ORIGINAL TEXT: FRENCH VERSION

1 - RECEIPT OF THE UNIT .......................................................................................................................................................... 4

2 - HANDLING .............................................................................................................................................................................. 4

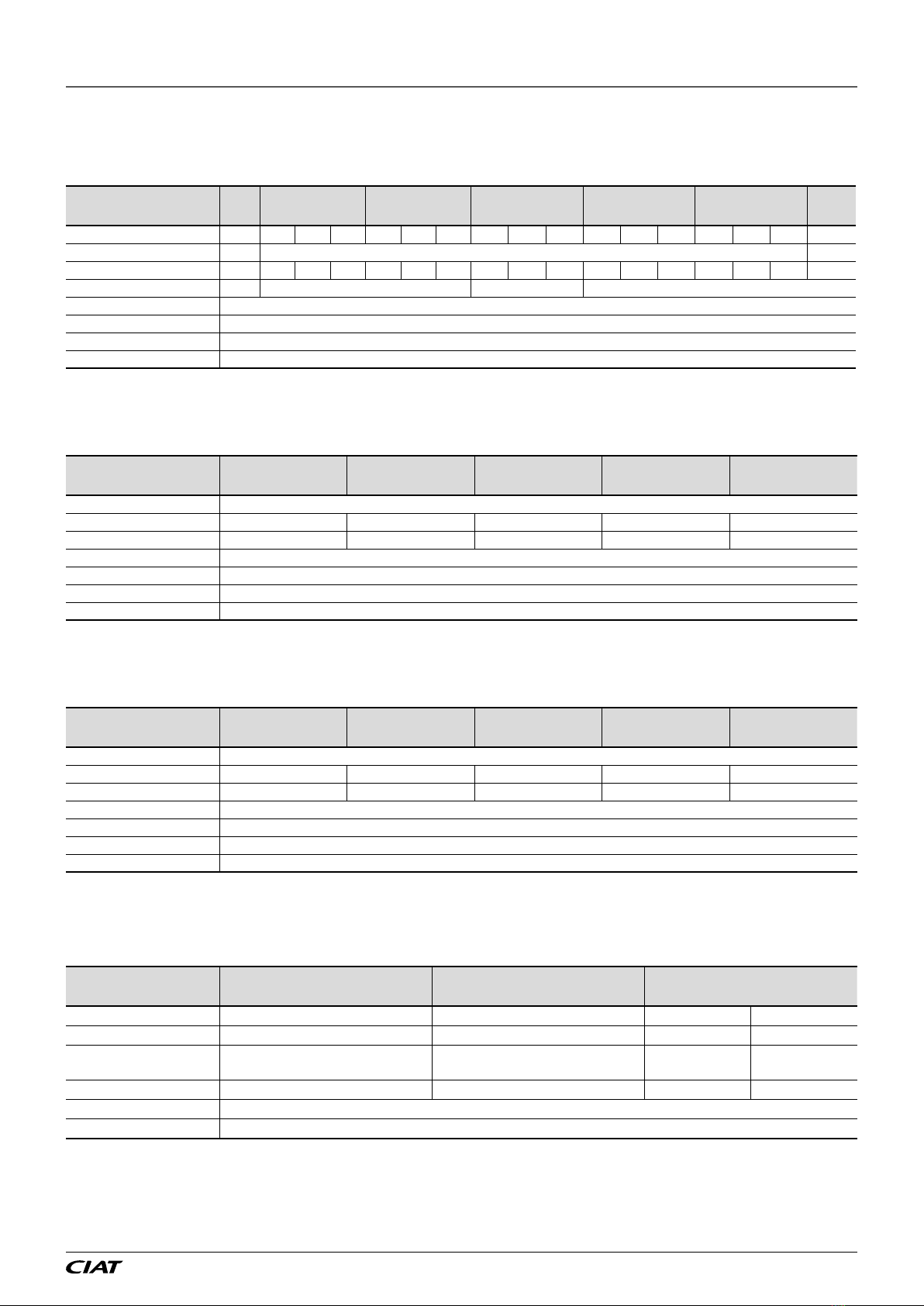

3 - TECHNICAL CHARACTERISTICS ......................................................................................................................................... 5

3.1 - ROTOREX fan motor assembly .......................................................................................................................................... 5

3.2 - CORROBLOC fan motor assembly..................................................................................................................................... 5

3.3 - HEE fan motor assembly (EC motor).................................................................................................................................. 6

4 - HEAT EXCHANGER................................................................................................................................................................ 7

4.1 - Low Pressure Water Coil..................................................................................................................................................... 7

4.2 - High Pressure Fluid Coil (superheated water, oil, etc.) ....................................................................................................... 7

4.3 - High Pressure Steam Coil (HPSC)...................................................................................................................................... 7

4.4 - Electric heater (EH)............................................................................................................................................................. 7

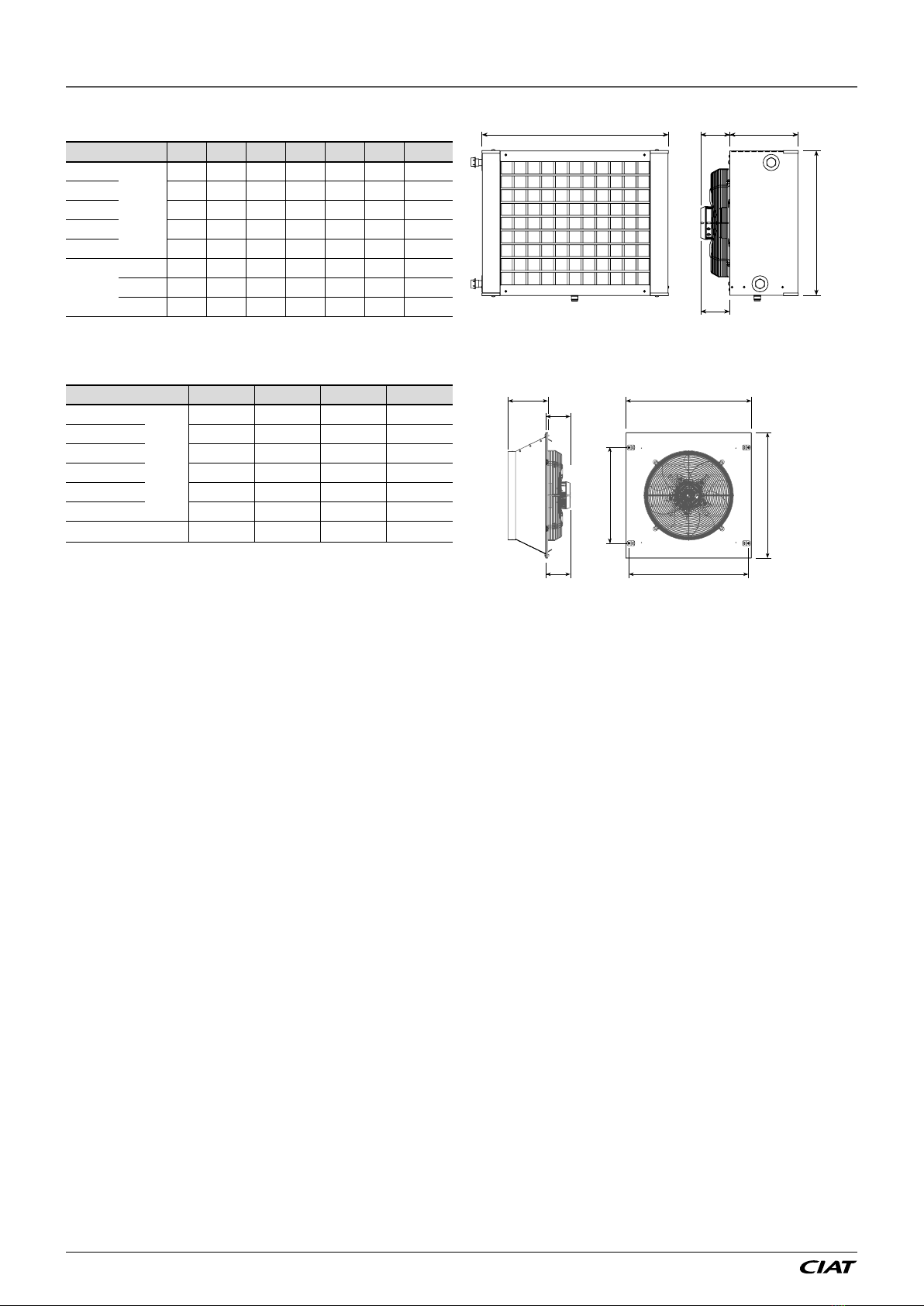

5 - DIMENSIONS........................................................................................................................................................................... 8

5.1 - H4000 Heliotherme ............................................................................................................................................................. 8

5.2 - TPL4000 Destratier ........................................................................................................................................................... 8

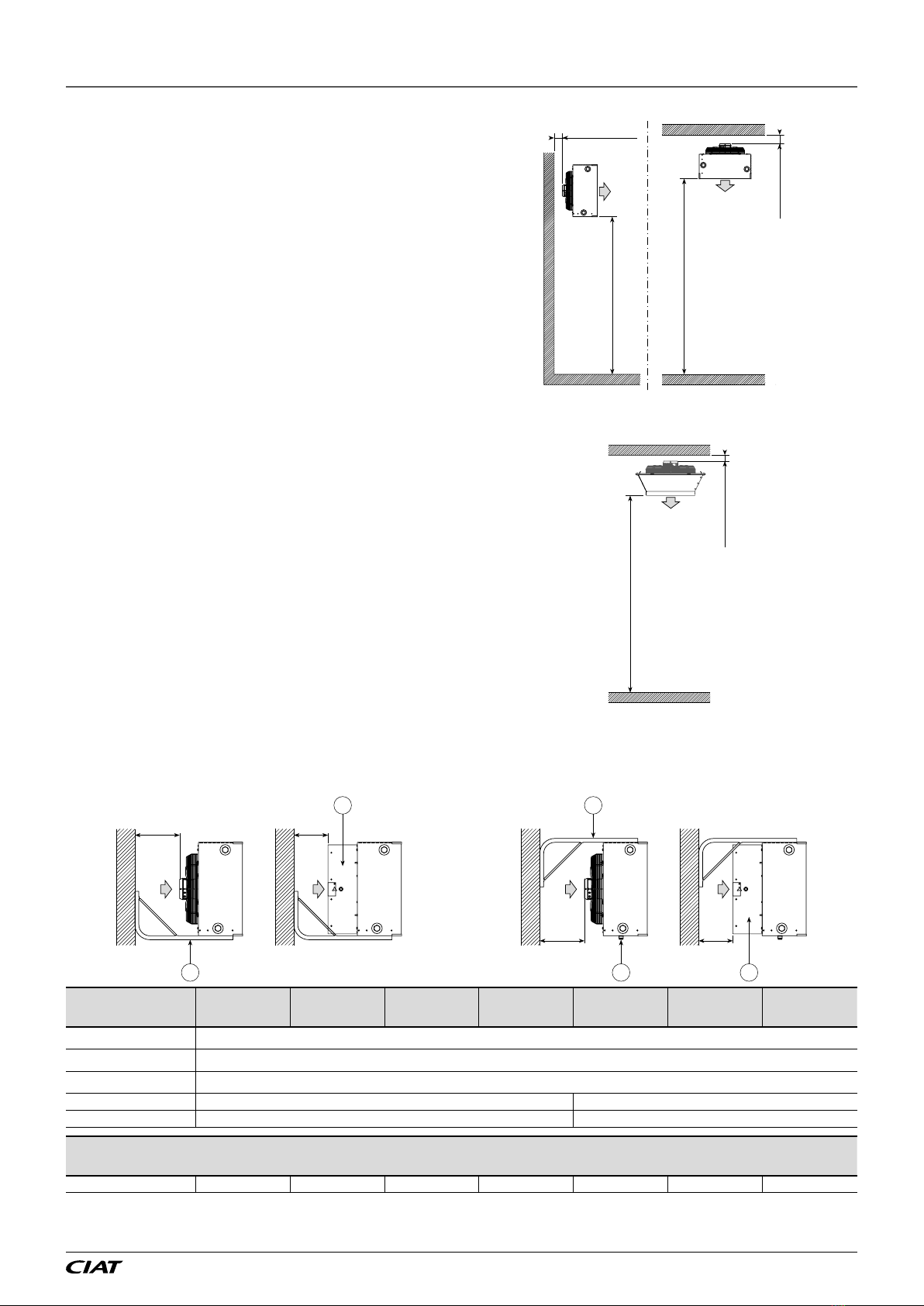

6 - SETUP ..................................................................................................................................................................................... 9

6.1 - H4000 Heliotherme ............................................................................................................................................................. 9

6.2 - TPL4000 Destratier ........................................................................................................................................................... 9

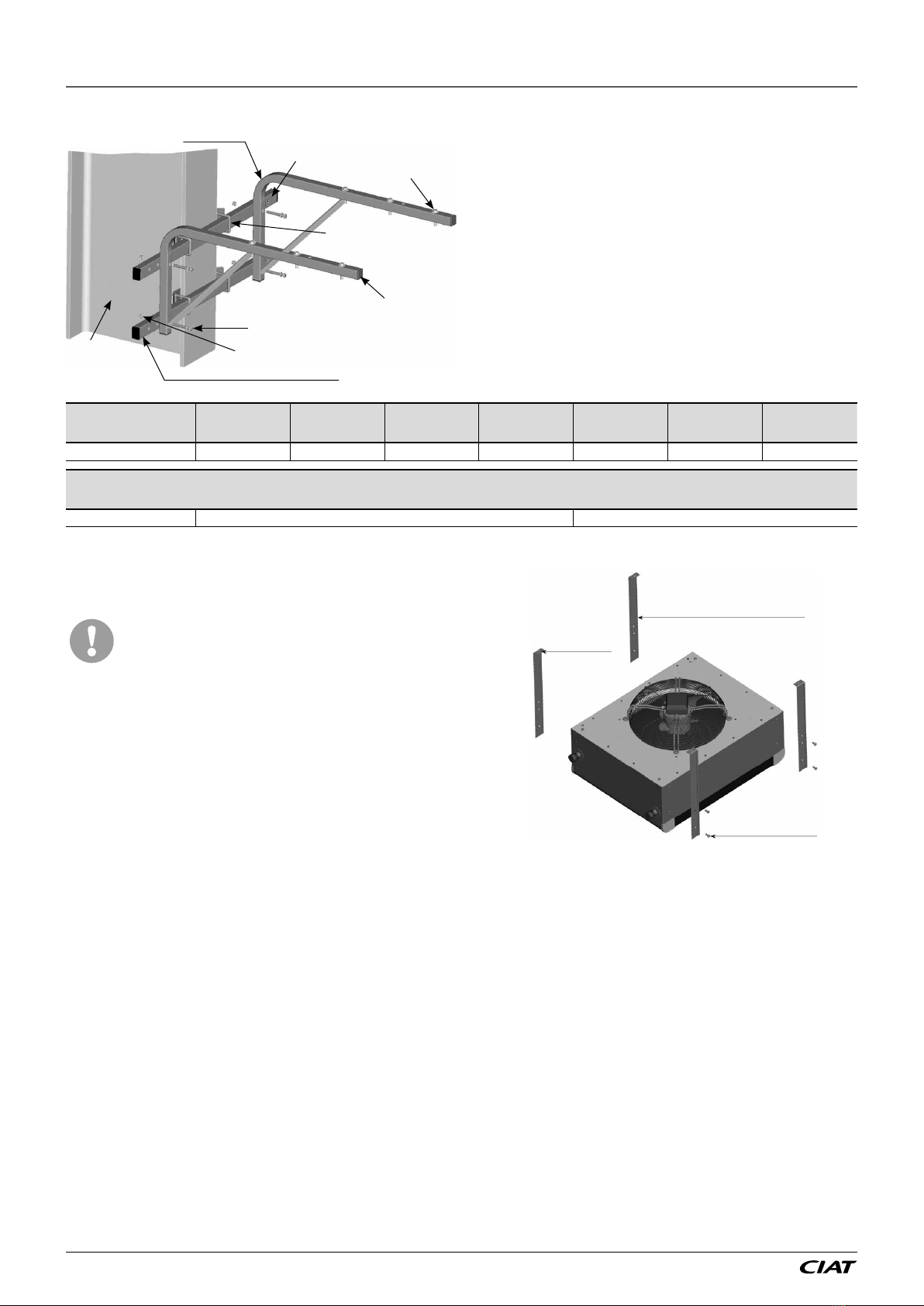

6.3 - Wall-mounted H4000 Heliotherme ...................................................................................................................................... 9

6.4 - Ceiling-mounted H4000 Heliotherme ................................................................................................................................ 10

7 - WATER CONNECTIONS ........................................................................................................................................................11

7.1 - Connection to be tightened (HELIOTHERME LP Water) ...................................................................................................11

7.2 - Connection to be welded (Heliotherme HP uid) ...............................................................................................................11

7.3 - Condensate drain connection (HELIOTHERME used for cooling or reversible purposes) ................................................11

8 - ELECTRICAL CONNECTIONS............................................................................................................................................. 12

9 - POWERING UP ..................................................................................................................................................................... 13

10 - MAINTENANCE................................................................................................................................................................... 13

11 - FREQUENTLY ASKED QUESTIONS.................................................................................................................................. 13

12 - TESTS AND WARRANTY ................................................................................................................................................... 14

13 - ASSEMBLY OPTIONS......................................................................................................................................................... 14

14 - CONTROL UNITS................................................................................................................................................................ 15

15 - WALL BRACKET................................................................................................................................................................. 17

16 - FILTER BOX ........................................................................................................................................................................ 18

17 - DIFFUSER ON DOOR ......................................................................................................................................................... 19

18 - DIFFUSER FOR LARGE SPACES...................................................................................................................................... 20

19 - FINAL SHUTDOWN............................................................................................................................................................. 21

CONTENTS

EN-3 H4000 HELIOTHERME