1224 East Warner Ave,

Santa Ana, Ca 92705

Tel: 1-714-545-5511

www.cherryaerospace.com

TS-H83HL-6MB Rev: A Date: 05/04/11 CR: 11-0486

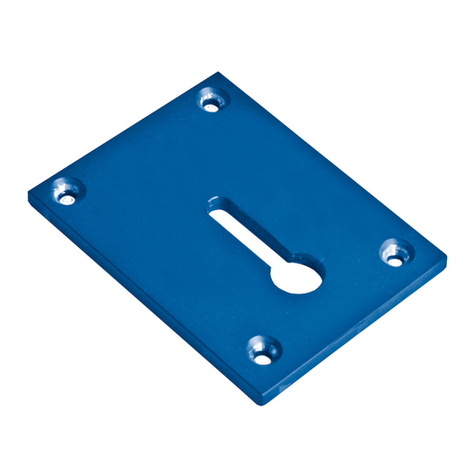

H83HL-6MB

PULLING HEAD FOR -6 DIA 130° MAXIBOLTTM TITANIUM FLUSH HEAD

Technical Data Sheet, Page 2 of 2

Sleeve Assembly

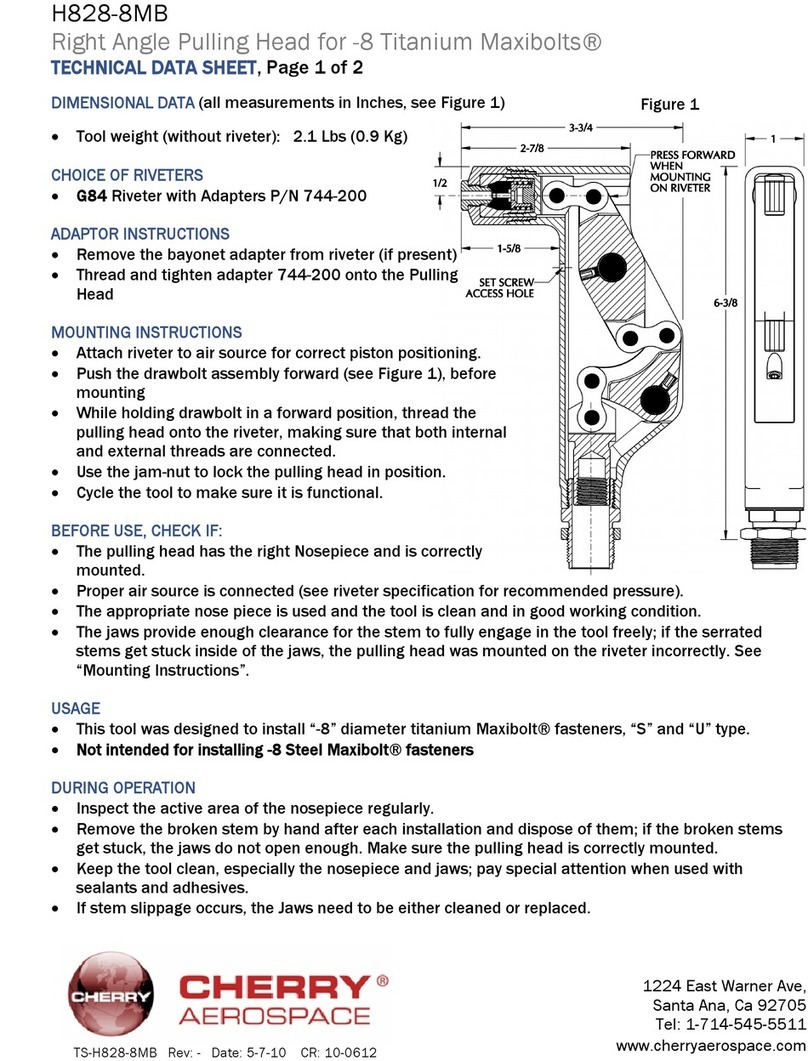

•Thread nosepiece (7) into sleeve (4).

•Thread load adjustment nut (12) over

sleeve (4) as far as it goes.

•Push the polyurethane spring (item 11),

retainer washer (item 10) and preload

sleeve (item 9) onto the sleeve.

•Insert the collet assembly into the sleeve.

Align retainer washer, sleeve and preload

sleeve slots and press the dowel pin (8) to

the collet inside; do not force. Rotate the

retainer washer out of alignment, to

prevent the dowel pin from disengaging

during use.

To disassemble remove the collet from

inside and carefully press the dowel pin

towards the center to remove it.

Preload Adjustment

•Thread the load adjustment nut (12) hand

tight against the polyurethane spring (11)

with the help of a wrench;

•To increase the pre-load, tighten the nut

(12) against the polyurethane spring (11).

•Caution: if not properly tightened, the

preload element will loose its

effectiveness!

GENERAL / TECHNICAL QUESTIONS

1224 E. Warner Avenue

Santa Ana, CA 92705 USA

1-714-850-6022 (Phone)

1-714-850-6093 (Fax)

LOCTITE®is a registered trademark of Henkel Corporation.

LUBRIPLATE® is a registered trademark of Fiske Brothers Refining Co.

WARRANTY

Seller warrants the goods conform to applicable specifications and drawings and will be manufactured and inspected according to generally accepted practices of companies manufacturing industrial or aerospace

fasteners. In the event of any breach of the foregoing warranty, Buyer’s sole remedy shall be to return defective goods (after receiving authorization from Seller) for replacement or refund of the purchase price, at

the Seller’s option. Seller agrees to any freight costs in connection with the return of any defective goods, but any costs relating to removal of the defective or nonconforming goods or installation of replacement

goods shall be Buyer’s responsibility. SELLER’S WARRANTY DOES NOT APPLY WHEN ANY PHYSICAL OR CHEMICAL CHANGE IN THE FORM OF THE PRODUCT IS MADE BY BUYER. THE

FOREGOING EXPRESS WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES; ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR

MERCHANTABILITY IS HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY SELLER. This warranty is void if seller is not notified in writing of any rejection of the goods within ninety (90) days after receipt

of the goods by buyer.

Seller shall not be liable under any circumstances for incidental, special or consequential damages arising in whole or in part from any breach by Seller, AND SUCH INCIDENTAL, SPECIAL, OR CONSEQUENTIAL

DAMAGES ARE HEREBY EXPRESSLY EXCLUDED.

Our policy is one of continuous development. Specifications shown in this document may be subject to changes introduced after publication.

NOTE: The properties, strength, dimensions, installed characteristics and all other information in these materials are for guidance only to aid in the correct selection

of the products described herein and is not intended or implied as part of the above warranty. All applications should be evaluated for functional stability and available

samples of the described parts can be requested for installed tests, suitability and evaluations.

For more information

lease contact our Technical Services De

artment at tel. 714-850-6022

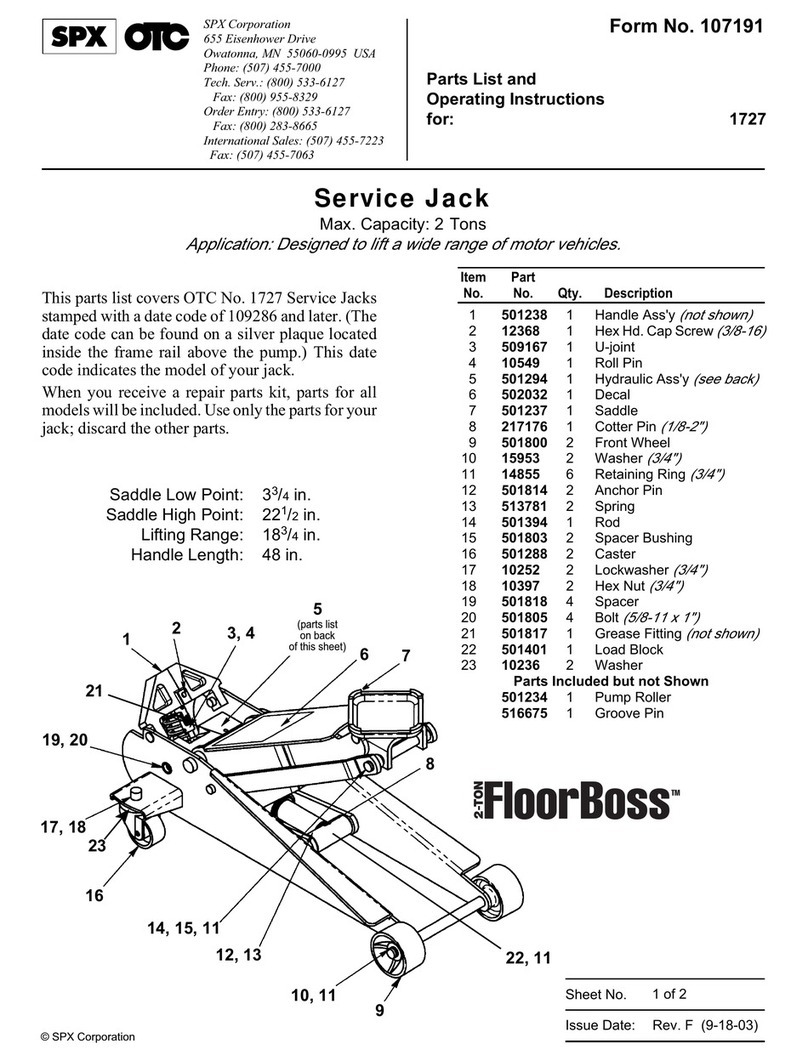

12 652-074 LOAD ADJUSTMENT JUT 1

11 P-1438 POLYURETHANE SPRING 1

10 652-075 RETAINER WASHER 1

9 652-077 PRELOAD SLEEVE (H83HL-6MB) 1

8 P-1440 DOWEL PIN 1

7 652-072 NOSE PIECE, -6MB 1

6 652-069 DRAWBOLT ADAPTOR 2

5 P-1 425 SPRING, C OMPRESSION 1

4 652-070 SLEEVE, H83HL & H84HL 1

3 652-031 JAW FOLLOWER 1

2 744C76 JAWS, -6MB 1

1 652-030 COLLET 1

ITEM

NUMBER

PART

NUMBER DESCRIPTION QTY. PER

ASSY.

PARTS LIST