4.WORKING TIME

1 RELEASE THE BARRIER AN MOVE THE ARM IN 45°

2 PRESS AN KEEP PRESSE P1\SET BUTTON FOR 5 SECON S

3 THE YELLOW LE START BLINKING

RELEASE THE BUTTON

4 IN 3 SECON S PRESS AGAIN THE BUTTON P2\RA

5 THE BARRIER PERFORM A BRIEF RE UCE SPEE OPENING

(If motor turns in reverse invert wires and start procedure again from the begnning.)

6 THE BARRIER PERFORM A RE UCE SPEE CLOSING UNTIL THE LIMIT SWITCH

7 PRESS P1 OR REMOTE CONTROL AN THE BARRIER PERFORM A NORMAL SPEE OPENING

MOVEMENT

WHEN THE ARM REACH THE POINT FOR THE ESIRE SLOW OWN PRESS P1 OR THE

REMOTE CONTROL

THE ARM REACH THE LIMIT SWITCH

8 PRESS P1 OR REMOTE CONTROL AN THE BARRIER PERFORM A NORMAL SPEE CLOSING

MOVEMENT

WHEN THE ARM REACH THE POINT FOR THE ESIRE SLOW OWN PRESS P1 OR THE

REMOTE CONTROL

THE ARM REACH THE LIMIT SWITCH

9 PROFESSIONAL LEARNING PROCE URE FINISHE

PROFESSIONAL learning

Slow down is setted by the operator

!!! ATTENTION !!!

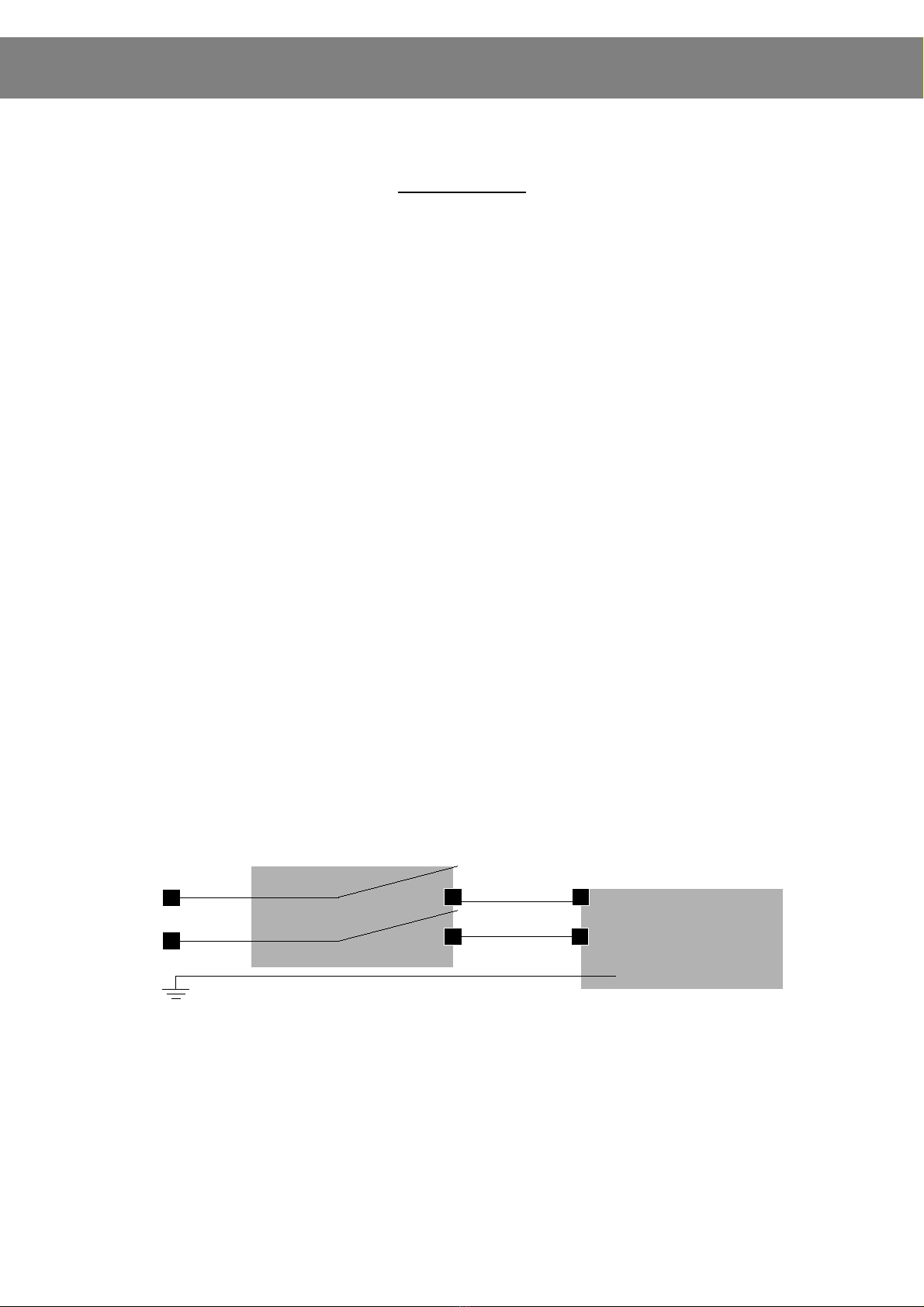

A JUST TRIMMERS IF NECESSARY

!!! ATTENTION !!!

A trimmer variation “FOR” (speed) requires the repetition of the learning procedure from

The beginning (vary the manoeuvre time).

9