Chipcon CC1000 User manual

CC1000

SWRS048A Page 1 of 55

CC1000

Single Chip Very Low Power RF Transceiver

Applications

•Very low power UHF wireless data

transmitters and receivers

•315 / 433 / 868 and 915 MHz ISM/SRD

band systems

•RKE – Two-way Remote Keyless Entry

•Home automation

•Wireless alarm and security systems

•AMR – Automatic Meter Reading

•Low power telemetry

•Game Controllers and advanced toys

Product Description

CC1000

is a true single-chip UHF trans-

ceiver designed for very low power and

very low voltage wireless applications. The

circuit is mainly intended for the ISM

(Industrial, Scientific and Medical) and

SRD (Short Range Device) frequency

bands at 315, 433, 868 and 915 MHz, but

can easily be programmed for operation at

other frequencies in the 300-1000 MHz

range.

The main operating parameters of

CC1000

can be programmed via a serial bus, thus

making

CC1000

a very flexible and easy to

use transceiver. In a typical system

CC1000

will be used together with a

microcontroller and a few external passive

components.

CC1000

is based on Chipcon’s SmartRF®

technology in 0.35 µm CMOS.

Features

•True single chip UHF RF transceiver

•Very low current consumption

•Frequency range 300 – 1000 MHz

•Integrated bit synchroniser

•High sensitivity (typical -110 dBm at 2.4

kBaud)

•Programmable output power –20 to

10 dBm

•Small size (TSSOP-28 or UltraCSP™

package)

•Low supply voltage (2.1 V to 3.6 V)

•Very few external components required

•No external RF switch / IF filter

required

•RSSI output

•Single port antenna connection

•FSK data rate up to 76.8 kBaud

•Complies with EN 300 220 and FCC

CFR47 part 15

•Programmable frequency in 250 Hz

steps makes crystal temperature drift

compensation possible without TCXO

•Suitable for frequency hopping

protocols

•Development kit available

•Easy-to-use software for generating the

CC1000

configuration data

CC1000

SWRS048A Page 2 of 55

Table of Contents

CC1000

...........................................................................................................................1

Single Chip Very Low Power RF Transceiver...........................................................1

1. Absolute Maximum Ratings...................................................................................4

2. Operating Conditions .............................................................................................4

3. Electrical Specifications.........................................................................................4

4. Pin Assignment.......................................................................................................8

5. Circuit Description..................................................................................................9

6. Application Circuit................................................................................................10

6.1 Input / output matching...............................................................................................10

6.2 VCO inductor..............................................................................................................10

6.3 Additional filtering.......................................................................................................10

6.4 Power supply decoupling ...........................................................................................10

7. Configuration Overview .......................................................................................12

8. Configuration Software ........................................................................................12

9. 3-wire Serial Configuration Interface ..................................................................13

Note: The set-up- and hold-times refer to 50% of VDD..........................................14

10. Microcontroller Interface....................................................................................15

10.1 Connecting the microcontroller ................................................................................15

11. Signal interface...................................................................................................16

11.1 Manchester encoding and decoding........................................................................16

12. Bit synchroniser and data decision ..................................................................19

13. Receiver sensitivity versus data rate and frequency separation....................22

14. Frequency programming....................................................................................23

15. Recommended RX settings for ISM frequencies .............................................24

16. VCO......................................................................................................................25

17. VCO and PLL self-calibration.............................................................................25

18. VCO and LNA current control............................................................................28

19. Power management............................................................................................28

CC1000

SWRS048A Page 3 of 55

20. Input / Output Matching......................................................................................31

21. Output power programming ..............................................................................32

22. RSSI output .........................................................................................................33

23. IF output ..............................................................................................................34

24. Crystal oscillator.................................................................................................35

25. Optional LC Filter................................................................................................36

26. System Considerations and Guidelines............................................................37

26.1 SRD regulations.......................................................................................................37

26.2 Low cost systems.....................................................................................................37

26.3 Battery operated systems.........................................................................................37

26.4 Crystal drift compensation........................................................................................37

26.5 High reliability systems.............................................................................................37

26.6 Frequency hopping spread spectrum systems.........................................................37

27. PCB Layout Recommendations.........................................................................38

28. Antenna Considerations.....................................................................................38

L = 7125 / f .................................................................................................................38

29. Configuration registers ......................................................................................39

30. Package Description (TSSOP-28)......................................................................48

31. Package Description (UltraCSP™) ....................................................................49

32. Plastic Tube Specification .................................................................................51

33. Waffle Pack Specification ..................................................................................51

34. Carrier Tape and Reel Specification..................................................................51

35. Ordering Information..........................................................................................52

36. General Information............................................................................................52

36.1 Document Revision History......................................................................................52

36.2 Product Status Definitions........................................................................................52

37. Address Information...........................................................................................54

38. TI Worldwide Technical Support .......................................................................54

39. Product Information Centers .............................................................................54

CC1000

SWRS048A Page 4 of 55

1. Absolute Maximum Ratings

Parameter Min. Max. Units Condition

Supply voltage, VDD -0.3 5.0 V

Voltage on any pin -0.3 VDD+0.3,

max 5.0 V

Input RF level 10 dBm

Storage temperature range

(TSSOP) -50 150

°C

Shelf life (UltraCSP™) 1 year Room temperature and oxygen

free cabinet

Reflow soldering temperature

(TSSOP) 260

°C IPC/JEDEC J-STD-020C

Peak reflow soldering temperature

(UltraCSP™) 255

°C IPC/JEDEC J-STD-020C

Under no circumstances the absolute

maximum ratings given above should be

violated. Stress exceeding one or more of

the limiting values may cause permanent

damage to the device.

Caution! ESD sensitive device.

Precaution should be used when handling

the device in order to prevent permanent

damage.

2. Operating Conditions

Parameter

Min. Typ. Max. Unit Condition / Note

RF Frequency Range 300

1000 MHz Programmable in steps of 250 Hz

Operating ambient temperature range -40 85 °C

Supply voltage

2.1 3.0 3.6 V

Note: The same supply voltage

should be used for digital (DVDD)

and analogue (AVDD) power.

3. Electrical Specifications

Tc = 25°C, VDD = 3.0 V if nothing else stated

Parameter

Min. Typ. Max. Unit Condition / Note

Transmit Section

Transmit data rate

0.6 76.8 kBaud NRZ or Manchester encoding.

76.8 kBaud equals 76.8 kbit/s

using NRZ coding. See page 16.

Binary FSK frequency separation

0 65 kHz

The frequency separation is

programmable in 250 Hz steps.

65 kHz is the maximum

guaranteed separation at 1 MHz

reference frequency. Larger

separations can be achieved at

higher reference frequencies.

CC1000

SWRS048A Page 5 of 55

Parameter

Min. Typ. Max. Unit Condition / Note

Output power

433 MHz

868 MHz

-20

-20

10

5

dBm

dBm

Delivered to 50 Ωload.

The output power is

programmable.

RF output impedance

433/868 MHz 140 / 80 ΩTransmit mode. For matching

details see “Input/ output

matching” p.31.

Harmonics

-20 dBc An external LC or SAW filter

should be used to reduce

harmonics emission to comply

with SRD requirements. See

p.36.

Receive Section

Receiver Sensitivity, 433 MHz

Optimum sensitivity (9.3 mA)

Low current consumption (7.4 mA)

Receiver Sensitivity, 868 MHz

Optimum sensitivity (11.8 mA)

Low current consumption (9.6 mA)

-110

-109

-107

-105

dBm

dBm

dBm

dBm

2.4 kBaud, Manchester coded

data, 64 kHz frequency

separation, BER = 10

-3

See Table 6 and Table 7 page 22

for typical sensitivity figures at

other data rates.

System noise bandwidth 30 kHz 2.4 kBaud, Manchester coded

data

Cascaded noise figure

433/868 MHz

12/13 dB

Saturation

10 dBm 2.4 kBaud, Manchester coded

data, BER = 10

-3

Input IP3

-18 dBm From LNA to IF output

Blocking

40 dBc At +/- 1 MHz

LO leakage -57 dBm

Input impedance

88-j26

70-j26

52-j7

52-j4

Ω

Ω

Ω

Ω

Receive mode, series equivalent

at 315 MHz

at 433 MHz

at 868 MHz.

At 915 MHz

For matching details see “Input/

output matching” p. 31.

Turn on time 11 128 Baud The turn-on time is determined by

the demodulator settling time,

which is programmable. See p.

19

IF Section

Intermediate frequency (IF)

150

10.7 kHz

MHz Internal IF filter

External IF filter

IF bandwidth

175 kHz

RSSI dynamic range

-105 -50 dBm

RSSI accuracy ±6

dB

See p.33 for details

RSSI linearity ±2 dB

CC1000

SWRS048A Page 6 of 55

Parameter

Min. Typ. Max. Unit Condition / Note

Frequency Synthesiser

Section

Crystal Oscillator Frequency

3 16 MHz Crystal frequency can be 3-4, 6-8

or 9-16 MHz. Recommended

frequencies are 3.6864, 7.3728,

11.0592 and 14.7456. See page

35 for details.

Crystal frequency accuracy

requirement

±50

±25

ppm 433 MHz

868 MHz

The crystal frequency accuracy

and drift (ageing and

temperature dependency) will

determine the frequency accuracy

of the transmitted signal.

Crystal operation

Parallel

C171 and C181 are loading

capacitors, see page 35

Crystal load capacitance

12

12

12

22

16

16

30

30

16

pF

pF

pF

3-4 MHz, 22 pF recommended

6-8 MHz, 16 pF recommended

9-16 MHz, 16 pF recommended

Crystal oscillator start-up time 5

1.5

2

ms

ms

ms

3.6864 MHz, 16 pF load

7.3728 MHz, 16 pF load

16 MHz, 16 pF load

Output signal phase noise

-85 dBc/Hz At 100 kHz offset from carrier

PLL lock time (RX / TX turn time)

200 µs Up to 1 MHz frequency step

PLL turn-on time, crystal oscillator

on in power down mode 250 µs Crystal oscillator running

Digital Inputs/Outputs

Logic “0” input voltage

0 0.3*VDD V

Logic ”1” input voltage

0.7*VDD VDD V

Logic “0” output voltage

0

0.4 V Output current -2.5 mA,

3.0 V supply voltage

Logic “1” output voltage

2.5

VDD V Output current 2.5 mA,

3.0 V supply voltage

Logic “0” input current

NA -1

µA Input signal equals GND

Logic “1” input current

NA 1

µA Input signal equals VDD

DIO setup time

20 ns TX mode, minimum time DIO

must be ready before the positive

edge of DCLK

DIO hold time

10 ns TX mode, minimum time DIO

must be held after the positive

edge of DCLK

Serial interface (PCLK, PDATA and

PALE) timing specification

See Table 2 page 14

Current Consumption

Power Down mode

0.2 1

µA Oscillator core off

CC1000

SWRS048A Page 7 of 55

Parameter

Min. Typ. Max. Unit Condition / Note

Current Consumption,

receive mode 433/868 MHz

7.4/9.6 mA Current is programmable and can

be increased for improved

sensitivity

Current Consumption,

average in receive mode using

polling 433/868 MHz

74/96 µA Polling controlled by micro-

controller using 1:100 receive to

power down ratio

Current Consumption,

transmit mode 433/868 MHz:

P=0.01mW (-20 dBm)

P=0.3 mW (-5 dBm)

P=1 mW (0 dBm)

P=3 mW (5 dBm)

P=10 mW (10 dBm)

5.3/8.6

8.9/13.8

10.4/16.5

14.8/25.4

26.7/NA

mA

mA

mA

mA

mA

The ouput power is delivered to a

50Ωload, see also p. 32

Current Consumption, crystal osc.

Current Consumption, crystal osc.

And bias

Current Consumption, crystal osc.,

bias and synthesiser, RX/TX

30

80

105

860

4/5

5/6

µA

µA

µA

µA

mA

mA

3-8 MHz, 16 pF load

9-14 MHz, 12 pF load

14-16 MHz, 16 pF load

< 500 MHz

> 500 MHz

CC1000

SWRS048A Page 8 of 55

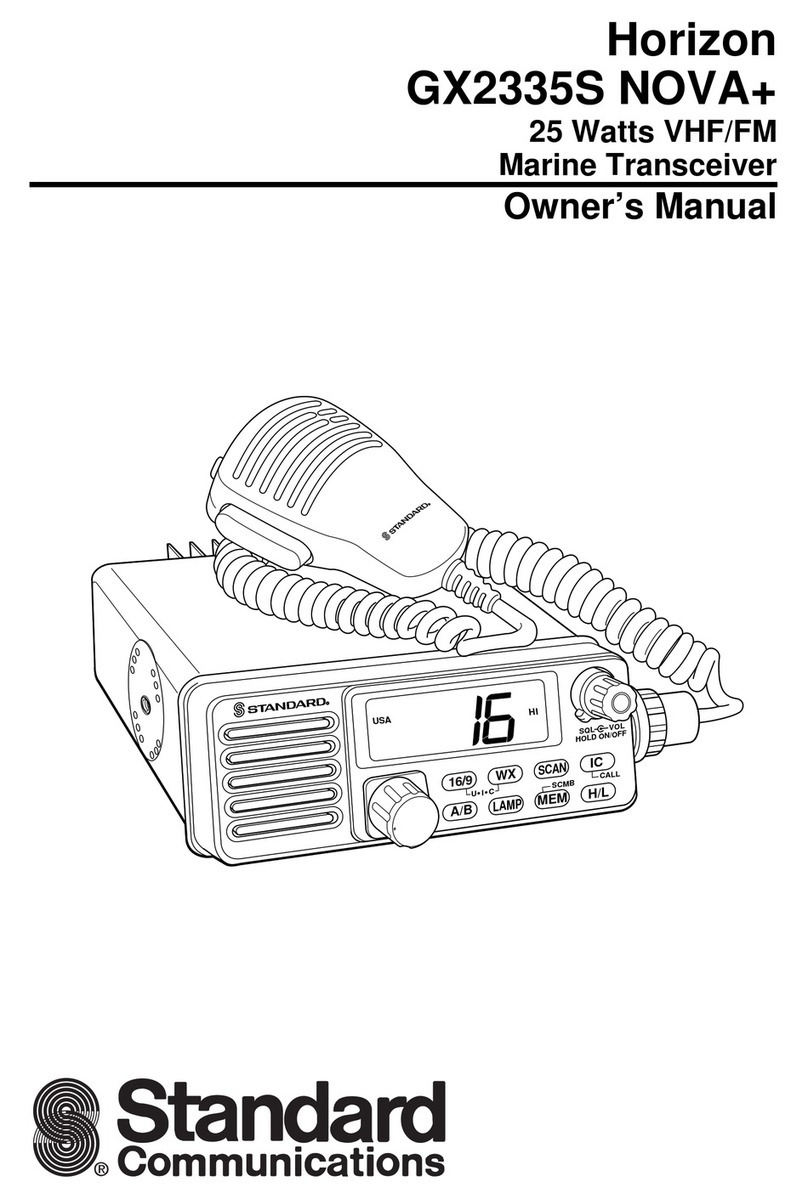

4. Pin Assignment

Pin no. UltraCSP

pin no. Pin name Pin type Description

1 G3 AVDD Power (A) Power supply (3 V) for analog modules (mixer and IF)

2 F2 AGND Ground (A) Ground connection (0 V) for analog modules (mixer and IF)

3 G2 RF_IN RF Input RF signal input from antenna

4 G1 RF_OUT RF output RF signal output to antenna

5 F1 AVDD Power (A) Power supply (3 V) for analog modules (LNA and PA)

6 E2 AGND Ground (A) Ground connection (0 V) for analog modules (LNA and PA)

7 E1 AGND Ground (A) Ground connection (0 V) for analog modules (PA)

8 D1 AGND Ground (A) Ground connection (0 V) for analog modules (VCO and prescaler)

9 C1 AVDD Power (A) Power supply (3 V) for analog modules (VCO and prescaler)

10 B1 L1 Analog input Connection no 1 for external VCO tank inductor

11 A1 L2 Analog input Connection no 2 for external VCO tank inductor

12 B2 CHP_OUT

(LOCK) Analog output Charge pump current output

The pin can also be used as PLL Lock indicator. Output is high

when PLL is in lock.

13 C2 R_BIAS Analog output

Connection for external precision bias resistor (82 kΩ, ±1%)

14 F3 AGND Ground (A) Ground connection (0 V) for analog modules (backplane)

15 A2 AVDD Power (A) Power supply (3 V) for analog modules (general)

16 B3 AGND Ground (A) Ground connection (0 V) for analog modules (general)

17 A3 XOSC_Q2 Analog output Crystal, pin 2

18 A4 XOSC_Q1 Analog input Crystal, pin 1, or external clock input

19 B4 AGND Ground (A) Ground connection (0 V) for analog modules (guard)

20 C3 DGND Ground (D) Ground connection (0 V) for digital modules (substrate)

21 C4 DVDD Power (D) Power supply (3 V) for digital modules

22 D4 DGND Ground (D) Ground connection (0 V) for digital modules

23 E4 DIO Digital

input/output Data input/output. Data input in transmit mode. Data output in

receive mode

24 F4 DCLK Digital output Data clock for data in both receive and transmit mode

25 G4 PCLK Digital input Programming clock for 3-wire bus

26 D3 PDATA Digital

input/output Programming data for 3-wire bus. Programming data input for

write operation, programming data output for read operation

27 D2 PALE Digital input Programming address latch enable for 3-wire bus. Internal pull-up.

28 E3 RSSI/IF Analog output The pin can be used as RSSI or 10.7 MHz IF output to optional

external IF and demodulator. If not used, the pin should be left

open (not connected).

A=Analog, D=Digital

(Top View)

1

14 15

AVDD

AGND

RF_IN

RF_OUT

AVDD

AGND

AGND

AGND

AVDD

L1

L2

R_BIAS

CHP_OUT

AGND

CC1000

2

3

4

6

5

7

8

9

11

12

13

10

28

RSSI/IF

PALE

PDATA

PCLK

DCLK

DIO

DGND

DVDD

DGND

AGND

XOSC_Q1

AGND

XOSC_Q2

AVDD

27

26

25

23

24

22

21

20

18

17

16

19

1

14 15

AVDD

AGND

RF_IN

RF_OUT

AVDD

AGND

AGND

AGND

AVDD

L1

L2

R_BIAS

CHP_OUT

AGND

CC1000

2

3

4

6

5

7

8

9

11

12

13

10

28

RSSI/IF

PALE

PDATA

PCLK

DCLK

DIO

DGND

DVDD

DGND

AGND

XOSC_Q1

AGND

XOSC_Q2

AVDD

RSSI/IF

PALE

PDATA

PCLK

DCLK

DIO

DGND

DVDD

DGND

AGND

XOSC_Q1

AGND

XOSC_Q2

AVDD

27

26

25

23

24

22

21

20

18

17

16

19

CC1000

SWRS048A Page 9 of 55

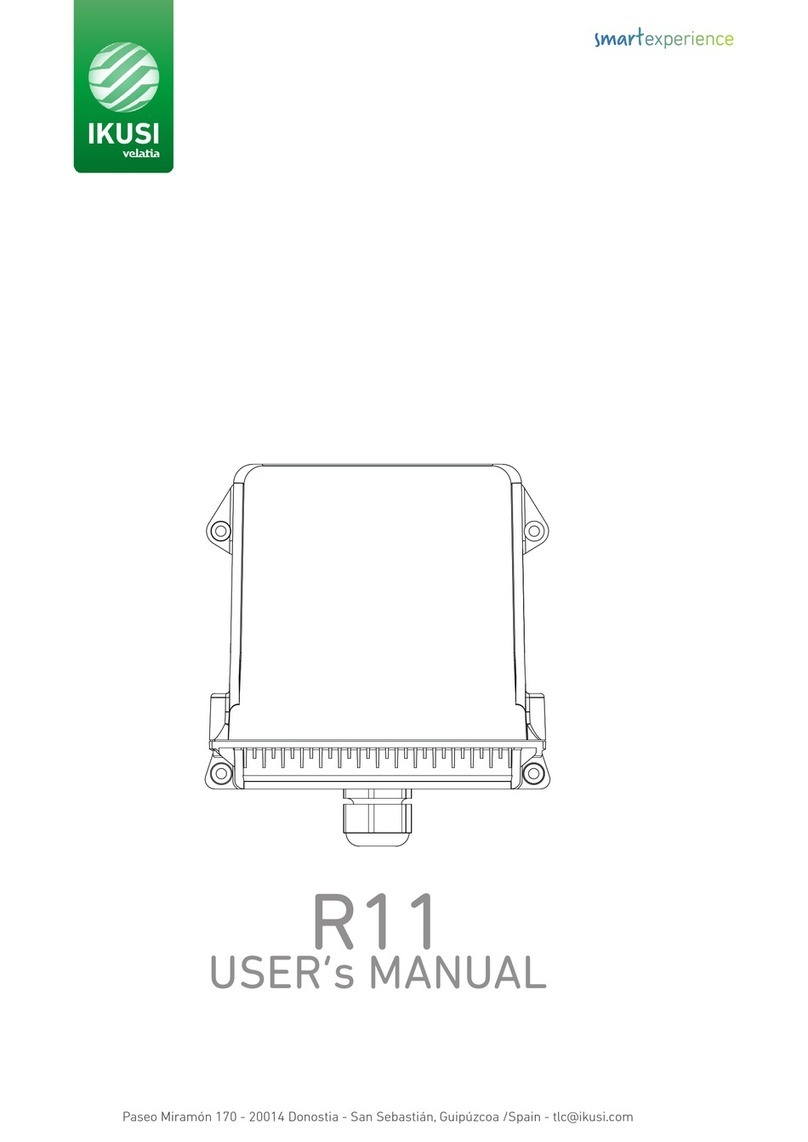

5. Circuit Description

Figure 1. Simplified block diagram of the

CC1000

A simplified block diagram of

CC1000

is

shown in Figure 1. Only signal pins are

shown.

In receive mode

CC1000

is configured as a

traditional superheterodyne receiver. The

RF input signal is amplified by the low-

noise amplifier (LNA) and converted down

to the intermediate frequency (IF) by the

mixer (MIXER). In the intermediate

frequency stage (IF STAGE) this

downconverted signal is amplified and

filtered before being fed to the

demodulator (DEMOD). As an option a

RSSI signal, or the IF signal after the

mixer is available at the RSSI/IF pin. After

demodulation

CC1000

outputs the digital

demodulated data on the pin DIO.

Synchronisation is done on-chip providing

data clock at DCLK.

In transmit mode the voltage controlled

oscillator (VCO) output signal is fed

directly to the power amplifier (PA). The

RF output is frequency shift keyed (FSK)

by the digital bit stream fed to the pin DIO.

The internal T/R switch circuitry makes the

antenna interface and matching very easy.

The frequency synthesiser generates the

local oscillator signal which is fed to the

MIXER in receive mode and to the PA in

transmit mode. The frequency synthesiser

consists of a crystal oscillator (XOSC),

phase detector (PD), charge pump

(CHARGE PUMP), VCO, and frequency

dividers (/R and /N). An external crystal

must be connected to XOSC, and only an

external inductor is required for the VCO.

The 3-wire digital serial interface

(CONTROL) is used for configuration.

PDATA, PCLK, PALE

LNA

PA

DEMOD

VCO PD OSC

~

/N

MIXER

CHARGE

PUMP

L1

RF_IN DIO

CHP_OUT

IF STAGE

RF_OUT

RSSI/IF

3

CONTROL

XOSC_Q2

XOSC_Q1

/R

DCLK

L2

LPF

BIAS

R_BIAS

PDATA, PCLK, PALE

LNA

PA

DEMOD

VCO PD OSC

~

/N

MIXER

CHARGE

PUMP

L1

RF_IN DIO

CHP_OUT

IF STAGE

RF_OUT

RSSI/IF

3

CONTROL

XOSC_Q2

XOSC_Q1

/R

DCLK

L2

LPF

BIAS

R_BIAS

CC1000

SWRS048A Page 10 of 55

6. Application Circuit

Very few external components are

required for the operation of

CC1000

. A

typical application circuit is shown in

Figure 2. Component values are shown in

Table 1.

6.1 Input / output matching

C31/L32 is the input match for the

receiver. L32 is also a DC choke for

biasing. C41, L41 and C42 are used to

match the transmitter to 50 Ω. An internal

T/R switch circuit makes it possible to

connect the input and output together and

match the

CC1000

to 50 Ωin both RX and

TX mode. See “Input/output matching”

p.31 for details.

6.2 VCO inductor

The VCO is completely integrated except

for the inductor L101.

Component values for the matching

network and VCO inductor are easily

calculated using the SmartRF®Studio

software.

6.3 Additional filtering

Additional external components (e.g. RF

LC or SAW-filter) may be used in order to

improve the performance in specific

applications. See also “Optional LC filter”

p.36 for further information.

6.4 Power supply decoupling

Power supply decoupling and filtering

must be used (not shown in the

application circuit). The placement and

size of the decoupling capacitors and the

power supply filtering are very important to

achieve the optimum performance.

Chipcon provides reference designs

(CC1000PP and CC1000uCSP_EM) that

should be followed very closely.

Figure 2. Typical

CC1000

application circuit (power supply decoupling not shown)

CC1000

SWRS048A Page 11 of 55

CC1000 TSSOP package

Item 315 MHz 433 MHz 868 MHz 915 MHz

C31 8.2 pF, 5%, C0G, 0603 15 pF, 5%, C0G, 0603 10 pF, 5%, C0G, 0603 10 pF, 5%, C0G, 0603

C41 2.2 pF, 5%, C0G, 0603 8.2 pF, 5%, C0G, 0603 Not used Not used

C42 5.6 pF, 5%, C0G, 0603 5.6 pF, 5%, C0G, 0603 4.7 pF, 5%, C0G, 0603 4.7 pF, 5%, C0G, 0603

C171 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603

C181 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603 18 pF, 5%, C0G, 0603

L32 39 nH, 10%, 0805

(Coilcraft 0805CS-390XKBC)

68 nH, 10%, 0805

(Coilcraft 0805CS-680XKBC)

120 nH, 10%, 0805

(Coilcraft 0805CS-121XKBC)

120 nH, 10%, 0805

(Coilcraft 0805CS-121XKBC)

L41 20 nH, 10%, 0805

(Coilcraft 0805HQ-

20NXKBC)

6.2 nH, 10%, 0805

(Coilcraft 0805HQ-

6N2XKBC)

2.5 nH, 10%, 0805

(Coilcraft 0805HQ-

2N5XKBC)

2.5 nH, 10%, 0805

(Coilcraft 0805HQ-

2N5XKBC)

L101 56 nH, 5%, 0805

(Koa KL732ATE56NJ)

33 nH, 5%, 0805

(Koa KL732ATE33NJ) 4.7 nH, 5%, 0805

(Koa KL732ATE4N7C) 4.7 nH, 5%, 0805

(Koa KL732ATE4N7C)

R131 82 kΩ, 1%, 0603 82 kΩ, 1%, 0603 82 kΩ, 1%, 0603 82 kΩ, 1%, 0603

XTAL 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load

CC1000 UltraCSP™ package

Item 315 MHz 433 MHz 868 MHz 915 MHz

C31 8.2 pF, 5%, C0G, 0402 15 pF, 5%, C0G, 0402 10 pF, 5%, C0G, 0402 10 pF, 5%, C0G, 0402

C41 Not used Not used Not used Not used

C42 4.7 pF, 5%, C0G, 0402 4.7 pF, 5%, C0G, 0402 6.8 pF, 5%, C0G, 0402 6.8 pF, 5%, C0G, 0402

C171 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402

C181 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402 18 pF, 5%, C0G, 0402

L32 39 nH, 5%, 0402

(Ceramic multilayer)

68 nH, 5%, 0402

(Ceramic multilayer)

120 nH, 5%, 0402

(Ceramic multilayer)

120 nH, 5%, 0402

(Ceramic multilayer)

L41 22 nH, 5%, 0402

(Ceramic multilayer)

15 nH, 5%, 0402

(Ceramic multilayer)

2.7 nH, 5%, 0402

(Ceramic multilayer)

2.7 nH, 5%, 0402

(Ceramic multilayer)

L101 56 nH, 5%, 0402

(Thin film inductor)

33 nH, 5%, 0402

(Thin film inductor) 7.5 nH, 5%, 0402

(Thin film inductor) 7.5 nH, 5%, 0402

(Thin film inductor)

R131 82 kΩ, 1%, 0402 82 kΩ, 1%, 0402 82 kΩ, 1%, 0402 82 kΩ, 1%, 0402

XTAL 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load 14.7456 MHz crystal,

16 pF load

Note: Items shaded are different for different frequencies

Table 1. Bill of materials for the application circuit

Note that the component values for

868/915 MHz can be the same. However,

it is important the layout is optimised for

the selected VCO inductor in order to

centre the tuning range around the

operating frequency to account for

inductor tolerance. The VCO inductor

must be placed very close and

symmetrical with respect to the pins (L1

and L2).

Chipcon provide reference layouts that

should be followed very closely in order to

achieve the best performance. The

reference design can be downloaded from

the Chipcon website.

CC1000

SWRS048A Page 12 of 55

7. Configuration Overview

CC1000

can be configured to achieve the

best performance for different

applications. Through the programmable

configuration registers the following key

parameters can be programmed:

•Receive / transmit mode

•RF output power

•Frequency synthesiser key

parameters: RF output frequency, FSK

frequency separation (deviation),

crystal oscillator reference frequency

•Power-down / power-up mode

•Crystal oscillator power-up / power

down

•Data rate and data format (NRZ,

Manchester coded or UART interface)

•Synthesiser lock indicator mode

•Optional RSSI or external IF

8. Configuration Software

Chipcon provides users of

CC1000

with a

software program, SmartRF®Studio

(Windows interface) that generates all

necessary

CC1000

configuration data

based on the user’s selections of various

parameters. These hexadecimal numbers

will then be the necessary input to the

microcontroller for the configuration of

CC1000

. In addition the program will

provide the user with the component

values needed for the input/output

matching circuit and the VCO inductor.

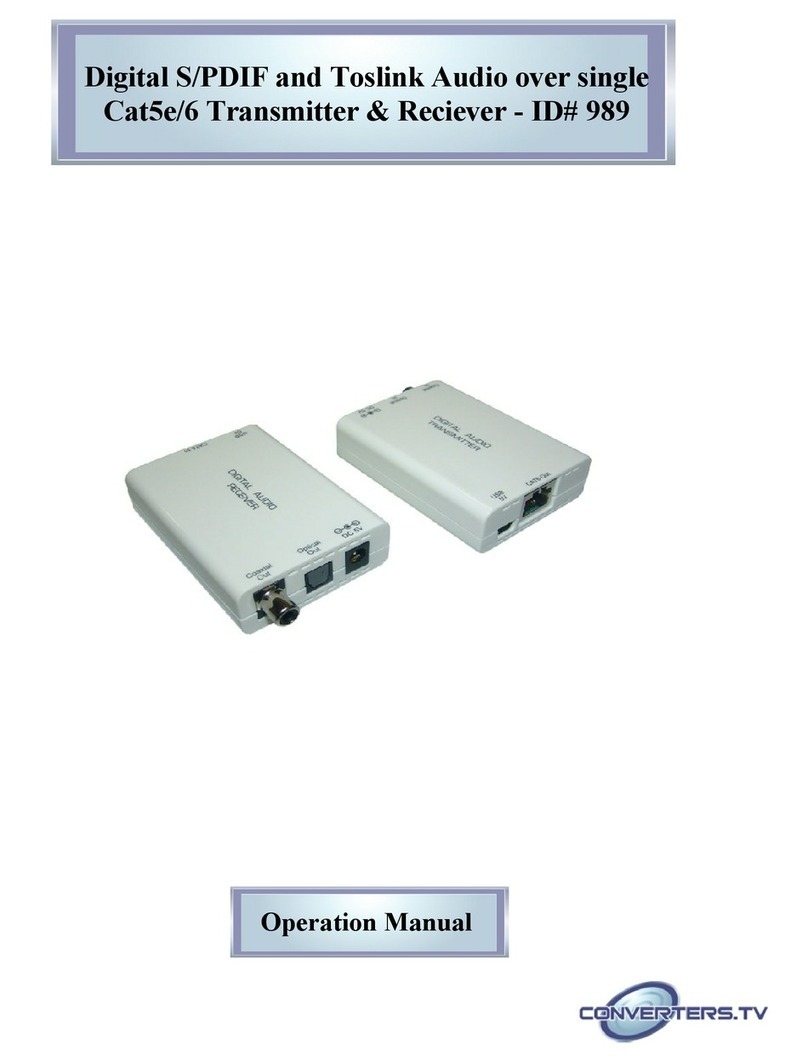

Figure 3 shows the user interface of the

CC1000

configuration software.

Figure 3. SmartRF®Studio user interface

CC1000

SWRS048A Page 13 of 55

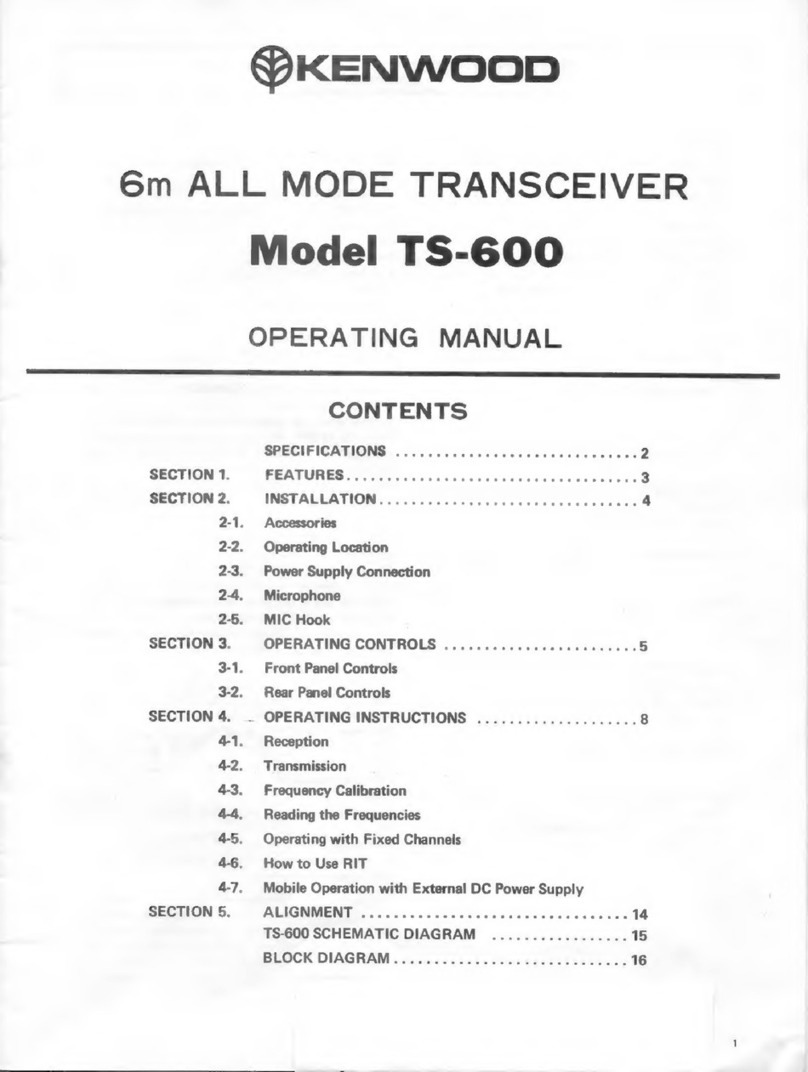

9. 3-wire Serial Configuration Interface

CC1000

is configured via a simple 3-wire

interface (PDATA, PCLK and PALE).

There are 28 8-bit configuration registers,

each addressed by a 7-bit address. A

Read/Write bit initiates a read or write

operation. A full configuration of

CC1000

requires sending 22 data frames of 16 bits

each (7 address bits, R/W bit and 8 data

bits). The time needed for a full

configuration depend on the PCLK

frequency. With a PCLK frequency of 10

MHz the full configuration is done in less

than 46 µs. Setting the device in power

down mode requires sending one frame

only and will in this case take less than 2

µs. All registers are also readable.

In each write-cycle 16 bits are sent on the

PDATA-line. The seven most significant

bits of each data frame (A6:0) are the

address-bits. A6 is the MSB (Most

Significant Bit) of the address and is sent

as the first bit. The next bit is the R/W bit

(high for write, low for read). During

address and R/W bit transfer the PALE

(Program Address Latch Enable) must be

kept low. The 8 data-bits are then

transferred (D7:0). See Figure 4.

The timing for the programming is also

shown in Figure 4 with reference to Table

2. The clocking of the data on PDATA is

done on the negative edge of PCLK.

When the last bit, D0, of the 8 data-bits

has been loaded, the data word is loaded

in the internal configuration register.

The configuration data is stored in internal

RAM. The data is retained during power-

down mode, but not when the power-

supply is turned off. The registers can be

programmed in any order.

The configuration registers can also be

read by the microcontroller via the same

configuration interface. The seven address

bits are sent first, then the R/W bit set low

to initiate the data read-back.

CC1000

then

returns the data from the addressed

register. PDATA is in this case used as an

output and must be tri-stated (or set high n

the case of an open collector pin) by the

microcontroller during the data read-back

(D7:0). The read operation is illustrated in

Figure 5.

Figure 4. Configuration registers write operation

PCLK

PDATA

PALE

Address Write mode

6543210 7 6 5 4 3 2 1 0

Data byte

T

HD

T

SA

T

CH,min

T

CL,min

T

HA

W

T

SD

T

SA

CC1000

SWRS048A Page 14 of 55

Figure 5. Configuration registers read operation

Parameter Symbol

Min Max Units Conditions

PCLK, clock

frequency

F

CLOCK

- 10 MHz

PCLK low

pulse

duration

T

CL,min

50 ns The minimum time PCLK must be low.

PCLK high

pulse

duration

T

CH,min

50 ns The minimum time PCLK must be high.

PALE setup

time T

SA

10 - ns The minimum time PALE must be low before

negative edge of PCLK.

PALE hold

time

T

HA

10 - ns The minimum time PALE must be held low after

the positive edge of PCLK.

PDATA setup

time T

SD

10 - ns The minimum time data on PDATA must be ready

before the negative edge of PCLK.

PDATA hold

time

T

HD

10 - ns The minimum time data must be held at PDATA,

after the negative edge of PCLK.

Rise time T

rise

100 ns The maximum rise time for PCLK and PALE

Fall time T

fall

100 ns The maximum fall time for PCLK and PALE

Note: The set-up- and hold-times refer to 50% of VDD.

Table 2. Serial interface, timing specification

PCLK

Address Read mode

6543210R 7 6 5 4 3 2 1 0

Data byte

PALE

PDATA

CC1000

SWRS048A Page 15 of 55

10. Microcontroller Interface

Used in a typical system,

CC1000

will

interface to a microcontroller. This

microcontroller must be able to:

•Program

CC1000

into different modes

via the 3-wire serial configuration

interface (PDATA, PCLK and PALE).

•Interface to the bi-directional

synchronous data signal interface

(DIO and DCLK).

•Optionally the microcontroller can do

data encoding / decoding.

•Optionally the microcontroller can

monitor the frequency lock status from

pin CHP_OUT (LOCK).

•Optionally the microcontroller can

monitor the RSSI output for signal

strength acquisition.

10.1 Connecting the microcontroller

The microcontroller uses 3 output pins for

the configuration interface (PDATA, PCLK

and PALE). PDATA should be a bi-

directional pin for data read-back. A bi-

directional pin is used for data (DIO) to be

transmitted and data received. DCLK

providing the data timing should be

connected to a microcontroller input.

Optionally another pin can be used to

monitor the LOCK signal (available at the

CHP_OUT pin). This signal is logic level

high when the PLL is in lock. See Figure

6.

Also the RSSI signal can be connected to

the microcontroller if it has an analogue

ADC input.

The microcontroller pins connected to

PDATA and PCLK can be used for other

purposes when the configuration interface

is not used. PDATA and PCLK are high

impedance inputs as long as PALE is

high.

PALE has an internal pull-up resistor and

should be left open (tri-stated by the

microcontroller) or set to a high level

during power down mode in order to

prevent a trickle current flowing in the pull-

up. The pin state in power down mode is

summarized in Table 3.

Pin Pin state Note

PDATA Input Should be driven high or low

PCLK Input Should be driven high or low

PALE Input with internal pull-

up resistor Should be driven high or high-impedance to minimize

power consumption

DIO Input Should be driven high or low

DCLK High-impedance

output

Table 3. CC1000 pins in power-down mode

CC1000

PDATA

PCLK

PALE

DIO

CHP_OUT

(LOCK)

Micro-

controller

DCLK (Optional)

RSSI/IF (Optional) ADC

Figure 6. Microcontroller interface

CC1000

SWRS048A Page 16 of 55

11. Signal interface

The signal interface consists of DIO and

DCLK and is used for the data to be

transmitted and data received. DIO is the

bi-directional data line and DCLK provides

a synchronous clock both during data

transmission and data reception.

The

CC1000

can be used with NRZ (Non-

Return-to-Zero) data or Manchester (also

known as bi-phase-level) encoded data.

CC1000

can also synchronise the data from

the demodulator and provide the data

clock at DCLK.

CC1000

can be configured for three

different data formats:

Synchronous NRZ mode.In transmit

mode

CC1000

provides the data clock at

DCLK, and DIO is used as data input.

Data is clocked into

CC1000

at the rising

edge of DCLK. The data is modulated at

RF without encoding.

CC1000

can be

configured for the data rates 0.6, 1.2, 2.4,

4.8, 9.6, 19.2, 38.4 or 76.8 kbit/s. For 38.4

and 76.8 kbit/s a crystal frequency of

14.7456 MHz must be used. In receive

mode

CC1000

does the synchronisation

and provides received data clock at DCLK

and data at DIO. The data should be

clocked into the interfacing circuit at the

rising edge of DCLK. See Figure 7.

Synchronous Manchester encoded mode.

In transmit mode

CC1000

provides the data

clock at DCLK, and DIO is used as data

input. Data is clocked into

CC1000

at the

rising edge of DCLK and should be in NRZ

format. The data is modulated at RF with

Manchester code. The encoding is done

by

CC1000

. In this mode

CC1000

can be

configured for the data rates 0.3, 0.6, 1.2,

2.4, 4.8, 9.6, 19.2 or 38.4 kbit/s. The 38.4

kbit/s rate corresponds to the maximum

76.8 kBaud due to the Manchester

encoding. For 38.4 and 76.8 kBaud a

crystal frequency of 14.7456 MHz must be

used. In receive mode

CC1000

does the

synchronisation and provides received

data clock at DCLK and data at DIO.

CC1000

does the decoding and NRZ data

is presented at DIO. The data should be

clocked into the interfacing circuit at the

rising edge of DCLK. See Figure 8.

Transparent Asynchronous UART mode.

In transmit mode DIO is used as data

input. The data is modulated at RF without

synchronisation or encoding. In receive

mode the raw data signal from the

demodulator is sent to the output. No

synchronisation or decoding of the signal

is done in

CC1000

and should be done by

the interfacing circuit. The DCLK pin is

used as data output in this mode. Data

rates in the range from 0.6 to 76.8 kBaud

can be used. For 38.4 and 76.8 kBaud a

crystal frequency of 14.7456 MHz must be

used. See Figure 9.

11.1 Manchester encoding and

decoding

In the Synchronous Manchester encoded

mode

CC1000

uses Manchester coding

when modulating the data. The

CC1000

also performs the data decoding and

synchronisation. The Manchester code is

based on transitions; a “0” is encoded as a

low-to-high transition, a “1” is encoded as

a high-to-low transition. See Figure 10.

The

CC1000

can detect a Manchester

decoding violation and will set a

Manchester Violation Flag when such a

violation is detected in the incoming

signal. The threshold limit for the

Manchester Violation can be set in the

MODEM1 register. The Manchester

Violation Flag can be monitored at the

CHP_OUT (LOCK) pin, configured in the

LOCK register.

The Manchester code ensures that the

signal has a constant DC component,

which is necessary in some FSK

demodulators. Using this mode also

ensures compatibility with CC400/CC900

designs.

CC1000

SWRS048A Page 17 of 55

Figure 7. Synchronous NRZ mode

Figure 8. Synchronous Manchester encoded mode

DIO

DCLK

“RF”

Clock provided by CC1000

FSK modulating signal (NRZ),

internal in CC1000

Data provided by microcontroller

Transmitter side:

Clock provided by CC1000

Demodulated signal (NRZ),

internal in CC1000

Data provided by CC1000

Receiver side:

“RF”

DCLK

DIO

DIO

DCLK

“RF”

Clock provided by CC1000

FSK modulating signal (NRZ),

internal in CC1000

Data provided by microcontroller

Transmitter side:

Clock provided by CC1000

Demodulated signal (NRZ),

internal in CC1000

Data provided by CC1000

Receiver side:

“RF”

DCLK

DIO

DIO

DCLK

“RF”

Clock provided by CC1000

FSK modulating signal (Manchester encoded),

internal in CC1000

Data provided by microcontroller (NRZ)

Transmitter side:

Clock provided by CC1000

Demodulated signal (Manchester encoded),

internal in CC1000

Data provided by CC1000 (NRZ)

Receiver side:

“RF”

DCLK

DIO

DIO

DCLK

“RF”

Clock provided by CC1000

FSK modulating signal (Manchester encoded),

internal in CC1000

Data provided by microcontroller (NRZ)

Transmitter side:

Clock provided by CC1000

Demodulated signal (Manchester encoded),

internal in CC1000

Data provided by CC1000 (NRZ)

Receiver side:

“RF”

DCLK

DIO

CC1000

SWRS048A Page 18 of 55

Figure 9. Transparent Asynchronous UART mode

Time

TX

data

10110001101

Time

TX

data

10110001101

Figure 10. Manchester encoding

DIO

DCLK

“RF”

DCLK is not used in transmit mode.

Used as data output in receive mode.

FSK modulating signal,

internal in CC1000

Data provided by UART (TXD)

Transmitter side:

DIO is not used in receive mode. Used only

as data input in transmit mode.

Demodulated signal,

internal in CC1000

Data output provided by CC1000.

Connect to UART (RXD).

Receiver side:

“RF”

DIO

DCLK

DIO

DCLK

“RF”

DCLK is not used in transmit mode.

Used as data output in receive mode.

FSK modulating signal,

internal in CC1000

Data provided by UART (TXD)

Transmitter side:

DIO is not used in receive mode. Used only

as data input in transmit mode.

Demodulated signal,

internal in CC1000

Data output provided by CC1000.

Connect to UART (RXD).

Receiver side:

“RF”

DIO

DCLK

CC1000

SWRS048A Page 19 of 55

12. Bit synchroniser and data decision

Sampler

Average

filter

Data

filter

Decimator

Frequency

detector Data slicer

comparator

Figure 11. Demodulator block diagram

A block diagram of the digital demodulator

is shown in Figure 11. The IF signal is

sampled and its instantaneous frequency

is detected. The result is decimated and

filtered. In the data slicer the data filter

output is compared to the average filter

output to generate the data output.

The averaging filter is used to find the

average value of the incoming data. While

the averaging filter is running and

acquiring samples, it is important that the

number of high and low bits received is

equal (e.g. Manchester code or a

balanced preamble).

Therefore all modes, also synchronous

NRZ mode, need a DC balanced

preamble for the internal data slicer to

acquire correct comparison level from the

averaging filter. The suggested preamble

is a ‘010101…’ bit pattern. The same bit

pattern should also be used in Manchester

mode, giving a ‘011001100110…chip

pattern. This is necessary for the bit

synchronizer to synchronize correctly.

The averaging filter must be locked before

any NRZ data can be received. If the

averaging filter is locked

(MODEM1.LOCK_AVG_MODE=’1’), the

acquired value will be kept also after

Power Down or Transmit mode. After a

modem reset

(MODEM1.MODEM_RESET_N), or a

main reset (using any of the standard

reset sources), the averaging filter is reset.

In a polled receiver system the automatic

locking can be used. This is illustrated in

Figure 12. If the receiver is operated

continuously and searching for a

preamble, the averaging filter should be

locked manually as soon as the preamble

is detected. This is shown in Figure 13. If

the data is Manchester coded there is no

need to lock the averaging filter

(MODEM1.LOCK_AVG_IN=’0’), as shown

in Figure 14.

The minimum length of the preamble

depends on the acquisition mode selected

and the settling time. Table 4 gives the

minimum recommended number of chips

for the preamble in NRZ and UART

modes. In this context ‘chips’ refer to the

data coding. Using Manchester coding

every bit consists of two ‘chips’. For

Manchester mode the minimum

recommended number of chips is shown

in Table 5.

CC1000

SWRS048A Page 20 of 55

Manual Lock Automatic LockSettling

MODEM1.

SETTLING

(1:0)

NRZ mode

MODEM1.LOCK_

AVG_MODE

=’1’

MODEM1.LOCK_

AVG_IN

=’0’=→’1’**

UART mode

MODEM1.LOCK_

AVG_MODE

=’1’

MODEM1.LOCK_

AVG_IN

=’0’=→’1’**

NRZ mode

MODEM1.LOCK_

AVG_MODE

=’0’

MODEM1.LOCK_

AVG_IN

=’X’***

UART mode

MODEM1.LOCK_

AVG_MODE

=’0’

MODEM1.LOCK_

AVG_IN

=’X’***

00 14 11 16 16

01 25 22 32 32

10 46 43 64 64

11 89 86 128 128

Notes:

** The averaging filter is locked when

MODEM1.LOCK_AVG_IN

is set to 1

*** X = Do not care. The timer for the automatic lock is started when RX mode is set in the

RFMAIN

register

Also please note that in addition to the number of bits required to lock the filter, you need to add the

number of bits needed for the preamble detector. See the next section for more information.

Table 4. Minimum preamble bits for locking the averaging filter, NRZ and UART mode

Settling

MODEM1.

SETTLING

(1:0)

Free-running

Manchester mode

MODEM1.LOCK_

AVG_MODE

=’1’

MODEM1.LOCK_

AVG_IN

=’0’

00 23

01 34

10 55

11 98

Table 5. Minimum number preamble chips for averaging filter, Manchester mode

Table of contents

Other Chipcon Transceiver manuals