Chemyx FUSION 4000-X OEM User manual

FUSION 4000-X OEM

USER MANUAL

INTELLECTUAL PROPERTY

All Intellectual Properties, as dened below, owned by or which is otherwise the property of Chemyx Inc. or its suppliers relating to the Chemyx syringe pumps, including but not limited to, accessories,

parts or software relating thereto (Chemyx Syringe Pumps), are proprietary to federal and state laws, and international treaty provisions. Intellectual Property includes but is not limited to, inventions

(patentable or unpatentable), patents, trade secrets, copyrights, software, rmware, computer programs, and related documentation and other works of authorship. Moreover, you agree that you will

not, and will not attempt to, modify, prepare derivative works of, reverse engineer, disassemble the Chemyx syringe pumps, decompile or otherwise attempt to create source code from the related

software/rmware. No title to or ownership in Intellectual Property is transferred to you. All applicable rights of the Intellectual Property shall remain with Chemyx and its suppliers.

2

Safety Information 3

Product Overview 4

Data Sheet 5

Loading a Syringe 6

Pump Control by Computer 7

Controller Programs 9

Commands 10

Pump Maintenance 11

Syringe Pump Accessories 12

Warranty and Repair Information 13

Appendix A: Syringe Volume/Diameter Reference Table 14

Table of Contents

3

Safety Information

Please read the following safety precautions to ensure personal safety and operational longevity of the Chemyx syringe pump.

Chemyx is not responsible for the equipment if used in a manner not specied by the manufacturer; warranty coverage

provided by the equipment may be dropped as a result.

CHEMYX PRODUCTS ARE NOT APPROVED FOR CLINICAL USE ON HUMANS.

Chemyx is not responsible for the use of power supplies outside the stated electrical specications or failure to switch the

power converter from 220V to 110 V while in the 220V environment or vice versa.

The product should be properly grounded.

Use Proper Power Supply

Ground Product

Warranty coverage will be lost if the pump is opened without authorization from Chemyx. Do not touch any electrical

connectors on or in the product.

Even though the pump can operate at extremely fast speeds, the user must determine the proper ow rate for any given

application. For instances, pumping at 90 mL/min using a 20-gauge needle will cause stalls and/or potential bursting of the

syringe. Chemyx is not responsible for any damage that might result from situations similar to the example above.

Do Not Open The Pump

Do Not Operate With Suspected Failures

Do not place ngers between the pusher block and the end block while the pump is running.

Read all labels on the product to ensure proper usage.

The user is responsible for wetting ground glass syringes and setting and tightening the safety collar/bar appropriately.

Pinch Hazard

Observe all Warning labels on Product

Chemyx is not Responsible for Syringe Damage

4

Product Overview

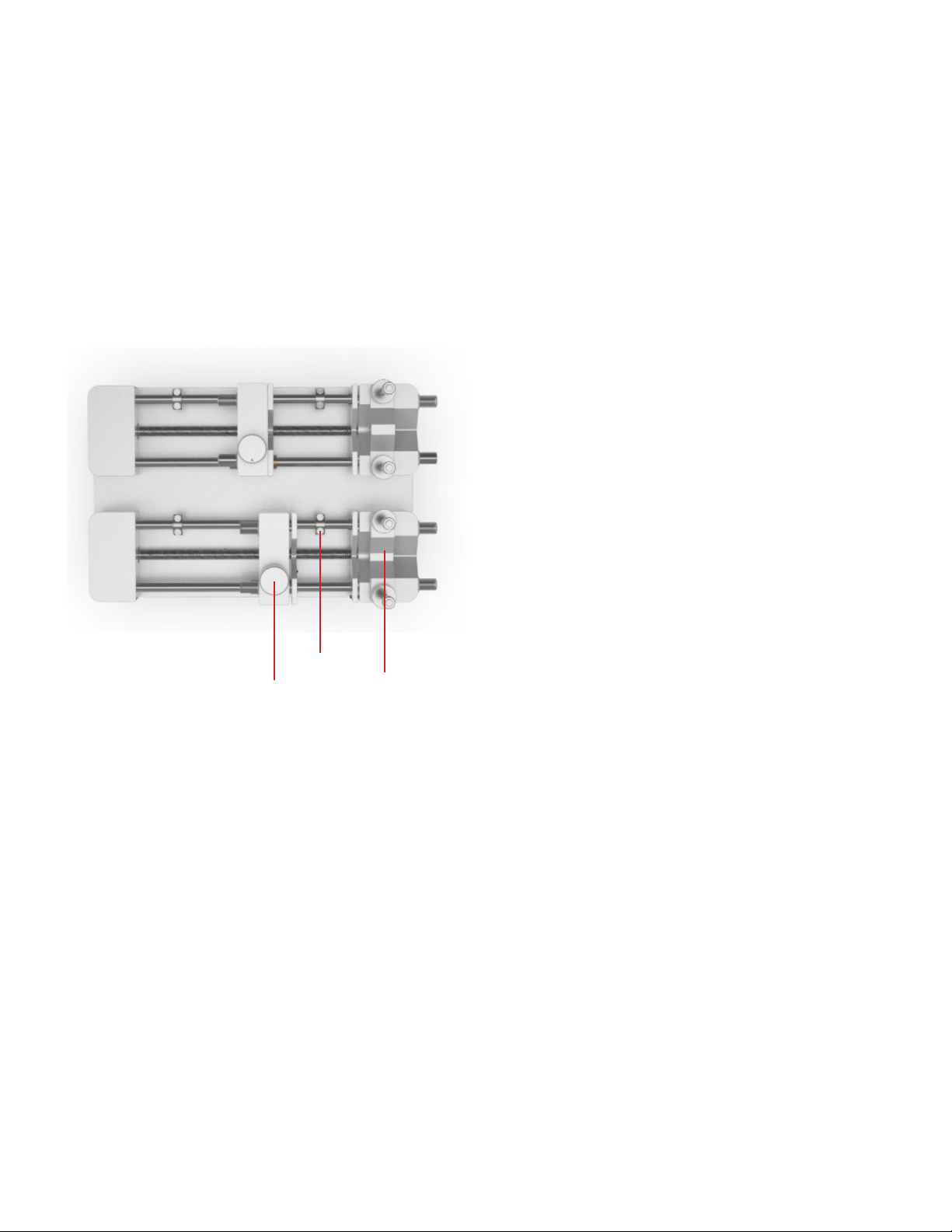

Fusion OEM 4000-X

The Fusion OEM 4000-X syringe pump comes with a dual drive system that allows two independent pumping channels to be

controlled for simultaneous infusion and withdrawal at same/dierent ows.

Fusion OEM 4000-X

7.5 in

12 in

7.5 in

4 in

5

80lb (36kg)

TECHNICAL SPECIFICATIONS

Infuse & Withdraw

± < 0.35%

± <0.2%

0.5µL to 100mL

Plasc and Glass

See Syringe Library for Min & Max Flow Rates on Website

0.0001 µL/min (with 0.5µL syringe)

170.5 mL/min (with 100mL syringe)

See Max Pressure on Website

None

USB-B, RS232 and TTL Ports

Mode

Accuracy

Reproducibility

Syringe Size (Min/Max)

Syringe Type

Syringe Flow Rates

Minimum Flow Rate

Maximum Flow Rate

Linear Force

Maximum Pressure

Display

Connecvity

Weight

Motor Drive

Step Resoluon

15lbs (7kg)

.

0.0293 µm/step

The Fusion 4000-x OEM syringe pump comes with

a dual drive system that allows two independent

pumping channels to be controlled for simultaneous

infusion and withdrawal at same/different flows.

Fusion 4000-X OEM Module Data Sheet

System Dimensions 11.3 x 7.1 x 7.5 inches (28.7 x 18 x 9 cm)

1.8˚ Stepper Motor with Micro-stepping

24V DC 4.6A

Power

For More Informaon visit chemyx.com Chemyx Syringe Pumps are not for human use

Storage Temperature -10°C to 70°C (14°F to 158°F)

Humidity 20% to 80% RH, non-condensing

Installaon Category II

Regulatory Compliance CE, RoHS, REACH, FCC

Operang Temperature 4°C to 40°C (40°F to 104°F)

6

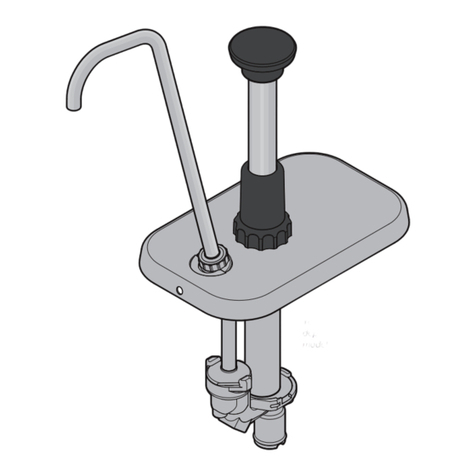

The OEM can accommodate one syringe. The volume of the syringes can vary from a minimum of 0.5 μL up to a maximum of 60

mL. Syringes of any material (e.g., glass, plastic, stainless steel, etc.) can be used; however, some use cases may require syringes

that are more accurate and durable.

1. If necessary, move and tighten the infusion safety collar

(see Adjusting the Safety Collar).

2. While pressing in the lock-release button, slide the pusher

block all the way to the left.

3. Pull up on the spring-loaded syringe clamp and place

the syringe in one of the channels of the syringe-holder

block. Ensure that the ange of the syringe barrel is ush

against the edge of the syringe-holder block. Slowly lower

the syringe clamp to secure the syringe in place.

The Fusion 4000-X OEM pump motor can generate up to a maximum of 80lbs linear force. Some syringes made of more fragile

materials may not be able to withstand the full linear force of the pump.

Loading a Syringe

Motor Power

FUSION 4000-X OEM

2

1

3

7

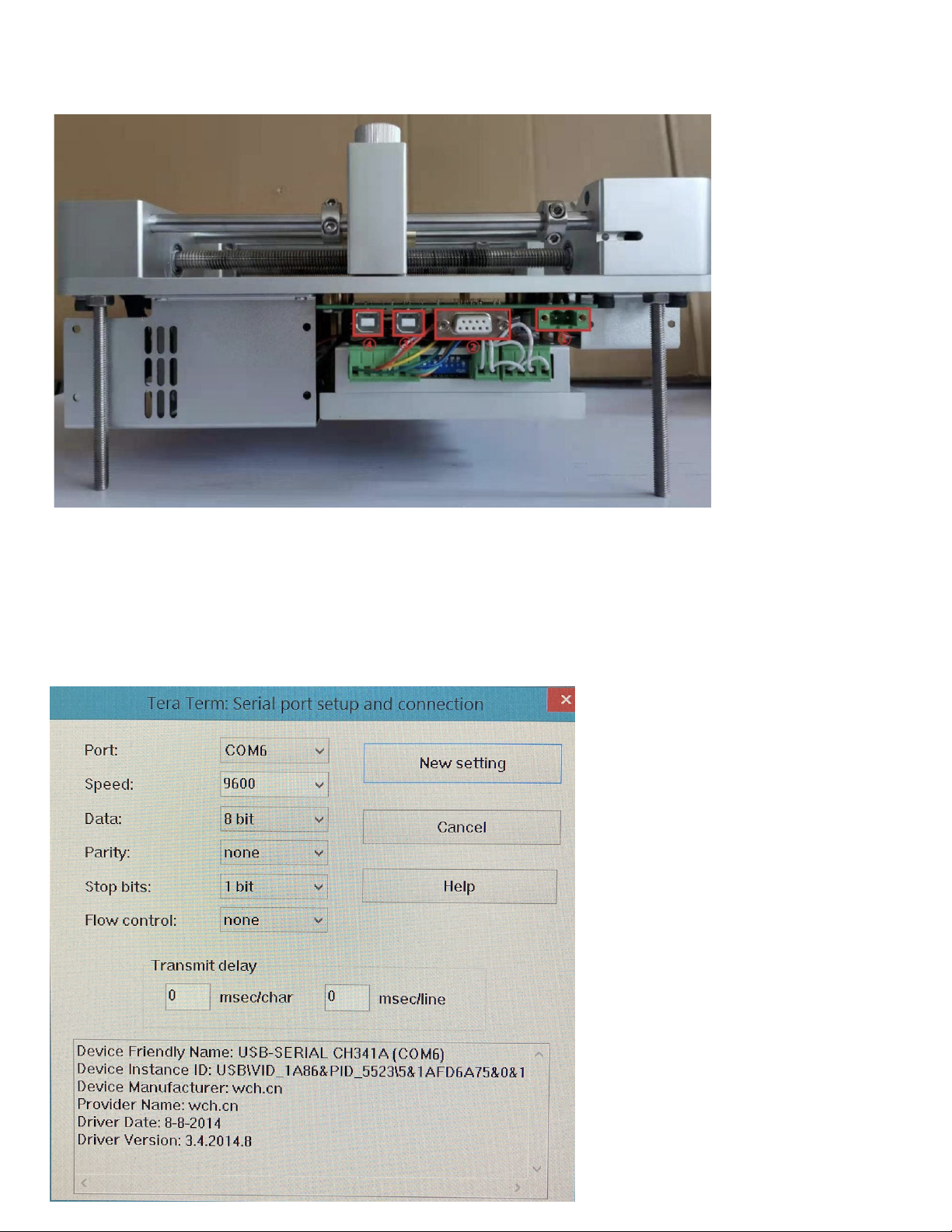

The OEM syringe pumps can be controlled with an external computer using an RS232 serial connection.

Two types of connections are available for external computer control: DB9 and USB, cables for each are available for purchase

through Chemyx (call 1-281-277-5499 or visit www.chemyx.com/contact-us).

Most computer operating systems (e.g., Windows, macOS, Linux, etc.) have built-in terminal programs that can be used to

type in the commands that run the pump. On Windows XP and earlier, HyperTerminal can be used to control to the pump. On

macOS and Linux, the screen command in Terminal can also be used to control the pump. There are also numerous third-party

programs for serial connections that exist for each operating system that may be easier to use and provide more features. A

third-party program will be necessary to connect with computers running Windows Vista and later.

For tips on operating the built-in terminal programs and information on available third-party programs, please visit www.

chemyx.com/support.

For the DB9 serial connection, a Male-to-Female DB9 cable must be used. Do not use any “null modem,” “crossover”, or “crossed-

over” cables. The cable can be of any length up to 50 ft; however, the speed of the connection is often detrimentally aected

at lengths over 15 ft.

For a USB serial connection, a USB-A to USB-B cable should be used. The maximum possible length of a single USB cable is 15 ft;

however, USB cables should be less than 10 ft for optimum performance. Multiple USB cables can be chained together to make

a longer connection as long as the hub connecting each individual cable is connected to a power supply.

A USB-to-DB9 serial adapter can be used to connect a DB9 serial connection to the USB port on a computer.

All of these connections require the proper drivers to be installed on the computer. Typically, most current operating systems

already contain drivers for the USB serial connection. They may also already have drivers for the DB9 serial connection. USB-to-

DB9 adapters typically need to have a USB-to-serial driver installed. For more information on downloading and installing drivers

please visit www.chemyx.com/support.

DB9 Serial Cable (Male-to-Female)

Cable Requirements

Connecting

TTL Connection

USB-A to USB-B cable

Pump Control by Computer

8

1 Power 2 RS232 3 USB 4 Foot switch

Hit foot switch once, both pumps will start; hit twice, both pumps will stop

Fusion OEM 4000-X Cable Connectors

1

23

4

Fusion OEM 4000-X Computer Connections

9

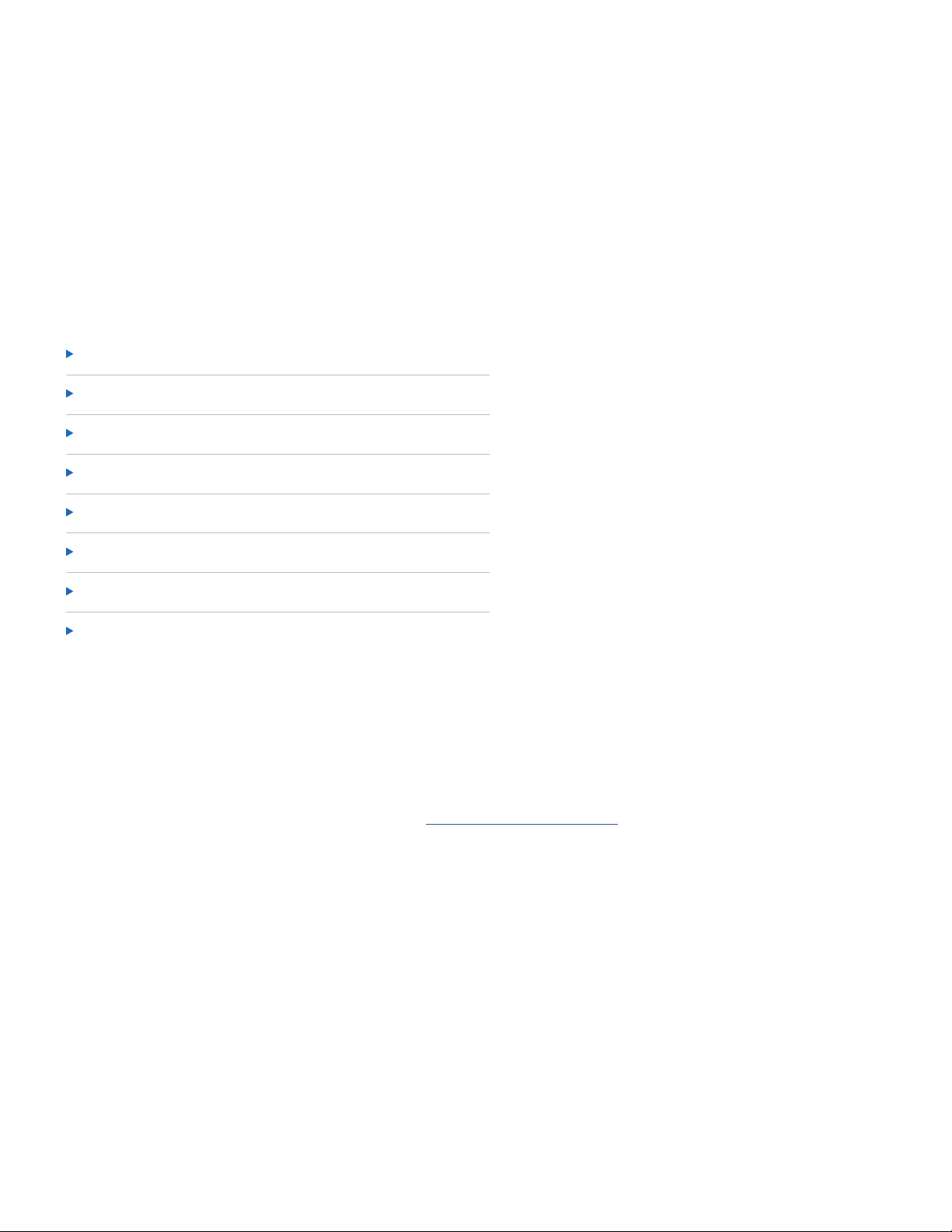

Regardless of the operating system being used, the terminal program controlling the serial connection should use the following

connection settings:

Baud Rate 9600 or 38400

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

The baud rate setting for the serial connection must match the baud rate set in the pump settings GUI (See Baud Rate in System

Settings). Generally, the pump should be set to use the higher baud rate (38400) if a USB-only connection is used. However, if

a DB9-only or USB-to-DB9 connection is used, the baud rate must be set to 9600. Typically, if the baud rate is not set correctly,

there will be garbled or no response to any command

The baud rate is the rate at which information is transferred through the serial connection. This rate is often limited by the type

of serial connection used. The OEM syringe pump provide two possible baud rates: 9600 and 38400. Serial connections using

the USB-B port on the back of the pump should use the faster baud rate of 38400. Serial connections using the DB9 port on the

back of the pump will need to use the slower baud rate of 9600.

See Pump Control by Computer for more information.

In addition to the manual control of the pumps through a terminal, Chemyx provides pump controller programs as an

unsupported open-source applications written in Python, a LabVIEW package, and a MATLAB package. More information on

these tools can be found on the website at www.chemyx.com/support.

COM Port Settings

Chemyx provides free downloads for LabVIEW™ and MATLAB™ as a courtesy to our customers. This

service is not supported by Chemyx, all customers are responsible for solving any technical issues

related to LabView and MATLAB computer control.

Chemyx Pump Controller Programs

Baud Rate

10

RS232 Protocol/Commands

* Explanation of command function is located after command name*

RS232 Comport Settings: All system from 11/1/2010

Bits per seconds - 38400

Data bits - 8

Parity - None

Stop bit - 1

Flow control - None

Note: Settings are same for both D9 and USB comports

help

------------------------------------------

help - Show Help Information

------------------------------------------

Movement Commands

------------------------------------------

start -Pump Run

stop -Pump Stop

pause -Pump Pause

restart -Pump Restart

------------------------------------------

Setting Commands

------------------------------------------

set units [xxx] -Pump Set Units(0,1,2,3 or ml/min,ul/hr)

set diameter [x.x] -Pump Set Diameter

set rate [x.x,x.x,...] -Pump Set Rate

set volume [x.x,x.x,...] -Pump Set Volume

set delay [xxx] -Pump Set Delay

set time [x.x,x.x,...] -Pump Set Time(will calculate rate)

set mode [x…] 1 Sets withdraw function

------------------------------------------

set units set unit increments for uid deliver (i.e, ul/min, ul/hr, ml/min,

ml/hr)

set diameter set syringe inner diameter measurement - this tells the

pump what syringe size you

are using. Example: 10ml syringe ID is 14.5mm, so you would enter

14.5

set rate set ‘ow rate’ or ow speed at which you want to

dispense/extract uid

set volume set volume delivery - this is how much volume you wish

to dose to or extract from

specied source

set delay If you want the system to run at a certain point in your setup

(i.e. after, 10-30 seconds,

1, 5, 10 minutes, etc.) you may set a time delay for appropriate time

for pump to begin run

set time set volume as a function of time. Example: users wants to

run the pump to run over 5

minutes (it will do so, but it will only administer as much volume as it

can within that ‘time’ parameter

set mode to 1 for withdraw function / to reset infuse, set mode to 0

------------------------------------------

Status Commands

------------------------------------------

read limit parameter -Pump Return Max/Min Volume & Rate

dispensed volume -Pump Return Volume Dispensed

elapsed time -Pump Return Time Elapsed

pump status -Pump Return System Status

------------------------------------------

Additional Optional Commands

------------------------------------------

hexw2 [units] [mode] [diameter] [volume] [rate] [delay]

- Sends All Settings

hexw2 [units] [mode] [diameter] [volume] [rate] [delay] start

- Sends All Settings and Starts

IMPORTANT

ALWAYS connect RS232 and

Power supply BEFORE powering

on the OEM Module!

Quick Start Guide - Commands

11

Pump lubrication is the most important part of regular pump maintenance. Proper lubrication ensures long service life, smooth

ow performance, and protection against corrosive lab fumes. The pump may not be adequately cleaned and lubricated if the

following occur: (1) grinding sounds are coming from the lead screw; (2) the block release button decouples under the load

before the pump stalls; or (3) the pump stalls with increased frequency.

Please contact Chemyx call +1 281-277-5499 or email us at [email protected] to conrm the safe use of a dierent lubricant.

1. Clean contact surfaces with a clean cloth. Remove any debris on the lead screw and the guide rods.

2. Apply lubricant along the length of the lead screw and the guide rods.

3. Press the block-release button and slide the pusher block to the left edge.

4. Run the pump end-to-end without a syringe to work the lubricant into the components.

Pump lubrication should be performed every three months.

Pump Maintenance

• Engine/motor oil

• Silicone oil

• Machine oil

• Tooling oil or “WD-40”

• Lithium-based grease

Lubricating the Pump

Lubrication Instructions

Approved Lubricants

12

Footswitch

Streamline laboratory operations with this electric foot switch

control that lets you start, stop, or pause your Chemyx syringe pump

systems—even when your hands are full. The electric foot pedal switch

connects seamlessly to computerized pumping programs, and its 10-

foot cable connection can be customized for either the Nexus series

(DB9 connection) or the Fusion 100/200/4000/6000 and 100-X/200-

X/4000-X/6000-X (USB-B connection).

USB Cable

Connect your Chemyx syringe pump directly to any computer with

this 6-ft USB-B cable. This communication USB cable can connect

with any of the Chemyx syringe pump systems to allow full remote

control through a variety of automation programs, such as LabVIEW

and MATLAB.

RS232 Cable

Remotely control your Chemyx syringe pump from any computer with

this 6-foot RS232 cable. The RS232 cable ensures a quick and easy

setup for seamless device communication with automation software

such as LabVIEW and MATLAB to streamline your laboratory workow.

Each end of the RS232 cable connects to a 9-pin port (DB9).

Syringe Pump Accesories

13

The serial number is located on the back, top left corner or center of the pump under a small barcode. Removal of the serial

number label will void the warranty.

Serial Numbers

Warranty and Repair Information

Chemyx provides a two-year limited warranty (1) rst year for parts and labor (2) second-year for parts only from the shipment

date for its pumps against defects in materials and workmanship. Chemyx will repair product that proves defective during its

stated warranty period. To get warranty repair the customer is responsible to send the pump to Chemyx.

The foregoing warranty will not apply to damage resulting from:

Chemyx can repair the syringe pump without major damage. You must contact Chemyx Inc by either email or phone before

returning the product. Chemyx will issue a Return Authorization (RA) number to you.

You must contact Chemyx (call +1 281-277-5499 or visit www.chemyx.com/contact-us) before returning a product. Chemyx will

issue a Return Authorization (RA) number to you.

Return products to:

Chemyx Inc.

10905 Cash Road | Staord, TX 77477 USA.

Warranty Information

Improper or inadequate maintenance or operation.

Unauthorized modication or misuse of the product.

Operation outside the electrical specications for the product.

Operation outside the temperature specications for the product.

User-induced internal and external contaminations of the instrument.

Failure to use proper surge protection.

Improper product return, packaging, and shipping

Removing serial number from syringe pump

Repair Information

14

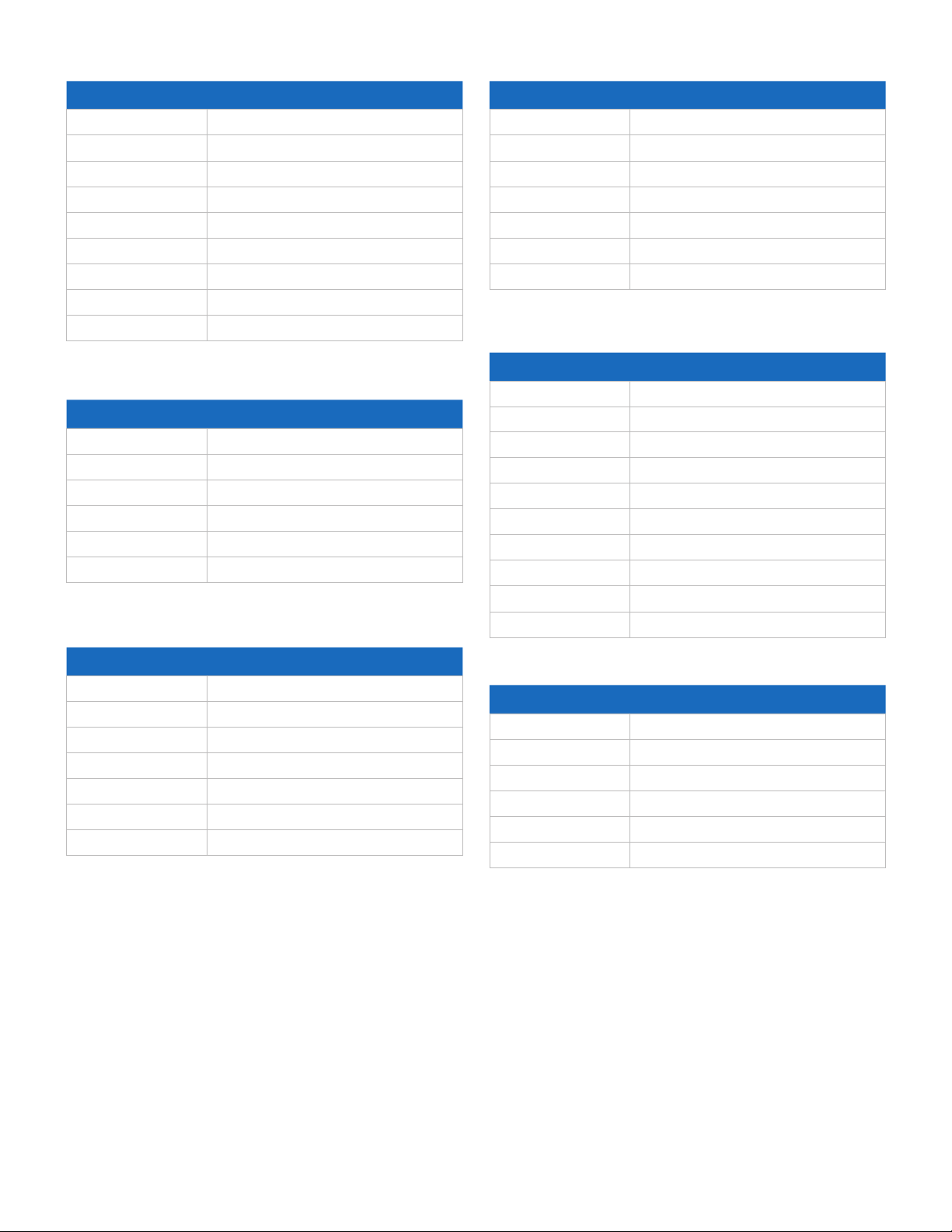

Size Diameter

0.50 mL 4.64 mm

1.00 mL 4.64 mm

2.00 mL 8.93 mm

2.50 mL 8.66 mm

3.00 mL 8.93 mm

5.00 mL 11.73 mm

10.00 mL 14.68 mm

20.00 mL 19.60 mm

30.00 mL 22.70 mm

50.00 mL 28.03 mm

60.00 mL 28.60 mm

Size Diameter

0.50 μL 0.10 mm

1.00 μL 0.15 mm

2.00 μL 0.21 mm

5.00 μL 0.33 mm

10.00 μL 0.48 mm

25.00 μL 0.73 mm

50.00 μL 1.03 mm

100.00 μL 1.46 mm

250.00 μL 2.30 mm

500.00 μL 3.26 mm

1.00 mL 4.61 mm

2.50 mL 7.28 mm

5.00 mL 10.30 mm

10.00 mL 14.57 mm

25.00 mL 23.03 mm

50.00 mL 32.57 mm

Size Diameter

1.00 mL 4.64 mm

3.00 mL 4.64 mm

5.00 mL 12.07 mm

10.00 mL 14.50 mm

20.00 mL 19.13 mm

30.00 mL 21.69 mm

60.00 mL 26.72 mm

Size Diameter

1.00 mL 4.80 mm

1.00 mL 6.70 mm

2.00 mL 6.70 mm

2.00 mL 9.20 mm

3.00 mL 10.30 mm

5.00 mL 12.20 mm

10.00 mL 15.00 mm

20.00 mL 19.00 mm

30.00 mL 22.50 mm

50.00 mL 25.50 mm

100.00 mL 34.00 mm

Chemyx Stainless Steel Hamilton Glass

Hoshi

BD Glass

BD Plastic

Appendices

Appendix A: Syringe Volume/Inner Diameter Reference

Size Diameter Inner | Outer

6.00 mL 9.5 mm inner | 13mm outer

20.00 mL 19.1 mm inner | 23 mm outer

50.00 mL 28.6 mm inner | 33 mm outer

100.00 mL 35 mm inner | 38 mm outer

200.00 mL 44 mm inner | 48 mm outer

15

Size Diameter

1.00 mL 4.66 mm

2.00 mL 6.90 mm

2.50 mL 9.10 mm

5.00 mL 12.62 mm

10.00 mL 14.34 mm

20.00 mL 19.68 mm

30.00 mL 22.44 mm

50.00 mL 28.80 mm

100.00 mL 36.68 mm

Size Diameter

0.25 mL 3.45 mm

0.50 mL 3.45 mm

1.00 mL 4.50 mm

2.00 mL 8.92 mm

3.00 mL 8.99 mm

5.00 mL 11.70 mm

10.00 mL 14.70 mm

20.00 mL 19.58 mm

30.00 mL 22.70 mm

50.00 mL 29.00 mm

Size Diameter

0.25 mL 2.60 mm

0.50 mL 3.20 mm

1.00 mL 4.30 mm

2.00 mL 6.30 mm

3.00 mL 7.30 mm

5.00 mL 9.50 mm

Size Diameter

2.00 mL 9.12 mm

5.00 mL 12.34 mm

10.00 mL 14.55 mm

20.00 mL 19.86 mm

30.00 mL 23.20 mm

50.00 mL 27.60 mm

Size Diameter

1.00 mL 4.71 mm

3.00 mL 9.50 mm

5.00 mL 12.91 mm

10.00 mL 15.40 mm

20.00 mL 19.30 mm

30.00 mL 23.40 mm

50.00 mL 29.00 mm

Size Diameter

1.00 mL 4.70 mm

2.50 mL 9.70 mm

5.00 mL 12.48 mm

10.00 mL 15.89 mm

20.00 mL 20.00 mm

30.00 mL 22.50 mm

50.00 mL 28.90 mm

JMC Air-Tite Plastic Norm-Ject Plastic

Popper & Sons Glass

Ranfac

Natsume

Nipro

16

Size Diameter

25.00 μL 0.73 mm

50.00 μL 1.03 mm

100.00 μL 1.46 mm

250.00 μL 2.30 mm

500.00 μL 3.26 mm

1.00 mL 4.61 mm

2.50 mL 7.28 mm

5.00 mL 10.30 mm

10.00 mL 14.57 mm

Size Diameter

1.00 mL 4.70 mm

2.00 mL 6.40 mm

3.00 mL 9.30 mm

6.00 mL 13.10 mm

12.00 mL 15.40 mm

25.00 mL 21.00 mm

30.00 mL 23.00 mm

50.00 mL 29.00 mm

Size Diameter

1.00 mL 4.65 mm

3.00 mL 8.94 mm

6.00 mL 12.70 mm

12.00 mL 15.90 mm

20.00 mL 20.40 mm

35.00 mL 23.80 mm

50.00 mL 26.60 mm

Size Diameter

1.00 mL 4.73 mm

3.00 mL 9.00 mm

5.00 mL 13.04 mm

10.00 mL 15.79 mm

20.00 mL 20.18 mm

30.00 mL 23.36 mm

60.00 mL 29.45 mm

Size Diameter

1.00 mL 4.73 mm

1.00 mL 6.50 mm

3.00 mL 8.65 mm

5.00 mL 13.00 mm

10.00 mL 15.80 mm

20.00 mL 20.15 mm

30.00 mL 23.10 mm

50.00 mL 29.10 mm

SGE Glass Terumo Japan

Top

Sherwood Plastic

Terumo

17

Size Diameter

10.00 μL 0.46 mm

25.00 μL 0.73 mm

50.00 μL 1.03 mm

100.00 μL 1.46 mm

250.00 μL 2.30 mm

500.00 μL 3.26 mm

1000.00 μL 4.61 mm

Size Diameter

1.00 mL 4.65 mm

3.00 mL 8.94 mm

6.00 mL 12.70 mm

12.00 mL 15.90 mm

20.00 mL 20.40 mm

35.00 mL 23.80 mm

60.00 mL 26.60 mm

Unimetrics

Kendall Monoject Plastic

Table of contents

Other Chemyx Water Pump manuals

Popular Water Pump manuals by other brands

Nibe

Nibe VVM 225 Service instruction

ProMinent

ProMinent DULCOflex DFDa operating instructions

Warren rupp

Warren rupp Sandpiper S05 Non-Metallic Service & operating manual

Eckerle

Eckerle EE 900M installation instructions

SFA

SFA SANICUBIC 1 OPERATING AND INSTALLATION Manual

Fiamma

Fiamma AQUA F 13 L Installation and usage instructions