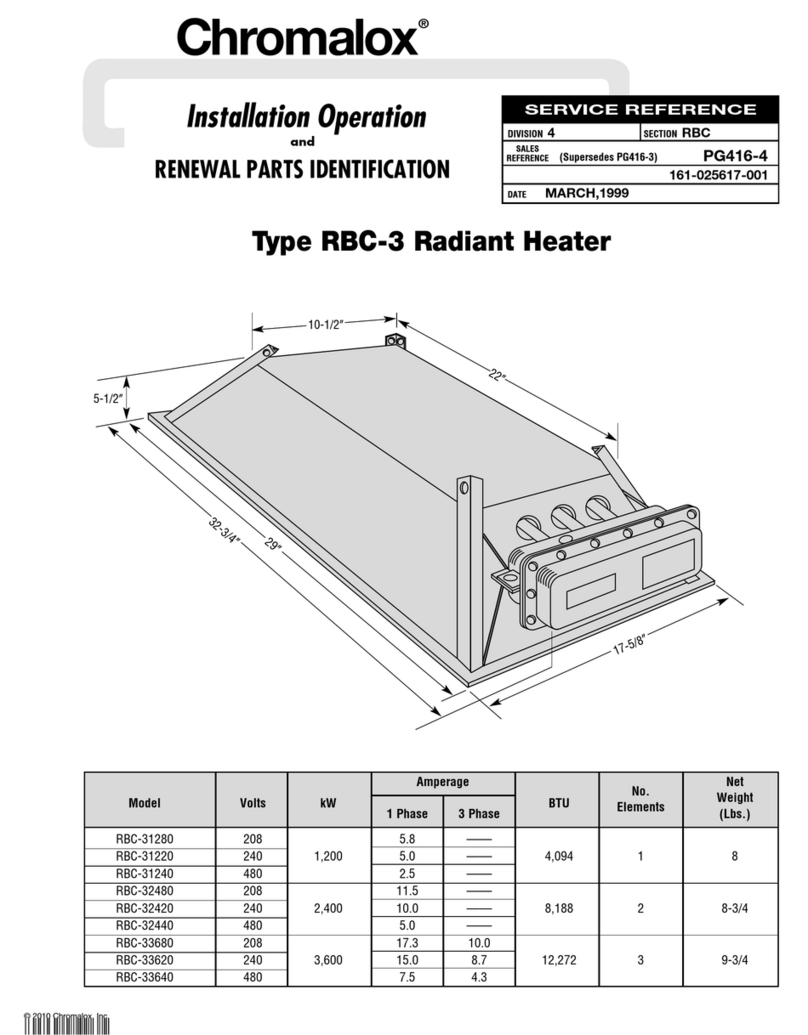

Model Volts Phase kW Heating Element

NWHO-1830R15 240 3 LL30 155-013185-331

NWHO(F)-1830R15 240 3 LL30 155-045301-013

NWHO-1830R15 480 3 LL30 155-013185-332

NWHO(F)-1830R15 480 3 LL30 155-045301-014

NWHO-1840R15 240 3 LL40 155-013185-004

NWHO(F)-1840R15 240 3 LL40 155-045301-016

NWHO-1840R15 480 3 LL40 155-013185-005

NWHO(F)-1840R15 480 3 LL40 155-045301-017

NWHO-1850R15 240 3 LL50 155-013185-007

NWHO(F)-1850R15 240 3 LL50 155-045301-019

NWHO-1850R15 480 3 LL50 155-013185-008

NWHO(F)-1850R15 480 3 LL50 155-045301-020

NWHO-1860R15 240 3 LL60 155-013185-010

NWHO(F)-1860R15 240 3 LL60 155-045301-022

NWHO-1860R15 480 3 LL60 155-013185-011

NWHO(F)-1860R15 480 3 LL60 155-045301-023

NWHO-1870R15 240 3 LL70 155-013185-013

NWHO(F)-1870R15 240 3 LL70 155-045301-025

NWHO-1870R15 480 3 LL70 155-013185-014

NWHO(F)-1870R15 480 3 LL70 155-045301-026

NWHO-1880R15 240 3 LL80 155-013185-016

NWHO(F)-1880R15 240 3 LL80 155-045301-028

NWHO-1880R15 480 3 LL80 155-013185-017

NWHO(F)-1880R15 480 3 LL80 155-045301-029

RENEWAL PARTS IDENTIFICATION

Note: The “F” in NWHO(F) means forced circulation (ie: equipped with baffles.) When replacing the heating element, care must be taken that the baffles line up properly with the inlet and outlet pipes. The top of the

flange of replacement heating elements for forced circulation heaters is stamped near one edge with the letter “P”. The sub-assembly is positioned correctly when the “P” on the flange is in line with the inlet and out-

let pipe. Incorrect placement will result in hindered circulation and possible failure of the element.

Note: When ordering parts for Model Numbers suffixed by “XX” or any other letter or letters not specifically identified on this instruction sheet, order Renewal Parts on special order basis, giving name of part, part

number and description.

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in

accordance with the National Electrical Code, NFPA

70.

1. Remove heating element assembly periodically to check heater

sheath for scaling, corrosion or excessive oxidation. Correct oper-

ating conditions to minimize sheath deterioration.

2. Periodically check temperature control and limit control operation

to insure accurate and safe process operation.

3. Check all electrical connections periodically and retighten connec-

tions which may have loosened in service. Replace wire and wire

terminals which show signs of oxidation which would interfere

with establishment of reliable electrical connections.

Regular Oil Heaters

Model Volts Phase kW Heating Element

NWHO-1820F15 240 3 LL20 155-013185-019

NWHO(F)-1820F15 240 3 LL20 155-045301-001

NWHO-1820F15 480 3 LL20 155-013185-020

NWHO(F)-1820F15 480 3 LL20 155-045301-002

NWHO-1825F15 240 3 LL25 155-013185-022

NWHO(F)-1825F15 240 3 LL25 155-045301-004

NWHO-1825F15 480 3 LL25 155-013185-023

NWHO(F)-1825F15 480 3 LL25 155-045301-005

NWHO-1830F15 240 3 LL30 155-013185-025

NWHO(F)-1830F15 240 3 LL30 155-045301-007

NWHO-1830F15 480 3 LL30 155-013185-026

NWHO(F)-1830F15 480 3 LL30 155-045301-008

NWHO-1835F15 240 3 LL35 155-013185-028

NWHO(F)-1835F15 240 3 LL35 155-045301-010

NWHO-1835F15 480 3 LL35 155-013185-029

NWHO(F)-1835F15 480 3 LL35 155-045301-011

NWHO-1840F15 240 3 LL40 155-013185-031

NWHO(F)-1840F15 240 3 LL40 155-045301-031

NWHO-1840F15 480 3 LL40 155-013185-032

NWHO(F)-1840F15 480 3 LL40 155-045301-032

NWHO-1845F15 240 3 LL45 155-013185-034

NWHO(F)-1845F15 240 3 LL45 155-045301-034

NWHO-1845F15 480 3 LL45 155-013185-035

NWHO(F)-1845F15 480 3 LL45 155-045301-035

Fuel Oil Heaters

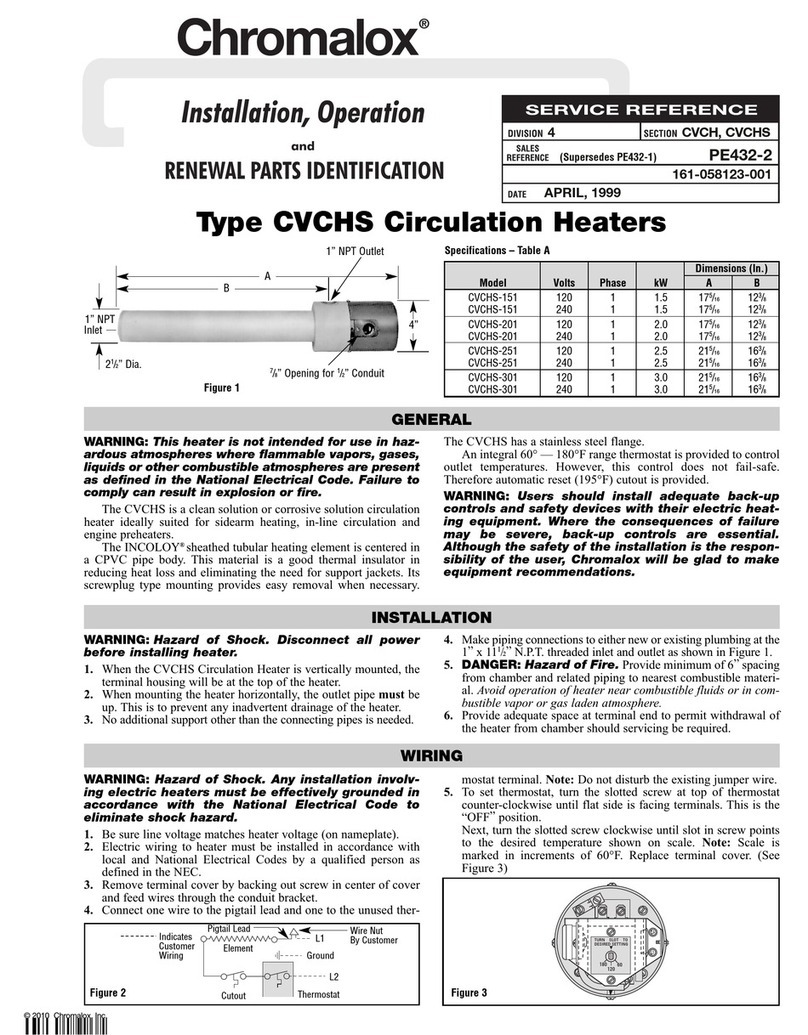

OPERATION

FIRE/EXPLOSION HAZARD. Do not exceed the

Pressure-Temperature rating of the flange as listed in

ANSI B16.5.

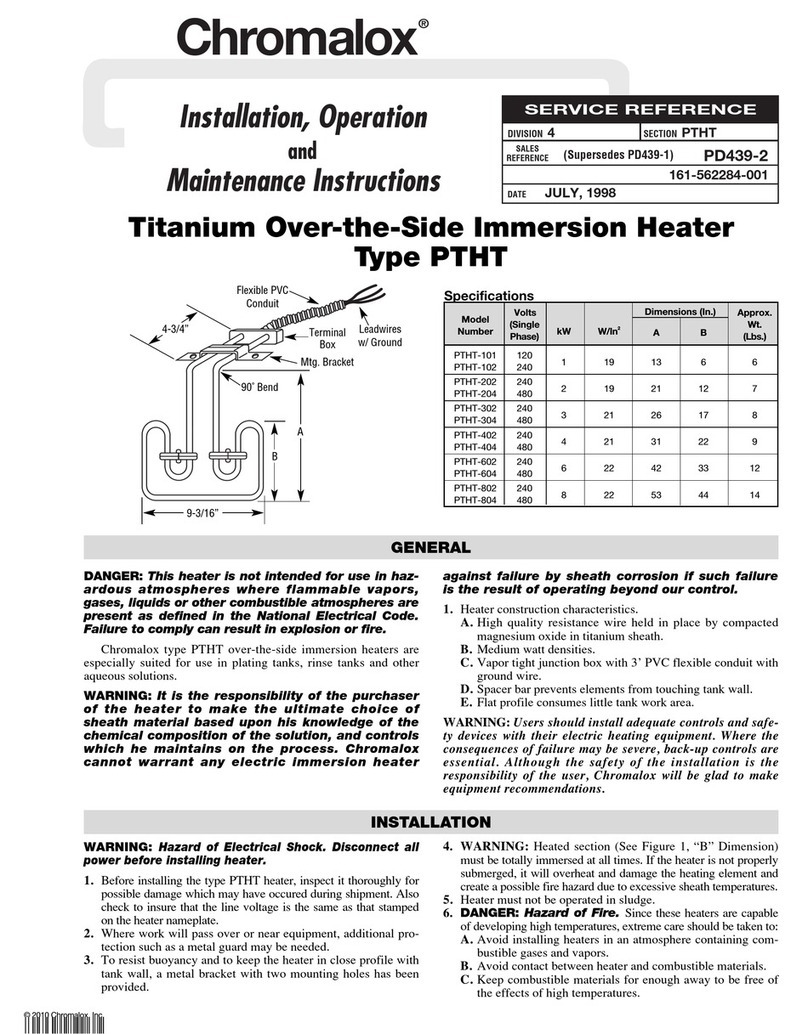

IMPORTANT: It is the responsibility of the purchas-

er of the heater to make the ultimate choice of

sheath material based upon his knowledge of the

chemical composition of the corrosive solution,

character of the materials entering the solution,

and controls which he maintains on the process.

Sheath corrosion can result in a ground fault

which, depending upon the solution being heated,

can cause an explosion or fire.

1. Do not heat solutions that are corrosive to the heating element

sheath or the heating chamber.

2. Terminal ends of heater must be protected from drippings, con-

densation, spray or direct spill-over of material. Their presence at

the terminals may damage heater electrical insulation. Liquid-tight

terminal enclosures are available to protect heater. Check with

local sales office.

3. If foreign material is carried by the liquid flow, install suitable fil-

ters in the inlet pipe line to the heater.

4. Do not allow heater to operate when liquid flow is interrupted.