VAF-4ProfessionalWirefeeder

1.03 Limited Warranty

LIMITED WARRANTY: CIGWELD, A Thermadyne Company, hereafter, “CIGWELD” warrants to customers ofits authorized distributors hereafter “Purchaser” that its

products will be free of defects in workmanship or material. Should any failure to conform to this warranty appear within the time period applicable to the CIGWELD products

as stated below, CIGWELD shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance with

CIGWELD’s specifications, instructions, recommendations and recognized standard industry practice, and notsubject to misuse, repair, neglect, alteration, or accident,

correct such defects by suitable repair or replacement, at CIGWELD’s sole option, of any components or parts of the product determined by CIGWELD to be defective.

CIGWELD MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHERS, INCLUDING, BUT NOT

LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: CIGWELD SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, SUCH

AS, BUT NOT LIMITED TO, LOST PROFITS AND BUSINESS INTERRUPTION. The remedies of the Purchaser set forth herein are exclusive and the liability of CIGWELD

with respect to any contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of

any goods covered by or furnished by CIGWELD whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly

provided herein, exceed the price of the goods upon which such liability is based. No employee, agent, or representative of CIGWELD is authorized to change this warranty

in any way or grant any other warranty.

PURCHASER’S RIGHTS UNDER THIS WARRANTY ARE VOID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH IN CIGWELD’S SOLE JUDGEMENT

MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY CIGWELD PRODUCT. PURCHASER’S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE PRODUCT IS

SOLD TO PURCHASER BY NON-AUTHORIZED PERSONS.

The warranty is effective for the time stated below beginning on the date thatthe authorized distributor delivers the products to the Purchaser. Notwithstanding the foregoing,

in no event shall the warranty period extend more than the time stated plus one year from the date CIGWELD delivered the product to the authorized distributor.

Terms of Warranty – July 2007

1. The Trade Practices Act 1974 (Commonwealth) and similar State Territory legislation relating to the supply of goods and services, protects consumers' interests by

ensuring that consumers are entitled in certain situations to the benefit of various conditions, warranties, guarantees, rights and remedies (including warranties as to

merchantability and fitness for purpose) associated with the supply of goods and services. A consumer should seek legal advice as to the nature and extent of these

protected interests. In some circumstances, the supplier of goods and services may legally stipulate that the said conditions, warranties, guarantees, rights and

remedies are limited or entirely excluded. The warranties set outin Clause 2 shall be additional to any non-excludable warranties to which the Customer may be entitled

pursuant to any statute.

2. Subject to Clause 3. CIGWELD gives the following warranties to the Customer:

Insofar as they are manufactured or imported by CIGWELD, goods will upon delivery be of merchantable quality and reasonably fit for the purpose for which they are

supplied by CIGWELD.

CIGWELD will repair or, at its option, replace those of the goods which, upon examination, are found by CIGWELD to be defective in workmanship and/or materials.

CIGWELD reserves the right to request documented evidence ofdate of purchase.

3. The Warranty in Clause 2;

Is conditional upon:

The Customer notifying CIGWELD or our Accredited Distributor in writing of its claim within seven (7) days of becoming aware of the basis thereof, and at its own

expense returning the goods which are the subject of the claim to CIGWELD or nominated Accredited Distributor/Accredited Service Provider.

The goods being used in accordance with the Manufacturer's Operating Manuals, and under competent supervision.

Does not apply to:

Obsolete goods sold at auction, second-hand goods and prototype goods.

Breakdown or malfunction caused by accident, misuse or normal wear and tear.

Repairs or replacement made other than by CIGWELD or Accredited Service Providers,unless by prior arrangement with CIGWELD.

Replacement parts or accessories which may affect product safety or performance and which are not manufactured, distributed orapproved by CIGWELD.

4. CIGWELD declares that, to the extent permitted by law, it hereby limits its liability in respect of the supply of goods which are not of a kind ordinarily acquired for

personal, domestic or household use or consumption to any one or more of the following (the choice of which shall be at the option of CIGWELD).

The replacement of the goods or the supply of equivalent goods.

The repair of goods.

The payment of cost of replacing the goods or acquiring equivalent goods.

The payment of the cost of having goods repaired.

5. Except as provided in Clauses 2 to 4 above, to the extent permitted by statute, CIGWELD hereby excludes all liability for any loss, damage, death or injury of any kind

whatsoever occasioned to the Customer in respect of the supply of goods including direct, indirect, consequential or incidental loss,damage or injury of any kind.

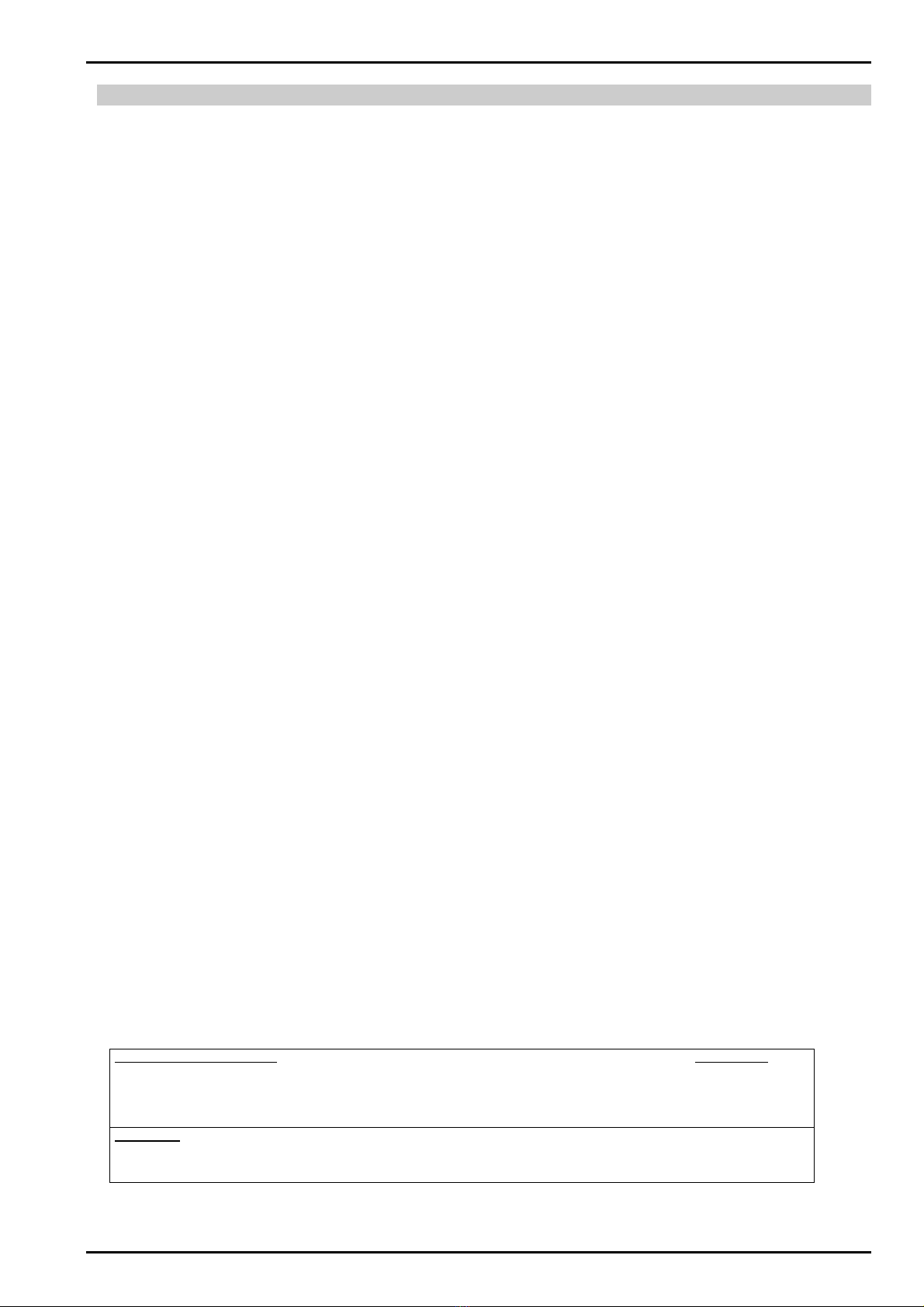

Warranty Schedule – January 2007

Thesewarranty periodsrelate tothewarranty conditionsinclause 2.Allwarranty periodsarefrom dateofsale fromtheAccredited Distributorofthe equipment.Notwithstandingthe

foregoing, in no event shall the warranty period extend more than the time stated plus one year from the date CIGWELD delivered the product to the Accredited Distributor. Unless

otherwisestated thewarrantyperiod includespartsandlabour.

CIGWELD reserves theright to request documentedevidenceofdate ofpurchase.

CIGWELD MIG WELDING EQUIPMENT WARRANTY PERIOD

TRANSMIG VAF-4 Professional Wirefeeder

Control Printed Circuit Board...............................................................................................................................................................

........................3 years

All other circuits and components including, but not limited to, relays, switches, contactors, solenoids, fans, power switch semi-

conductors...........................................................................................................................................................................................

.........................1 year

ACCESSORIES

MIG torch (where fitted).......................................................................................................................................................................

.......................3 months

MIG torch consumable items...............................................................................................................................................................

...........................NIL

Please note that the information detailed in this statement supersedes any prior published data produced by CIGWELD.

Mar 15, 2007 9