Altronic DE-3000+ Series User manual

1

Operating Instructions

DE-3000+ Series Configurable Safety Shutdown and Control System

with Graphing Capabilities

Form DE-3000+ IOI 8-15

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 2

1.0 OVERVIEW

1.1 For help locating subjects in this document, a section index is provided on page 68.

A glossary of technical terms begins on page 66.

1.2 The Altronic DE-3000+ controller system is an electronic, microprocessor-based

system designed to sense various analog and digital input points to control and

monitor industrial compressors. The system is field-programmable using a PC

and the supplied terminal program and contains a non-volatile memory to store

the setup. A panel-mounted 10" color MIDAS HMI serves as the user interface.

The DE-3000+ provides for both the safety shutdown functions needed to pre-

vent unnecessary damage to remotely-operated equipment and the closed-loop

automatic control functions needed to optimize their efficiency of operation.

The DE-3000+ also provides for remote data acquisition and supervisory con-

trol in a compact, low cost package for industrial compressor applications. The

optimization strategies available for the management of compressor throughput

include automatic prime mover speed setting as well as capacity control. On

rotary screw compressors, capacity control can be done via suction throttling,

or using an internal gas bypass technique employing poppet valves, turn valves

or slide valves. On reciprocating compressors, capacity can be controlled us-

ing external gas bypass loops or pressure regulation techniques. A wide range

of output options, including both analog current loops and digital outputs, are

provided to interface with the large variety of actuation systems currently in use.

In addition, automatic load limiting based upon prime mover power capabilities

or other application specific limitations, such as cooling capacity, are readily

implemented. There are also AUTO START and OEM ENGINE CONTROL options

that are enabled using the terminal program.

1.3 The DE-3000+ has four components: 10" color MIDAS HMI (G10S0000),

computer module (DE-3000+), terminal module (691171-1), and power supply

module (691122-1). The MIDAS HMI and the computer module communicate

via the Ethernet port using a CAT 5e cable. The computer module connects to

the terminal module via a DB-25 cable. An additional terminal board may be

added for 30 extra channels (691171-2) or 15 extra channels (691175-2). This

increases the channel selections from 1-30 to 1-60 or 1-45 respectively.

To download the terminal program, a DB-9 cable must be connected to the to

the DE-3000+.

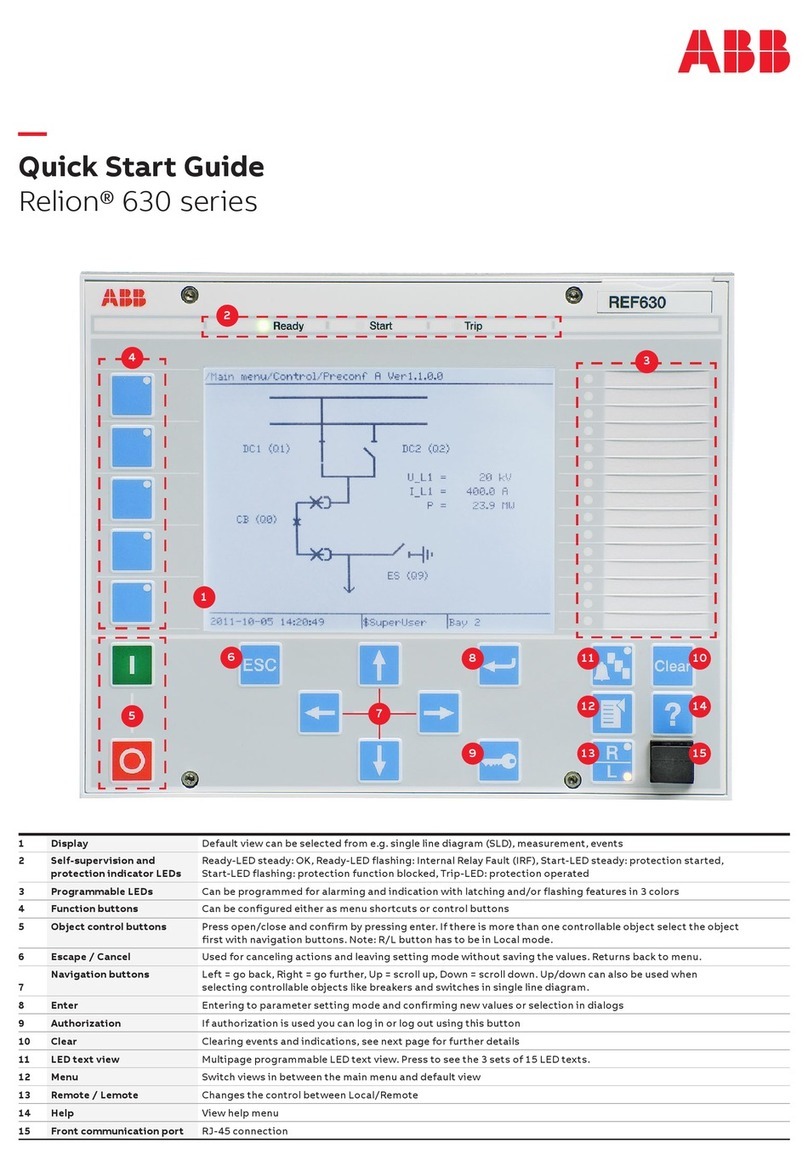

2.0 10"COLOR MIDAS HMI

2.1 The 10" color MIDAS HMI serves as the user interface for the DE-3000+ sys-

tem. It is a VGA color standard touchscreen (640 x 480) outdoor model. The

MIDAS HMI has one 10/100 Base-TX Ethernet Port and three fully isolated Se-

rial Communication Ports (two RS-232 and one RS-422/485). In addition, the

MIDAS HMI has one USB Type B Port and two High-retention USB Host Ports.

WARNING: THE CONTROLLER SYSTEM

MUST BE CONFIGURED PRIOR TO USE

ON A COMPRESSOR SYSTEM. REFER-

ENCE THE PROGRAMMING INSTRUC-

TIONS (PAGE 43) FOR INSTRUCTIONS

DESCRIBING HOW TO CONFIGURE THE

CONTROLLER FOR THE SPECIFIC AP-

PLICATION. VERIFY THE PROGRAM IN

NONVOLATILE MEMORY (THE EEPROM)

PRIOR TO STARTING THE SYSTEM.

WARNING: DEVIATION FROM THESE

INSTRUCTIONS MAY LEAD TO IMPROP-

ER ENGINE OPERATION WHICH COULD

CAUSE PERSONAL INJURY TO OPERA-

TORS OR OTHER NEARBY PERSONNEL.

NOTE: THE DE-3000+ REQUIRES

TWO 10-32VDC, 0.2A (MAX) POWER

SOURCES, ONE FOR THE POWER SUP-

PLY BOARD AND THE OTHER FOR THE

COMPUTER MODULE.

TYPE B

USB

STATUS

USB HOST

STATUS

PORT B

PORT A

COMM

RTS (PIN 6)

Tx

CTS (PIN 1)

Rx

COMM

RTS (PIN 6)

Rx

COMM

Tx

COMM

CTS (PIN 1)

(NIC)

ETHERNET

RxB

TxA (PIN 8)

COMM

TxB

TxEN

TxB (PIN 1)

RxA

TxA

AUXILIARY

ETHERNET

(NIC)

COMMS PORTPGM PORT COMMS PORT

RS232 RS485 RS232

DEVICE

USBPOWER

-+USB HOST PORT A (PGM)

ETHERNET RS232 RS232

PORT BPORT A

RS485

AUXILIARY

ETHERNET

POWER

CHASSIS

COMMON

+DC VOLTAGE

1

2

3

CONNECTOR

[OPTIONAL]

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 3

2.2 The MIDAS HMI available with the DE-3000+ system uses a status strip to

display the controller status on top of all the screens. The 10 inch screen dis-

plays colored trends for analog values and temperatures, and bar graphs for all

the PIDs. In addition, log files can be stored on the SD card, if mounted on the

MIDAS HMI.

2.3 The MIDAS HMI communicates with the DE-3000+ computer module through

the Modbus TCP/IP protocol. The DE-3000+ computer module has to be cor-

rectly configured to establish communication with the MIDAS HMI.

3.0 COMPUTER MODULE (DE-3000+)

3.1 The Computer Module is designed to be rail-mounted and is the interface be-

tween the Terminal and 10" MIDAS HMI and to other systems. It typically plugs

directly into the Terminal Module using the DB-25 connectors and is held to-

gether with screws and screw locks.

3.2 The computer module must be supplied with 10-32VDC, .2A Max current.

3.2 The computer module comes with a default IP address of 10.1.100.100. In

order to configure the DE-3000+, connect it to a computer through the CAT 5e

cable and type in the default IP address on the web browser. The Home page

appears. User can navigate to the Network Settings and Port Settings by click-

ing on the menu on the left of the web page.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 4

3.3 The Home page gives an overview of the DE-3000+ status. The Status shows

the active time for the computer module along with the firmware and web-

page version.

3.4 The Network Settings page displays the communication configuration of the DE-

3000+. This is the page where the user can change the IP configuration of the

system to match their network. To change the IP configuration, type in the new IP

settings under “Change Settings to:” and press “Apply.” The web page will reload.

Reboot the computer module and access the web browser again. The new IP set-

tings should have been accepted by the computer module.

3.5 The Serial Port Settings page displays the serial port configuration of the DE-

3000+. The settings shown below under “Current” is the default setting and

should be kept this way for optimum communication with the DE-3000+ termi-

nal board(s).

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 5

4.0 POWER SUPPLY MODULE

4.1 The Power Supply Module accepts up to four industry-standard, commercial-

ly-available 0.6 inch plug-in Output Modules. The Output Modules provide a

means of using the DE-3000+ Controller Safety Shutdown System status to

interface with other systems on the engine/motor and compressor. A typical

application would be as a relay or solenoid coil driver. The Output Modules are

optically isolated, solid-state switches which are isolated from power supply mi-

nus and engine ground. The Output Modules will be in the open (de-energized)

condition when the unit is not powered.

4.2 Outputs 1 and 2 can be software-configured for either normally-open (N/O) or

normally-closed (N/C) operation and have an LED indicator associated with them.

Outputs 3 and 4 are pre-programmed normally-open for use with the optional

OEM Engine Control or Auto start feature. If an Output Module is programmed for

normally-closed (energized for run), the LED will be ON in the normal run condi-

tion and OFF for a fault condition. For Normally-open configured modules the LED

will be OFF for normal run condition and turn ON for a fault condition.

4.3 The standard Output Module outputs use the top row of the dual 16-position

terminal strip which is marked OUT 1 through OUT 4. Each of these outputs

are fused with a replaceable 6.3 amp slow-blow fuse, Altronic P/N 601653.

In addition to accepting industry-standard Output Modules, a custom Altronic

Output Module P/N 691124 is available for tripping ignition powered CD fuel

valves and shorting CD ignition shutdown leads upon a fault. When making use

of OEM Engine Control, outputs 1 and 2 will not be wired to trip the fuel and ig-

nition valves. When both functions are required, two of these modules are used

as follows: OUT 1 slot must be used to trip the fuel valve, and OUT 2 slot must

be used to short the ignition. If 12-24Vdc is lost to the DE-3000+ annunciator

system, the custom Output Modules will trip the fuel valve and short the igni-

tion shutdown lead. This mimics the “fail-safe” operation of a normally-closed

Output Module and therefore the LED will be ON in the normal run condition

and OFF for a fault condition. In programming the system, these modules are

identified by using the IGN/FUEL selection. Terminals IGN+ and IGN− are used

to connect the shutdown lead, and FV1 and FV2 are used for the CD fuel valve.

A capacitor is included in the Power Supply Module to supply the energy to trip

the fuel valve.

4.4 The 12-24Vdc power for the DE-3000+ system is applied to the power supply

terminals marked (+) and (−) 12–24Vdc INPUT POWER. A 6.3 amp replaceable

slow-blow fuse protects the system from over-currents, and a power LED lights

when power is applied to the system.

4.5 The external connection for the two serial RS-485 communication ports is on

the Power Supply Module terminal strips. Port 2 is for RS-485 serial com-

munication to future Altronic instruments, and port 3 communicates internally

between two different boards within the computer module. Nothing should be

plugged into ports 2 and 3 for normal operations.

4.6 Terminals marked IGN IN and PU IN are used by the DE-3000+ system to de-

tect either engine rotation or ignition system firings. This input monitors chang-

ing signals such as those seen on either the ignition shutdown lead or a mag-

netic pickup monitoring an engine mounted gear.

THE MAGNETIC PICKUP INPUT MUST BE USED FOR APPLICATIONS EN-

ABLING THE AUTO START OR OEM ENGINE CONTROL FUNCTION.

•The IGN IN terminal connects to the positive (+) C.D. ignition shutdown lead.

•The PU IN terminal connects to one magnetic pickup input; the other pickup

wire connects to the minus (−) terminal on the Power Supply Module.

NOTE: AN INSTALLATION MAY USE ONLY

ONE OF THE TERMINALS IGN IN, PU IN,

OR T+.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 6

5.0 TERMINAL MODULE

5.1 The Terminal Module is made to be rail-mounted and is the point of interface

between the field sensor wiring and the DE-3000+ control system. A removable

dual terminal strip is used for the connection of the system to the equipment

mounted discrete sensors which may consist of up to 30 inputs, where any of

the 30 can be used for either a normally-open, normally-closed switch, or analog

inputs including K- or J-type thermocouples. These are listed as channels 01–

30 for the 691171-1 terminal board. They accept industry-standard transducer

signals in the range of 0-5 VDC. Connections from the Terminal Module to the

Display Module are made using the 693115-x series Cable Assembly.

5.2 The DE-3000+ is designed to operate with industry-standard voltage or current-

amplified output transducers in the range of 0 to 5Vdc or 0 to 25mA. Four se-

ries of transducers are available from Altronic: pressure transducers 691201-x,

691204-x and temperature transducers 691202/203-300, 691212/213-450.

5.3 Another terminal board assembly may be added to increase the inputs from 30

to either 45 or 60 inputs. Use cable 693133-1 to connect the two boards. The

691175-2 provides an additional 15 inputs, 4 digital outputs, 2 analog outputs

and an extra speed (pickup) input. The 691171-2 provides an additional 30

inputs, 8 digital outputs, 2 analog outputs, and an extra speed (pickup) input.

5.4 PRESSURE TRANSDUCERS

The pressure transducers, Altronic P/N 691201-x and P/N 691204-x, are pack-

aged in a rugged sealed case with a NPT pressure port, a corrosion resistant

media cavity, and a Packard Electric Metri-Pack connector. The ranges available

are 0-100, 300, 500, 1000, 2000, and 5000 PSIG for the 691201-x series

and 0-50,100, 300, 500 PSIA for the 691204-x series, all of which have an

overload rating of 1.5 times full scale without damage. The three wires from the

transducer are: +5 volt excitation, +0.5 to 4.5 volt output, and minus return.

These three wires connect directly to the back of the Terminal Module using

cable assembly P/N 693008-x.

5.5 DIFFERENTIAL MEASUREMENTS

Differential pressures or temperatures may be measured by using two consecu-

tive channels. The transducers used to measure differential values must be of

the exact same type and range. The first channel of the pair will display the

basic parameter it is monitoring and the second channel of the pair will display

the numeric difference in engineering units of its value subtracted from the first

channel’s value. Setpoints for each channel monitor the displayed value of that

channel. The second channel setpoints monitor the differential value.

5.6 TEMPERATURE TRANSDUCER

The temperature transducers, Altronic P/N 691202-300, 691203-300 with a tem-

perature measurement range of +5 to 300°F and the 691212-450, 691213-450

with a temperature range of -40 to +450°F are packaged in a sealed, stainless steel

housing with a 5/8"-18 UNF threaded body, and a Packard Electric Metri-Pack

connector. During configuration the standard calibration for the 691202/203-300

sensor is selected as dEG1 and the standard calibration for the 691212/213-450 is

selected by choosing dEG2. The three wires from the transducer are: +5 volt excita-

tion, temperature output voltage, and minus return. These wires connect directly to

the Terminal Module using cable assembly P/N 693008-x.

5.7 THERMOCOUPLE INPUTS

The Terminal Modules can accept industry-standard type J or K thermocouples

on inputs 01–60. Automatic cold junction compensation is built-in. The units

can be configured to °F or °C. Both a high and low setpoint is associated with

each channel. The monitor can read type J thermocouples between -76°F and

+1382°F (-60°C and +750°C) and type K thermocouples between -76°F and

+1472°F (-60°C and +800°C).

5.8 N/O and N/C INPUTS

The inputs can also accept standard normally-open and normally- closed con-

tacts. For normally-open input, place the wire between the corresponding in-

puts. Ground the connection to cause a fault. Similarly, for normally-open, wire

the sensor in a normally-closed connection and open it to cause a fault.

691171-1 FOR CHANNELS 01-30

691171-2 FOR CHANNELS 31-60

691175-2 FOR CHANNELS 31-45

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 7

5.9 4-20mA inputs

The terminal module can accept 4-20mA inputs by selecting the internally-

connected 200-ohm resistors, creating a termination voltage of .8 to 4.0 volts.

The jumper wires between the + and – terminals for that channel must be con-

nected for proper operation.

5.10 For each input, the corresponding CHANNEL SWITCH must be set according

to the input type. Switches are turned ON by moving them toward the ANALOG

OUT labeling.

5.11 Digital outputs 1 through 8 are pilot-duty, and turn on to common ground when

closed. Outputs 1 through 8 are rated at 500mA, 60V. See FIG. 8 for wiring details.

6.0 MOUNTING

6.1 10" COLOR MIDAS HMI

The operator interface is designed for through-panel mounting. Four VESA mount

tapped screw-holes (M4 x 0.7, 5 mm deep) are present on the rear of the panel to

allow for stand or wall mounting. Care should be taken to remove any loose material

from the mounting cut-out to prevent that material from falling into the operator in-

terface during installation. A gasket is provided to enable sealing to NEMA 4X/IP66

specification. Install the mounting clips provided and tighten to 6.0 pound-force

inch (96 ounce-force inch) evenly for uniform gasket compression.

6.2 POWER SUPPLY MODULE

Mount the Power Supply Module in the panel either on the bottom or the side of

the main panel. The Power Supply Module is made to be rail-mounted onto com-

mercially available 32 or 35mm DIN mounting rails. It is also made to plug directly

into the Terminal Module using the DB-25 connectors and is held together with

screws and screw locks. Two end brackets P/N 604199 should be used to keep

the modules from sliding off the ends of the mounting rail.

Alternatively, the Power Supply Module and the Terminal Module can be mount-

ed separate from each other on the DIN mounting rails but in the same panel;

in this case, a DB-25 male/female cable such as P/N 693115-1 is used to elec-

trically connect these modules. The operating temperature range of the Power

Supply Module is −31°F to +176°F (−35°C to +80°C).

6.3 TERMINAL MODULE

Mount the Terminal Module either on the bottom or the side of the main panel.

The Terminal Module and Power Supply Module can be rail-mounted onto com-

mercially available 32 or 35mm DIN mounting rails. The Terminal Module plugs

directly into the Power Supply Module using the DB-25 D-Sub connectors and

is held together with screws and screw locks. Two end brackets P/N 604199

are used to keep the modules from sliding off the ends of the rail. The Terminal

Module and the Display Module are electrically connected with a DB-25 male/

female cable, 693115-x series or equivalent. The operating temperature range

of the Terminal Module is −31°F to +176°F (−35°C to +80°C).

6.4 PRESSURE TRANSDUCER

Mount the pressure transducer in the panel or in a manifold or tube off of the

engine. Do not expose the pressure transducer to temperatures above 221°F

(105°C). The second terminal module should be placed close to the first and the

wire connecting them should be free of high-powered panel signals.

NOTE: FOR HAZARDOUS LOCATION

INSTALLATION, THIS DEVICE MUST BE

MOUNTED IN A SUITABLE DUST TIGHT

END-ENCLOSURE AND MUST BE WIRED

USING DIVISION 2 WIRING METHODS AS

SPECIFIED IN ARTICLE 501-4 (B), 502-4

(B), AND 503-3 (B) OF THE NATIONAL

ELECTRICAL CODE, NFPA 70 FOR INSTAL-

LATION WITHIN THE UNITED STATES, OR

AS SPECIFIED IN SECTION 19-152 OF

CANADIAN ELECTRICAL CODE FOR INSTAL-

LATION IN CANADA.

IMPORTANT: PRESSURE TRANSDUCERS

WILL WITHSTAND OVERLOADS AS HIGH

AS 1.5 TIMES RATED PRESSURE. IF THE

OVERLOAD RATING IS EXCEEDED, FAIL-

URE MAY OCCUR. PRESSURE FLUCTUA-

TIONS OCCUR IN MOST RECIPROCATING

SYSTEMS; PICK THE TRANSDUCER

WITH A RATING HIGH ENOUGH TO PRE-

VENT OVERLOAD BY PEAK PRESSURES

OF PULSATIONS. IT IS RECOMMENDED

THAT A PRESSURE SNUBBER BE USED

WHICH WILL REDUCE THE PEAK PRES-

SURE APPLIED TO THE TRANSDUCER.

THE LIFE OF THE TRANSDUCER WILL BE

EXTENDED WITH THE USE OF A SNUB-

BER OR PULSATION DAMPENER.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 8

6.5 TEMPERATURE TRANSDUCER

Mount the temperature transducer in a thermowell on the engine or machine.

The actual sensor is located at the bottom of the transducer body; to ensure

accuracy, the tip of the probe should be surrounded by the measured media.

7.0 WIRING (SEE WIRING DIAGRAMS)

7.1 SYSTEM COMPONENT WIRING

A DB-25 male/female cable, 693115-x series or equivalent, is used to connect

the Terminal Module to the Computer Module and secured with the cable lock

screws. If mounted on the same mounting rail, plug the Terminal Module directly

into the Power Supply Module using the DB-25 D-Sub connectors at the ends

of the modules and secure them together with the screws and screw locks cap-

tive to the connectors. If the Power Supply Module and the Terminal Module are

mounted separate from each other (must be mounted in the same panel) a DB-25

male/female cable such as P/N 693115-1 or equivalent is used to connect these

modules. The HMI connects to the computer module through a CAT E5 cable.

7.2 Connect the supply power wires to the 10-32V input power terminals on the

computer board. Connect the ‘+’ to the ‘DC+’ and connect the ‘-’ to the ‘DC-’

input. Do not connect any other wires into the green Phoenix module. The power

rating for the computer module is 10-32V, .2A Max.

7.2 POWER SUPPLY WIRING

Connect the supply power wires to the 12-24Vdc input power terminals on the

power supply, plus to terminal (+) and minus to terminal (−); power requirement

is 12 to 24Vdc (10 watts max.). The DC− terminal must be connected to panel

ground which should be the same as engine ground.

This is the return path for normally-open sensors and MUST be connected for

proper operation. DO NOT ground this device directly to the ignition system

common coil ground.

7.3 CONNECTING THE 10" MIDAS HMI TO EARTH GROUND

The third pin of the power connector is chassis ground for the unit. The unit

should be connected to earth ground (protective earth).

The chassis ground is not connected to signal common of the unit. Maintaining

isolation between earth ground and signal common is not required to operate

the unit. But, other equipment connected to this unit may require isolation be-

tween signal common and earth ground. To maintain isolation between signal

common and earth ground, care must be taken when connections are made. For

example, a power supply with isolation between its signal common and earth

ground must be used. Also, plugging in a USB cable may connect signal com-

mon and earth ground. The USB’s shield may be connected to earth ground at

the host. USB’s shield, in turn, may also be connected to signal common.

7.4 10" MIDAS HMI POWER SUPPLY REQUIREMENTS

The MIDAS HMI panel requires a 24 VDC power supply. The unit may draw con-

siderably less than the maximum rated power depending upon the features be-

ing used. As additional features are used the unit will draw increasing amounts

of power. Items that could cause increases in current are modules, additional

on-board communications, SD card, and other programmed features.

In any case, it is very important that the power supply is mounted correctly if the

unit is to operate reliably. Please take care to observe the following points:

•The power supply must be mounted close to the unit, with usually not

more than 6 feet (1.8 m) of cable between the supply and the operator

interface. Ideally, the shortest length possible should be used.

•The wire used to connect the operator interface’s power supply should

be at least 22-gage wire suitably rated for the temperatures of the

environment to which it is being installed. If a longer cable run is used,

a heavier gage wire should be used. The routing of the cable should be

kept away from large contactors, inverters, and other devices which may

generate significant electrical noise.

IMPORTANT: DO NOT EXCEED THE

ABSOLUTE MAXIMUM RATING OF THE

TRANSDUCERS, 350°F (176°C) FOR THE

691202/203-300 OR 450°F (232°C) FOR

THE 691212/213- 450. CARE SHOULD

BE TAKEN TO PROTECT THE WIRING AND

CONNECTORS FROM CONTACT WITH HOT

SURFACES.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 9

•A power supply with an NEC Class 2 or Limited Power Source (LPS) and

SELV rating is to be used. This type of power supply provides isolation to

accessible circuits from hazardous voltage levels generated by a mains

power supply due to single faults. SELV is an acronym for “safety extra-

low voltage.” Safety extra-low voltage circuits shall exhibit voltages safe

to touch both under normal operating conditions and after a single fault,

such as a breakdown of a layer of basic insulation or after the failure of

a single component has occurred. A suitable disconnect device shall be

provided by the end user.

7.5 SENSOR WIRING DISCRETE INPUTS

The sensor leads connect to the removable terminal strips on the Terminal Mod-

ule. The terminal numbers correspond to the display numbers which also have a

user assigned 20-character label associated with it. The sensor inputs are num-

bered 01-30, 01-45 or 01-60. With AUTO START enabled, the Remote Reset

on the terminal board is wired for a start switch. Sensor inputs 01–60 can be

configured as class A, class B or class C logic. Any discrete sensor point can be

wired for normally-open or normally-closed operation.

•Normally-open (N/O) sensor switches are wired with one wire to the

bottom terminal strip of the respective sensor number and the other to

engine ground which should be the same as power minus (−). A short

jumper from the bottom terminal to the top terminal must be connected

for normally-open sensors. (See wiring diagrams)

•Normally-closed (N/C) sensor switches are wired with one wire to the bot-

tom terminal strip and the other to the top terminal strip of the respective

sensor number. Note that the short jumper wire must be removed.

•Remote stop and remote reset are wired the same as the sensor

switches, and can be used with either normally-open or normally-closed

contacts.

Use a wire size between 16 AWG (max.) and 24 AWG (min.) to connect the sen-

sor switches to the terminal strip connector. Strip the insulation back 3/8"; twist

the exposed wires tightly together. Insert the exposed wire completely into the

terminal strip and securely tighten the clamping screw. Wires running to sensor

switches must be in good condition or replaced with new wires. When running

wires, take care not to damage the insulation and take precautions against later

damage from vibration, abrasion, or liquids in conduits. An explosion-proof con-

duit is not required. However; wires should be protected from damage by run-

ning them in a protective conduit or in sheaths where appropriate. In addition, it

is essential that the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as the AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

C. Sensor switches may be connected to any passive device using contacts

such as standard switch gauges, pressure or level switches. DO NOT con-

nect sensor leads to any voltage producing element.

D. In the case of a field conversion, where sensors have previously been

used with Murphy tattletales, it is recommended that the sensors be

checked frequently when the DE system is first put into use. Sensor

contacts may be burned or pitted from past exposure to ignition system

primary voltage. It is advisable to replace such sensors.

E. If it becomes necessary to check sensor switch to panel wiring with an

ohmmeter or other checker, first DISCONNECT the plug-in terminal strips

from the Terminal Module. Applying voltage to the DE-3000+ system

through the sensor leads may damage the device. The area should be

tested as non-hazardous before such testing commences.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 10

ANALOG SENSOR WIRING

For each analog monitored point, inputs 01–60, select a transducer - either an

Altronic pressure or temperature transducer listed above or one that outputs a

signal in the range of 0 to 5 Vdc or 0 to 25 mA. Mount as described above. Use

cable assembly 693008-x or similar to wire transducer to the Terminal Module.

An internal 5 volt sensor supply (500 mA. max.) is available to power the Altronic

transducers; See wiring diagrams. If the 5 volt sensor supply exits the panel, it

must be fused with a 0.5 ampere fuse. If 24Vdc powered sensors are used, the

24 volt supply to them must be fused appropriately. Take care not to damage the

insulation when installing and take precautions against later damage from vibra-

tion, abrasion, or liquids in conduits. In addition, it is essential that the following

practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

7.6 THERMOCOUPLES AND THERMOCOUPLE EXTENSION WIRE

Grounded or ungrounded type J or K thermocouples may be used. Use thermo-

couple extension wire of the same type as the thermocouple probe to connect to

the terminal module. Use stranded thermocouple wire having a moisture-resis-

tant insulation such as PVC; for higher ambient temperatures, Teflon or B-fibre

insulated thermocouple wire is recommended. To ensure that an accurate signal

is transmitted to the device, avoid any added junctions, splices and contact with

other metals. On unused channels, leave the small jumper wire supplied with the

system in place. Take care not to damage the insulation when installing and take

precautions against later damage from vibration, abrasion, or liquids in conduits.

In addition, it is essential that the following practices be adhered to:

A. Never run sensor wires in the same conduit with ignition wiring or other

high energy wiring such as AC line power.

B. Keep secondary wires to spark plugs and other high voltage wiring at

least eight inches (200mm) away from sensor and sensor wiring.

7.7 LUBE/NO-FLOW SENSOR:

Channels 27 and 28 may be used for a lube/no-flow proximity cycle switch as

an option. Wire the sensor according to section 5.8. The Sensor may be wired

as either a N/O or a N/C with a jumper. The DIP switches on the terminal board

must be set as an analog configuration. The lube/no-flow channels generate a

fault when the time between pulses exceeds the programmed run pulse time.

7.8 OUTPUT SWITCH WIRING

The Power Supply Module accepts an industry-standard 0.6" Output Module.

The following modules are available from Altronic:

691124 This custom module has two uses: connection to a Murphy fuel valve

and directly grounding a C.D. ignition system.

A. Use in position OUT 1 to connect to a C.D. ignition-type Murphy

fuel valve. Connect terminals 3 and 8 of the fuel valve to the

Power Supply Module terminals marked F1 (FV1) and F2 (FV2).

B. Use in position OUT 2 to directly ground-out (stop) a C.D. ignition

system. Wire the C.D. ignition shutdown lead and ignition ground

to the Power Supply Module terminals marked I+ (IGN+) and I-

(IGN-) observing the proper polarity for the ignition system.

DO NOT connect directly to the ignition system common coil ground.

691125 This module is rated for 5-48 Vdc, 5.0 A., and may be used in any of

the four output slots OUT 1 through OUT 4. It may be used to inter-

rupt the DC supply to DC-powered ignition systems such as Altronic

CD1, CPU-90, II-CPU or DISN.

691056 This module is rated for 5-60 Vdc, 2.0 A., and may be used in any of

the four output slots OUT 1 through OUT 4.

NOTE: ADDITIONAL CHANNEL SET UP WILL

BE REQUIRED IN THE TERMINAL SOFT-

WARE PROGRAM.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 11

691066 This module is rated for 5-200 Vdc, 0.67 A. and may be used in any

of the four output slots OUT 1 through OUT 4.

691065 This module is rated for 24-280 Vac, 2.0 A. and may be used in any

of the four output slots OUT 1 through OUT 4.

7.9 RS-485 COMMUNICATIONS WIRING

•Port 2 is for communication between the display and terminal boards.

•Port 3 is for RS-485 serial communication between the computer mod-

ule and the HMI.

These should not be connected for normal operation.

7.10 SENSE ROTATION INPUT

Terminals marked IGN IN and PU IN on the Power Supply Module are used by

the DE-3000+ system to detect either engine rotation or ignition system firings.

On applications using multiple terminal board assemblies, the T+ terminal on the

second terminal board (the one not directly connected to the power supply) can

be used to add a second RPM value. The T+ input is only for use with magnetic

pickups. This input monitors voltage signals such as those seen on either the igni-

tion shutdown lead or a magnetic pickup monitoring an engine-mounted gear.

•The IGN IN terminal connects to the positive (+) C.D. ignition shutdown lead.

•The PU IN terminal connects to one magnetic pickup input; the other pickup

wire connects to the minus (−) terminal on the Power Supply Module.

•The T+ terminal connects to one magnetic pickup input; the other pickup

wire connects to the terminal on the terminal module.

THE MAGNETIC PICKUP INPUT MUST BE USED FOR APPLICATIONS ENABLING

THE OPTIONAL AUTO START OR OEM ENGINE CONTROL FUNCTION.

8.0 HAZARDOUS AREA OPERATION

8.1 The DE-3000+ system is CSA-certified for CLASS I, DIVISION 2, GROUPS C

and D areas when mounted in a suitable enclosure.

In addition, the following requirements must be met (refer to NFPA standard no. 493):

•The low voltage sensor switch wires within the panel enclosure must

be kept at least two (2) inches away from other wiring. Run the sensor

switch wires leaving the panel in a separate conduit from all other wiring

and keep them separate

•Wiring to the sensors must have a grade of insulation capable of with-

standing an AC voltage of 500 volts RMS.

•Sensor wires must be run in separate conduits and junction boxes from high

voltage wires such as ignition, fuel valve, and other high voltage wiring.

NOTE: AN INSTALLATION MAY USE ONLY

ONE OF THE TERMINALS IGN IN, PU IN,

OR T+.

WARNING: SUBSTITUTION OF COMPO-

NENTS MAY IMPAIR INTRINSIC SAFETY

AND/OR SUITABILITY FOR CLASS I, DIV.

2, GROUPS C AND D. DO NOT DISCON-

NECT EQUIPMENT IN DIV. 2 ENVIRON-

MENT UNLESS POWER IS SWITCHED

OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 12

9.0 10"MIDAS HMI MAIN MENU

9.1 The 10" MIDAS HMI has three buttons on its bezel. The red triangle directs to

the Alarms page, the horizontal button in the middle directs to the Main Menu

page, and the green home button directs to the Home page.

9.2 The 10" MIDAS HMI screens can be accessed through the Main Menu and MIDAS

HMI Utility screens as shown below. The HMI Utility screen can be accessed by

clicking on the “HMI UTILITY” button on the Main Menu screen.

To return from the HMI Utility screen to Main Menu screen, click on the “MAIN

MENU” button on the HMI Utility screen.

NOTE: THE SCREENS SHOWN IN THIS

SECTION ON THE HMI REFLECT A

GENERAL LAYOUT AND MAY APPEAR

DIFFERENTLY DUE TO DIFFERENCES IN

ENGINE CONFIGURATIONS.

NOTE: THE HORIZONTAL BLUE BUT-

TON IN THE MIDDLE ONLY LIGHTS UP

WHEN THERE IS A MEMORY CARD (SD)

INSERTED IN THE HMI.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 13

9.3 To log-in to the MIDAS HMI, click on the credentials button on the Main Menu

screen. When the Log-in popup appears, the status displays whether the user is

logged in or not. If the “LOGOUT” is selected, click on the “LOGIN” button and

enter the credentials.

Once the credentials are authorized, the “LOGIN” button will be selected show-

ing that the user has successfully been logged in.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 14

9.4 Write control needs to be enabled whenever a value is to be written to the DE-3000+

controller. To be able to enable write control, press on the “CONTROL WRITE” button

on the Main Menu screen.

If the user is not logged in, credentials would be required before accessing the

write control popup. Once the popup appears, press the “WRITE” button to en-

able write control.

The write control should be set to “Read” mode when not editing DE-3000+

controller registers. To avoid the write control from staying at “Write” all the

time, a timer is implemented on the MIDAS HMI that changed the write control

to “Read” mode after it expires. The default value of the timer is set to 120 sec,

but the user can increase it up to 600 sec.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 15

To access the write control timer, press the “WRITE TIMER” button on the HMI Utility.

After the credentials are verified, the write control timer popup appears. The

Control Write Time (in sec) can be modified to increase or decrease the time for

the write feature to expire. The Time Elapsed (in sec) shows how much time is

left before the write control will revert to “Read” mode.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 16

9.5 The Alarms on the DE-3000+ controller are setup and executed through the

MIDAS HMI. There is a two-step alarm activation system in place that needs to

be setup before alarms will become active.

The first step is to enable the alarm on the DE-3000+ system. By default, the

DE-3000+ system have the alarms disabled. To enable, press the “ENABLE

ALARMS” button on the HMI Utility page.

After the credentials are verified, the Alarm Enable/Disable popup screen appears.

Click on the “ENABLE” button to enable the alarms on the DE-3000+ system.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 17

The second step is to enable the High or Low alarm on each channel. This can

be done on the Channel Status page. When the High/Low Alarms are armed, and

the alarm condition is met, the alarms show up as yellow on the data box and the

alarm strip describing the nature of the alarm appears at the bottom of the screen.

9.6 In addition to the Main Menu and HMI Utility screens, all the screens on the

MIDAS HMI can be accessed through the Menu Popup at the bottom of every HMI

screen.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 18

Once the Menu popup is pressed, screen navigation buttons appear at the bot-

tom of the screen. To view more navigation buttons, press the “EXTENDED

MENU” button.

The Menu Popups can be canceled by pressing the red exit button.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 19

9.7 The MIDAS HMI screens can also be navigated through up and down arrow keys

at the bottom of every screen. The blue arrow keys are used to move to the next

or previous category of screens while the maroon arrow keys are used to move to

the next or previous screen.

9.8 The Home Screen can be accessed by clicking on the “HOME” button on the

Main Menu screen. Through the Home screen, the user can control the opera-

tion and monitor the status of the DE-3000+ controller. The screenshot shows

the Home screen for a DE-3000+ system. Home screens may vary based on the

project configuration.

DE-3000+ IOI 8-15

All rights reserved © ALTRONIC, LLC 2015 20

9.9 The START button on the Home screen sends a command to the DE-3000+

controller to start.

9.10 STOP key is used for a manual stop condition. By pressing the STOP key, the

controller activates the configured output modules in the power supply.

Table of contents

Other Altronic Control System manuals