1. Technical Data (see Fig 3.)

CP9362, CP9363 & CP9373 Series

Chipping Hammers

max pressure 6.3 bar (90 psi)

ahd :Vibration level, kUncertainty ; LpA Sound pressure level dB(A), KpA = KWA = 3 dB Uncertainty.

Declaration of noise (ISO 15744) and vibration emission (ISO 28927-10)

All values are current as of the date of this publication.

These declared values were obtained by laboratory type testing in accordance with the stated standards and are suitable for comparison with the declared va-

lues of other tools tested in accordance with the same standards. These declared values are not adequate for use in risk assessments and values measured

in individual work places may be higher. The actual exposure values and risk of harm experienced by an individual user are unique and depend upon the way

the user works, the workpiece and the workstation design, as well upon the exposure time and the physical condition of the user.

We, CHICAGO PNEUMATIC TOOLS , cannot be held liable for the consequences of using the declared values, instead of values reflectingtheactual

exposu-re, in an individual risk assessment in a work place situation over which we have no control.

2. Machine Type

• This product is designed for removing material using a chisel or suitable needles. No other use is permitted. For professional use only.

• Please read the product safety information carefully!

3. Implementation and Operation

• Fix the accessories properly to the tool.

• Connect device as shown in Fig.1.

• To start the machine, simply pull the trigger (A). Machine speed is increased by increasing pressure on the trigger. Release the trigger to stop.

• Remember that it is always the tool that must do the work. There is no need for the operator to apply extra pressure on the tool when it is working. Maintain

the contact with the work surface by applying enough pressure to stop the tool from bouncing.

• Always shut off air supply, drain hose of air pressure and disconnect tool from air supply when not in use, before changing accessories or when making

repairs.

4. Lubrication

Use an air line lubricator with SAE #10 oil, adjusted to two (2) drops per minute. If an air line lubricator cannot be used, add air motor oil to the inlet once

a day.

Recommended lubricant CP Oil PROTECTO-LUBE:

- 4 oz (0.12l) P/N: CA149661

- 20.8 oz (0.591l) P/N: CA000046

- 1gal (3.8l) P/N: P089507

5. Maintenance

•Follow local country environmental regulations for safe handling and disposal of all components

• Disassemble and inspect the tool every three 3 months if the tool is used every day. Replace damaged or worn parts.

• Always ensure that the machine is disconnected from energy source (compressed air) to avoid accidental operation.

• High wear parts are underlined in the parts list.

• To keep downtime to a minimum, the following service kits are recommended:

Tune-Up Kit: see part list

6. Disposal

• The disposal of this equipment must follow the legislation of the respective country.

• All damaged, badly worn or improperly functioning devices MUST BE TAKEN OUT OF OPERATION.

•Repair only by technical maintenance staff.

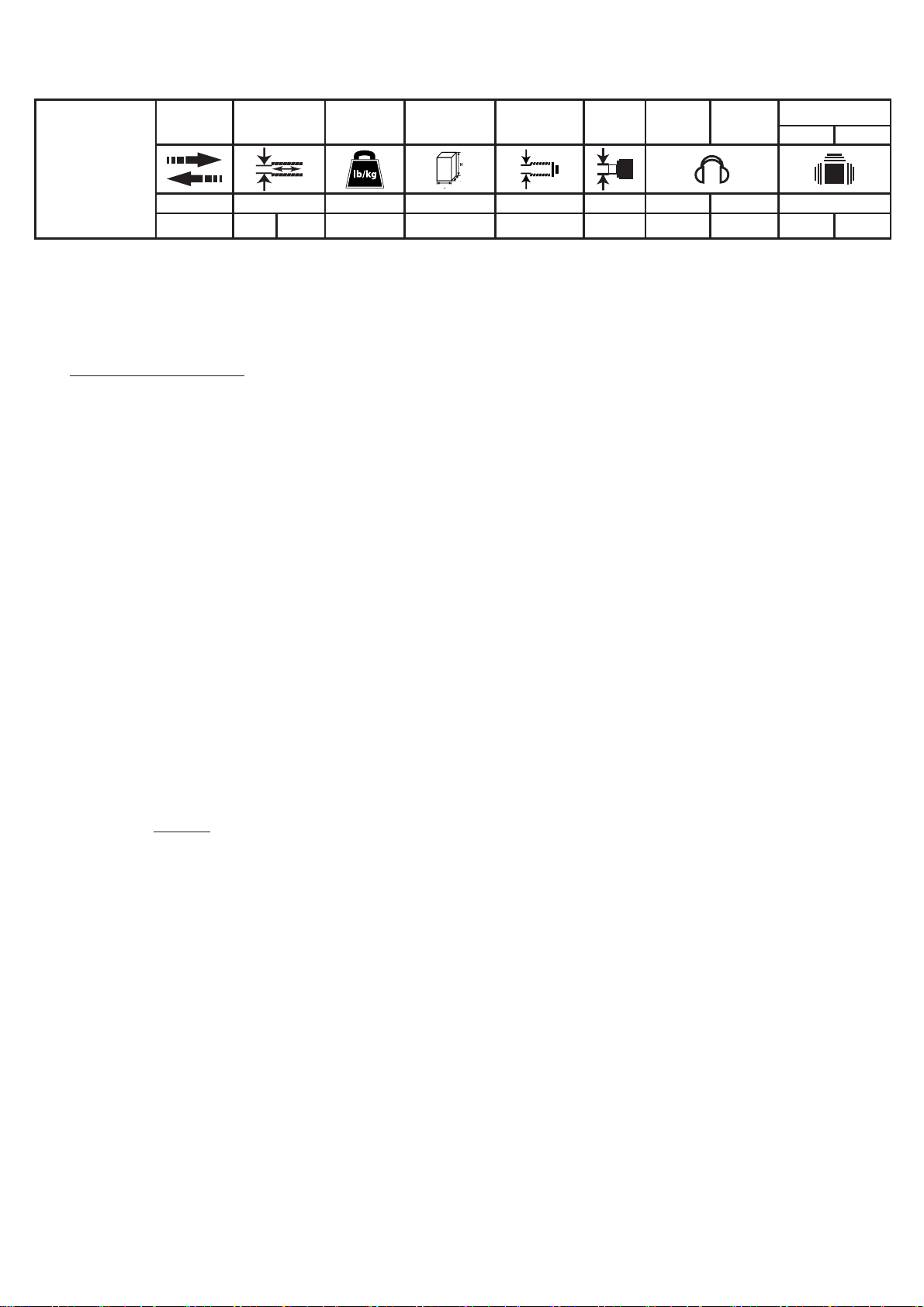

Model

Blows per

mInute Stroke & bore Weight Dimension

L x W x H

Inner hose Air inlet

Sound

pressure

LpA

Sound-

power

LwA

Vibrations

diameter ahd k

W

L

1234 5678 9

[min-1] [mm] [mm] [lb] [kg] [inch.] [mm] [inch.] [mm] [inch] [dB(A)] [dB(A)] [m/s²] [m/s²]

Learn more about air tools and compressors on our website.