Operating Principles Air Chicago Express

5-6

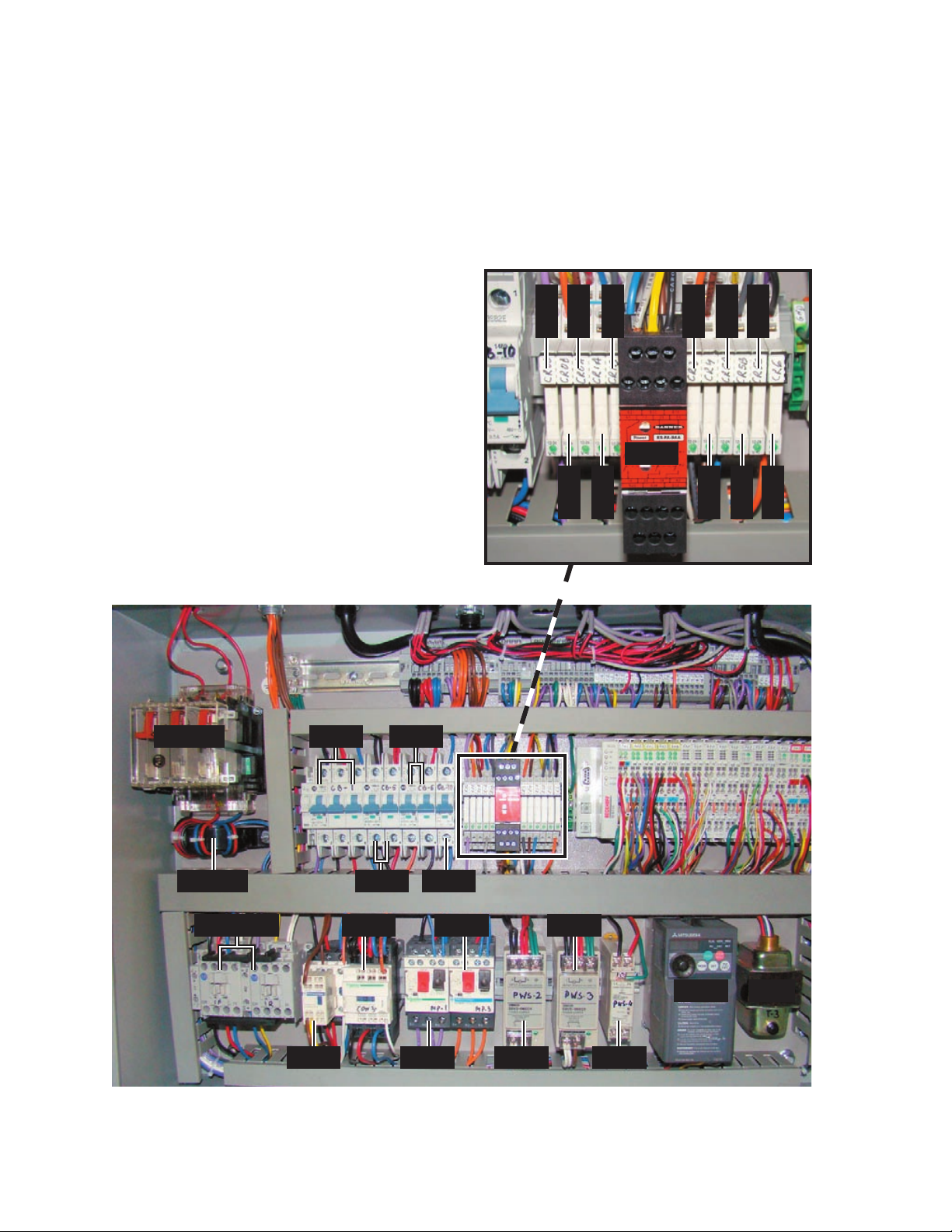

Control System

Control of the machine is done in two areas.

Input from the operator takes place at the

CHI•Touch screen, located on the outside of the

unit. These commands are combined with internal

signals in microprocessor unit.

CHI•Touch Screen

Operators control the folder with the Chicago

High Intelligence (CHI) touch screen located

at the right front of the unit (Figure 5-4). The

CHI•TOUCH OPERATION bulletin discusses

the use of this screen.

The touch screen accepts the operator touch

and sends them to the microprocessor unit, which

in turn sends operation and diagnostic messages

to the screen for display.

Communication between the CHI•Touch

screen and the microprocessor unit is handled

via a USB connection.

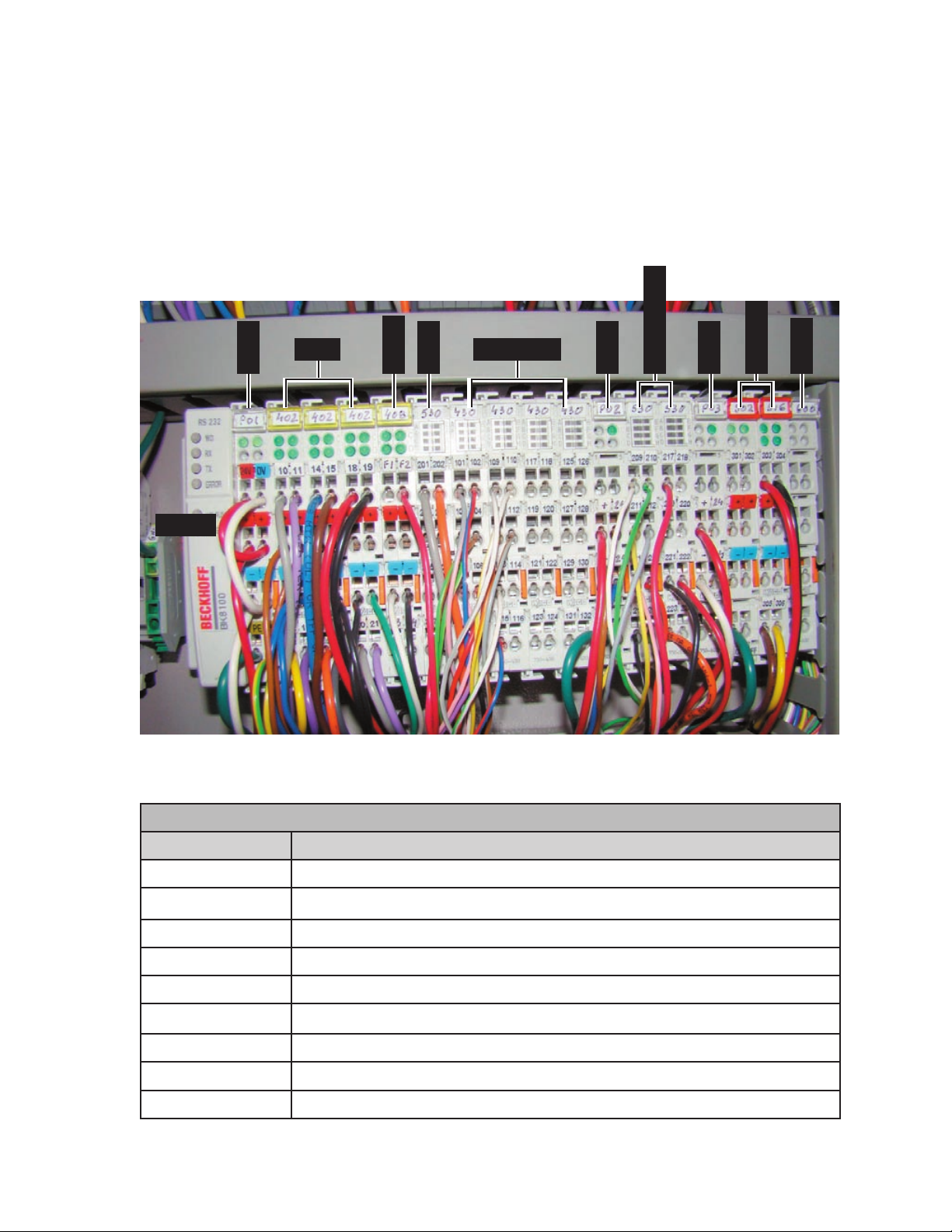

Communications and the I/O Panel

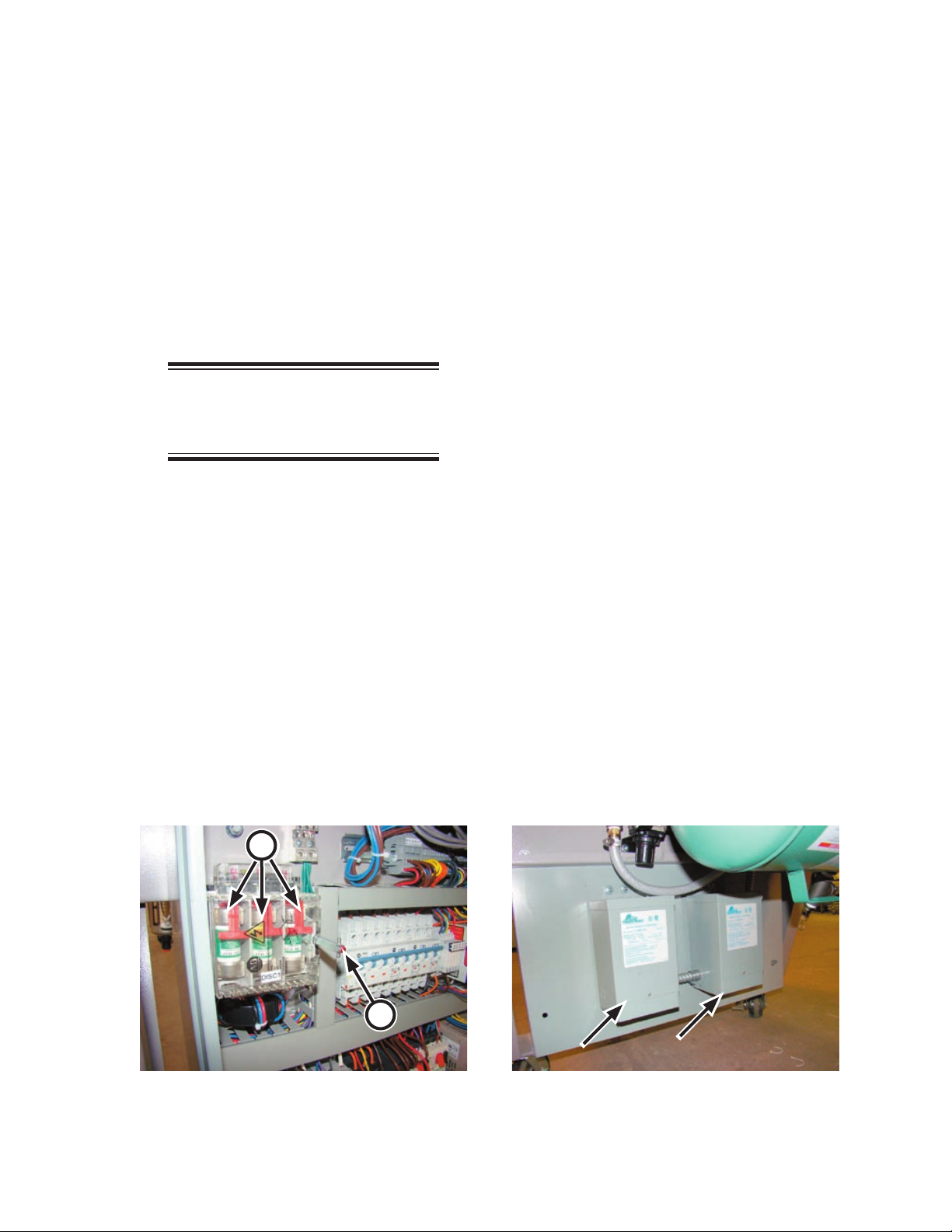

Inside the electrical panel box is the I/O control

panel. A serial cable provides communication

between the microprocessor and the I/O control

panel. Two LED’s on the communications head

of the control panel show when it is receiving

information from the microprocessor (RX) and

sending data to it (TX).

All the input signals from the sensors go

through the I/O control panel, which also powers

the sensors. When the appropriate LED on the

I/O control panel come on, it means that a signal

has been received from a sensor. Each LED is

numbered for easy identification.

Output signals from the I/O control panel go

directly to the output devices. These devices are

also powered via the I/O control panel.

Most output devices like air valves, relays, and

indicators run on the 24 VDC that comes right

from the I/O control panel. For other devices that

require a different voltage, the I/O control panel

sends an open collector output signal to drive the

logic input on a separate driver board.

When the appropriate LED on the I/O control

panel comes on, it shows that a signal has been

sent to a device. The LED on the I/O control panel

comes on to show that the panel is functioning

properly.

For open collector output, the LED means that

the I/O control panel is sending the signal to the

output device. Each LED is numbered for easy

identification.

Microprocessor

The microprocessor, located in the right

endframe (Figure 5-5) provides all of the control

logic for operating the unit.

Figure 5-5: The microprocessor unit controls all

machine operations.

Figure 5-4: CHI•Touch screen.