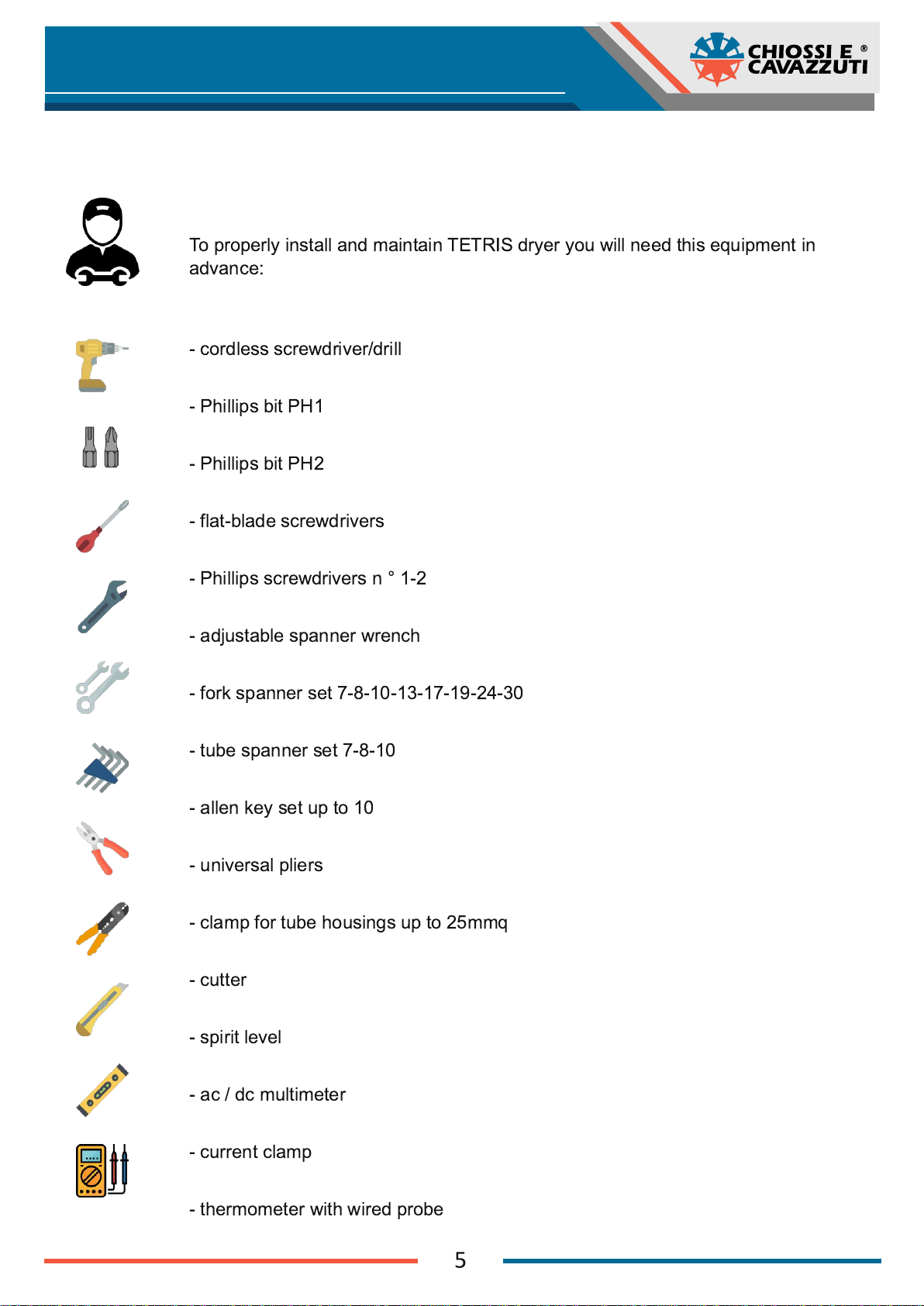

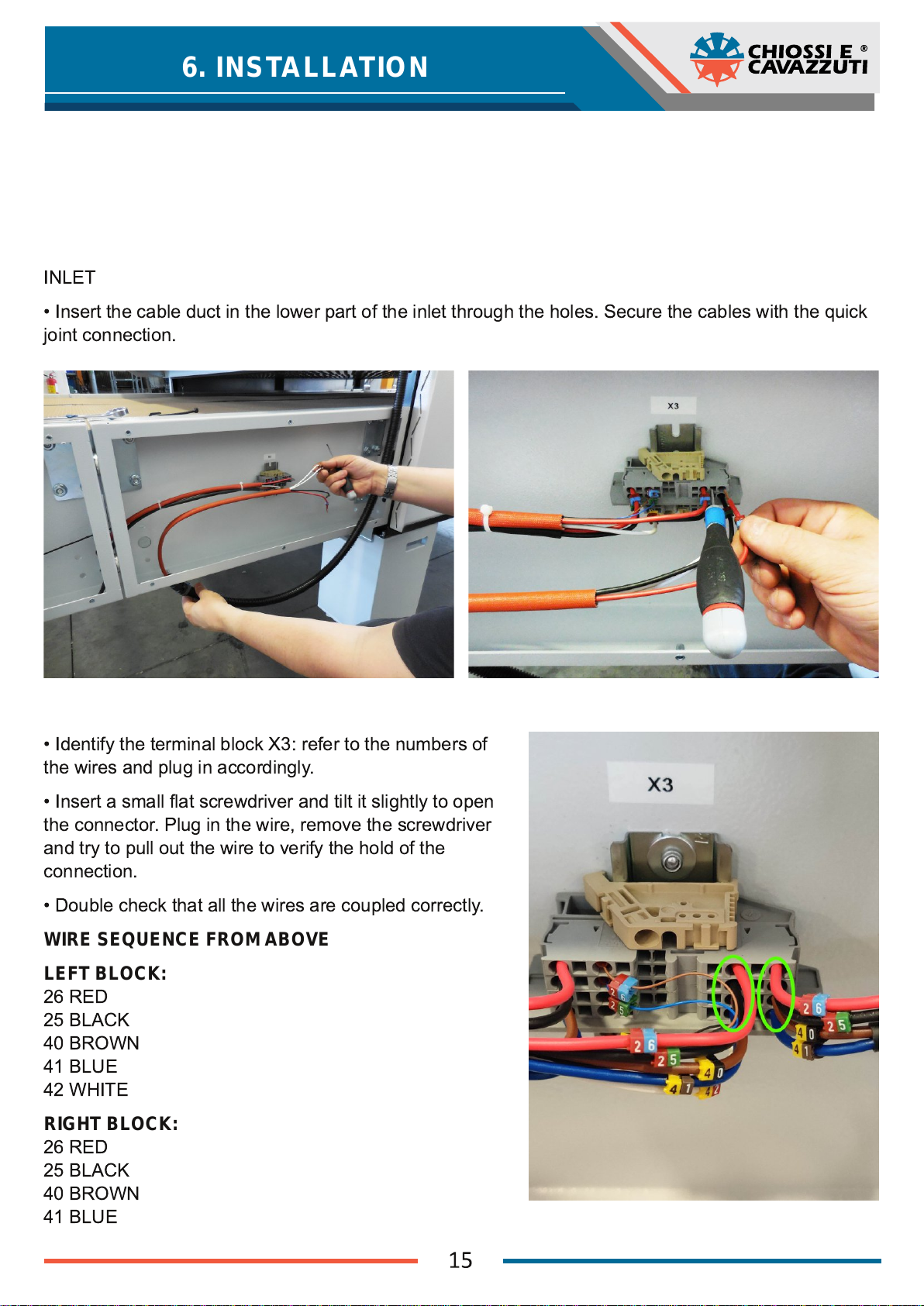

CHIOSSI E CAVAZZUTI ACE 950 Instruction sheet

This manual suits for next models

3

Table of contents

Other CHIOSSI E CAVAZZUTI Dryer manuals

Popular Dryer manuals by other brands

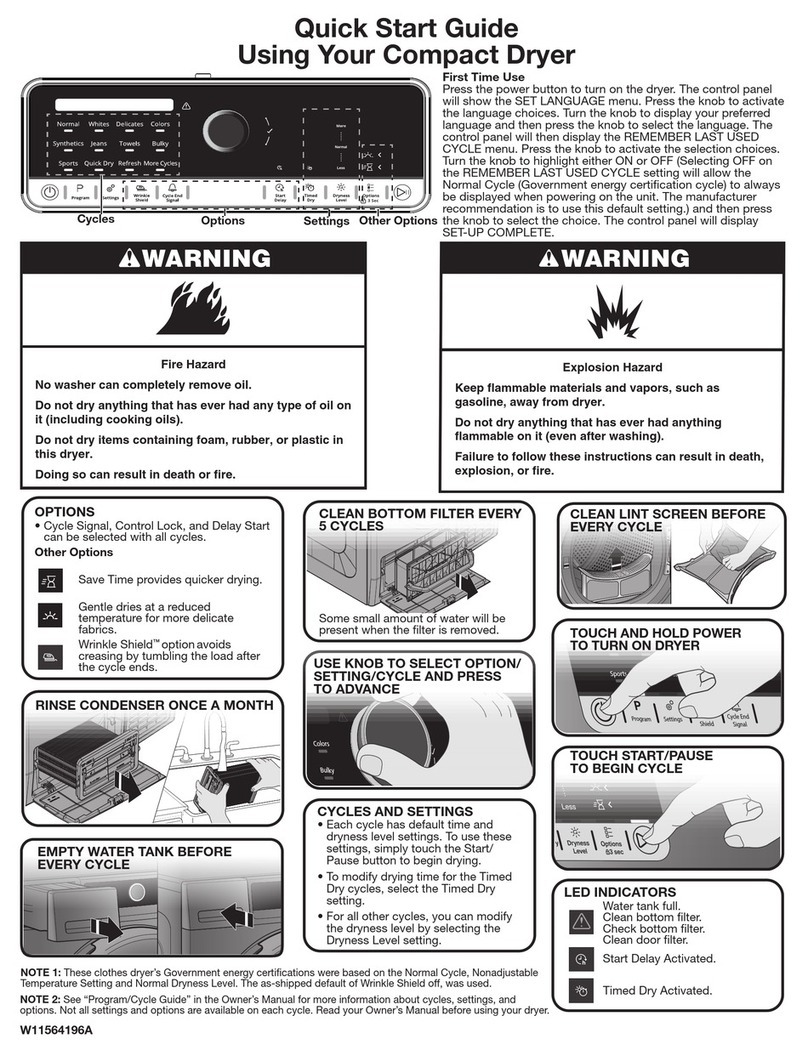

Whirlpool

Whirlpool WCD5090JW quick start guide

Alliance Laundry Systems

Alliance Laundry Systems LWS01M series operating instructions

Electrolux

Electrolux EDE56140W user manual

NovaTec

NovaTec NovaDrier ND-7 instruction manual

Whirlpool

Whirlpool LER5624BN0 Top and console parts

American Dryer Corp.

American Dryer Corp. Phase 7 / OPL ensor Activated Fire Extinguishing System... installation manual

arcelik

arcelik 3886 KT user manual

Mediclinics

Mediclinics M23A Installation and operating manual

Indesit

Indesit IDPE G45X A1 ECO instruction manual

Samsung

Samsung DVE45T6100 Series user manual

Alliance Laundry Systems

Alliance Laundry Systems ADEE9BGS433XW34 installation instructions

ADC

ADC AD-170SE installation manual