Chicago Dryer King Edge User manual

KING EDGETM

Large Piece

Spreader/Feeder

INSTRUCTION MANUAL

©Chicago Dryer Company

Instruction Manual #3018-029d

CHICAGO DRYER COMPANY

2200 N. Pulaski, Chicago, Illinois USA 60639-3737

Telephone: (773) 235-4430 Fax: (773) 235-4439 www.chidry.com

King Edge Table of Contents

i

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

1.1 Warranty .................................................................................................. 1-2

1.2 Scope of Manual ..................................................................................... 1-2

1.3 Safety ...................................................................................................... 1-3

Safe Work Habits .................................................................................... 1-3

Safety Features ....................................................................................... 1-4

1.4 Equipment Description ............................................................................ 1-6

Machine Widths ....................................................................................... 1-6

Optional Equipment ................................................................................. 1-6

CHAPTER 2 INSTALLATION

2.1 Site and Utility Requirements .................................................................. 2-2

2.2 Installation Procedures ............................................................................ 2-3

Inspection ................................................................................................ 2-3

Uncrating, Placement and Alignment ...................................................... 2-4

Floor Trough Installation .......................................................................... 2-6

Inlet Conveyor Upper Pulley Installation ................................................. 2-6

Compressed Air Supply Connection ....................................................... 2-7

Electrical Connection .............................................................................. 2-8

2.3 Pre-Operational Checkout ..................................................................... 2-12

Final Protective Wrapper Removal ........................................................ 2-12

Security of Hardware ............................................................................. 2-12

Clean the Corner Photosensors ............................................................ 2-13

Compressed Air Supply Checkout ........................................................ 2-13

Safety Device/Control Function Checkout ............................................ 2-15

Spread/Feed Function Check ............................................................... 2-17

Checkout Completion ............................................................................ 2-18

Cleaning the Unit ................................................................................... 2-18

Table of Contents King Edge

ii

CHAPTER 3 OPERATING GUIDELINES

3.1 Safety Features ....................................................................................... 3-2

Main Disconnect Switch .......................................................................... 3-2

Safety Guards ......................................................................................... 3-2

Safety STOP Buttons .............................................................................. 3-2

Safety Interlock Switches ........................................................................ 3-3

Safety Labels .......................................................................................... 3-3

3.2 Operating Controls .................................................................................. 3-4

3.3 Daily Operating Procedures .................................................................... 3-6

Start-Up ................................................................................................... 3-6

Interconnected Stop Circuit (option) Operation Notes ............................ 3-7

Flatwork Handling ................................................................................... 3-8

Handling Jams and Misfeeds Safely ......................................................3-11

Shut-Down ............................................................................................ 3-12

3.4 Operating Techniques ........................................................................... 3-12

Maximum Efficiency .............................................................................. 3-12

Maximum Feeding Speed ..................................................................... 3-12

CHAPTER 4 PREVENTIVE MAINTENANCE

4.1 Daily PM (8 hours) ................................................................................... 4-2

Watch and Listen for Anything Abnormal ................................................ 4-2

General Cleanliness ................................................................................ 4-2

Check Safety Equipment ......................................................................... 4-3

4.2 Weekly PM (50 hours) ............................................................................. 4-3

Clean The Photosensors and Reflectors ................................................. 4-3

Check and Clean Inverters ...................................................................... 4-4

Check For String Accumulation ............................................................... 4-4

Check Rodless Air Cylinder Bearings ..................................................... 4-4

Inspect Inlet Transfer Rodless Air Cylinder ............................................. 4-5

Check The Clutch-Brake Roller Alignment .............................................. 4-7

Check Spreader Clamp Linear Assembly Bearings ................................ 4-7

Lubricate Upper Spreader Rail, Carriage Rails and Rail Bearings ......... 4-8

Inspect Air Filter/Regulator/Drain ............................................................ 4-9

Check Air Pressure Settings ................................................................... 4-9

Check Ribbon Condition ........................................................................4-11

King Edge Table of Contents

iii

4.3 Monthly PM (200 hours) ........................................................................ 4-12

Clean and Lubricate Drive Chains and Friction Roll Hinge ................... 4-12

Check Upper and Lower Spreader Belt Condition and Tension ............ 4-13

Inspect Drive Belt Condition .................................................................. 4-14

Check Setscrews................................................................................... 4-14

4.4 Semi-Annual PM (1000 hours) .............................................................. 4-14

Clean Air Filter/Drain ............................................................................. 4-15

Check and Grease Bearings ................................................................. 4-16

Replace Rodless Air Cylinder Bearings ................................................ 4-18

4.5 Annual PM (2000 hours) ....................................................................... 4-20

Check All Electrical Connections ........................................................... 4-21

Check Insulation Resistance to Earth Ground ...................................... 4-21

CHAPTER 5 OPERATING PRINCIPLES

Safety ................................................................................................................ 5-2

5.1 Electrical System ..................................................................................... 5-2

Power System ......................................................................................... 5-2

Control System ........................................................................................ 5-9

5.2 Compressed Air System ........................................................................ 5-16

Air Filter/Regulators............................................................................... 5-16

Air Pressure Switch ............................................................................... 5-16

Air Reservoir .......................................................................................... 5-16

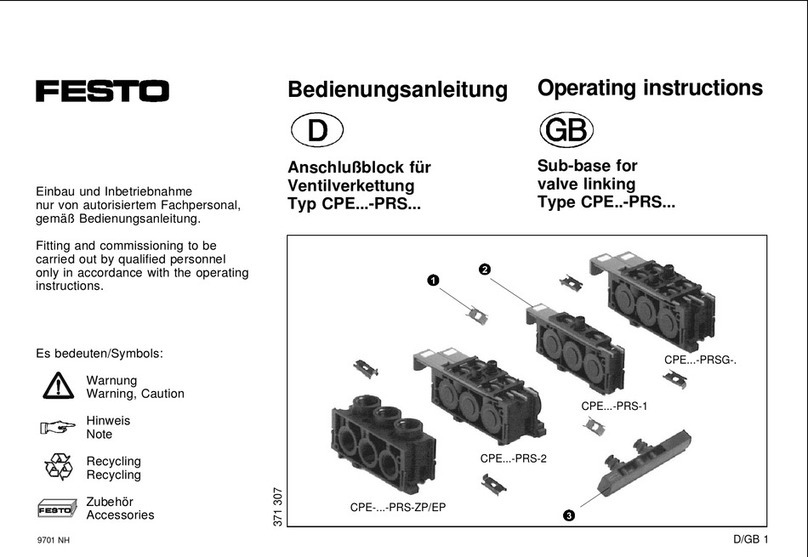

Air Valves/Air Valve Solenoids .............................................................. 5-16

Air Cylinders .......................................................................................... 5-17

Flow Controls ........................................................................................ 5-17

Air Bars .................................................................................................. 5-17

Pneumatic Clutch/Brake ........................................................................ 5-17

5.3 Mechanical System ............................................................................... 5-18

Prefeed Drive System ........................................................................... 5-18

Inlet Drive System ................................................................................. 5-19

Spread Drive System ............................................................................ 5-20

Discharge Drive System ........................................................................ 5-21

By-Pass Drive System ........................................................................... 5-21

Table of Contents King Edge

iv

5.4 Sequence of Operation ......................................................................... 5-22

Stand-by Phase ..................................................................................... 5-23

Start-up Phase ...................................................................................... 5-23

Prefeed/Input Phase ............................................................................. 5-24

Transfer Phrase ..................................................................................... 5-24

Spread Phase ....................................................................................... 5-25

Large Piece Discharge Phase ............................................................... 5-25

Small Piece (Bypass Conveyor) Discharge Phase ............................... 5-26

Error Conditions .................................................................................... 5-26

CHAPTER 6 TROUBLESHOOTING

6.1 CHI Diagnostic Message Index ............................................................... 6-6

6.2 LED Diagnostics ...................................................................................... 6-8

6.3 Electrical ................................................................................................ 6-10

6.4 Mechanical ............................................................................................ 6-14

6.5 Prefeed/Inlet Section ............................................................................. 6-15

6.6 Transfer Section .................................................................................... 6-18

6.7 Spread Section ...................................................................................... 6-20

6.8 Discharge Section ................................................................................. 6-24

6.9 Sensor Function .................................................................................... 6-26

6.10 CHI Panel .............................................................................................. 6-27

6.11 Compressed Air System ........................................................................ 6-28

CHAPTER 7 REPAIR

7.1 Safety Considerations ............................................................................. 7-2

7.2 Parts Availability ...................................................................................... 7-2

7.3 Prefeed/Inlet Section ............................................................................... 7-3

Prefeeder Carriage Linear Bearing Adjustment ...................................... 7-3

Prefeeder Carriage Belt Tension Adjustment .......................................... 7-4

Prefeeder Carriage Belt Replacement .................................................... 7-4

Clutch-Brake Roller Alignment ................................................................ 7-5

King Edge Table of Contents

v

7.3 Prefeed/Inlet Section (cont)

Clutch-Brake Roller Drive Belt Tension Adjustment ................................ 7-7

Inlet Conveyor Drive Belt Tension Adjustment ........................................ 7-8

Enabling/Disabling Automatic Misfeed Reject ......................................... 7-8

7.4 Transfer Section ...................................................................................... 7-9

Transfer Clamp Check and Adjustment ................................................... 7-9

Transfer Clamp Assembly Replacement ............................................... 7-12

Transfer Clamp Roller Adjustment ........................................................ 7-14

Rodless Air Cylinder Carrier Bracket Tension Adjustment ..................... 7-15

7.5 Spreader Section .................................................................................. 7-15

Spreader Clamp Mechanical Adjustment .............................................. 7-16

Upper Spreader Belt Tension Adjustment ............................................. 7-16

Upper Spreader Belt Replacement ....................................................... 7-17

Upper Spreader Clamp Linear Bearing Replacement ........................... 7-18

Lower Spreader Drive Belt Tension Adjustment .................................... 7-19

Lower Spreader Drive Belt Replacement .............................................. 7-20

Lower Spreader Belt Replacement ....................................................... 7-20

Lower Spreader Belt Gap Adjustment ................................................... 7-21

7.6 Discharge/ByPass Section .................................................................... 7-23

Discharge/ByPass Conveyors Ribbons Tension Adjustment ................ 7-23

Discharge/ByPass Conveyors Ribbons Replacement .......................... 7-24

Discharge Conveyor Guide Ribbons

Tension Adjustment/Replacement ......................................................... 7-27

Discharge Conveyor Drive Belt Tension Adjustment ............................. 7-28

ByPass Conveyors Drive Belt Tension Adjustment ............................... 7-28

Discharge/ByPass Conveyor Drive Roll

Tracking Tape Replacement .................................................................. 7-29

Discharge Conveyor Doffer Roll Pressure Adjustment .......................... 7-33

Discharge Conveyor Doffer Roll Cover Replacement ........................... 7-34

7.7 Sensors ................................................................................................. 7-36

General Photosensor Alignment ........................................................... 7-36

Corner Photosensors Alignment ........................................................... 7-37

Roller Photosensors Alignment ............................................................. 7-38

Taut Photosensors Alignment ................................................................ 7-39

General Photosensor Sensitivity Adjustment ........................................ 7-40

Roll Photosensors Sensitivity Adjustment ............................................. 7-41

Table of Contents King Edge

vi

7.7 Sensors (cont)

Photosensor Replacement .................................................................... 7-42

Proximity Sensor Positioning Adjustment .............................................. 7-43

Proximity Sensor Replacement ............................................................. 7-44

7.8 Compressed Air System ........................................................................ 7-44

General Air Cylinder Adjustment ........................................................... 7-45

Inlet Clamps Air Pressure Adjustment ................................................... 7-47

Roller Counterpoint Air Pressure Adjustment ........................................ 7-48

Inlet Transfer Rodless Air Cylinder Service ........................................... 7-49

Tighten the Drive T ................................................................................ 7-49

Tighten the Drive Blocks ....................................................................... 7-50

Tighten the Carriage Block .................................................................... 7-51

Increase the Air Cushion ....................................................................... 7-52

Tighten the Inner Band .......................................................................... 7-53

Left Spreader Clamp Air Pressure Adjustment ...................................... 7-56

Air Bar Alignment .................................................................................. 7-57

Air Foil Adjustment ................................................................................ 7-58

Air Laydown Assist (option) Air Pressure Adjustment ........................... 7-59

CHI PANEL BULLETIN

PARTS LIST

SCHEMATICS

APPENDIX

King Edge Introduction

1-1

Chapter 1

INTRODUCTION

This chapter includes the following sections:

1.1 Warranty 1.3 Safety

1.2 Scope of Manual 1.4 Equipment Description

The King Edge automatic cornerless spreader/feeder allows operators to feed sheets or other large

pieces of flatwork into a flatwork ironer or automatic folder from two stations. A built-in bypass conveyor

allows feeding of small pieces through the King Edge without altering the position of the feeder or its

discharge conveyor.

Like the rest of the CHICAGO® product line, the King Edge (Figure 1-1) is designed, manufactured,

and assembled in Chicago, Illinois. Before the CHICAGO® nameplate is affixed to any machine, a final

inspection is performed, including thorough testing under load conditions.

Any questions concerning the installation, operation, or repair of the unit should be directed to a local

authorized CHICAGO® dealer or the Chicago Dryer Company factory Service Department at:

Chicago Dryer Company (773) 235-4430

2200 North Pulaski Fax (773) 235-4439

Chicago, Illinois USA 60639-3737 Email service@chidry.com

Figure 1-1: The King Edge provides high quality spreading and feeding.

Introduction King Edge

1-2

1.1 Warranty

A full page warranty statement is located at

the front of this instruction manual. Please take

the time to review this warranty and understand

its provisions.

1.2 Scope of Manual

This instruction manual will help you keep

your CHICAGO® product operating safely,

efficiently and with minimum expense. Individual

chapters in this manual provide the necessary

information required for safe installation,

operation, maintenance, troubleshooting, and

repair of the unit.

Updates

Occasionally, new information about the

unit becomes available after publication of this

manual. If you receive a CHICAGO® FYI Service

Bulletin pertaining to our unit, insert the bulletin

in the front of the manual.

Chapter 1 - Introduction

Provides an overview of the unit and its key

features, of this manual, and of important safety

features.

Chapter 2 - Installation

Describes recommended procedures for

determining a suitable location for the unit and

connecting the electrical and the compressed air

supplies. This chapter also includes checkout

procedures to ensure all systems are working

properly. Local requirements often vary, so follow

local codes at all times.

Chapter 3 - Operating Guidelines

Gives recommendations for operating the unit

at maximum efficiency. This chapter also includes

instructions for the operators and suggestions for

work organization.

Chapter 4 - Preventive Maintenance

Contains procedures for Daily, Weekly,

Monthly, Semi-Annual, and Annual

maintenance. Follow these procedures to keep the

unit operating safely and at maximum efficiency.

A Preventive Maintenance schedule is located at

the front of the chapter.

Chapter 5 - Operating Principles

Describes the operation of the unit in detail. A

good understanding of this chapter will help avoid

operation errors and assist with trouble shooting

and maintenance.

Chapter 6 - Troubleshooting

Contains issues, possible causes, and solutions

in all areas of operation.

Chapter 7 - Repair

Contains procedures for making adjustments,

repairs and parts replacement for the unit. Please

follow all safety recommendations carefully.

CHI Panel Operation Bulletin

Describes in detail the operation of the

CHI Panel spreading/feeding control system.

Programming, adjustment and test modes are

detailed in this bulletin.

Parts List

Contains detailed drawings and part

specifications to assist in ordering replacement

parts. It is divided into views in which the parts

are grouped by function.

Schematics

Contains electrical drawings showing power

and motor circuits, control circuits and interlock

circuits, and other relevant drawings.

Appendix

Contains Technical Specifications, a Floor

Plan, and other relevant information for the

unit.

King Edge Introduction

1-3

1.3 Safety

Safe operation and maintenance of the unit

must be the first priority of all supervisors,

operators and maintenance personnel. Safety

begins with safe work habits. In addition, the

unit is equipped with built-in features to promote

safety.

Safe Work Habits

During Daily Operation

Take the flatwork only after it has

cleared the unit. Do not pull on the

flatwork while it is still in the machine.

Post the “Operator Safety” reminders

in a place where everyone will see it.

Read these reminders and follow the

recommendations.

Read and follow all safety labels.

Keep hands and clothing away from

the moving parts of the spreader/feeder

while it is operating.

Always turn off the unit before clearing

a jam.

Operate the unit only with all guards and

endframe doors in place and all safety

features operating correctly. Never

operate the unit with any safety features

bypassed.

•

•

•

•

•

•

Maintenance and Repair

WARNING

Always use extreme caution

when performing any repair

procedure that requires the

unit to be operating.

Keep hands and loose

clothing from coming into

contact with any of the

moving parts.

Serious Injury Could Result.

When the unit is running, one

person should be ready at a

red safety STOP button

at all times.

Before attempting any repair work, review

these safety steps and precautions to protect

yourself and the unit.

Safety should be the primary concern

of anyone performing corrective

maintenance.

Except where specifically directed, make

sure that the main disconnect switch to

incoming power is OFF.

It is recommended that all maintenance

procedures be handled by at least two

qualified persons. Using the “buddy

system” decreases the risk of an

accident.

Your site should have procedures that

comply with government regulations and

standards for equipment lockout/tagout

during maintenance and repair. Ask your

supervisor for specific information. It

is the users’ responsibility to make sure

they comply with all safety procedures.

•

•

•

•

Introduction King Edge

1-4

WARNING

Know the proper procedure

for locking out and tagging

equipment during repair

procedures.

Follow the rules of your work

site. Failure to do so could

result in serious injury.

Make sure the power

is disconnected before

servicing the unit.

Do not repair or correct any

condition without reading

and understanding the

REPAIR chapter.

Only qualified personnel

should troubleshoot and

repair this unit.

Safety Features

There are several general categories of safety

features:

Main Disconnect Switch

Safety Guards

Safety Interlock Switches

Safety STOP Buttons

Safety Labels

Safety Messages in the Manual

Main Disconnect Switch

The main disconnect switch is located on the

outside of the main electrical box. When turned

to OFF, this switch shuts off incoming electrical

power to the unit.

Unless otherwise indicated, turn the main

disconnect switch to OFF before performing any

maintenance or repair work.

For more information on operating the main

disconnect switch, refer to the INSTALLATION

chapter, Installation Procedures section,

Electrical Connection procedure.

Safety Guards

A front safety guard runs the entire length of

the unit’s working area and physically restricts

hands from coming into contact with moving

parts.

Both endframes and other appropriate areas

of the unit are covered with protective panels to

prevent fingers or hands from coming into contact

with moving parts. The guards and panels also

serve to keep foreign objects from entering the

unit and damaging components.

When a panel is removed or the front guard is

raised, all rotating parts stop moving.

•

•

•

•

•

•

King Edge Introduction

1-5

Figure 1-2: Safety labels remind operators and

maintenance personnel that care must

be taken when working near these

areas.

Safety Interlock Switches

Safety interlock switches are located behind

each endframe panel and the front guard.

Whenever any of these components is opened or

removed, its associated interlock switch is opened

and all rotating parts stop moving.

The safety interlock switches are not intended

to lockout the unit. Site management is responsible

for developing and implementing lockout/tagout

procedures that comply with government

standards for use when servicing the unit.

Safety STOP Buttons

There are six red safety STOP buttons arrayed

around the unit, one at each corner and one at each

operator station. Pressing any of these buttons

immediately stops all rotating and moving parts,

releases compressed air pressure, and shuts down

the machine. To reset a pressed red safety STOP

button, twist it.

The preferred method of stopping the operation

of the unit is by pressing one of the square red

Stop buttons located at each operator station.

Safety Labels

Orange Warning and yellow Caution labels

(Figure 1-2) are placed at locations around the

unit to keep operators and maintenance personnel

alert in particular areas.

WARNING message labels alert personnel that

personal injury may result from not following

recommended procedures.

CAUTION message labels alert personnel that

the machine may be damaged if conditions,

practices, or procedures are not observed.

When training operators, take the time to

review, understand, and locate all areas where

labels are posted.

NOTE: Do not remove safety

labels at any time. If a label

needs to be replaced, contact

Chicago Dryer Company for free

replacements.

Introduction King Edge

1-6

Safety Messages in this Manual

WARNING and CAUTION messages also

appear in this manual to highlight essential safety

information.

WARNING messages alert personnel that

personal injury may result from not following

recommended procedures.

WARNING

Never bypass any of the

safety devices. This could

result in serious injury.

BLACK BOX WARNING messages alert

personnel of the operating condition a unit

must be in before performing any procedure.

Personal injury may result from not following

recommended procedures.

Perform only when the unit is OFF

with power disconnected.

CAUTION messages alert personnel that the

unit may be damaged if conditions, practices,

or procedures are not observed.

CAUTION

The incoming electric power

must match the electrical

requirements as shown on

the nameplate.

1.4 Equipment Description

A general overview of the King Edge spreader/

feeder includes:

Machine Widths

Optional Equipment

Machine Widths

The King Edge comes in a standard 120” (3050

mm) width. Extra wide models including 130”

(3300 mm), 136” (3455 mm) and wider are also

available for processing California kings, banquet

cloths or other oversized items.

Optional Equipment

The following optional equipment is available

on all models:

Rear Air Bar/Smoothing Brush: Additional

equipment for improving laydown and smoothing

flatwork before it enters the ironer.

Interconnected Stop Circuit: Pressing a red

safety STOP button on the feeder, ironer or folder

stops the entire finishing line.

Variable Speed Interconnect: The speeds of

each machine in a finishing line are automatically

coordinated for maximum efficiency.

Single Point Electrical Connection: Allows

the unit to receive its electrical supply from the

ironer.

Chicago Automatic Reject Processor:

Allows operator to press a stain or tear reject

button after a piece is fed into the unit for

automatic handling by the Chicago® folder at the

end of the finishing line.

Pacing Lights: Allows operating standards

to be set and provides a visual signal to indicate

whether operators are reaching target production

rates.

Lifting Conveyor: Uses compressed air to

raise and position the discharge conveyor.

ChiLinc: Production data collection and

reporting system for archiving and analysis of

production and efficiency information.

•

•

King Edge Installation

2-1

Chapter 2

INSTALLATION

This chapter contains installation instructions for the King Edge spreader/feeder and includes the

following sections:

2.1 Site and Utility Requirements

2.2 Installation Procedures

2.3 Pre-Operational Checkout

The spreader/feeder is tested under load conditions at the factory and inspected to ensure proper

operation. It is shipped in working condition and is completely assembled, requiring only setup of the

exit conveyors. Sufficient strapping, blocking, and bracing were provided to give reasonable assurance

that no shipping damage would occur.

NOTE: If the spreader/feeder is received in damaged condition, notify the carrier

at once.

Chicago Dryer Company’s responsibility for shipping damage, other than the standard warranty,

ceases upon delivery to the carrier. For more information on the warranty, see the full page warranty

statement at the front of this manual.

Installation King Edge

2-2

2.1 Site and Utility

Requirements

Figure 2-1 shows the clearances required for

the spreader/feeder. The dimensions noted are the

minimums recommended for efficient production

and service, as well as maintenance access. It is

strongly recommended that enough clear space

be provided around the spreader/feeder to allow

for efficient access.

NOTE: The correct location of

the spreader/feeder is of extreme

importance.

The site must have a level, sturdy floor capable

of supporting the spreader/feeder’s weight without

significant flexing. For weight specifications

and other technical information refer to the

APPENDIX, Technical Specifications.

No special foundation, floor grouting, or

installation of anchors is required. Generally,

the locking wheels will hold the spreader/feeder

in position and still allow for repositioning

when necessary. Floor grouting or installation

of anchors may be required to comply with local

codes or conditions, or aboard a ship.

Figure 2-1: Recommended clearances for installation of the King Edge.

36”

(915 mm)

36”

(915 mm)

72” (1830 mm)

King Edge Installation

2-3

Compressed air that is clean and dry must

be provided for the unit. This is very important

because the air will blow directly on the flatwork.

The compressed air supply must meet the

pressure and air flow requirements noted in the

APPENDIX, Technical Specifications.

The electrical requirements of the spreader/

feeder are shown on the nameplate (Figure 2-

2), located on the back of the right endframe.

Additional information can be found in the

APPENDIX, Technical Specifications. Wiring

and a separate, fused disconnect switch of suitable

size must be locally supplied if local codes require

one. Check local codes for clearance requirements

to any electrical box.

2.2 Installation

Procedures

The spreader/feeder should be moved on

its casters whenever possible. When this is

impractical, and when removing it from the skids,

be sure that it is handled only by qualified riggers

using proper equipment.

Installation of the spreader/feeder includes:

Inspection

Uncrating, Placement and Alignment

Floor Trough Installation

Inlet Conveyor Upper Pulley Installation

Compressed Air Supply Connection

Electrical Connection

Final Protective Wrapper Removal

Inspection

NOTE: Notify the carrier if

any damage has been done

to the spreader/feeder during

shipment.

It is in the interest of the buyer to carefully

inspect all shipments before they are accepted

from the carrier. Upon delivery, be sure that all

items listed on the bill have been received.

Any shortage, breakage, or damage noticed at

the time of delivery should be indicated on the

carrier’s freight bill and signed by the driver or

carrier’s representative.

Damage noticed after delivery should be

reported to the carrier at once. Request their

inspection of the shipment and fill out a concealed

damage inspection report.

•

•

•

•

•

•

•

Figure 2-2: The nameplate gives important

information about the unit.

Installation King Edge

2-4

Uncrating, Placement and Alignment

Required Tools

forklift, crowbar, sledgehammer, wire

cutters/knife, wrenches

Before unpacking the unit, make sure

that the proposed site is acceptable and

any necessary foundations have been

prepared.

Remove the crating, strapping, and other

packaging materials from the unit. Leave

the protective plastic covers on the con-

trols. These protective coverings should

be left in place until the unit is ready for

use.

Open both endframe doors and remove

any materials that shipped with the unit.

Close and secure the doors.

CAUTION

The unit should only be

moved by qualified riggers

using proper equipment.

With the unit still on its skid, move it into

approximate position. Remove the bolts

which secure the unit to the skid.

CAUTION

Do not drop or twist the unit.

As appropriate:

If the unit is equipped with eye bolts,

lift the unit straight up using the two eye

bolts on top of each endframe and care-

fully remove the skid from under it.

OR

Lift one endframe and carefully re-

move the skid from under it and then

repeat for the other endframe.

1.

2.

3.

4.

5.

•

•

While either the entire unit or one side

of the unit is suspended, attach the lock-

ing floor castors (Figure 2-3) which were

removed for shipping.

NOTE: For units equipped

with the optional discharge lifting

conveyor, follow the steps to

connect the compressed air

supply. Turn ON the compressed

air supply and the discharge

conveyor will automatically

rise. It will still be necessary to

manually position the bypass exit

conveyor.

Carefully lift the bypass and discharge

conveyors. Position the bypass conveyor’s

threaded rod in its tube (Figure 2-4, A).

There is one on each side.

6.

7.

Figure 2-4: Bypass conveyor support and

positioning bolt location.

A

C

B

Figure 2-3: Locking floor casters stored in an

endframe for shipping.

King Edge Installation

2-5

Move the unit into final position in front

of the ironer.

Figure 2-5 shows the desired relative

positioning of the bypass conveyor and

the discharge conveyor idler rolls to the

ironer inlet.

Use the stop nut (Figure 2-4, B) to adjust

the height of the bypass conveyor. Tighten

down the locknut (Figure 2-4, C) to secure

the position.

If necessary, adjust the positioning of the

discharge conveyor by turning its posi-

tioning bolt (Figure 2-6, A). Secure the

adjustment with the stop nut (B).

NOTE: Secure the unit to its

foundation if required by local

code. Always follow local codes.

Set the locking casters.

Attach the provided locking floor pads to

the front crossbar (Figure 2-7, A). There is

one for the left and one for the right side

of the machine.

Adjust each pad so that it will rest firmly

against the floor when fully extended

(Figure 2-7, B). Secure the adjustment by

tightening the locking nut (C).

Push the locking lever (Figure 2-7, D)

fully down to extend the pads and firmly

secure the unit in position.

8.

9.

10.

11.

12.

13.

14.

15.

Ironer inlet

Bypass conveyor

Discharge conveyor

Figure 2-5: Position the bypass exit conveyor so

that it is just slightly higher than the

ironer inlet.

Figure 2-7: The locking floor pads help secure the

unit in position.

A

B

C

D

Figure 2-6: Discharge conveyor positioning bolt.

A

B

Installation King Edge

2-6

Figure 2-10: Two bolts secure the upper pulley arm

in position.

Figure 2-11: After positioning the pulley, roll the

inlet conveyor belt into place.

B

A

Floor Trough Installation

Now it is time to install the floor trough which

will catch wet linen which is dropped during

processing.

Install the four trough brackets which

shipped with the machine, two in front

and two in the back, on the crossbars. If

necessary, push the front bypass conveyor

forward a little to seat the rear brackets.

Position them about 12-18” (305-460 mm)

away from each endframe and facing each

other (Figure 2-8).

Slide the galvanized steel trough into posi-

tion so that it is firmly resting on the sup-

port brackets (Figure 2-9). Make sure the

angled corners face the machine front.

1.

2.

3.

Inlet Conveyor Upper Pulley

Installation

For facilities with low clearance, the inlet

conveyor upper pulleys are sometimes reversed

for shipping (Figure 2-10). They must be correctly

positioned before connecting the utilities.

Required Tools

wrench

Remove the two bolts which secure each

upper pulley arm in position (Figure 2-

10).

Turn the arm so the pulley is on top and

re-install using the same two bolts.

Pull the drive belt over the rim of the pul-

ley (Figure 2-11, A) and roll it into posi-

tion. Make sure it is positioned within the

safety stop mechanism (B).

1.

2.

3.

Figure 2-8: Position the floor troughs facing each

other about 12-18” from the endframe.

Figure 2-9: The angled corners must face front to

accommodate the locking floor pads.

Table of contents

Other Chicago Dryer Industrial Equipment manuals