to step through this sub menu until you reach the

“Calibrate EC” screen. Press “Enter” to get into the “Calibrate EC screen”.

•Press either the Up or Down arrow keys, to get the calibrated reading to correspond with

the Standard calibrating solution (2.77mS/cm,). When this is achieved, press the save

button.

Calibrate pH sensor

•The glass bulb at the end of the pH electrode should be shiny and clear. If necessary,

clean the glass bulb at the tip of the sensor with a very soft “child’s” toothbrush or a

special cleaning tool with a little liquid dish washing soap. The bulb is very delicate –

TAKE CARE.

•Rinse thoroughly in water and then place in the pH 7 buffer solution. NOTE: YOU MUST

ALWAYS CALIBRATE AT pH 7 BEFORE pH 4.

•Allow a few minutes for the reading to stabilise, press menu button to reach the Calibration

screen. Press Enter to get into the Calibration sub-menu, “Enter” the Calibrate pH 7 screen.

Press the up and down arrows until the reading matches the calibration solution (within +/-

0.1). Press “Save” to store the calibration.

•Rinse the probe and place in pH 4 buffer solution. Allow to stand for at least 5 minutes until

there is no further change in the pH reading. Use the Menu and Enter keys to navigate to the

Calibrate pH 4 screen. Press the up and down arrows to get the calibrated reading to match

the calibration solution (within +/-0.1) and then press “Save” to save the calibration and exit

from that screen.

The EC probe should be cleaned regularly and calibrated every other week. The pH probe should

be calibrated weekly. In addition, it is advisable to use a hand-held meter to check the EC and pH

every day. If ever the hand-held instrument and controller readings differ, then all probes should

be cleaned, checked and recalibrated.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 17

Section D –Dosing Settings

Best dosing accuracy is achieved with longer dose times. If any ratios of a multi-part mix are set to

a short dose time, then it is important to ensure dose time is still above 1 second.

For example, a dose time is set to 5 seconds, and one part is set to a ratio of 10%. This means that a

ratio of 100% = 5 seconds, a ratio of 10% will equal only ½ second, an insufficient time for a pump to

run. The solution is to increase the dose time to 10 or 20 seconds. At 10 seconds the 10% component

will dose for 1 second (just long enough but still not as accurate). At 20 seconds a 10% component

will dose for 2 seconds (which will be more accurate).

However, you may see each of these larger nutrient doses increase the EC by more than the desired

0.1 EC (50ppm). The only solution to this is either dilute the stock solutions or use a larger reservoir

tank or a combination of both. If diluting stock solutions, it is important to dilute them all to the same

ratio. E.g. 1-part nutrient to 3-parts water (makes a 25% solution). This would result in each dose

causing the EC to rise by ¼ of its previous value.

Another approach is to dilute only the nutrient parts that require the lower ratios. For example, a

recipe recommends 100:50:10. If the dose time is set to 5 seconds then part A would dose for 5

seconds, part B for 2.5 and part C for only 1/2 second. By diluting part C in water with 1-part C to 4-

parts water, it would reduce its strength to 1/5th of the original. Then you would schedule 100:50:50

which will be more accurate.

In “Configure” on the controller or “Functions” on IntelliGrow, select how many nutrient parts you will

be using. Then, choose whether you will be using pH raise, pH lower or both. Most frequently, pH

lower (acid dosing) is used. If you see the pH continually drifts down below 5.5pH, change this to pH

raise, ensure you have a dosing pump connected to the pH raise output and to a stock tank containing

pH raise (alkali).

Set desired EC & pH Set Points - On IntelliDose Keypad

•Navigate Menu > Dosing > EC > EC Set Point

This should be set so that each dose raises the EC by 0.1mS/cm (1CF or 50ppm)

•Navigate Menu > Dosing > EC > EC Dose Time

The amount of time the pumps will run when a dose is activated.

•Navigate Menu > Dosing > EC > EC Dosing Interval

Time taken for each dose to mix in and for the EC and pH readings to stabilise. For a small system, 2 or

3 minutes is typical. Larger systems may require 10 minutes or more. Note that dosing will not occur

unless the reading has been below the setpoint continuously for this amount of time

•Navigate Menu > Dosing > pH > pH Set Point

The pH dose time so that each dose alters the pH by about 0.1pH

•Navigate Menu > Dosing > pH > pH Dose Time

The amount of time the pumps will run when a dose is activated.

•Navigate Menu > Dosing > pH > pH Dosing Interval

Time taken for each dose to mix in and for the EC and pH readings to stabilise. For a small system, 2 or

3 minutes is typical. Larger systems may require 10 minutes or more. Note that dosing will not occur

unless the reading has been below the setpoint continuously for this amount of time

Set desired EC & pH Set Points - On IntelliGrow

•Set the desired EC and pH set points on the home screen.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 18

Section E –Proportional Dosing (default OFF)

Proportional dosing allows rapid dosing toward the set point. A maximum and minimum dose time

must be entered. The maximum time should be set so that a dose of this size would raise the EC from

its raw water value to 80% of the setpoint value in a single dose. The minimum dose time should be

set to achieve a rise in EC of 0.1mS/cm (CF=1, ppm=50). The controller will then select the most

appropriate dose time within this range, depending on the measured EC. This means that when

starting with a tank of pure water, the controller will make one very large dose followed by smaller

doses as the setpoint is approached. Note that proportional dosing is not available for use with 3 (or

more) part mix.

Section F –Sequential Dosing (default ON)

By selecting sequential dosing, the dosing outputs will operate in sequence, one after the other. This

allows a small power supply to be used with dosing devices that draw a heavy current. For example,

small peristaltic pumps typically draw 1.2 Amps at 24V DC. If three-part dosing is used, and three

pumps allowed to come on at the same time, the power supply would need to be rated at about 4 or

5 Amps. Selecting sequential dosing a 2 Amp supply could be used.

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 19

Section G - Installation

The IntelliDose controller should be installed in a cool, dry place out of direct sunlight.

Remove the screws holding the back, fit the mounting feet, then screw to the wall. If using the dry

wall (plaster board) anchors, use the longer screws supplied. If fixing to a plywood back board use the

shorter screws.

Typical Installation for NFT

Installation for NFT with solenoid valve to automatically add water to dilute EC

Ver 5.6 IntelliDose Installation Guide (30 June 2020) Copyright© 2020 Autogrow Systems Ltd 20

Installation for NFT with solenoid valve to automatically control water and Irrigation

pump via contactor panel

Other manuals for IntelliDose

1

Table of contents

Other Autogrow Controllers manuals