The machine's cooling liquid contains ethylene glycol which is

harmful if swallowed and can cause redness and irritation if it

comes into contact with your eyes. Be careful when replacing

arms and electrodes.

If this machine comes into contact with water that penetrates into

its inner parts, power off the machine immediately and unplug

the power plug. Follow this same procedure whenever there is

any situation where there may be a risk of electric shock. After

an emergency, the machine may be restarted solely by trained

personnel who know which checks must be performed on the

machine.

In addition to the information provided in this paragraph, always

keep in mind the relevant prevailing regulations.

INSTALLATION

Firstly, make sure the place in which the machine is used

complies with the specifications outlined in the "SAFETY

RULES" paragraph.

On receiving the Vulcan ADU, check that the outside of the

packing is intact, otherwise report any anomalies to the person in

charge. Any damage to the packing should give rise to doubts as

far as what condition its contents might be in.

In order to handle the packing, use only a forklift or a transpallet,

paying attention to its weight and other handling instructions

reported on it.

Remove the packing and visually inspect machine integrity.

Ensure the machine has all the accessories that come with it

(page 4) as well as the optional items indicated in the compiled

and signed check-list (page 20). Promptly report any missing

parts to the supplier.

Use a suitable lifting device and straps to unload the machine

from the pallet.

All the material that makes up the packing should be disposed of

in full compliance with current environmental protection

regulations.

ASSEMBLY

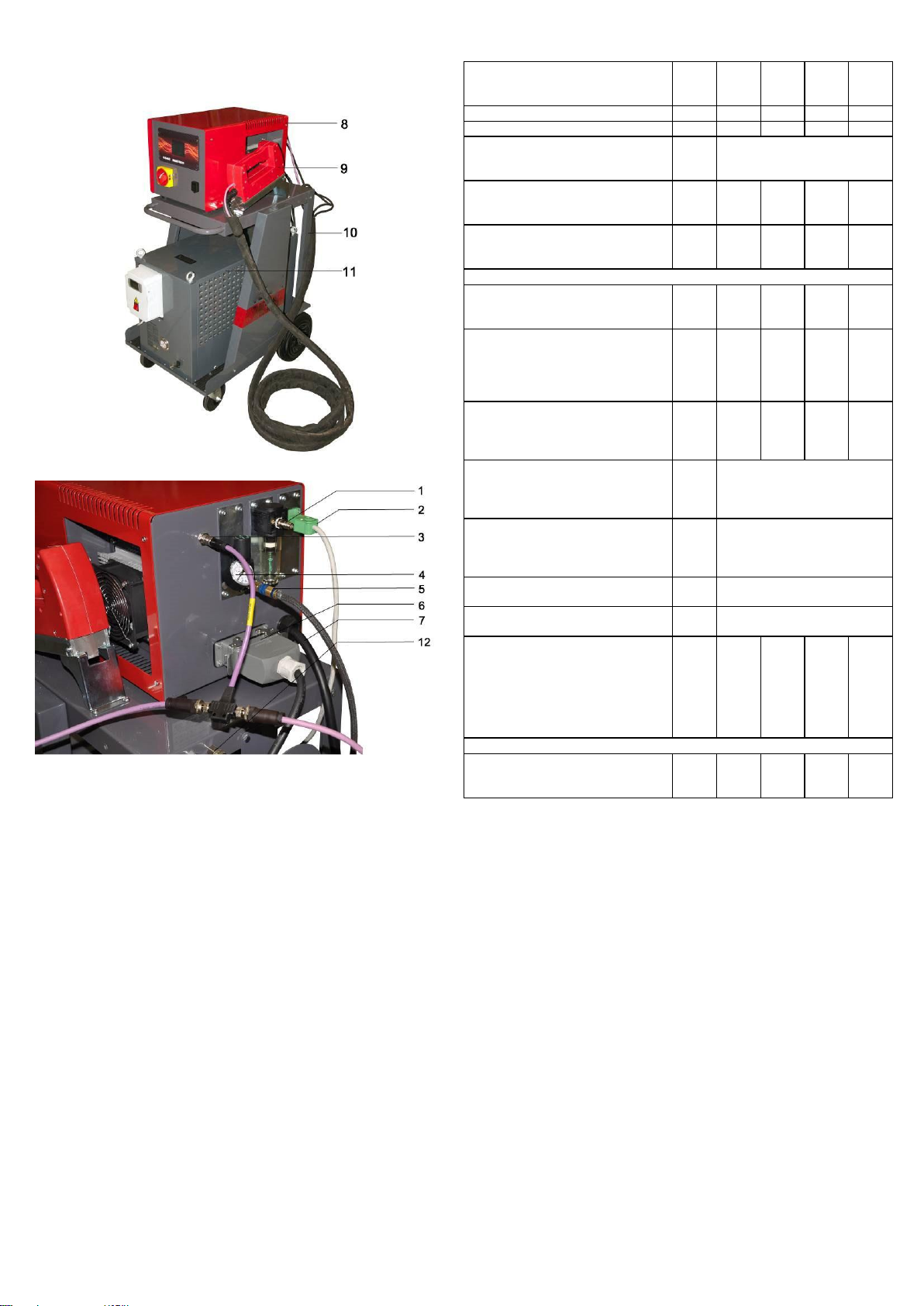

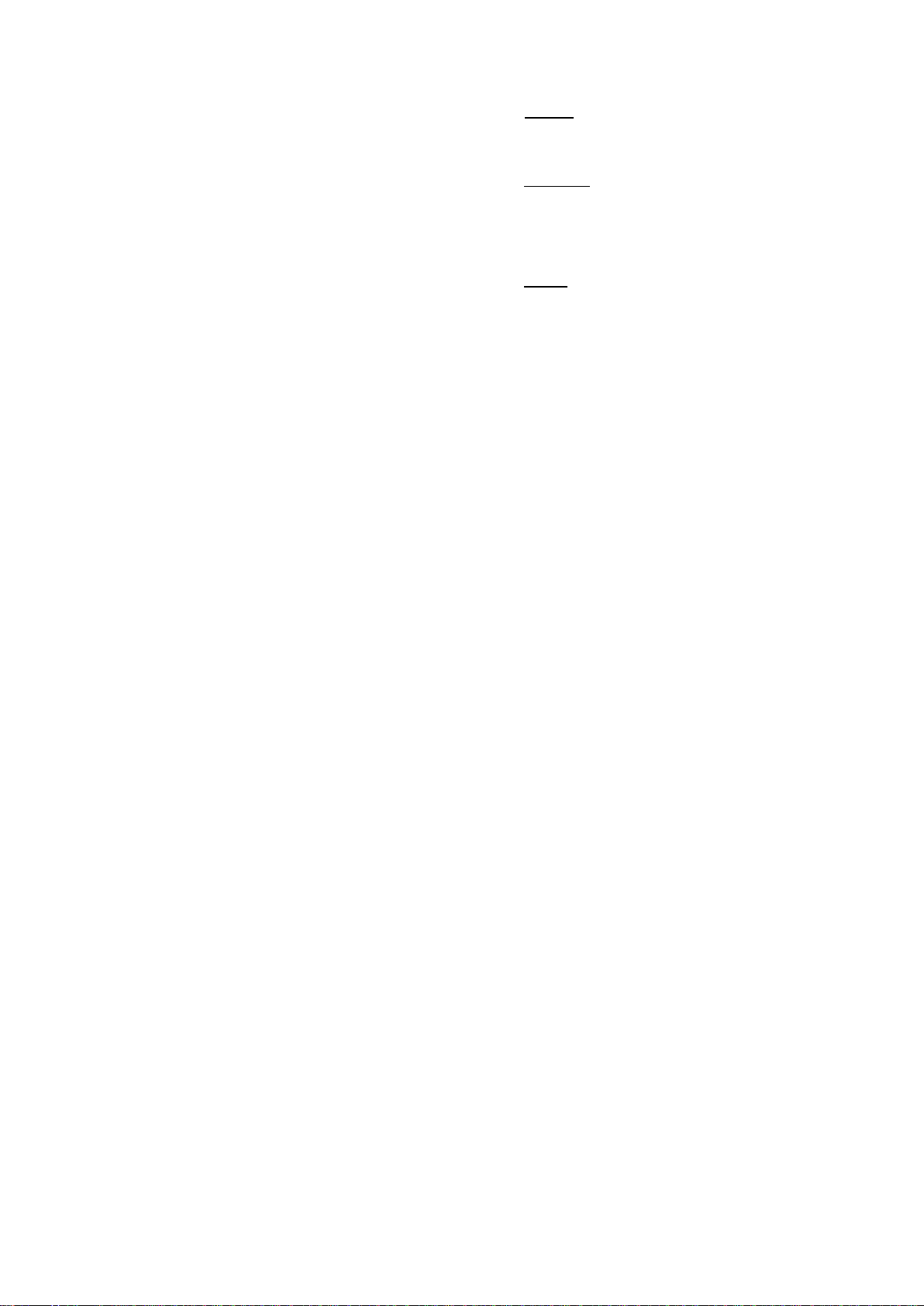

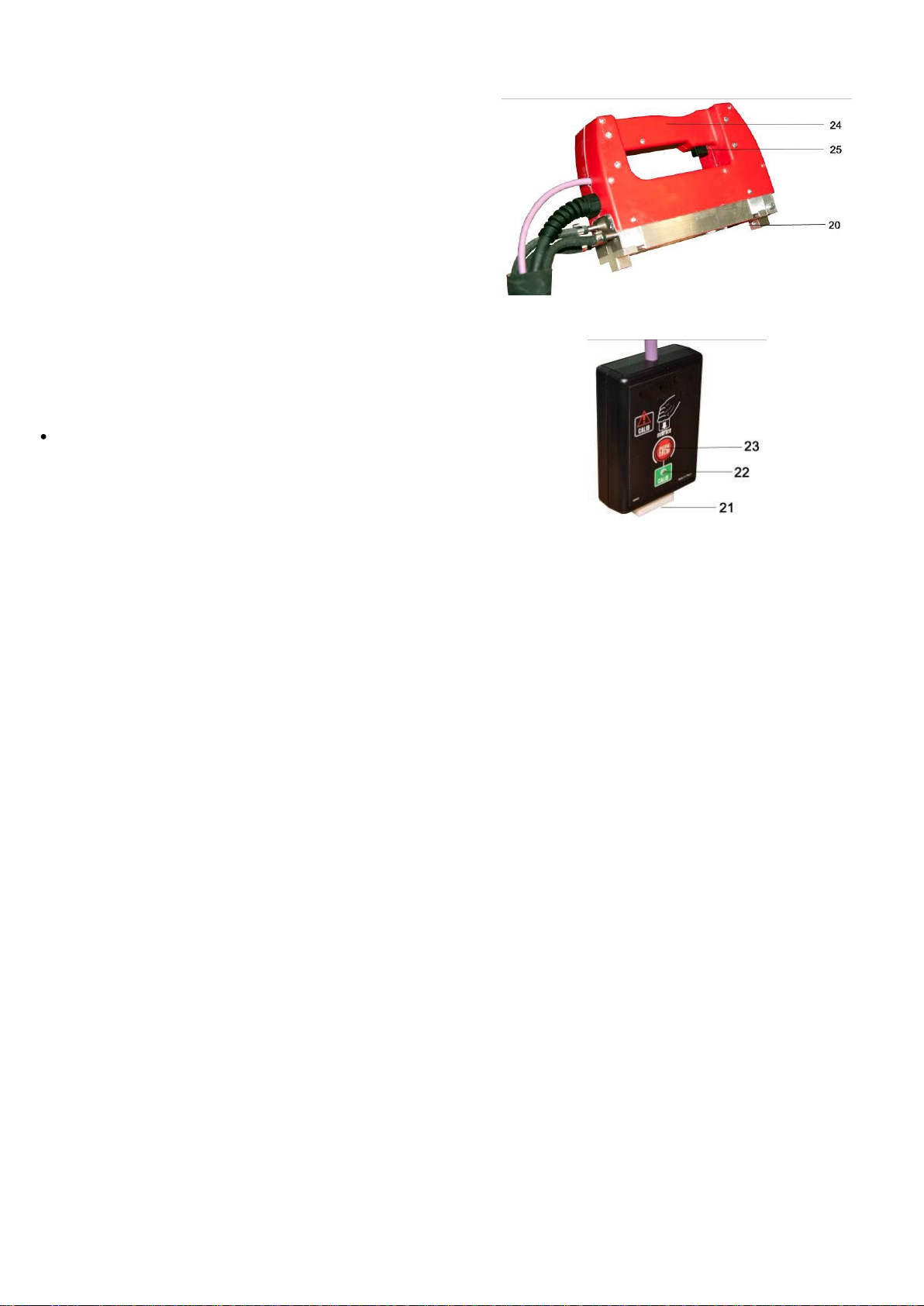

Refer to the following instructions and directions shown in Fig. 2

(page 15) to assemble parts that are supplied disassembled.

If you purchased only the generator Item CHH5402, with lamp

included, be sure to have performed the following steps:

1. Connect the machine from an electric standpoint:

a. Connect the lamp power supply through the

appropriate ilme connector.

b. Connect the chiller power supply to the

generator.

c. Connect the CAN cable to the lamp's control

and also, where applicable, to the optional

calibrator through a "T" connection.

2. Connect the machine from a pneumatic standpoint;

3. Connect the machine from a hydraulic standpoint.

If you also purchased the chiller art. Item CHH5480, repeat steps

from 1 to 3 using the chiller in question.

If you also purchased the trolley Item CHH5404, place the chiller

and the generator above it and repeat steps from 1 to 3.

COOLING SYSTEM

In order to cool the machine adequately, it is equipped with a

chiller that maintains the water in the cooling circuit at a

temperature of 68°F. This machine cannot be used if connected

to a heat exchanger.

Fill the tank using only a mixture of water and antifreeze liquid for

car radiators. The antifreeze liquid is necessary for its anti-

corrosive properties.

Use only antifreeze liquid similar to that supplied: ethylene

glycol-based, in a concentration of about 50%, with the addition

of corrosion inhibitors.

Mix the antifreeze liquid with water in a range of 10 to 20%.

Use a higher percentage if you need to prevent the liquid from

freezing when the machine is kept in cold environments. Keep in

mind that this reduces machine performance, since increasing

glycol percentage decreases cooling efficiency.

Follow the antifreeze liquid manufacturer's instructions to

determine the amount to be used, in relation to the desired

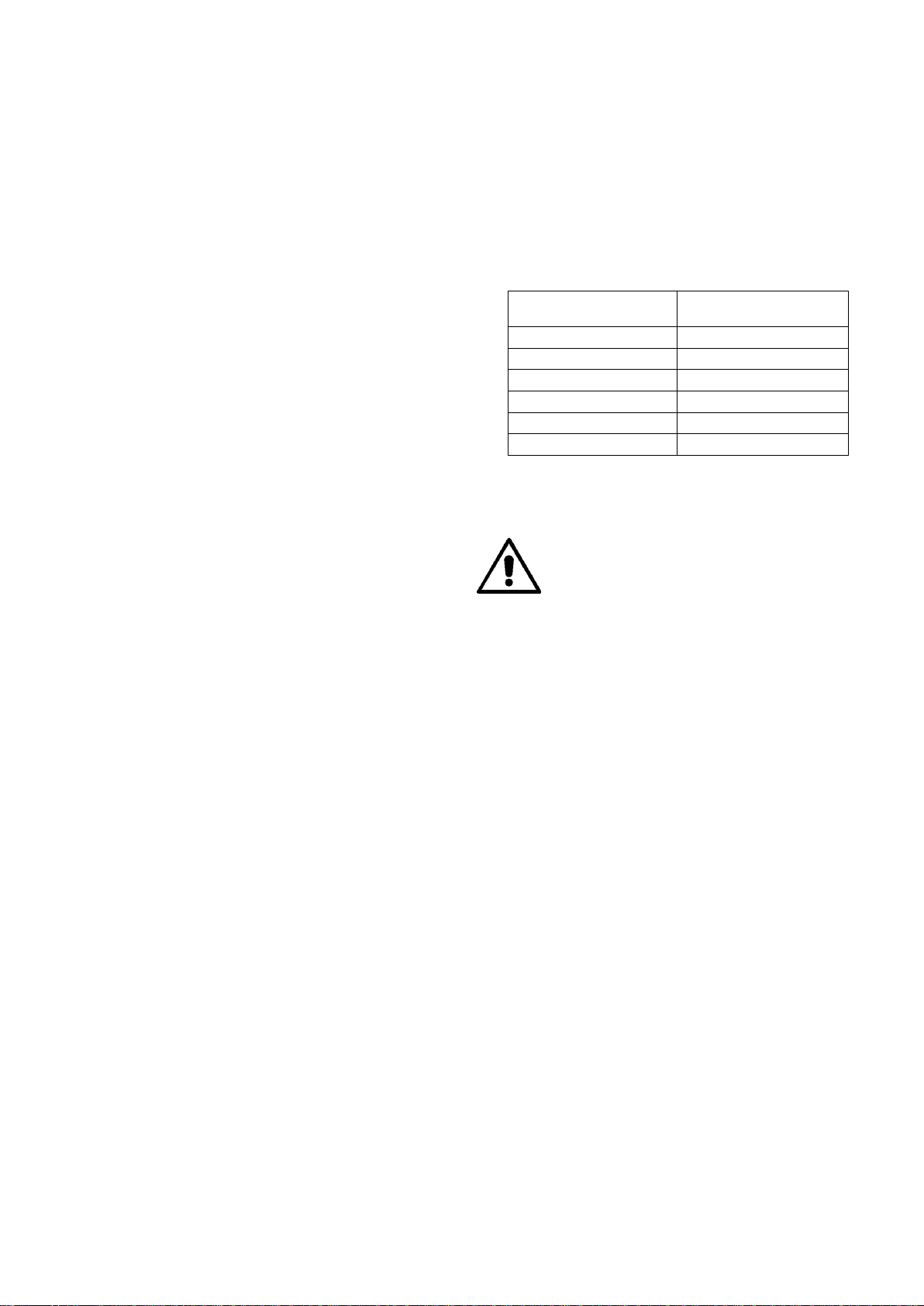

freezing temperature. The table below shows an example for the

antifreeze liquid supplied (50% of glycol).

Percentage of antifreeze

liquid with 50% of glycol

When filling and/or topping up the coolant, always be sure to use

perfectly clean liquids and containers.

ELECTRIC INSTALLATION

The installation should be carried out by

qualified personnel, aware of safety rules, who

closely adhere to the directions contained in this

manual.

The machines described in this manual are designed solely for

professional use in an industrial environment.

WARNING: the machines in question are not intended for use in

public low-voltage power lines that power buildings used for

household purposes. This can cause radio frequency

interference.

Before connecting the machine to the line, check that the mains

voltage matches that indicated on the plate. This machine was

built to be used solely at the supply voltage indicated on the

plate and is not set-up to be adjusted to other supply voltages.

Install a plug on the power cord; its required flow rate is indicated

in the technical specifications table (page 4). Figure 2 (page 13)

shows some connection examples,

It is mandatory to connect the machine to the ground wire.

Ensure the system's protective conductor is efficient and

complies with current regulations.

The technical features table (page 4) outlines supply line

requirements.

Do not use extension leads but if strictly necessary they should

be as short as possible and have a core section appropriate to

their length (indicated in the technical features table on page 4).

This machine is not designed to be powered by electricity

generating units. Using a unit of that type should be carefully

evaluated to avoid the presence of surges that could damage the

machine.