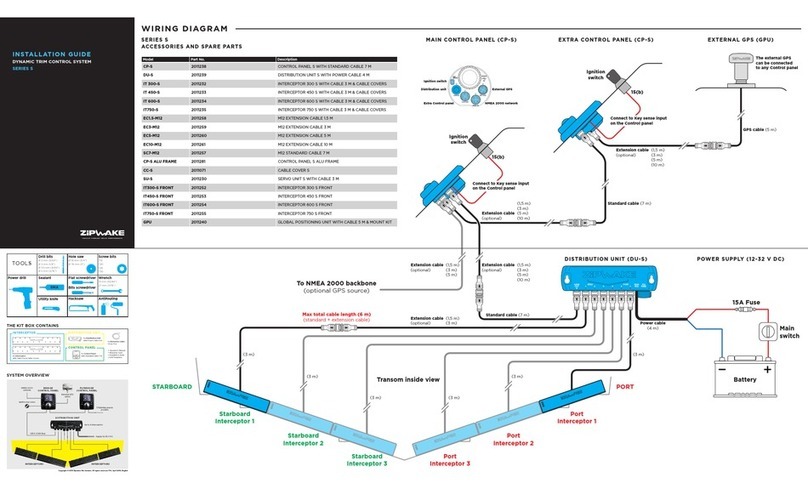

WIRING DIAGRAM

ACCESSORIES

CONTROL PANEL

Model Part No. Description

CP-E 2012032 CONTROL PANEL E WITH STANDARD CABLE 15 M

DU-E 2012033 DISTRIBUTION UNIT E WITH POWER CABLE 6 M

DU-EX 2012034 DISTRIBUTION EXPANSION UNIT E WITH POWER CABLE 6 M

IT400-E 2012215 INTERCEPTOR 400 E WITH CABLE 3 M & CABLE COVER

IT600-E 2012018 INTERCEPTOR 600 E WITH CABLE 3 M & CABLE COVER

IT800-E 2012019 INTERCEPTOR 800 E WITH CABLE 3 M & CABLE COVER

IT1000-E 2012020 INTERCEPTOR 1000 E WITH CABLE 3 M & CABLE COVER

IT600-E TUNNEL R500 2012021 INTERCEPTOR 600 E TUNNEL R500

WITH CABLE 3 M & CABLE COVER

IT600-E TUNNEL R600 2012022 INTERCEPTOR 600 E TUNNEL R600

WITH CABLE 3 M & CABLE COVER

IT600-E TUNNEL R800 2012023 INTERCEPTOR 600 E TUNNEL R800

WITH CABLE 3 M & CABLE COVER

IT400-E CHINE PORT 2012216 INTERCEPTOR 400 E CHINE PORT SIDE

WITH CABLE 3 M & CABLE COVER

IT400-E CHINE STBD 2012217 INTERCEPTOR 400 E CHINE STARBOARD SIDE

WITH CABLE 3 M & CABLE COVER

IT600-E CHINE PORT 2012024 INTERCEPTOR 600 E CHINE PORT SIDE

WITH CABLE 3 M & CABLE COVER

IT600-E CHINE STBD 2012025 INTERCEPTOR 600 E CHINE STARBOARD SIDE

WITH CABLE 3 M & CABLE COVER

EC1.5-M12 2011258 M12 EXTENSION CABLE 1.5 M

EC3-M12 2011259 M12 EXTENSION CABLE 3 M

EC5-M12 2011260 M12 EXTENSION CABLE 5 M

EC10-M12 2011261 M12 EXTENSION CABLE 10 M

EC15-M12 2012038 M12 EXTENSION CABLE 15 M

EC20-M12 2012039 M12 EXTENSION CABLE 20 M

SC15-M12 2012037 M12 STANDARD CABLE 15 M

CP ALU FRAME 2011281 CONTROL PANEL ALU FRAME

CP COVER 2011381-

2011385

CONTROL PANEL COVER

WHITE, LIGHT GRAY, MID GRAY, DARK GRAY, BLACK

CC-EX 2012036 CABLE COVER EXTENSION E KIT

GPU 2011240 GLOBAL POSITIONING UNIT WITH CABLE 5 M & MOUNT KIT

GB 2011622 GIMBAL BRACKET FOR CONTROL PANEL

All readings must be green!

Corrective action is always necessary when excessive torque levels are observed.

The root cause is usually the flatness of the transom behind the interceptor and/

or excess antifouling between its blades.

IMPORTANT

Always use the controls to move the interceptor blades. Never try to force

the interceptor blades by hand.

5

61

2

Snap on the frame

Apply sealant (x4)

When waterproofing

is required

Control panel:

T10 (ST 2.9x19)

(x4)

INTERCEPTOR CHECK

4 INITIAL START

Press and hold the POWER/MENU button until the

Zipwake logo appears on the display and follow

the steps on the screen.

Carry out an Interceptor Check to verify function imme-

diately after installation and before launching the boat.

Repeat this before every launch.

NOTE! Interceptor Check will not start if no interceptor

configuration has been saved to the system (refer to the

Operator's Manual).

The check repeats a 5 stroke sequence, where each interceptor blade is extended,

one by one, from port to starboard and then retracted in the same order. Visually

confirm that the interceptors move accordingly during the check. This confirms

that the interceptors are correctly connected to the distribution unit(s).

SET UP THE SYSTEM

Refer to the Operator’s Manual for detailed information about setting up

and operating the system.

1524

678

3