Chery QQ User manual

CheryQQServiceManual MechanicalPartofSQR472Engine

1

SQR472 Engine

Service ManualforMechanicalPart)

After-salesDepartment ofCheryAutomobile SalesCo.,Ltd.

CheryQQServiceManual MechanicalPartofSQR472Engine

1

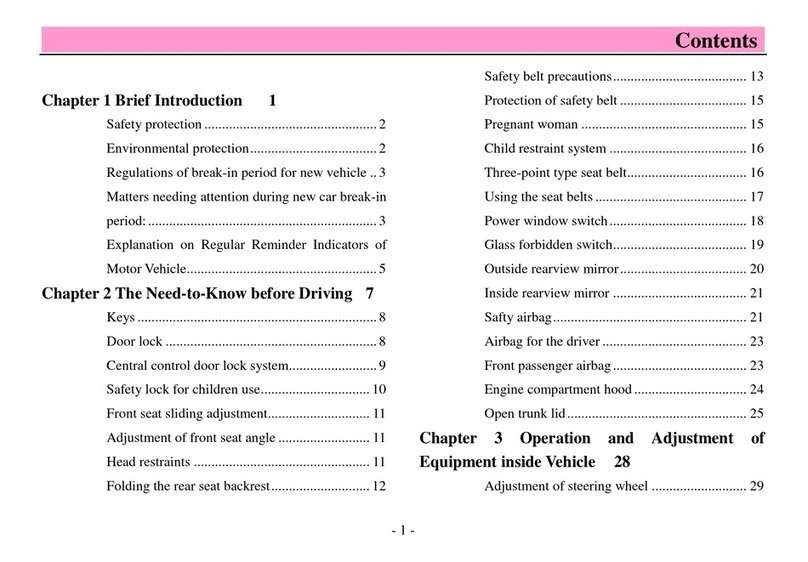

CONTENTS

Chapter1 ReadingInstruction......................................................................................................................................2

1)ReadingmethodofMaintenance Instruction............................................................................................................2

2)MeaningofMarksandAbbreviations......................................................................................................................3

3)SpecialMaintenance Tool.........................................................................................................................................4

Chapter2 Disassembly,Assemblyand Maintenance....................................................................................................6

1)TimingBelt...............................................................................................................................................................6

1. StructureDiagram.............................................................................................................................................6

2. Disassembly......................................................................................................................................................7

3. Installation......................................................................................................................................................10

2)Camshaft.................................................................................................................................................................13

1. StructureDiagram...........................................................................................................................................13

2. Disassembly....................................................................................................................................................14

3. Installation......................................................................................................................................................16

4. RoutineInspection ofValve............................................................................................................................19

3)CylinderHead.........................................................................................................................................................22

1. StructureDiagram...........................................................................................................................................22

2. Disassembly....................................................................................................................................................23

3. RoutineInspection..........................................................................................................................................23

4)WaterPump............................................................................................................................................................29

1. StructureDiagram...........................................................................................................................................29

2. Disassembly....................................................................................................................................................29

3. Cleanup...........................................................................................................................................................29

4. RoutineInspection..........................................................................................................................................29

5. Assembly.........................................................................................................................................................29

5)Oil Pump.................................................................................................................................................................29

1. StructureDiagram...........................................................................................................................................30

2. Disassembly....................................................................................................................................................30

3. Cleanup...........................................................................................................................................................30

4. Disassemblyand AssemblyofEngineOil Pump............................................................................................43

4.1 StructureDiagram.................................................................................................................................42

4.2 Disassembly..........................................................................................................................................42

4.3 RoutineInspection................................................................................................................................42

4.4 Installation.............................................................................................................................................44

5. DisassemblyofOil Seal..................................................................................................................................45

5.1 StructureDiagram.................................................................................................................................45

5.2 Disassembly..........................................................................................................................................46

5.3 Inspection..............................................................................................................................................46

5.4 AssemblyofOil Seal............................................................................................................................46

6Assembly..........................................................................................................................................................46

6)Crank ConnectingRodMechanism........................................................................................................................46

1. StructureDiagram...........................................................................................................................................48

2. DisassemblyofCrankConnectingRodmechanism.......................................................................................48

3. Cleanup...........................................................................................................................................................49

4. RoutineInspection..........................................................................................................................................52

5. AssemblyofCrankConnectingRodMechanism...........................................................................................53

CheryQQServiceManual MechanicalPartofSQR472Engine

2

Chapter3 TableofMainFit Clearance forSQR472 Engine......................................................................................55

Chapter4 TableofMeasurementParametersofSQR472 Engine..............................................................................59

Chapter5 TableofMainFittingTorqueforSQR472 Engine.....................................................................................61

Chapter6 PositionsonSQR472 EnginetobeLubricated..........................................................................................62

Chapter7 PositionsonSQR472 EnginetobeSpreadwithSealant............................................................................65

CheryQQServiceManual MechanicalPartofSQR472Engine

3

Chapter 1.ReadingInstruction

1)ReadingMethodofMaintenanceInstruction

.1 AuxiliaryMaterials

If it isrequiredintheoperationinstructiontopreparetheauxiliarymaterialssuchasspecialtools,tools,measuring

instrumentsandgreaseinadvance,youshouldlistallauxiliarymaterialsrequiredinatablebeforecarrying outeach

operation.

Sincetheordinarytools,lifterandsparepartsareconventionalmaterialsusedinthemaintenance,theyareomitted

here.

.2 OperatingSequence and StructureDiagram

(1)Thediagramofstructureandcomponents,nameofcomponentsandinstallationstatusaresetforthatthe

beginningofeachchapterorsection.

(2)Thenumberinthefigurereferstothedisassemblysequenceofeachcomponent.Thecomponentswhichmaynot

bereusedand thetighteningtorqueareindicatedinthefigure.

Seal Ring

②EngineOilPumpCoverSheet

③EngineOilPumpOuterRotor

④EngineOilPumpInnerRotor

⑤CotterPin

⑥Oil DrainValveSpringSeat

⑦Oil DrainValveSpring

⑧SlideBlock

⑨CrankshaftFrontOilSeal

⑩EngineOilPumpHousing

1 .3 ContentOmittedinthisManual

Thefollowingoperating procedureshavebeenomittedinthisManual,andtheyshouldbecarriedoutintheactual

operation:

(1)Operation relating tothelifterandthesmall-sizedelevator;

(2)Cleaningandwippingofcommon components;

(3)Relevantvisualinspection.

※:C omponentswhichmay

not bereused

Unit:N m(kg cm)

CheryQQServiceManual MechanicalPartofSQR472Engine

4

1 .4 Definitions

Referstoallowedvalueduringinspection,maintenance andadjustment.

Referstothemaximumorminimumvaluethatshouldnotbeexceededduring

inspection,maintenanceandadjustment

Setthestandardvalueforsimplemeasurementtopreventfromitsmeasuring

difficultyandinconsistencytofacts.

Referstothedifferencebetweenmaximumvalueandminimumvalue.

Itcarriesthecasesofdamaging thevehicleandpartssoyoushouldpayattention

totheoperationdescription.

Itrecordstheoperationdescriptionsofcasesaboutperson accident.

2)MeaningofMarksandAbbreviations

Mark OriginalWords Intepretation

RH RightHand RightHand

LH LeftHandLeftHand

FR Front Front

RR Rear Rear

IN Intake Intake

EX Exhaust Exhaust

SAE SocietyofAutomotiveEngineers SocietyofAutomotiveEngineers

API AmericanPetroleumInstitute AmericanPetroleumInstitute

SPECIAL

TOOL SpecialTool SpecialTool

T Torque Torque

Ay Assembly Assembly

S/A SubAssembly SubAssembly

W/ With With

M/T ManualTransmission ManualTransmission

A/T AutomaticTransmission AutomaticTransmission

T/C TurboCharger TurboCharger

Standardvalue

Limit

Reference

Difference

Notice

Warning

CheryQQServiceManual MechanicalPartofSQR472Engine

5

3)SpecialMaintenanceTools:

Outsideview Nameorsymbol Purpose

Enginedisassemblyandinspectionauxiliary

device

Mountontheengineservice

stand

Engineservicestand Disassemblyandassembly

ofengine

Clampholewrenchforcamshafttiming gears

Disassemblyofcamshaft

timinggears

Springbushingpuller AssemblyofcamshaftOil

seal

Valvekeeperremovetool

Auxiliarytools

Assemblyanddisassembly

ofvalvespring retainerlock

Flywheelclamp Assemblyanddisassembly

ofcrankshaftgear

Valveguidepunchpin Disassemblyandassembly

ofValveguide

AxialOil sealreplacingdevice

Oil sealbasedrive

CheryQQServiceManual MechanicalPartofSQR472Engine

6

Outsideview Nameorsymbol Purpose

Piston pinpuller Disassemblyandassembly

ofpistonpin

Embededcombinationoil sealandhelical

gearpuller Installationofoil seal

Crankshaftpulleyholdingtool Disassemblyandassembly

ofcrankshaftpulley

Wrench Disassemblyandassembly

ofcrankshaftdrivengear

Replace valveclearance

adjustmentgasket

Waterpumppulleylockingwrench Assemblyofcoolantpump

Measuring

tools

Feelergauge.Micrometercaliper.Ruler.Dialgauge.Cylindergauge.Caliber.Pressuregauge.Torque

wrenchtorquewrench

Tool Piston ringextractor

Oil EngineOil, adhesive

CheryQQServiceManual MechanicalPartofSQR472Engine

7

Chapter 2.Disassembly,Assemblyand Maintenance

Disassembleorassembletheenginewithroll overstand.

Disassembleorassembletheenginepartson theroll over

stand.

1)TimingBelt

1.StructureDiagram

①Waterpumppulley

②Timingshroud

③Timingbelt

④Torsionaldamper

⑤Timing beltbackplate

⑥Tensionpulley

⑦Camshafttimingpulley

※:C omponentswhichmay

not bereused.

Unit:N m(kg cm)

CheryQQServiceManual MechanicalPartofSQR472Engine

8

2.Disassembly

2.1 Removethewaterpumppulleyastheviewshowing.

Itwill bebetterofdisassemblingwithspecialtool.

Torque:25±1.5 N.m

2.2 DisassemblyofTimingBelt Cover

Torque:6±1N.m

2.3 Disassemblyoftorsionaldamper

Usespecialtoolstopreventthegearring from

rotating.Whendisassemblingthefixingboltsofthe

torsionaldamper,makesurethatthemarksonthe

crankshafttimingpulleymatchwiththetimingmarks

ontheengineoil pump.

2.4 Removethetimingbelt backplate.

CheryQQServiceManual MechanicalPartofSQR472Engine

9

2.5 Disassemblyoftensionpulley

2.5.1 Compressthetopdeadcenteratthefirstcylinder

piston.Afterdisassemblyoftimingcover,pull the

bolt andclockwiserotatethetiminggearwith

wrench.Andthenalignthetimingmarkofcamshaft

timinggearandtheraisedmarkoncamshaftcover;

2.5.2 Screwoffthebolt oftensionpulleyandremovethe

tensionpulley.

2.6 Disassemblyoftimingbelt

Notice:Donotusesharptoolslikescrewdriverduring

disassemblyofbelt.

Notice:Payattentiontothefollowingitemsduringusing

thetimingbelt:

lDonotbendthebelt withsmall angle,ortheriggingin

belt willbreak.

lDonotpollutegreaseandwaterbecausetheusing

expectancyofbeltisshort.

lOnlyclockwiserotatetheengineaftermountingthe

belt.

2.7 Disassemblyofcrankshafttiminggear

TimingMark

TimingMark Clockwise

CheryQQServiceManual MechanicalPartofSQR472Engine

10

2.8 Inspectthetimingbelt carefully,andreplacenewcomponentsunderanyofthefollowingcircumstancesorwhen

themileageisuptotheconditionsofreplacement:

2.8.1 Chapofback-siderubber

2.8.2 Chapofdedendum, chapofseparatedcordfabric.

2.8.3 Wearing,gearmissingandincompletegearofcordfabric.

2.8.4 Abnormalwearingofbelt flank.

2.8.5 Notice:Replacethebelt asanyfollowingsituationoccurs,eventhoughabrasion cannotbefounddirectly:

Thewaterpumpleakswaterout,and requirescontinuinginfusion.If thebelt isspottedwithmuchoilstains,andthe

rubbermaybedamagedduetoexpansion,youshouldreplace thebelt.

Timingbelt modelandtype

Partnumber 372-1007081

Widthofbelt 25.3mm

TensionPulleyofTimingBeltRotatethebolt oftension pulleybracketandhearifit isnoisy;checkthecontacting

surface andlookifit isdamaged.Modelandtypeoftensionpulleyoftiming belt

Partnumber 372-1007030

Width 27.0mm

Outerdiameter φ50mm

Checkiftheoutisdamaged.Timingbelt modeland type

EFType

Item GL, ZL, GS, ZS

Camshafttimingpulleydiameter(mm) φ110.7+0.1-0.2

Camshafttimingpulleydiameter(mm) φ54.65+0.7-0.13

Chap

Chap

Wearing

Abnormal

Gear

Falloff with

CheryQQServiceManual MechanicalPartofSQR472Engine

11

Checkthetimingbelt backplateforany deformation.

Standardsizeofcrankshafttiminggear

Width 28.6mm

3.Installation

3.1 Assemblyofcrankshafttimingpulley.

3.2 Installationoftiming(atthetopdeadcenterofthe

firstcylinderpiston)

3.2.1 Putthecamshafttiminggearon thefrontend ofthe

exhaustcamshaft,alignthelocatingslotonthegearwith

thelocatingpinontheendofthecamshaft,andthenfix

thetiminggearwithbolts.Thetighteningtorqueforthe

boltsis100±5Nm.

Makesurethattheclashing markofcrankshafttiming

pulleyalignswiththemarkofoil pump.

3.3 Install thetensionpulley.Afteradjustthetensionof

timingbelt,install thetensionpulleybolt andtightenit

withthetorquespecified.Adjustthetensionofthetiming

belt acording tothefollowing instruction,andinstall the

tensionpulley.

3.3.1 Asindicatedinthefigure,makethetensioner

swingtotherightwithascrewdriversothatthedistance

betweentheedgeofthetensionpulleyandthecirculararc

ofthewaterpumpbodyis8mm,andthentightenthe

tensionpulleyboltswiththetorqueof25±3Nm.

TimingMark

TimingMark

CheryQQServiceManual MechanicalPartofSQR472Engine

12

3.3.2 Rotatethecrankshaftalongtherotatingdirectionof

theenginefor2roundssothatthetiming markonthe

timing gearofcamshaftandcrankshaftismatched

respectively,andthentightenthecrankshaftbelt pulley

bolts.

3.3.3 Theforcerequiredtopressdownthecentral

positionbetweenthe2pulleysatthein-tensionsideofthe

timingbelt forabout5mmis:

[Reference]19.6-29.4N(2.0-3.0kg)

Notice:whenthedeflectioncannotreachthestandard,it

isnecessarytoadjustthefixingbolt oftensionpulley

mentionedabove.

Tightenthefixingbolt ofthetension pulleywiththetorque

asspecified. Thetighteningtorqueis25±3N.m

3.4 AssemblyofTimingBeltBackPlate.

Notice:Install thetimingbelt backplateinthedirectionas

indicatedintherightfigure.

3.5 Install thetorsionaldamperwithspecialtools.

3.5.1 Withoutflywheel

3.5.1.1 Hitchthepartofcrankshaftpulleywiththebelt

ofspecialtool.

3.5.1.2 Holdonthehandleofthespecialtooland

preventthetoothedbelt fromrotating.Tightenthebolts

withthespecifiedtorque.

Torque:98.0±10N.m{10±1kgm}

Inside Outside

CheryQQServiceManual MechanicalPartofSQR472Engine

13

3.5.2 Withflywheel

3.5.2.1 Preventthegearfromrotatingwithspecialtool.

3.5.2.2 Thenscrewdownthebolt oftorsionaldamper.

3.6 Assemblyoftimingcover.

Mountthesealingstripsatthepositionsasindicatedinthe

rightfigure.Thesealingstripsattheposition1and2

shouldbemountedbeforetheassemblyofthecylinder

headassembly,andthesealingstripattheposition3

shouldbemountedbeforetighteningthewaterpump.

Install thetimingcover,screwintheboltswithhand and

thentightenthem.

Torque:6±1N.m

3.7 Installationofwaterpumppulley.

Torque:6±1N.m

1

2

3

CheryQQServiceManual MechanicalPartofSQR472Engine

14

2)Camshaft

1.StructureDiagram

(1) Cylinderheadchambercoverassembly

(2) Cylinderheadcovergasket

(3) Camshafttimingbelt

(4) Camshaftcover

(5) Blankingcover

(6) Camshaftbearingcap

(7) Exhaustcamshaftassembly

(8) Intakecamshaftassembly

(9) Camshaftoilseal

(10)Axialspringretainerring

(11)Saddlewasher

(12)Intakecamshaftsubgear

(13)Transmissionring

※:C omponentswhichmay

not bereused

Unit:N m(kg cm)

CheryQQServiceManual MechanicalPartofSQR472Engine

15

2.Disassembly

2.1 Cylinderheadchambercoverassembly;

②Disassemblysequence of cylinderhead

chambercover;

2.2 Removethecamshafttiminggearwithspecialtool.

Notice: Thespecialtoolshouldbemadeasindicatedin

therightfigure.

Usethespecialtooltopreventthecamshaftfrom

rotating.

2.3 Removethecamshaftbearingcap

2.3.1 Themarksonthecamshaftgearshouldmatch

witheachotherasindicatedintherightfigure.

TimingMark

Gearof Intake

Camshaft

GearofExhaust

Camshaft

CheryQQServiceManual MechanicalPartofSQR472Engine

16

2.3.2 Positionthemainsubgearon intakecamshaft

withbolts, ascanbeseenfromtherightpicture.

Notice:Inordertoeliminatetheradialforceofthe

camshaft,thecamshaftshouldbekeptatthehorizontal

positioninthecourseofdisassemblysoastopreventthe

damagecausedbytheexcessivelyhighradialforce.

2.4 Disassembletheboltsintheorderasindicatedinthe

rightfigure,andthendisassemblythecamshaftbearing

cap.

2.5 Removethesparkplug

2.6 Disassemblethesubgearofthecamshaft.

2.6.1 If usingthespecialtools,operateasindicatedin

therightfigure.

Clampthecamshaftandplugthepinsofspecialtoolinto

theholeongear;rotatethegeartokeepthemeshing of

drivengearanddrivinggear,andthenremovethefixing

bolt ofdrivengear.

Notice:Thesurface ofthecamshaftmaynotbedamaged.

2.6.2 If notusingthespecialtools,operateasindicated

intherightfigure.

(1)ScrewM6boltsontothesubgearoftheintake

camshaftatthepositionasindicatedintherightfigure.

(2)Usethescrewdrivertoturnthegearasindicatedin

thefigure,anddisassemblethefixingboltsofthesub

gear.

Notice:Thesurface ofthecamshaftmaynotbedamaged.

(3)Disassembletheaxialelasticretainerring with

tensionerand removethesaddlespringwasher,

transmissionring, andsoon.

2.7 Camshaft

ForFixing

Bolt

FixingBolt

CheryQQServiceManual MechanicalPartofSQR472Engine

17

2.7.1 Measurethecamshaftwithmicrometercaliper.Ifit

isbelowtothespecifiedlimit, replace withanewone.

CamshaftjournalUnit: mm

EFType

Item ZL, RL

GL, GS, ZS

IN φ23.0-0.02-0.033

Standardvalue

EX φ23.0-0.02-0.033

IN 22.9

Limit: 0.10 EX 22.9

2.7.2 Inspectionofcamshaftaxialclearance

(1)Replace thecamshaftwhentheaxialclearancevalue

measuredwithdialgaugeexceedsthestandardvalue.The

axialclearance ofintakecamshaftis0.1~0.170mm.

Theaxialclearance ofexhaustcamshaftis0.1~0.173mm.

Limit: 0.18mm.

2.7.3 Inspecttheclearance oftheengaging toothof

camshaft

(1)Install thecamshaftintothecylinderhead.

(2)Confirmthemarkforwardsonthebearingcapas

well astheaxlenumber, andthentightenthebolts.

(3)Measuretheclearance ofengagingtoothoftheintake

camshaftwithdiaindicator.

Notice: Measureat4 pointsonthecircleofthepiston

Turntheintakecamshaftwithspecialtools.

Makesurethatthemarksonthedrivengearand

thedrivinggearofthecamshaftmatchwitheach

other.

Inspecttheclearance oftheengagingtoothofcamshaft:

Item Standardvalue Limit

Singletootj 0.04-0.13 0.30

3.Installation

3.1 Underthecircumstance thatspecialtoolsareused:

3.1.1 Fixthe2holes(φ6)ofthecamshaftgear

assemblywithspecialtool.

3.1.2 Rotatethedrivengeartotherightwithspecial

toolandtallythemarkholeofdrivengearwiththatof

camshaftdrivinggear,ortheirmarkingwaycomplieswith

eachother,fixthedrivengearwithbolts.(Thread:M5;

Threadpitch:0.8)

ForFixing

CheryQQServiceManual MechanicalPartofSQR472Engine

18

3.2 Underthecircumstancethatspecialtoolsarenot

available:

3.2.1 ScrewtheM6 boltsintothecamshaftdrivengear

attheposition indicatedintherightfigure.Inserta

screwdriverintothegapbetweentheM6bolt andthe

camshaftjournalandtrunthedrivengearrightwardsso

thatthefittingmarkofthe2gearsmatchwitheachother

orthetoothheadofthe2 gearsaccord witheach other, and

thenfix thedrivengearwithbolts(M5×0.8).

Notice:Don’tdamagethejournal, adjusttheoperation.

3.3 Assemblyofcamshaft

Notice:Payattentiontotheaxialclearance ofthecamshaft

3.3.1 Spreadgreaseonthegearofcamshaftandtheaxial

ofcylinderhead.

3.3.2Removethefixing boltsforcamshaftdriven

gearaftermountingthecamshaft.

3.3.3 Mountthecamshaft,alignthetimingmarkascan

beseenfromtherightpicture

3.3.4 Spreadoil fullyonthecamofcamshaftassembly,

gearsand axialofcylinderhead.

3.4 Tightenthecamshaftbearingcapbytheorderofright

picture.

3.5 Screwoffthefixingboltsfordrivengearofintake

camshaftassembly.

TimingMark

GearofExhaust GearofIntake camshaft

ForFixing

Bolt

CheryQQServiceManual MechanicalPartofSQR472Engine

19

3.6 Assemblyofcamshaftcove

Spreadsealantontheposition(slot)ofcamshaftcoveras

canbeseenfromtherightpicture.

3.6.1 AssemblyofCamshaftCover

Tightentheboltsintheorderasindicatedintheright

figureandwiththespecifiedtorque.

3.6.2 Afterspreadingoil ontheblankingapertureof

cylinderheadandthemountingsurface ofblanking cover,

press theblankingcoverwithspecialtool.

Notice:Theblankingcovershouldbeinstalledinthe

direction asindicatedintherightfigure.

Afterbeingpressed,theblankingcovershouldbe

1±1mm higherthanthesurfaceofthecylinder

head.

3.7 Spread theedgeofthecamshaftoilsealwithoil,and

press it intothecylinderheadwithM10 bolt (length:

50-60mm)andspecialtools.

Notice:If theoil sealisreused,spreaditwithoil before

pressingit intothecylinderhead.

Afterremoving thebolt,knockitwith handsoasto

inspectandconfirmit.

3.8 Assemblyofcamshafttiminggear

Afterspreadingsealantonthebolt,preventit fromrotating

withspecialtooland screwdowntheboltofcamshaft

timinggearinspecifiedtorque.

Torque:100±5N.m

Notice:Process thespecialtoolsasindicatedintheright

figurebeforeusingthem.

GlueSpreadLine

Outside

Table of contents

Other Chery Automobile manuals

Chery

Chery A113 User manual

Chery

Chery Automobile User manual

Chery

Chery A1 2008 Instruction Manual

Chery

Chery T21 2014 User manual

Chery

Chery V5 User manual

Chery

Chery Tiggo 2009 User manual

Chery

Chery M16 Arrizo 7 2014 User manual

Chery

Chery Tiggo 5 T21 User manual

Chery

Chery A5 2007 Service manual

Chery

Chery SQR480ED User manual