Chery A113 User manual

MaintenanceManualofCheryA113

(Chassis)

CheryAutomobileCo., Ltd

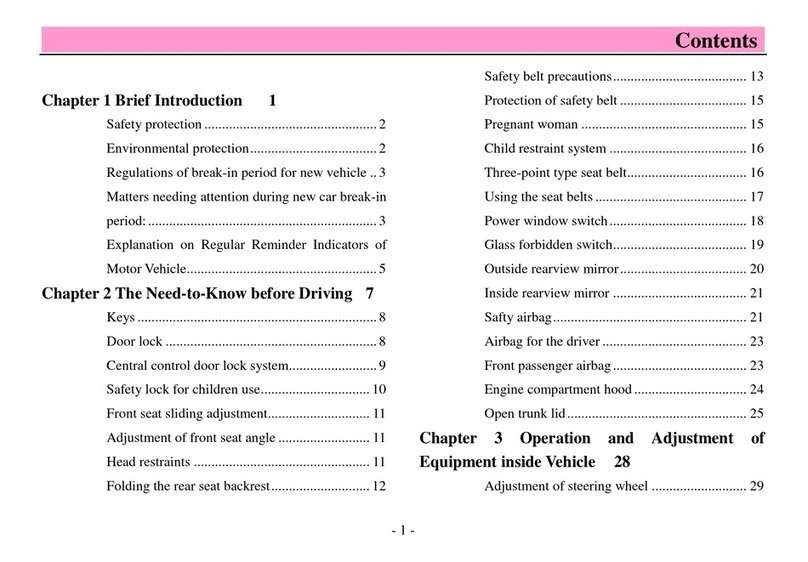

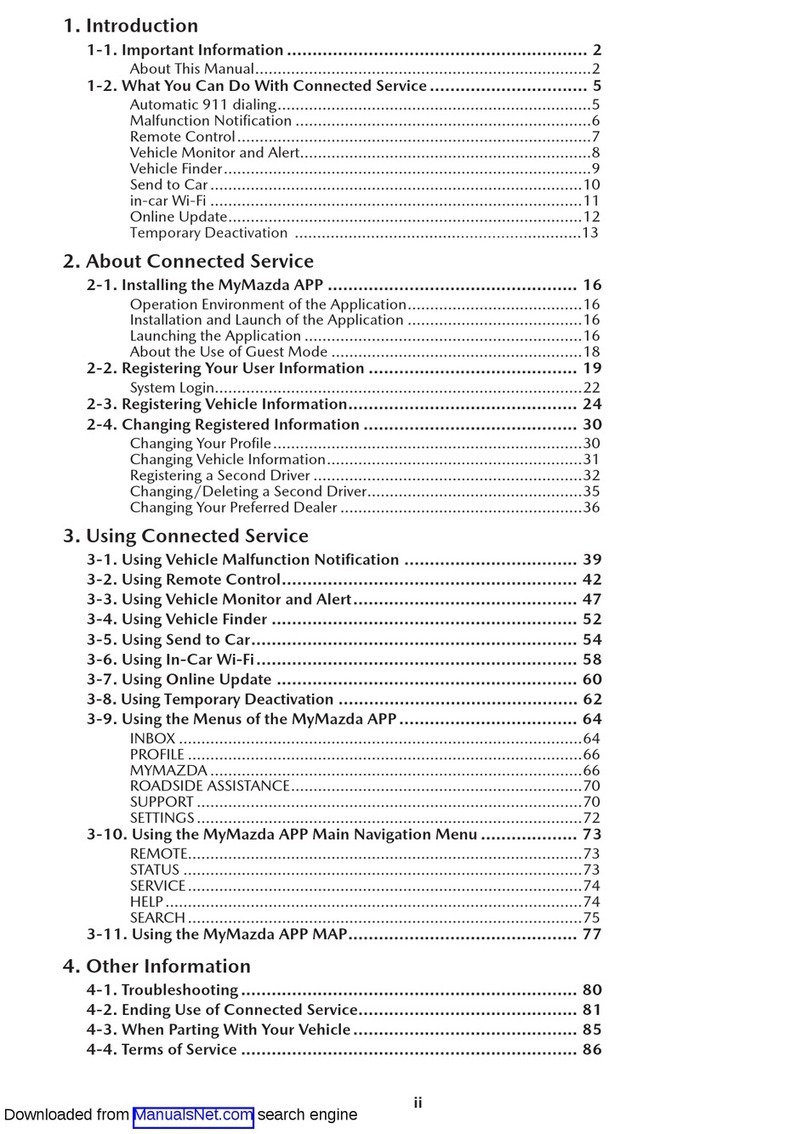

CONTENT

Chapter1BrakeSystem.................................................................................................................4

I. SystemCheckingParameters..................................................................................................4

1. Checkbrakedisc.....................................................................................................................4

2. Thickness checking.................................................................................................................4

3. Checkingofbrakefrictionlining thickness............................................................................4

4. Checkingofbrakediscrun-out..............................................................................................4

II. Removal/Installationand OverhaulofFrontBrakeandBrake Calliper...........................5

1. SystemStructuralDiagram.....................................................................................................5

2. Preparations............................................................................................................................6

3. Notices....................................................................................................................................6

4. RemovalandOverhaul...........................................................................................................6

III. Removal/Installationand OverhaulofRear Brake..........................................................10

1. SystemStructuralDiagram...................................................................................................10

2. Preparations..........................................................................................................................10

3. Notices..................................................................................................................................10

4. RemovalProcedure..............................................................................................................11

4. InstallationProcedure...........................................................................................................13

IV. AdjustmentandReplacementofHandbrake....................................................................14

1. SystemCompositionIllustration..........................................................................................14

2. Preparations..........................................................................................................................14

3. Notices..................................................................................................................................14

4. Removal/InstallationProcedure...........................................................................................14

Chapter 2 AdjustmentofSuspensionSystemandFour-WheelAlignment...............................18

I. Removal/Installationand OverhaulofFrontAxleandSuspension...................................18

1. SystemStructuralDiagram...................................................................................................18

2. Preparations..........................................................................................................................20

3. Notices..................................................................................................................................20

4. Removal/InstallationProcedure...........................................................................................20

4.1RemovalofShockabsorberassembly............................................................................20

4.2RemovalofControlArmAssembly...............................................................................21

4.3RemovalofFrontAxle Assembly...................................................................................22

5. InstallationProcedure...........................................................................................................24

II. Removal/Installationand OverhaulofRearAxleandSuspension...................................25

1. SystemStructuralDiagram...................................................................................................25

2. Preparations..........................................................................................................................26

3. Notices..................................................................................................................................26

4. Removal/InstallationProcedure...........................................................................................26

4.1RemovalofShockAbsorberAssemblyandShockAbsorberSpring.............................26

4.2Cross StayAssembly......................................................................................................27

4.3RearTrailingArmAssembly..........................................................................................27

4.4.RemovalofRearAxle Assembly...................................................................................28

5. InstallationProcedure...........................................................................................................29

III.AdjustmentofFour-WheelAlignment...............................................................................30

1. AdjustmentofFrontWheelToe-In......................................................................................30

2. AdjustmentofFrontWheelCamberAngle..........................................................................30

3. AdjustmentofCasterAngle andKingpinInclination..........................................................30

4. AdjustmentofRear-WheelAlignmentParameters..............................................................31

IV. Tire InstallationandAir PressureAdjustment.................................................................31

1. InstallationofAirValve.......................................................................................................31

2. Tire Assembling...................................................................................................................31

3. Tire Inflation.........................................................................................................................32

4. InstallationofWheeland Tire Assembly.............................................................................32

5. Tightening Method ofWheelBolts......................................................................................32

6. InstallationofDecorative Cover...........................................................................................32

Chapter3Removal/InstallationandOverhaulofSteeringSystem............................................33

I. Removal/InstallationofSteeringGear..................................................................................33

1. SystemCompositionIllustration..........................................................................................33

2. Preparations..........................................................................................................................34

3. Notices..................................................................................................................................34

4. Removal/InstallationProcedure...........................................................................................35

5. InstallationProcedure...........................................................................................................36

II. Removal/InstallationofSteeringColumn...........................................................................37

1. SystemCompositionIllustration..........................................................................................37

2. Preparations..........................................................................................................................37

3. Notices..................................................................................................................................37

4. RemovalProcedure..............................................................................................................38

5. InstallationProcedure...........................................................................................................43

III.AdjustmentofSteeringGearClearance............................................................................44

IV.AdjustmentofPowerSteeringSystem................................................................................44

Chapter1BrakeSystem

I. SystemCheckingParameters

1. Checkbrakedisc:

Thefrictionsurface ofbrake discshouldbe flatandhasnoapparentgrooves;otherwise,brakediscshouldbe

replaced.

2.Thicknesschecking

Thestandardthickness offrontdisc(ventilation disc)is17 mmwithitsoperatinglimit of15 mm;when

exceedingtheoperating limit,the frontdisc shouldbe replaced.

3. Checkingofbrakefrictionliningthickness

Standardthickness offrontbrakelining shall be 10 mm,applicationlimitshall be1 mm, and the remaining

thickness oflimitbrakepadthickness shall be notlessthan1mm.

Standardthickness ofrearbrakelining shallbe 5 mm,application limit shallbe1 mm,and the remaining

thickness oflimitbrakepadthickness shall be notlessthan1 mm.

4. Checkingofbrakediscrun-out

Usedialgauge tocheckthe face runoutofbrake disk, theapplicationlimitoffrontdiskshallbe 0.03mm, the

application limit ofreardiskshall be0.03mm,otherwise replace it.

Importantnotice:

Aftercompletion ofreplacing friction liningorbrake disk,applythe brake forseveraltimestoenable breaking-in

betweenbrakelining andbrake disk.Alwaysensure safety!

Afterreplacing brakelining, checkbrake fluidleveltoensure itisbetweenMINandMAX.

II. Removal/InstallationandOverhaul ofFront BrakeandBrake Calliper

1. SystemStructuralDiagram

StructuralDiagramofFrontBrakeAssembly

(1)Brakedisc positioningbolt(2)Brake disc

(3)Wheelhub bearingunit;(4)ABSspeedsensorplug

(5)Dustcover(6)Steeringjoint

(7)Fixing bolt (8)Friction lining

(9)Frictionlining thickness sensorplug(10)Brakebracket

(11)Brake calliperassembly(12)Fixing bolt

2.Preparations

Tools: Ratchetwheel,ratchetlever, 13#, 14#,16#,18#, 19#,8#,

30#socket, 10#,13#,14#,16# ring wrench, vice,

torquewrench,measure ruler..

Accessories: brake fluid

3.Notices

3.1Pleasewearnecessarylaborprotectionsuppliestoavoid

accidents.

3.2Thebrakeliquidisonetoxicliquid.Ineventofcontactwiththe

skinoreyesduetocarelessness,flushwithagreatamountofwater

andifnecessarycall formedicaltreatmenttimely.

3.3Thescrappedbrakeliquidshouldbeaccommodatedinthe

container.It sprohibitedtodrainit intothesewagesystemorstack

withotherhouseholdgarbage.

3.4Donotdepress thebrakepedalnormovethevehicleduringthe

removal/installationoperation.

3.5Donotmakethefrictionliningorbrakedisccomecontactwith

the oil substances, whichwill impairthebraking effects.

4.RemovalandOverhaul

4.1Removetheprotectivecoverfromthetirerimwithslotted

screwdriver.

4.2Removethetirefixing nutswith19#torquewrenchorvehicle

attachedtoolandremove thetire.

Torque:110±10Nm.

4.3Liftthevehiclewithelevator.

4.4Removethe 2nuts(upperand lower) from

the brakecalliperand steering jointwith18# wrench.

4.5Removethe nutsfrombrake hosewith13#wrench.

Notice:Thebrakeliquidisonetoxicliquid.Donotsplashthebrake

liquidtotheclothesorskinduringthe removalofthe brake hose.

Torque:16±3Nm.

4.6Pulloutthe brake disc withhand.

4.7Measurethethickness offriction lining.Ifbelow3mm,replace

timelyinpairs.

4.8Removethe brake calliperandbrake pumpwith14# wrench.

4.9Removethedustproofsealandcheckforthedamageofthe

dustproofseal.Ifnecessary,renewthedustproofseal.Cleanthe

contactsurfaceofthebrakepistonand applywithonefilmof

silencing grease.

Notice:It'sprohibitedtomakethedustproofsealcomecontactwith

thesilencing grease, whichwillcausetheswelling ofthedustproof

seal.

4.10Removethepiston.Prepareonewoodboardtoholdthepiston

and place thewoodboardbetweenthepistonandthewallofthe

brakecalliper.Press outthepistonwiththecompressedaircarefully

throughtheconnectingbore. Place theguardplate(suchashard

wood)atthe notchofthebrake callipertoprotectthe piston.

Notice:Donotholdthepistonwithfingers –dangerofclamping!

Thebrakecalliperpiston isprohibitedfromremovalatwilland

shouldberemoved/installedonlybyprofessionalsorunderthe

guidance oftheprofessionals.

4.11Checktheguidesleeve.Theguidesleeveshouldmove

smoothlyand freelywhenpushedwithhand.Replacetheguide

sleeveineventofjammingorstiffness.Notice:Applythe

lubricating greaseontotheguide sleeve during assembling.

4.12Remove the sealringcarefullywiththeplastic needle,cleanthe

brakecylinderand componentswithalcoholandblowdrywith

compressedair.Carefullycheckthesurfacesofbrakecylinder,

piston,and flange. It sprohibitedtoconductthemachiningprocess

onthe brake cylinderand piston.

4.3Installationofbrakebranchpump:Applyonefilmofbrake

cylindercreamontothecylinderbody,plunger,and sealsleeve.

Attachthesealring ontothecirculargrooveattherearofthebrake

cylinder.Attachthedustproofsealringontothefrontcirculargroove

andpress itincompletely.

4.14Thearea betweenthedustproofsealringandthebrakeclamp

housingmustbekeptdry.Itshouldbekeptawayfromthebrake

cylindercreamorthebrakeliquid,inordertoensurethecorrect

position ofdustproofsealring.

4.15Securethebrakepiston withthereinforcementpartsavailable

inmarketand press it ontothedustproofsealring slightly.Blowthe

dustproofsealringwithcompressedair(upto3.0bar)toattachthe

piston ring ontothe piston.

Notice:Dipthe dustproofsealring and piston withbrake

liquidtofacilitate the passingofthe sealring.

4.16(Checkingofbrakedisc)Checkthethicknessofbrakedisc.

Replace the brakedisc ifthe thickness isless thanthe minthickness.

Notice:Thetwobrakediscsatthesameaxleshouldbereplacedata

time.Thefrictionliningsmustbereplacedfollowing the

replacementofthe brakediscs.

4.17Checkthemaxrun-outoftheend surfaceofbrakediscwith

dialgage.Ifabove0.03mm,replace it.(Providedthatthebrakedisc

thickness isguaranteed,itmayconductthepropermachiningto

meetwiththe maxrun-out.)

4.18InstallationofotherportionswithreferencetotheRemoval

Procedure.

III. Removal/InstallationandOverhaul of RearBrake

1. SystemStructuralDiagram

1. Rearbrake assembly2.Brake drum

3. Rearwheelhubbearing assembly4.Oilseal

5. Endcap6.Bolt

7. Rearwheelsensor8.Rearbrake hoseretainingclip

9. Dual-portpipe clip10. Tierod

11.Rearshoe pressurespringplate12.Rearshoepressure spring

2.Preparations

Tools:

Ratchetwheel,ratchetlever,10#,19#, 32#socket,10# ringwrench,

vice, torque wrench,slottedscrewdriver.

Accessories:brakefluid

3.Notices

3.1Pleasewearnecessarylaborprotectionsuppliestoavoid

accidents.

3.2Thebrakeliquidisonetoxicliquid.Ineventofcontactwiththe

skinoreyesduetocarelessness,flushwithagreatamountofwater

andifnecessarycall formedicaltreatmenttimely.

3.3Thescrappedbrakeliquidshouldbeaccommodatedinthe

container.It sprohibitedtodrainit intothesewagesystemorstack

withotherhouseholdgarbage.

3.4Donotdepress thebrakepedalnormovethevehicleduringthe

removal/installationoperation.

3.5Donotmakethefrictionliningorbrakedisccomecontactwith

the oil substances, whichwill impairthebraking effects.

4.RemovalProcedure

4.1Removetherearwheels(see theremovalprocedureoffront

wheels).

4.2Removetwopositionboltsfromthebrakedrumwiththecross

screwdriver.

4.3Removethe bearingdustcapwithslottedscrewdriver.

4.4Vibratethebrake drumtoremove it.

4.5Observetherearbrakingstructure.

4.6Ifit snecessarytocheckthebrakedrumbearing,removethe

locknutsshowninthefigurewith30# socketand torquewrench

andremove the brake drumbearing.

Torque:250±10Nm

4.7Removethe handbrakecable withcalliper.

4.8Removethe upperreturntensionspring withcalliper.

4.9Removethe lowerreturntensionspringwithcalliper.

4.10Depress thespringstripofthebrakeshoepositioningtierod

withcalliperand thenrotateclockwiseorcounterclockwisefor90°

toremove twobrake shoepositiontie rods.

4.11Pullouttwobrake shoes.

4.12Remove thetensionspringtoseparatethebrake shoe.

4.13Intheeventofdetectionofover-tightrearbrake, itmayadjust

the lengthofthepushrod:Rotate clockwise toeliminate the friction.

4.14Removethethreeboltsshowninthefigurewith10#ring

wrench.

4.15Removethebranchpumpandbreakitdownforchecking of

intactness.

4.InstallationProcedure

Refertoremovalprocedures.

Bolts

Removethis

tension spring.

IV. AdjustmentandReplacement ofHandbrake

1. SystemCompositionIllustration

1.Handle2.Fixingbolts3. Cable4, 5.Left/Rightrearwheelcable

2. Preparations

Tools:Ratchetwheel, ratchetlever, 10#,13#,14#, 16#socket,10#

13#,14#ringwrench,vice, torque wrench,slottedscrewdriver.

3. Notices

3.1Please wearnecessarylaborprotectionsuppliestoavoidaccidents.

3.2Duringtheremoval/installation ofthespringparts,enough cautionsshouldbetakentopreventtheejection

ofsuchpartsfromcausingbodyinjuries.

3.3Theremoval/installationatthevicinityoftheexhaustpipemustbeconductedonlyafterthetemperatureof

theexhaustpipe isloweredtonormaltemperature soastopreventscald.

4.Removal/InstallationProcedure

4.1Withreferencetotheremoval/installationoftherearbrake,

loosenthehandbrake cable oftherearwheels.

T

oleft

rear

brake

assembly

Toright

rear

brake

assembly

4.2Removethe handbrakeclipwithpriers.

Notice:It sunderthe rearwheels.

4.3Removethefixingbracketboltsofthehandbrakecableshown

belowwith8#ringwrench.

Torque:9~12 Nm

4.5Pryouttheprotectivecoveratthehandbrakeandgearposition

withslottedscrewdriver.

4.6Removeall fixing screwsfromthesecondaryinstrumentpanel

assemblywithringscrewdrivertoremovethesecondaryinstrument

panelassembly.

4.7Removethe handbrakeadjustmentnutswith10# wrench.

4.5Loosenthe twohandbrake cableswithhand.

4.9Pulloutthe handbrake cable fromtheunderside ofthe vehicle

body.

Notice:Removethehandbrakecableatanothersideinaccordance

withthe same method.

4.10 (Handbrake adjustment) The lengthofthe handbrakecable

equippedonthismodelisdesignedtobe the fixedlength.Toadjust

the handbrakeeffects,refertothepart “removalofrearbrake”.The

adjustmentofthe ejectorrodlength(clockwise forlooseness and

counterclockwisefortightness)canachievethe handbrake

adjustment.

4.11Theinstallation procedureshouldbeconductedwithreference

tothe removalprocedure.

Rotate thisplace

Chapter2AdjustmentofSuspensionSystemand Four-Wheel

Alignment

I. Removal/InstallationandOverhaul ofFront Axle andSuspension

1. SystemStructuralDiagram

ThefrontaxleofCheryS21 modeladoptsthesplit steeringdriveaxle, withMacPherson independent

suspension.Theupperend ofthesuspension isconnectedwiththevehiclebodyasthelowerendisconnected

withthesecondaryvehicleframe.ThefrontMacphersonsuspensionundertakesthedualfunctionsofdriving

andsteering.Subframeconnectswithvehiclebodyviaelasticelement, whichimprovesdivingstabilityandride

comfort.

StructuraldiagramofFrontAxle and SuspensionSystem

1

Nut 9 Nut 17

Nut

2

Gasket 10

Leftcontrolarm 18

Nut

3

RubbergasketI 10

Rightcontrolarm 19

Bolt

4

RubbergasketII 11

Nut 20

Bolt

5

Leftpropellingrodweldmentassembly 12

Secondaryvehicleframe 21

Clamp

5

Rightpropelling rod weldmentassembly

13

Frontstrutassy. 22

Rubberbush

6

Nut 14

Nut 23

Bolt

7

Bolt 15

Frontconnectingrod assy. 24

Bolt

8

Bolt 16

Frontstabilizerbar 25

Bolt

CompositionListforFrontAxleand SuspensionSystem

2. Preparations

Tools:8#, 15#,18#,19# socket;10#,13#,15# wrench.

3. Notices

2.1Please wearnecessarylaborprotectionsuppliestoavoidaccidents.

2.2Whencarryoutmaintenance and repairtochassis,pleasenotethatwhetherthesafetylockoflifting

machine islocked.

2.3Whencarryoutremoval/installationtoshockabsorberspring,preventspringejectionfrombeing injured.

2.4It sprohibitedtoconducttheweldingandcorrectiononthebearing componentsofthewheelsuspension

and the guiding componentsofthe wheels.

2.5During theremovalofthechassiscomponent, renewthe self-locknutsandrustednutssoastoguarantee the

safety.

4.Removal/InstallationProcedure

4.1Removalofshockabsorberassembly

4.1.1Removethetirefixingnutswith19#socketorvehicle attached

wrenchtoremovethe tire(take leftside forinstance).

Torque:110±10 Nm

4.1.2RemovetheABSpipeline fromthe fixingseatwithhand.

4.1.3Removethefixingboltsofsteering jointandshockabsorber

with18# socket.

Torque:110±10Nm

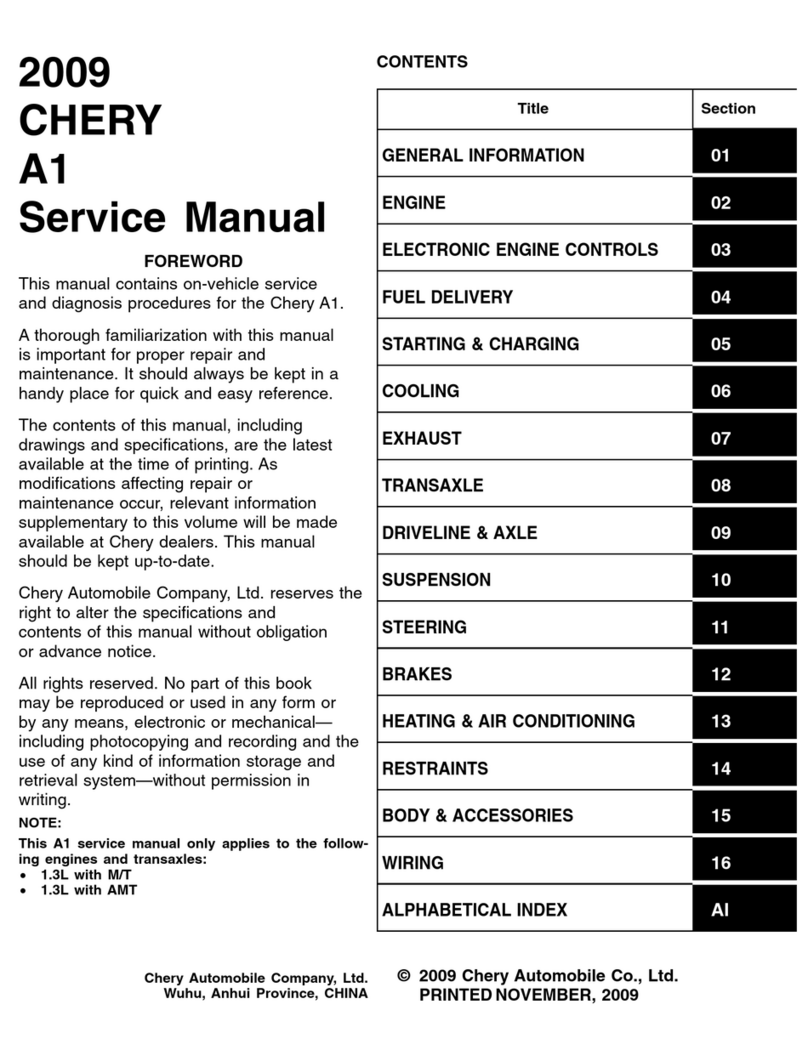

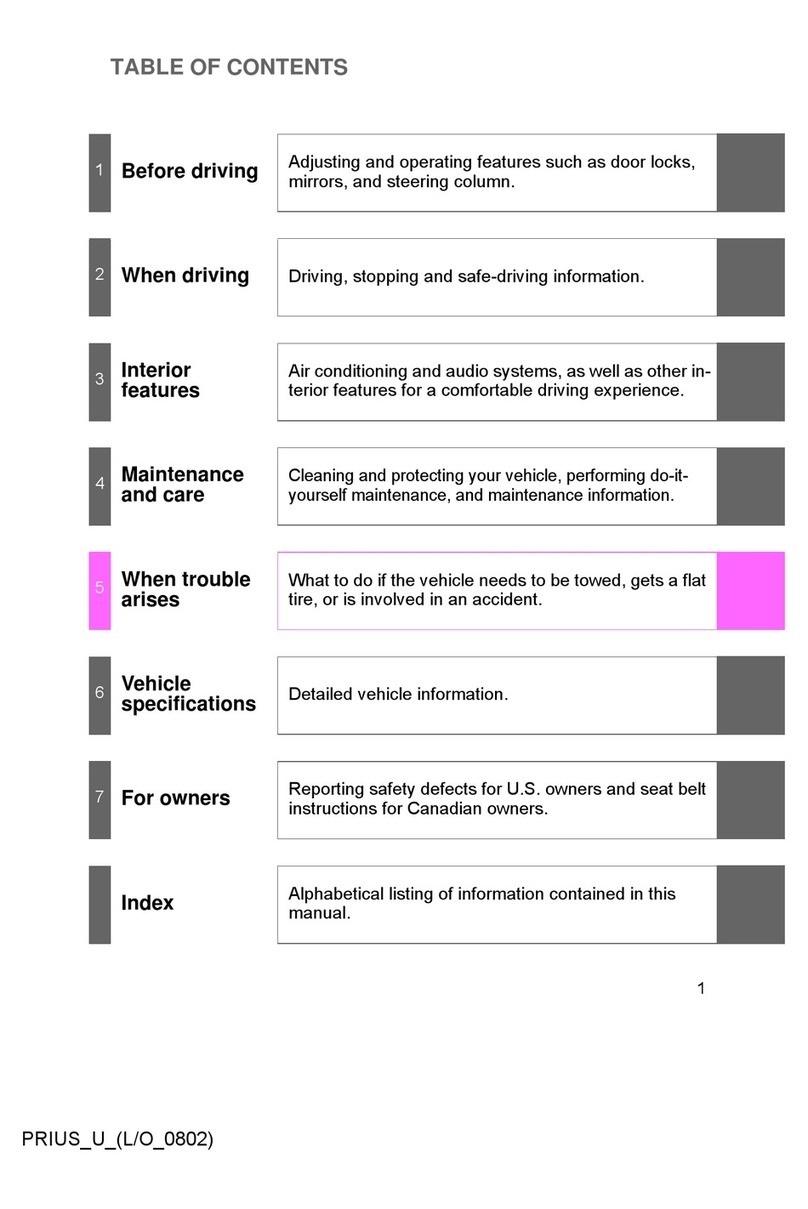

Table of contents

Other Chery Automobile manuals

Chery

Chery Tiggo 5 T21 User manual

Chery

Chery Automobile User manual

Chery

Chery QQ6 User manual

Chery

Chery Tiggo 2009 User manual

Chery

Chery A3 User manual

Chery

Chery TIGGO User manual

Chery

Chery M16 Arrizo 7 2014 User manual

Chery

Chery A5 2007 Service manual

Chery

Chery Karry series User manual

Chery

Chery V5 User manual