Chery QQ6 User manual

Service Manual forChery

QQ6

(QR513 TransmissionCase)

AfterSales ServiceDepartmentofChery

AutomobileSalesCo., Ltd

1

CONTENTS

Foreword...........................................................................................................................................................2

ChapterOneIntroduction ofQR513Transmission...........................................................................................3

I.AssemblyDrawingofQR513 Transmission..........................................................................................3

II. Driving CharacteristicsofQR513 Transmission..................................................................................4

III. SNofQR513 Transmission................................................................................................................4

1. Printposition ofSNofQR513transmission.................................................................................4

2. CompositionandconnotationofSNofQR513transmission.......................................................4

IV. SpecificationofQR513 Transmission.................................................................................................6

V. Maintenance Instruction.......................................................................................................................7

ChapterTwoDecompositionofQR513Transmission......................................................................................8

I.Decomposition Process forQR513Transmission.................................................................................8

1. Bleedinglubricantintransmission................................................................................................8

2. Disassemblyofexternalpartsoftransmission..............................................................................8

3. Separation ofgearshiftmechanismandtransmission...................................................................9

4. Disassemblyoftheconnecting boltsforclutchand transmission housings................................10

5. Separation oftransmissionand clutchhousings..........................................................................10

6. Separation ofinteriortransmission partsandforkmodulefromthehousing.............................11

7. Separation ofdifferentialassemblyandclutchhousing..............................................................12

8. Disassemblyofgearshiftforkmechanism..................................................................................12

9. Disassemblyofgearshiftmechanism..........................................................................................13

10.Disassemblyofinputshaft........................................................................................................13

11.Disassemblyofoutputshaft......................................................................................................15

12.Disassemblyofdifferential.......................................................................................................15

13.Disassemblyofreleasemechanismofclutch............................................................................16

14.Disassemblyoftransmissionhousing.......................................................................................17

ChapterThree Assemblyand RegulationofQR513 Transmission.................................................................18

I.AssemblyofQR513 Transmission.......................................................................................................18

1.Assemblyofdifferentialassembly..............................................................................................18

2.Assemblyofclutchhousing........................................................................................................19

3.Assemblyoftransmissionhousing..............................................................................................23

4.Assemblyofgearshiftmechanismassembly...............................................................................23

5.Assemblyofgearshiftforkassembly..........................................................................................24

6. Regulationandassemblyofinputshaftassembly.......................................................................24

7. Regulationandassemblyofoutputshaftassembly.....................................................................26

8.Assemblyand regulationoftransmissionassembly....................................................................28

9. Disassemblyofexternalaccessoriesoftransmission..................................................................31

10.Refillingandvolume regulationoftransmissionlubricant.......................................................32

II.TighteningTorqueTableforFasteners...............................................................................................34

ChapterFour GeneralFailuresandTroubleshooting...........................................................................35

2

Foreword

1.Thisservicemanual applies touseandmaintenance ofQR513transmission

manufacturedby Chery AutomobileCo., Ltd.

2. ServiceManualforQR513 Transmission describesrelations among various

parts and assemblies of this transmission,whichprovidethe maintenance

personnelwith areference whenmaintaining andrepairingQR513transmission.

3.Due torestrictionsofthe compiler slevel andother conditions,errorsand

imperfectionsmayexistin this servicemanual.Duringmaintenanceanduse,

pleaseinformus ofanyproblemin andimprovementideaonQR513

transmissionand this servicemanual,sothatwe cancorrect andperfect this

servicemanual,forwhichwe express our thanksherein.

3

Chapter OneIntroductionofQR513 Transmission

I.AssemblyDrawingofQR513 Transmission

12

3 4

1.Inputshaft2.Clutch3.Outputshaft4.Differential

4

II. DrivingCharacteristicsofQR513 Transmission

Thistransmission achievesfiveforwardgearsandonereversegearthroughthree groupsof

synchronizersandtwoshafts-inputshaftandoutputshaft;allforwardgearsadoptconventionalengagement

systemwhilereversegearadoptsaglidingidlerdevice. Thesynchronizersofthefirstand second gearsare

installedon outputshaftwhilethesynchronizersofthethird,fourthandfifthgearsareinstalledon input

shaft.Whenthe transmissionisshiftedtovariousgears,thesesynchronizerswill engage withcorresponding

gearhub toenabletransmission ofpower,andthenthedrivinggearofmaindeceleratorwilldrivethedriven

gearofmaindeceleratorand differentialassemblytorotate, whichwilldrivethedriveshafttodrivethe

wheelstorotate.

III. SNofQR513 Transmission

1. Print positionof SNof QR513 transmission

Theprintposition ofSNofQR513seriestransmission isasshowninthe figure:

2. Composition andconnotationof SNof QR513transmission

SNofQR513seriestransmission isconsistedofmodelandleavingfactorynumberofthetransmission case.

Positionofnumber

5

1)Modelofthetransmission case

ModelofthetransmissioncaseiscomposedofcodeQR,numberofshiftgearsofthetransmission,

maximumtransmissiontorque,characteristic code andstructure specification number.

Acompletetransmission casemodelisasfollows:

□□○○○ □□□

Structure specificationnumber

Characteristic code

Maximumtransmissiontorque (kg·m)

Numberofshiftgearsofthetransmission case

Code QR

Amongwhich, ○indicatesanArabic numeralwhile □indicatesa letter.

2)Leavingfactorynumber

Leavingfactorynumberiscomposedofendnoteofassemblypartnumber(forthatwithoutendnote,us

AA),charactercodeoftheyearofproduction,charactercodeofthemonthofproduction,sequence

numberofthistransmission caseamongthetransmissioncasesmanufacturedinthatmonthandstart

stopsign “*”. See Table 1and Table2forchecklistofcharactercodesoftheyearandofthe month.

Completeformofleaving factorynumberofa transmissioncaseisasfollows:

* □□

□□○○○○○ *

Charactercodeofthemonth

Amongwhich, ○indicatesanArabicnumeral, □indicatesaletterand indicatesanArabicnumeralora

letter.Theendnotelocatesattailendofthepartcode,forafundamentalmodel,noendnote. Theendnote

shouldbemodifiedwhenmodificationismade tostructure,dimension, material, heattreatmentrequirements

andsurfacetreatmentetc. ofthepartorassemblyon thebasisoforiginalproduct. TheEnglishletterinthe

codeshouldbeuppercaseletter(useinsequencewith “A”asthefirst),inordertoavoidconfusion,do not

use “I”, “O”and “X”.Whenthemodificationdoesnotaffectinterchangeability,use “A”asthefirst; when

themodification affectsinterchangeability, skip “A”,use “B”asthe first.

Table 1CharacterCodesIndicatingtheYears

Year Code Year Code

1999 X 2015 F

2000 Y 2016 G

2001 1 2017 H

2002 2 2018 J

2003 3 2019 K

Sequencenumberamongthe

productofthe

samemodelmanufacturedinthatmonth

Charactercodeoftheyear

Endnoteofassemblypartnumber

6

2004 4 2020 L

2005 5 2021 M

2006 6 2022 N

2007 7 2023 P

2008 8 2024 R

2009 9 2025 S

2010 A 2026 T

2011 B 2027 V

2012 C 2028 W

2013 D 2029 X

2014 E 2030 Y

Table 2CharacterCodesIndicating the Months

Month Code Month Code

January A July G

February B August H

March C September J

April D October K

May E November L

June F December M

3)Illustration

Forexample:QR513MHAMH5H00001indicatesthefirsttransmissioncasewiththemodelas

QR513MHAmanufacturedinAugust, 2005.

IV. SpecificationofQR513 Transmission

QR513SeriesTransmission

Type Machine GearMesh

Model QR513MHA QR513MHB

GearshiftVelocity

Ratio TeethRatio Velocity

Ratio TeethRatio

FirstGear 3.545 39/11 3.167 38/12

SecondGear 2.05 41/20 2.05 41/20

ThirdGear 1.423 37/26 1.423 37/26

FourthGear 1.065 33/31 1.065 33/31

FifthGear 0.865 32/37 0.865 32/37

Reverse Gear 3.364 37/11 3.364 37/11

Mainreduction ratio

4.056 73/18 75 16

7

Speedometer 0.806 29/36 0.806 29/36

Largestinputtorque 130 Nm

Lubricantoiltype GL-475W-90

Volume oflubricant 1.8L

V. Maintenance Instruction

l Inordertoensuremaintenancequalityofthetransmission,whenoperating,pleasebecareful

and ensurecleanness ofeachpartofthe transmission.

l Useappropriate toolsorspecialtools.

l Strictlyfollowthespecificationtoassemblyoradjustmenttomaintainsoastoensurethatthe

transmissioncanaccomplisha favorable workingposition.

8

Chapter Two DecompositionofQR513 Transmission

I. DecompositionProcessforQR513 Transmission

1. Bleeding lubricant in transmission

First,drivethevehicleontoamaintenance platformorhoistthevehicleandkeepit onahorizontal

plane, screwoffthebleedingplugasshownbythearrowhead,and thenuseacleancontainerto

accommodatelubricantofthe transmissiontocompletelybleedthe lubricantinthetransmission.

Figure 1

2. Disassembly of externalpartsoftransmission

SwitchthetransmissiontoNEUTRALposition;useanappropriatetooltoremovethelocatingseatof

theforkshaftasshowninFigure2;Connecting boltsforgearshifthousingand transmission housing and the

screwsforbackuplampswitchandidlershaft.

9

Screwsforidle gearshaft

Bolts-forgearshifthousingand Backuplampswitchassembly

Transmissionhousing (5)

Figure 2

3. Separationof gear shiftmechanismandtransmission

Removethegearshiftmechanismassemblyfromtheplace asshowninFigure3;asaresultofsealant,

thedisassemblyprocess maybedifficult,so,usesuchtoolsasahandhammeretc. toknockon thebulgeat

flank ofhousingofthegearshiftmechanism,andthentakeoutthewholegearshiftmechanismassembly

untilthetwohousingscompletelyseparate;remembertobeslowwhentaking outthegearshiftmechanism

assembly,soastopreventthereturnspring asshowninthefigurefromdropping outinside thetransmission;

duringdisassembly,becarefulnottodamagethejunction planesofthe twohousings, soastoavoidoilleak

afterre-assembly.

Gearshiftmechanismassembly

Locatingseatofforkshaft

forall gears(3)

Assemblyoflocating

seatofforkshaft

Returnspring(remembertoprevent

itfromdroppingout)

10

Figure3

4. Disassembly of theconnectingbolts forclutch andtransmissionhousings

Useatooltoremovetheconnecting boltsfortransmission andclutchhousingsasshowninFigure4.

Remembertoremovetheboltsbothinsideandoutsidetheclutchhousing whendisassembling,and asleeve

withlong connecting rod isrequiredwhenremoving the boltsinsidethe clutch.

Connecting boltsfortransmission andclutchhousings

Figure 4

5. Separationof transmissionandclutchhousings

Aftertheboltsfortransmission andclutchhousingsareremoved,separateclutchhousing and

transmissionhousing (Figure5).asaresult ofsealant,theseparationprocess maybedifficult,so,usesuch

toolsasahand hammeretc. toknockonthebulgeatflankofhousingofthetransmission,and thentakeout

thewholetransmissionhousinguntilthetwohousingscompletelyseparate;duringdisassembly,becareful

nottodamagethejunctionplanesofthetwohousings,soastoavoidoilleakofthetransmissionafter

re-assembly.

11

Transmissionhousing Clutchhousing

Figure 5

6. Separationof interiortransmissionparts andfork module fromthe housing

Aftertransmissionhousingandclutchhousing are separated,keeptheclutchhousingflatatthe placeas

showninFigure6,removetheboltsforbracketofreversegearrockerarm,takeoutthereversegearrocker

armassemblyandthepinon idlerdrive,and thentakeoutinputshaft,outputshaftand forkmechanism

together(whentakingout,gentlyshake, meanwhile, press thedrivengearofmaindeceleratoralong the

directionofarrowheadasshowninthefiguretotakeouttheassemblyofinputshaft,outputshaftandidler

aswell asforkmechanism);whentaking out,remembertoavoidinterferencebetweenbearingretainerof

outputshaftandbiggearringofdifferentialandpreventthe bearing retainerfromdamage.

Boltsforreversegearrockerarmbracket(2intotal)

Reversegearrockerarm

Reverse gearidlerassembly

Figure 6

12

7. Separationof differentialassemblyandclutchhousing

Separatedifferentialassemblyandclutchhousing,andthensimplytakeoutthedifferentialassemblyas

showninFigure 7.

DifferentialAssembly

Figure7

8. Disassembly of gearshiftfork mechanism

Useahammerand aspecialtooltoknockoffallspringpinsandthenuseasnapringpliersorother

specialtooltotakethesplitwasherofftheforkshaft(whentaking offthesplit washer,preventitfrom

deformation),andthendisassemble eachpartofthegearshiftmechanism.

SplitwasherSpringpin

13

Figure 8

9. Disassembly of gearshiftmechanism

AsshowninFigure9, removethe gearshiftarmbracketboltsandreversegearlockupmechanismbolts

first,useahammerandaspecialtooltoknockoffallspringpins,useaspecialtooltoremovethesplit

washer,andthendisassemble eachpartofthe gearshiftmechanism.

Gearshiftarmbracketbolts(2intotal)

Reverse gearlockup mechanismbolts(2intotal)

Split washer

Figure 9

10. Disassembly of input shaft

AsshowninFigure10,Useaspecialtool(suchasbearing removeretc.)toremovethetwobearingson

theinputshaftfirst,useaspecialtooltoremovetherearsnapring,andthentakeoff thefifthgear

synchronizerassembly.

14

RearsnapringFifthgearsynchronizer

Figure 10

Afterthefifthgearsynchronizerassemblyisremoved,removetheremainingpartssuchasshiftgears,

needlebearingsand synchronizersinturnasshowninFigure11;whendisassembling,besuretokeepthe

synchronizerofeachgearconcurrentwithitscorresponding synchronizerring.

Figure 11

Bearing(whendisassembling,be

carefuland use a specialtool)

15

11. Disassembly ofoutputshaft

Themethodand process fordisassemblyofoutputshaftarebasicallythesameasthoseforinput

shaftandthe outputshaftcanbe disassembledtothe statusasshowninFigure 12.

Figure 12

12. Disassembly of differential

AsshowninFigure13,useaspecialtooltotakeoffthetwobearingsfirst,removetheboltsfordriven

gearanddifferentialhousing,removethedrivengear,knockoffthefixingpinoftheplanetarygear,and then

takeouteverypartinside the differential(Figure 14).

Fixing pinofplanetarygear Boltsfordrivengearand differentialhousing(8intotal)

Figure13

16

Figure14

13. Disassembly of releasemechanismof clutch

AsshowninFigure15,takeoff releasebearingofthe clutchfirst,removetheboltsforrelease fork, and

thendrawthereleaseshaftassemblyofftheclutchhousing(duringthedrawingoffprocess,besureto

preventthereleasereturnspring fromejection);also,removethebushanddismountreleasemechanismof

theclutchfromthe clutchhousing.

Release bearingofclutch Boltsforreleasefork Release forkRelease arm

BushRelease returnspring

17

Figure 15

Besuretousespecialtoolandbecarefultoremovetheoilsealontheclutchhousing,because

excessivedeformationordamageoftheoilsealmayresult inoilleakofthetransmission.Useaspecialtool

toremovethetwooilsealson theclutchhousing,andthenremovetheremainingbushes,oil ductsand outer

ringsofbearingsasshowninFigure16.Replacingwithnewoil sealsaftertheformeronesareremovedis

recommended.

Oil sealForkshaftbearing(3)

Outerring ofbearing Oil ductFigure 16

14. Disassembly of transmissionhousing

AsshowninFigure17,useaspecialtooltoremovetheoilsealoftransmission housing,andthen

remove oil drainchannel,forkshaftbushand linearbearing.

18

Linearbearing Forkshaftbush

Oil sealOil drainchannel

Figure 17

Chapter ThreeAssemblyand RegulationofQR513 Transmission

I.AssemblyofQR513Transmission

Afterdisassembly,visuallyinspectpartsforanyabnormalconditionsuchasdeformation etc,andmake

records;Replace thedamagedparts, cleanand washallparts, thenreassemble.

1.Assembly of differentialassembly

Fitadjustmentgasketsrespectivelyatbacksidesofthe twohalfaxlegears,andtheninstall thetwohalf

axlegearstogetherwiththeirgasketsintothedifferential.Whenfittingadjustmentgasketsforthehalfaxle

gears,selectthegasketwiththicknessas1.2mmfirst.Fitsphericalwashersfortheplanetarygear,and then

simultaneouslyengagethetwoplanetarygearswiththetwohalfaxlegears(fitthemtocorrectpositions

whileturningthe gears).Inserttheplanetarygearshaft; notethatthefixingpinholeonthe shaftshouldalign

correctlywiththatonthedifferentialhousing bothinthepositionandalongthedirection.Measurethe

clearance betweenthehalfaxlegearandtheplanetarygear,and thenormalizedvalueshouldbe

0.025~0.150mm;iftheclearance doesnotconformtothenormalizedvalue, replacetheadjustmentgaskets

forthehalfaxlegear,andthenre-measuretheclearance untilitconformstothestandardwithuniform

clearance atbothsides.Drivedownthefixingpinofplanetarygearshaftfromthefixingpinholeattheside

ofdifferentialhousingwithflangewiththepinwithendsurface ofthepinhole. Installdrivengearofmain

deceleratorand ensurethattheinstallationend surface ofthegearfitswellwiththeend surface ofthe

differentialhousing,andthenfixthedrivengearofmaindeceleratorwithbolts(applysealanttofullthread

19

oftheboltbeforeinstallation);screwtheboltshomewiththetorqueas 130 5Nm cornerwiseand alternately;

respectivelypress inaninnerring offrontandrearbearingsfromeachofbothendsofthedifferential

housing andcheckifit hasbeenpressedtothedesignatedposition.Notethatthelubricantappliedonto

adjustmentgasketsforhalfaxlegears,planetarygeargaskets,junctionsurface ofplanetarygearand

planetarygearshaft,junction surfaceofhalfaxlegearand differentialhousingshouldbethesameasthat

usedinside thetransmission. RefertoFigure 18.

Planetarygear (2) Planetarygear shaft Connecting bolt(8)

Halfaxle gear(2)

Figure 18

2.Assembly of clutchhousing

Useahammerandaspecialtooltofitoilsealofinputshaftwithspringsideoftheoil sealupand

greaseappliedtolipoftheoil seal.Useaspecialtoolandahampertofitrightsideoilsealofdifferential

withendsurface oftheoilsealflushwiththehousingsurface, and thenapplygrease tolipofthe oilseal.See

Figure 19.

Innerringof

bearing (2)

Adjustmentgasket

forplanetarygear

(2sheets)

Fixingpinofplanetary

gearshaft

Adjustmentgasketforhalf

axle gear(2sheets)

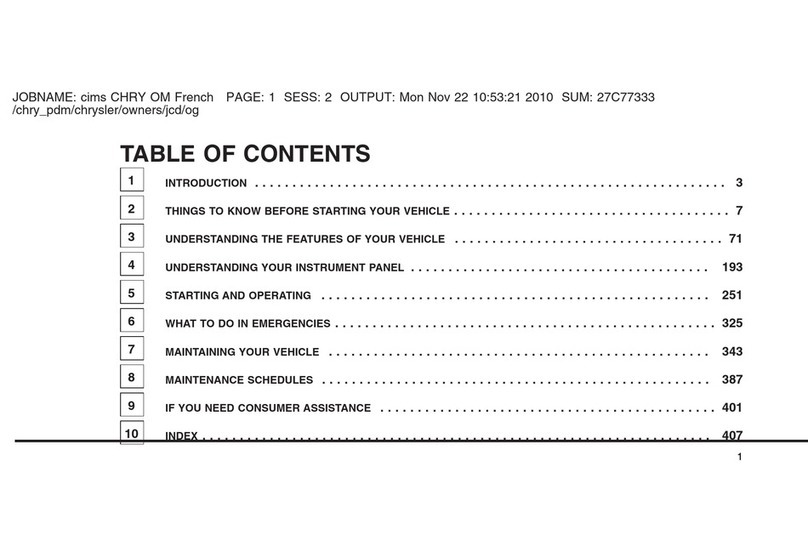

Other manuals for QQ6

3

Table of contents

Other Chery Automobile manuals

Chery

Chery SQR7240T User manual

Chery

Chery V5 User manual

Chery

Chery T21 2014 User manual

Chery

Chery A21 2005 User manual

Chery

Chery QQ User manual

Chery

Chery A113 User manual

Chery

Chery TIGGO User manual

Chery

Chery Tiggo 2009 User manual

Chery

Chery Automobile User manual

Chery

Chery A1 2008 Instruction Manual

Chery

Chery SQR480ED User manual

Chery

Chery QQ6 User manual

Chery

Chery Karry series User manual

Chery

Chery A11 2003 Operating instructions

Chery

Chery S18D User manual

Chery

Chery TIGGO User manual

Chery

Chery M16 Arrizo 7 2014 User manual

Chery

Chery QQ3 User manual

Chery

Chery A21 User manual

Chery

Chery QQ6 User manual