Cimberio Cim 790 Instruction Manual

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

AUTOMATIC FLOW

BALANCING VALVE

790

Main features:

Cim 790 is used for balancing the flow in cooling, heating and domestic water systems.

Cim 790 is an automatic balancing valve with following features:

• Constant flow regardless system pressure fluctuations;

• System balancing is assured automatically, even under fluctuating pressure condi-

tions;

• Automatic balancing is achieved by means of cartridges that provide constant flow

within a fixed range of differential pressures;

• The self-cleaning cartridge design makes very difficult for any particles to accumulate

and compromise the accuracy of the valve.

It is supplied with internal thread.

It is made of “CR” brass (“CR” - Corrosion Resistant).

This article is made in compliance with the quality management requirements of ISO

9001:2008 standard.

All articles are tested according to the EN 12266-1:2003 standard.

It can be used in a wide variety of sectors: heating, air conditioning, water, sanitary systems

and generally with any non corrosive liquid.

PN 25

Approved by:

Technical data:

Max. static working pressure 25 bar

Max. flow temperature 120 °C

Min. temperature -20°C

Fluids: Water and Glycol

Material of parts in contact with water:

Valve body;

Cartridge, etc.

Materials:

“CR”Brass (EN 12165-CW602N-M)

O-rings: EPDM Perox

Threads: ISO 228

1

Rev. 3 del 03/2015

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

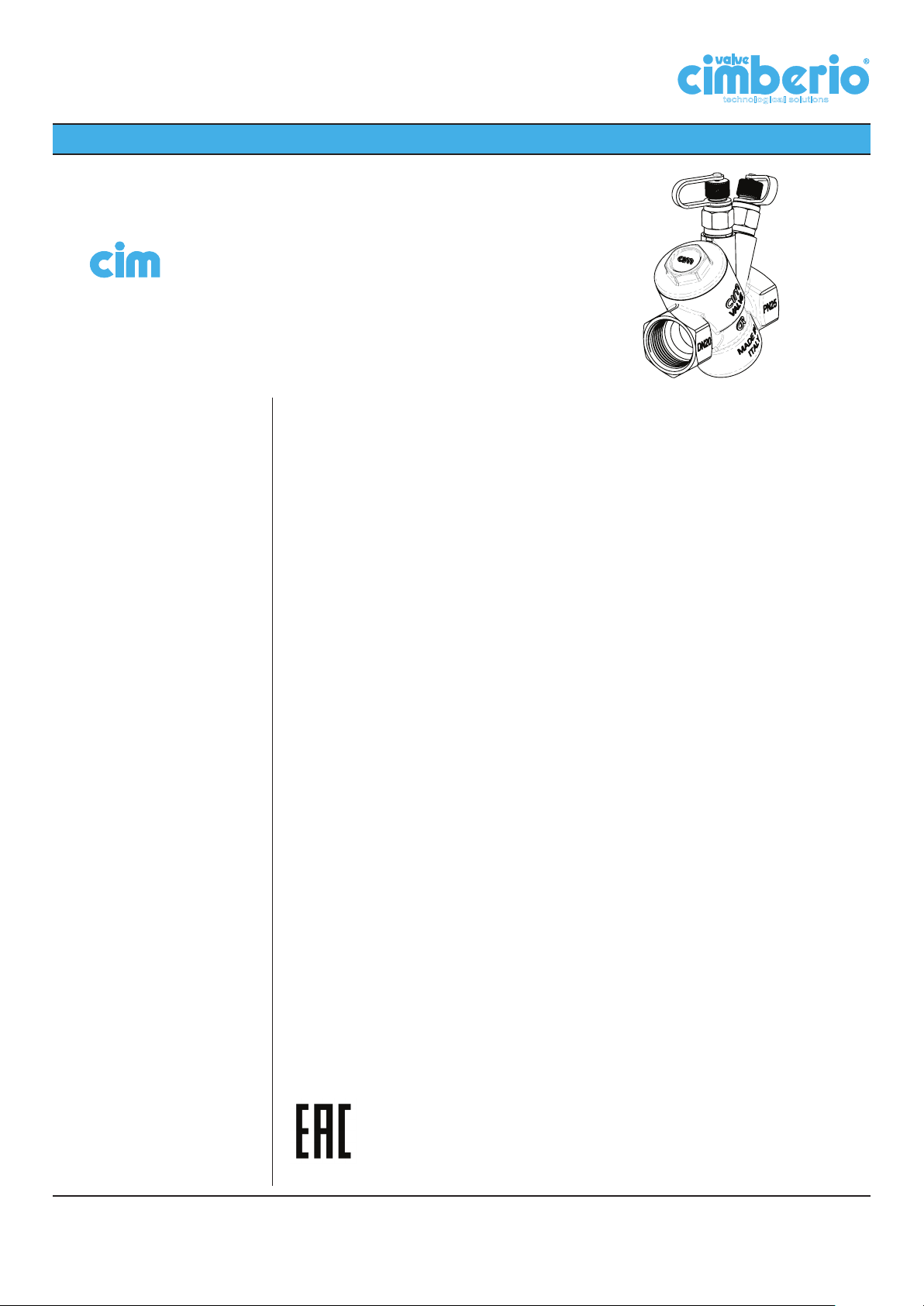

Models:

2

Cim 790 - Automatic balancing valve - PN 25 - “CR” Brass*

DN Material Thread Flow rate range

(l/s) (l/h) (GPM)

15

CR Brass

EN 12165-CW602N-M

G. 1/2” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

20 G. 3/4” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25 G. 1” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25L G. 1” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

32 G. 1”1/4 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

40 G. 1”1/2 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

50 G. 2” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

Cim 790/2P - Automatic balancing valve - PN 25 - “CR” Brass - without test points*

DN Material Thread Flow rate range

(l/s) (l/h) (GPM)

15

CR Brass

EN 12165-CW602N-M

G. 1/2” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

20 G. 3/4” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25 G. 1” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25L G. 1” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

32 G. 1”1/4 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

40 G. 1”1/2 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

50 G. 2” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

* The valve is supplied with the cartridge already installed. For orders specify the

code of the required cartridge in accordance with the attached tables.

Cim 790B - Automatic balancing valve - PN 25 - “CR” Brass - without cartridge

DN Material Thread Flow rate range

(l/s) (l/h) (GPM)

15

CR Brass

EN 12165-CW602N-M

G. 1/2” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

20 G. 3/4” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25 G. 1” 0.00694 ÷ 0.68 25 ÷ 2448 0.111 ÷ 10.78

25L G. 1” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

32 G. 1”1/4 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

40 G. 1”1/2 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

50 G. 2” 0.187 ÷ 3.15 674 ÷ 11355 2.97 ÷ 50.00

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A. 3

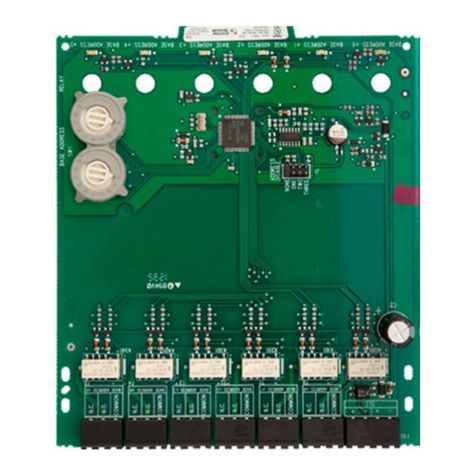

Cross section:

8

7

6

51

2

3

4

1. Valve body

2. Cartridge

3. Orifice

4. Elastic ring

5. O-ring

6. Plug

7. Blue binder point

8. Red binder point

Installation procedure:

Before installation of Cim 790, check that inside the valve and the pipes there are no foreign

matters which might damage the tightness of the valve.

Burr pipe connections after having threaded them and distribute the sealing material on

pipe threads only and not on valve threads.

It is advisable to install a filter and an intercepting valve on the feed line.

Before installation of Cim 790, check that cartridge flow rate is properly matching the pro-

ject requirements and that pump is able to assure the minimum differential pressure (Δp

min) stated in the tables of following pages (section “Tables”).

Valves may be installed either on horizontal or vertical pipelines, following the arrow direc-

tion casted on the valve body, which shall be the same as the flow one.

For assembly purposes, use a spanner, not a pipe wrench, by applying necessary work-

ing torque only on the valve end nearest the pipe. This helps get a firmer grip and avoids

potential damages to valve body.

Make sure that pipe threading length is not longer than valve threads.

It is advisable to flush the installation before service. To this purpose, remove all cartridges

of the installed valves, following the instructions detailed in “Maintenance” part of the pre-

sent brochure.

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A. 4

Balancing:

Flow rate balancing is achieved automatically by Cim 790, regardless pressure fluctua-

tions. The flow rate of each cartridge depends on the fixed orifice installed therein. Each

fixed orifice has a four digit code number,corresponding to the last four digits of Cimberio

cartridge code.

Once the cartridge is identified by Cimberio code, the relevant flow rates and minimum Δp

can be read in the tables shown in “Tables” section of this brochure.

Using the electronic differential manometer Cim 726, check that the differential pressure is

higher or the same as the minimum value shown in said tables. The differential manometer

interfaces with the balancing valve through two sensors inserted in the binder points of the

valve.

→

Calibrated orifice

Typical installations:

LOAD:

Power (kW)

Differential

temperature (°C)

Controller

LOAD:

Power (kW)

Differential

temperature (°C)

Controller

Cim 790 is suitable for constant volume system, where diverting or mixing valves are in-

stalled as fancoil control. Below a typical installation with a diverting valve: in each moment

the flow rate will result constant and there will not be extra-flow due to the pressure fluc-

tuations introduced by the hidraulic shortcircuit that would be created when the flow goes

across the by-pass.

The automatic flow balancing valves can also be used with variable speed pumps. By us-

ing a 2 ports control valve (ON/OFF), the flow in each emitters can be stopped as soon as

the desired room temperature in reached. In this way the branches that are still opened will

not be affected by the total flow variations. The effect is that there is an energy saving due

to the reduction of the total pumped flow.

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

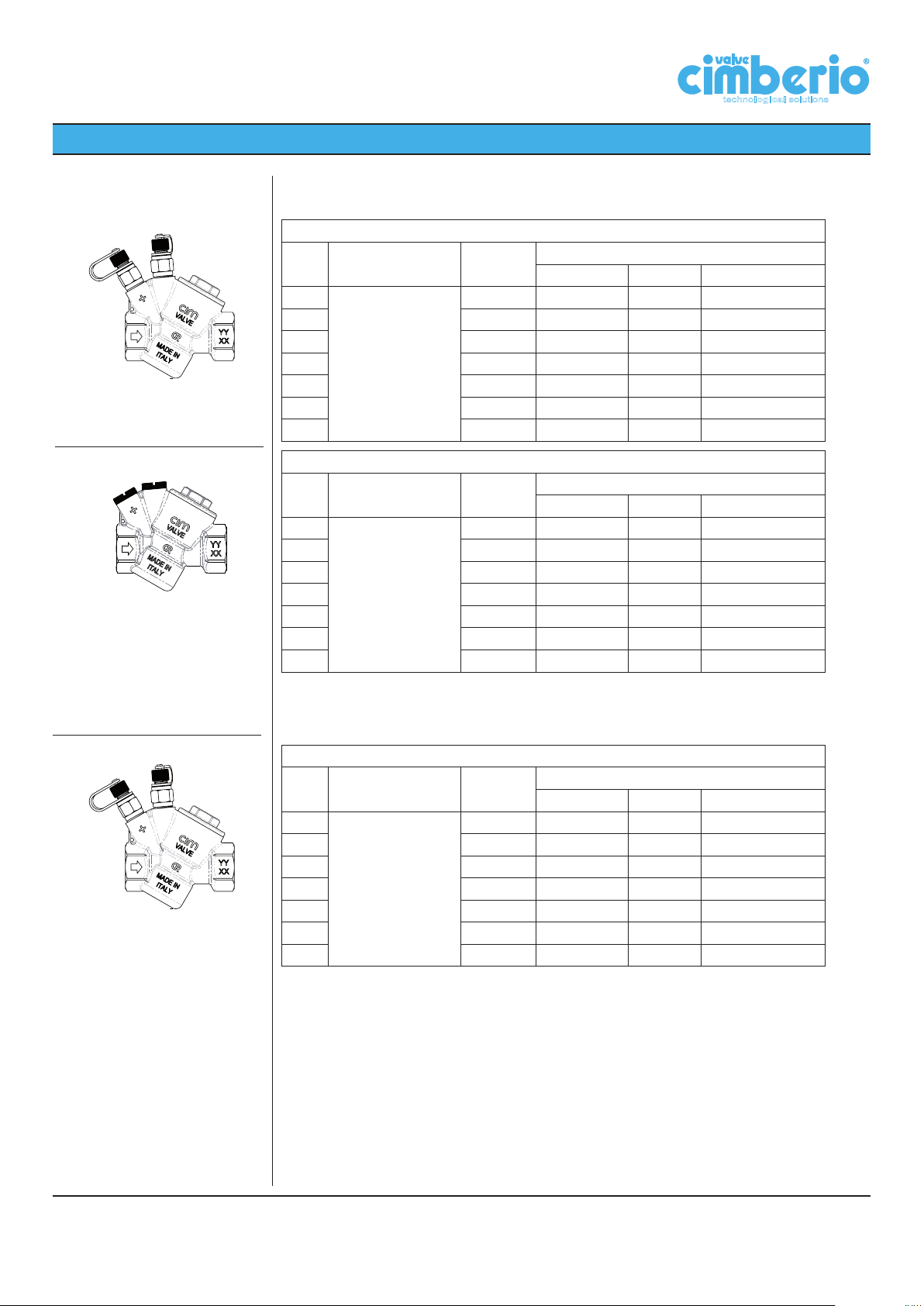

When the pressure increases, the spring is compressed and the piston reduces outlet win-

dows, in order to maintain the same flow rate; when ∆p decreases the windows start to

open again (see picture on the right).

Constant flow is obtained through the valve, despite pressure fluctuations.

By simply measuring differential pressure across the valve, the flow through the cartridge

is obtained as follows:

• If measured differential pressure is above ∆pmin (start-up pressure), the flow rate is the

same as the one stated on the cartridge table;

• If measured differential pressure is below minimum ∆pmin stated on cartridge table,

flow rate is calculated with one of the following formula:

where:

Q is the flow rate in m3/h, r is the relative density, ∆p is the pressure drop across the valve .

Sizing:

Kvs

Kvs - Kv across the valve when it is

fully open (at start up pressure)

FLOW COEFFICIENT

Kv, in metric system represents the flow in m3/h of water at the temperature of 15.5°C

(density =998 kg/m3) which causes a pressure drop of 1 bar. In the USA flow coefficient is

called Cv (Kv = 0.865 Cv).

Relative density

Fluid r

Water 1.000

Water and glycol 10% 1.012

Water and glycol 20% 1.028

Water and glycol 30% 1.040

Water and glycol 40% 1.054

Water and glycol 50% 1.067

0

0.02

0.04

0.06

0.08

0.10

0.12

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340

Differential pressure - kPa

Flow rate - l/s

∆pmin

5

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

Δ

p

b

Pressure drop across Cim 790

Δ

p

m

Pressure drop across the control valve

Δ

p

c

Circuit pressure drop

Δ

p

a

Available pressure for the riser

Δ

p

a

=

Δp

b

+ Δp

c

+ Δp

m

Δ

p

a

Δ

p

b

Δ

p

m

Δ

p

c

Q

EXAMPLE

It is required to balance the circuit in the figure, the given data are:

• Circuit pressure drop: ∆pc=10 kPa;

• Pressure drop across the control valve: ∆pm= 8 kPa;

• Flow rate: Q= 3.2 m3/h=0.889 l/s;

• Maximum head: ∆pa,max = 60 kPa (Pump head);

• Pipeline size: DN 32.

It is possible to install a valve with the same diameter of the pipe, to avoid fittings installa-

tion. Using a Cim 790 DN32, it is possible to select from the list of the installable cartridges

the closest value of nominal flow rate to the required one.

It is possible to install the cartridge CA3156 with nominal flow rate of 0.886 l/s (the error is

less than 2.5 %).

This cartridge needs at least 21 kPa of differential pressure in order to work properly, the

available pressure on the riser should be at least:

6

SUGGESTED VALUES AND TIPS:

• Velocities in the pipeline:

Max = 1.15 m/s

Min = 0.75 m/s

For the preliminary sizings where the

value of maximum available pressure is

not known, it is possible to use the ma-

ximum head of the pump directly.

The maximum allowable differential pressure across the balancing valve is 350 kPa, it

means that the maximum head at the riser shall be:

Being the maximum head less than the calculated limit, the installation is correct.

If it wasn’t, it would be possible to install the high differential pressure version: CA3156H

(up to 600 kPa).

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A. 7

Pressure-temperature

ratings:

p [bar]

4

0

T [°C]

20

40

60

80

100

120

140

160

180

8 12 16 20 24 282 6 10 14 18 22 26

58 116 174 232 290 349 406

29 87 145 203 261 319 377

p

[lbf/in ]

0

0

2

32

38

104

140

176

212

248

284

320

356

T [°F]

FROM MULTIPLY BY

TO OBTAIN

inches 0,0254 m, metres

inches 2,54 cm, centimetres

feet 0,3048 m, metres

feet 30,48 cm, centimetres

yards 0,9144 m, metres

square inches 0,00064516 m2, metri quadrati

square feet 0,09290304 m2, square metres

square inches 6,4516 cm2, square centimetres

square feet 929,0304 cm 2, square centimetres

square yards 0,8361274 m2, square metres

l, litres 0,001 m3, cubic metres

gallons 0,003789412 m3, cubic metres

cubic yards 0,7645549 m3, cubic metres

cubic feet 0,02831685 m3, cubic metres

cubic inches 0,0000164 m3, cubic metres

cubic inches 16,38706 cm 3, cubic centimetres

cubic feet 28,31685 l, litres

gallons 3,875412 l, litres

TO OBTAIN DIVIDE BY

FROM

Pressure

Length, Area, Volume, Density

FROM

MULTIPLY BY TO OBTAIN

Pa, Pascal 0,001 kPa, kiloPascal

Pa, Pascal 0,000001 MPa, Mega Pascal

Pa, Pascal 0,00001 bar

Pa, Pascal 0,00010972 mH2O , metres of water

Pa, Pascal 0,000145038 psi, pound per square inch

bar 1,01325 atm, atmosphere

bar 0,980665

Kg/cm2,kilograms per square centimetre

bar 10,1972 mH2O , metres of water

bar 14,5038 psi, pound per square inch

atm, atmosphere 1,03323

Kg/cm2,kilograms per square centimetre

atm, atmosphere 10,3323 mH2O , metres of water

atm, atmosphere 14,6959 psi, pound per square inch

Kg/cm 210 mH2O , metres of water

Kg/cm 214,2233 psi, pound per square inch

mH2O 1,42233 psi, pound per square inch

TO OBTAIN DIVIDE BY

FROM

FROM MULTIPLY BY

TO OBTAIN

inches 0,0254 m, metres

inches 2,54 cm, centimetres

feet 0,3048 m, metres

feet 30,48 cm, centimetres

yards 0,9144 m, metres

square inches 0,00064516 m2, metri quadrati

square feet 0,09290304 m2, square metres

square inches 6,4516 cm2, square centimetres

square feet 929,0304 cm 2, square centimetres

square yards 0,8361274 m2, square metres

l, litres 0,001 m3, cubic metres

gallons 0,003789412 m3, cubic metres

cubic yards 0,7645549 m3, cubic metres

cubic feet 0,02831685 m3, cubic metres

cubic inches 0,0000164 m3, cubic metres

cubic inches 16,38706 cm 3, cubic centimetres

cubic feet 28,31685 l, litres

gallons 3,875412 l, litres

TO OBTAIN DIVIDE BY

FROM

Pressure

Len

gth, Area, Volume, Density

FROM

MULTIPLY BY TO OBTAIN

Pa, Pascal 0,001 kPa, kiloPascal

Pa, Pascal 0,000001 MPa, Mega Pascal

Pa, Pascal 0,00001 bar

Pa, Pascal 0,00010972 mH2O , metres of water

Pa, Pascal 0,000145038 psi, pound per square inch

bar 1,01325 atm, atmosphere

bar 0,980665

Kg/cm2,kilograms per square centimetre

bar 10,1972 mH2O , metres of water

bar 14,5038 psi, pound per square inch

atm, atmosphere 1,03323

Kg/cm2,kilograms per square centimetre

atm, atmosphere 10,3323 mH2O , metres of water

atm, atmosphere 14,6959 psi, pound per square inch

Kg/cm 210 mH2O , metres of water

Kg/cm 214,2233 psi, pound per square inch

mH2O 1,42233 psi, pound per square inch

TO OBTAIN DIVIDE BY

FROM

Measurement conversion

chart:

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A. 8

Cartridges

DN 15, DN20, DN25

Cim 790

∆p ≥∆pmin --> Q = Qnom

∆p < ∆pmin --> Q = Kvs √∆p

Cartridge code Flow rate ∆pmin Kvs

Max. 350

kPa

Max. 600

kPa

l/s l/h GPM kPa (m3/h)/bar0.5

CA1150 - 0.007 25 0.11 7 0.09

CA1170 - 0.010 35 0.15 7 0.14

CA1190 CA1190H 0.012 46 0.20 7 0.16

CA1210 CA1210H 0.015 55 0.24 7 0.21

CA1230 CA1230H 0.021 75 0.33 8 0.27

CA1260 CA1260H 0.023 84 0.37 9 0.28

CA1290 CA1290H 0.029 104 0.46 10 0.33

CA1300 CA1300H 0.032 114 0.50 10 0.36

CA1320 CA1320H 0.036 129 0.57 11 0.39

CA1350 CA1350H 0.043 154 0.68 11 0.46

CA1370 CA1370H 0.049 175 0.77 12 0.51

CA1400 CA1400H 0.057 204 0.90 12 0.59

CA1430 CA1430H 0.067 241 1.06 12 0.70

CA1460 CA1460H 0.078 279 1.23 12 0.81

CA1490 CA1490H 0.089 320 1.41 13 0.89

CA1510 CA1510H 0.097 350 1.54 13 0.97

CA1540 CA1540H 0.111 400 1.76 13 1.11

CA1570 CA1570H 0.132 477 2.10 14 1.27

CA1620 CA1620H 0.151 545 2.40 14 1.46

CA1725 CA1725H 0.171 615 2.71 14 1.64

CA1730 CA1730H 0.186 670 2.95 14 1.79

CA1735 CA1735H 0.204 736 3.24 14 1.97

CA1740 CA1740H 0.222 799 3.52 16 2.00

CA1745 CA1745H 0.242 870 3.83 19 2.00

CA1750 CA1750H 0.260 936 4.12 21 2.01

CA2070 CA2070H 0.283 1020 4.49 22 2.17

CA2074 CA2074H 0.300 1081 4.76 22 2.30

CA2077 CA2077H 0.332 1195 5.26 22 2.55

CA2082 CA2082H 0.371 1335 5.88 23 2.78

CA2086 CA2086H 0.412 1438 6.53 23 3.09

CA2088 CA2088H 0.439 1581 6.96 23 3.30

CA2092 CA2092H 0.493 1774 7.81 24 3.62

CA2094 CA2094H 0.509 1833 8.07 24 3.74

CA2099 CA2099H 0.578 2080 9.16 25 4.16

CA2103 CA2103H 0.625 2251 9.91 26 4.41

CA2106 CA2106H 0.644 2319 10.21 27 4.46

CA2109 CA2109H 0.680 2448 10.78 28 4.63

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

Cartridges

DN 25L, DN32, DN40, DN 50

Cim 790

Cartridge code Flow rate ∆pmin Kvs

Max. 350

kPa

Max. 600

kPa

l/s l/h GPM kPa (m3/h)/bar0.5

CA3073 CA3073H 0.187 674 2.97 12 1.95

CA3082 CA3082H 0.239 861 3.79 12 2.49

CA3089 CA3089H 0.283 1020 4.49 12 2.94

CA3094 CA3094H 0.315 1136 5.00 12 3.28

CA3096 CA3096H 0.331 1190 5.24 12 3.44

CA3098 CA3098H 0.353 1272 5.60 13 3.53

CA3102 CA3102H 0.375 1349 5.94 13 3.74

CA3107 CA3107H 0.413 1485 6.54 13 4.12

CA3111 CA3111H 0.435 1567 6.90 14 4.19

CA3112 CA3112H 0.453 1631 7.18 14 4.36

CA3118 CA3118H 0.504 1815 7.99 14 4.85

CA3124 CA3124H 0.556 2001 8.81 15 5.17

CA3125 CA3125H 0.568 2044 9.00 16 5.11

CA3129 CA3129H 0.603 2171 9.56 16 5.43

CA3132 CA3132H 0.631 2271 10.00 17 5.51

CA3135 CA3135H 0.661 2380 10.48 17 5.77

CA3138 CA3138H 0.694 2498 11.00 18 5.89

CA3142 CA3142H 0.733 2639 11.62 18 6.22

CA3148 CA3148H 0.797 2871 12.64 19 6.59

CA3156 CA3156H 0.886 3191 14.05 21 6.96

CA3161 CA3161H 0.946 3407 15.00 22 7.26

CA3163 CA3163H 0.968 3486 15.35 22 7.43

CA4148 CA4148H 1.009 3635 16.00 20 8.13

CA4152 CA4152H 1.023 3681 16.21 21 8.03

CA4156 CA4156H 1.136 4090 18.00 21 8.92

CA4164 CA4164H 1.199 4315 19.00 21 9.42

CA4168 CA4168H 1.262 4540 20.00 22 9.68

CA4173 CA4173H 1.325 4770 21.00 22 10.17

CA4176 CA4176H 1.388 4995 22.00 23 10.42

CA4182 CA4182H 1.514 5450 24.00 24 11.12

CA4191 CA4191H 1.640 5905 26.00 25 11.81

CA4194 CA4194H 1.816 6539 29.00 26 12.82

CA4200 CA4200H 1.893 6815 30.00 27 13.11

CA4205 CA4205H 2.019 7265 32.00 28 13.73

CA4211 CA4211H 2.145 7720 34.00 30 14.10

CA4217 CA4217H 2.271 8175 36.00 31 14.68

CA4222 CA4222H 2.397 8630 38.00 33 15.02

CA4229 CA4229H 2.523 9085 40.00 34 15.58

CA4235 CA4235H 2.650 9540 42.00 36 15.90

CA4241 CA4241H 2.776 9990 44.00 38 16.21

CA4248 CA4248H 2.902 10445 46.00 40 16.51

CA4250 CA4250H 3.028 10900 48.00 42 16.82

CA4262 CA4262H 3.154 11355 50.00 44 17.12

∆p ≥∆pmin --> Q = Qnom

∆p < ∆pmin --> Q = Kvs √∆p

9

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A.

Main dimensions:

Cim 790

DN 15 20 25 25L 32 40 50

Grms. 505 520 600 600 1500 1565 1670

B 74 74 74 93 93 93 93

C 78 78 85 123 123 123 132

C1 89 89 93 125 125 125 130

D 11.5 12.5 14.5 14.5 16.8 16.8 21.1

CH 25 31 38 38 46 52 64

10

CA1150÷CA2109 CA3073÷CA4262

B 40

C 28

B1 64

C1 48

technological solutions

TECHNICAL DATA SHEET

Cav. Uff. Giacomo Cimberio S.p.A. 11

Maintenance:

As a rule, the balancing valve does not need any maintenance. In case of replacement or

need of disassembling of some components of the valve, make sure that the installation is

not under service or pressure.

When flushing the installation, follow these instructions:

• unscrew the plug (6);

• take off the cartridge (2) from the valve body (1) using a common grab acting on the pin

placed at the end of the cartridge;

• close the valve with the plug (6) and let flow the water to flush the installation;

• remove the plug (6), insert the cartridge (2) and then reassemble the plug (6).

If flow rate has to be changed, proceed as above by replacing the installed cartridge with

the one corresponding to the required flow rate. The features of different types of cartridge

are available in the prevoius tables.

8

7

6

51

2

3

4

28017 San Maurizio d’Opaglio (NO) - Italy - Via Torchio, 57 - C.P. 106

Tel. +39 0322 923001 - Fax: +39 0322 967216 / 967755

skype: cimberiosk1, cimberiosk2

®

www.cimberio.com

© Copyright - Cav. Uff. GIACOMO CIMBERIO S.p.A. - All rights reserved. Tutti i diritti riservati.

IMR 562637 FM 01820 SA 551551 EMS 551553 OHS 551552 ENMS 577357

This manual suits for next models

2

Table of contents

Other Cimberio Control Unit manuals

Popular Control Unit manuals by other brands

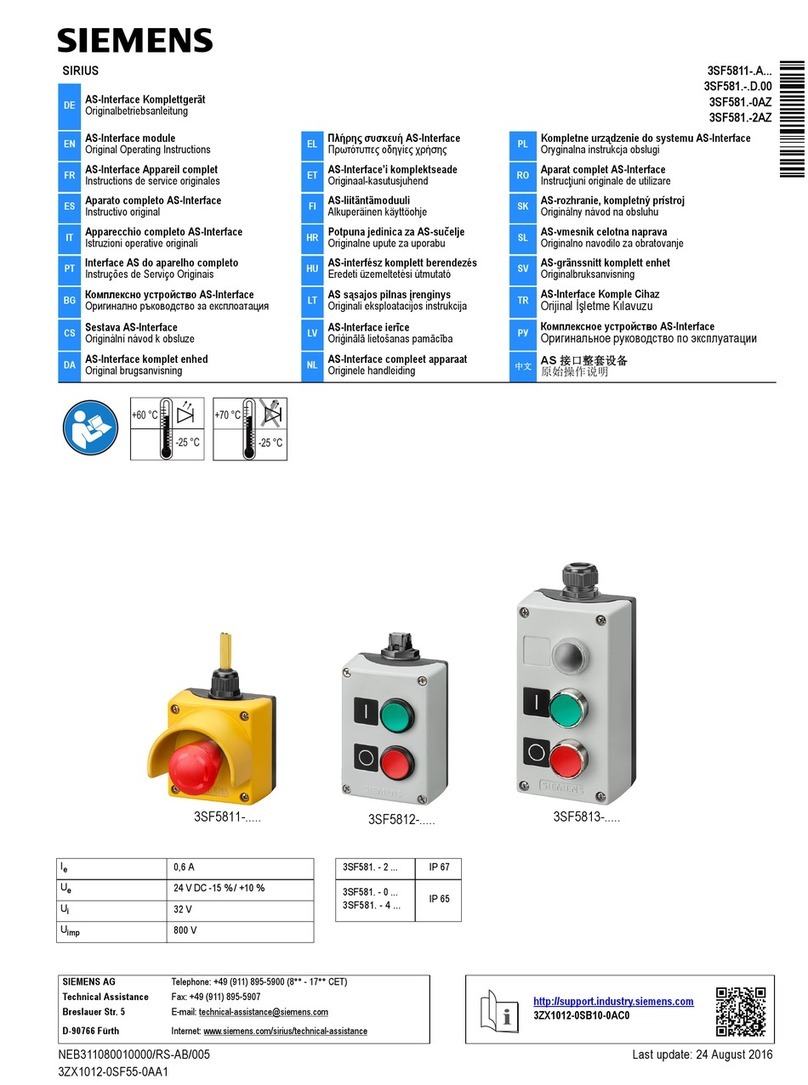

Siemens

Siemens SIRIUS 3SF5811 A Series Original operating instructions

Advantech

Advantech B+B SmartWorx IE-iMcV-2xLIM user manual

Mitsubishi

Mitsubishi FX1N-5DM user manual

Ara-Unicontrol

Ara-Unicontrol UNICONTROL user manual

LSIS

LSIS S100 Series manual

AvL Technologies

AvL Technologies AAQ IntelliTrack Module Setup & operation guide