Cimel CE318-N User manual

Multiband photometer CE318-N

User’s Manual (rev. Apr. 2015)

Firmware version 5.0 and above

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 2/70

Dear Customer and users,

You have just purchased a Cimel sunphotometer and we would like to thank you.

We have placed in this instrument all our passion and know-how so that it best meets

your needs. Innovation and performance: we designed it so that it is always easy to

use.

In the line of Cimel products, you will also find a wide range of remote sensing and

automatic Sun Sky Photometer CE318-N that can be coordinated with your new

Cimel CE372 LIDAR.

Of course, in an ongoing effort to satisfy your demands as best as possible

concerning our products, our after-sales service department is at your disposal and

ready to listen and answer to all your questions and suggestions (contact information

at the end of this booklet).

Please visit our website at www.cimel.fr: you will find all our products, as well as

additional and useful information.

Cimel

As part of our commitment to constantly improve our products, we reserve the right to

make changes to their technical, functional and/or esthetic properties in line with their

technological development.

Caution: Before installing and using your instrument, please read carefully this

guide, which will help you to be quickly familiarized yourself with its operation.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 3/70

Table of Contents

1Product overview..........................................................................................................................4

1.1. Presentation ............................................................................................................................................... 4

1.2. System components quick description ........................................................................................... 4

1.3. Sensor head types ..................................................................................................................................10

1.4. Data transmission..................................................................................................................................11

2Installation ................................................................................................................................... 12

2.1. Installation site recommendations.................................................................................................12

2.2. Hardware installation and setup.....................................................................................................12

2.2.1. eeded tools......................................................................................................................................12

2.2.2. Tripod mounting..............................................................................................................................12

2.2.3. Case mounting ..................................................................................................................................14

2.2.4. Robot and sensor head mounting.............................................................................................15

2.3. Communication protocol installation and configuration ......................................................23

2.3.1. RS232 communication ..................................................................................................................23

2.3.2. Satellite transmission installation and configuration ......................................................25

3CU navigation menu ..................................................................................................................31

3.1. Basic Display ............................................................................................................................................31

3.2. PW menu....................................................................................................................................................31

3.3. SC menu ..................................................................................................................................................34

3.4. VIEW menu...............................................................................................................................................34

3.5. Man menu..................................................................................................................................................35

4Description of the scenarios measurements proceedings.......................................... 36

4.1. Scenario description and sequencing............................................................................................36

4.2. Group of measurement scenarios ...................................................................................................42

4.3. Measurement schedule in Auto mode ...........................................................................................43

4.3.1. Standard and polarized.................................................................................................................43

4.3.2. BRDF and BRDF 12 filters............................................................................................................44

4.4. Customized scenario programming ...............................................................................................45

ASTPWin software..................................................................................................................... 46

5.1. General........................................................................................................................................................46

5.2. Tools ............................................................................................................................................................48

5.3. Configuration menu ..............................................................................................................................49

5.4. Processing .................................................................................................................................................51

6Maintenance / Troubleshooting / FAQ .............................................................................. 2

6.1. Preventive maintenance......................................................................................................................52

6.2. Corrective maintenance ......................................................................................................................53

6.2.1. Solar panel and wet sensor replacement ..............................................................................53

6.2.2. Robot leveling adjustment...........................................................................................................54

6.3. Troubleshooting .....................................................................................................................................55

6.3.1. Communication and data transfer is down ..........................................................................55

6.3.2. Bad sun tracking ..............................................................................................................................56

6.3.3. InGaAs / silicon and A / K discrepancy..................................................................................58

6.3.4. High dark current............................................................................................................................58

6.3.5. Constant humidity...........................................................................................................................59

6.3.6. Robot errors ......................................................................................................................................60

6.3.7. Dissymmetric Almucantar...........................................................................................................61

6.3.8. Battery low.........................................................................................................................................61

7Technical specifications ..........................................................................................................62

7.1. General........................................................................................................................................................62

7.2.

Dimensional drawings .........................................................................................................................63

8After-Sales Service and Customer Relations ......................................................70

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 4/70

1 Product overview

1.1.Presentation

This high-precision multiband photometer measures the optical properties of the

atmosphere especially by measuring on one hand, the sun irradiance and on the

other hand the soil and sky radiance. It provides the quantification and physical-

optical characterizations of the aerosols.

Due to its very low power consumption thanks to the MicroAmps

®

technology, to its

self-powered system and to its rugged design, the CE318 fully meets the operational

requirements of continuous monitoring in terms of reliability, long lifetime and very

low maintenance cost.

The CE318 photometer technology is constantly enhanced to match the new

technological challenges for climate observation and monitoring. Cimel’s

photometers are still the benchmark devices for most aerosol observing networks

and more specifically for the international federation of AERONET.

The large range of parameters that are derived and calculated from the

measurements and from the atmospheric physics equations make the CE318

photometer a worldwide benchmark device for the following applications:

•Characterization and quantification of aerosols

•Satellite calibration of aerosol measurements

•Detection of volcanic ashes plumes in real time

•Determination of Aerosol Optical Depth (AOD)

•Determination of fine mode and coarse mode AODs

•Determination of the optical properties of the atmosphere for satellite imaging

•Determination of the ocean's colour

•Determination of the amount of precipitable water vapor

•Air quality monitoring

•Volume size distribution

•Nature of aerosols

1.2.

System components quick description

The photometer system is delivered with:

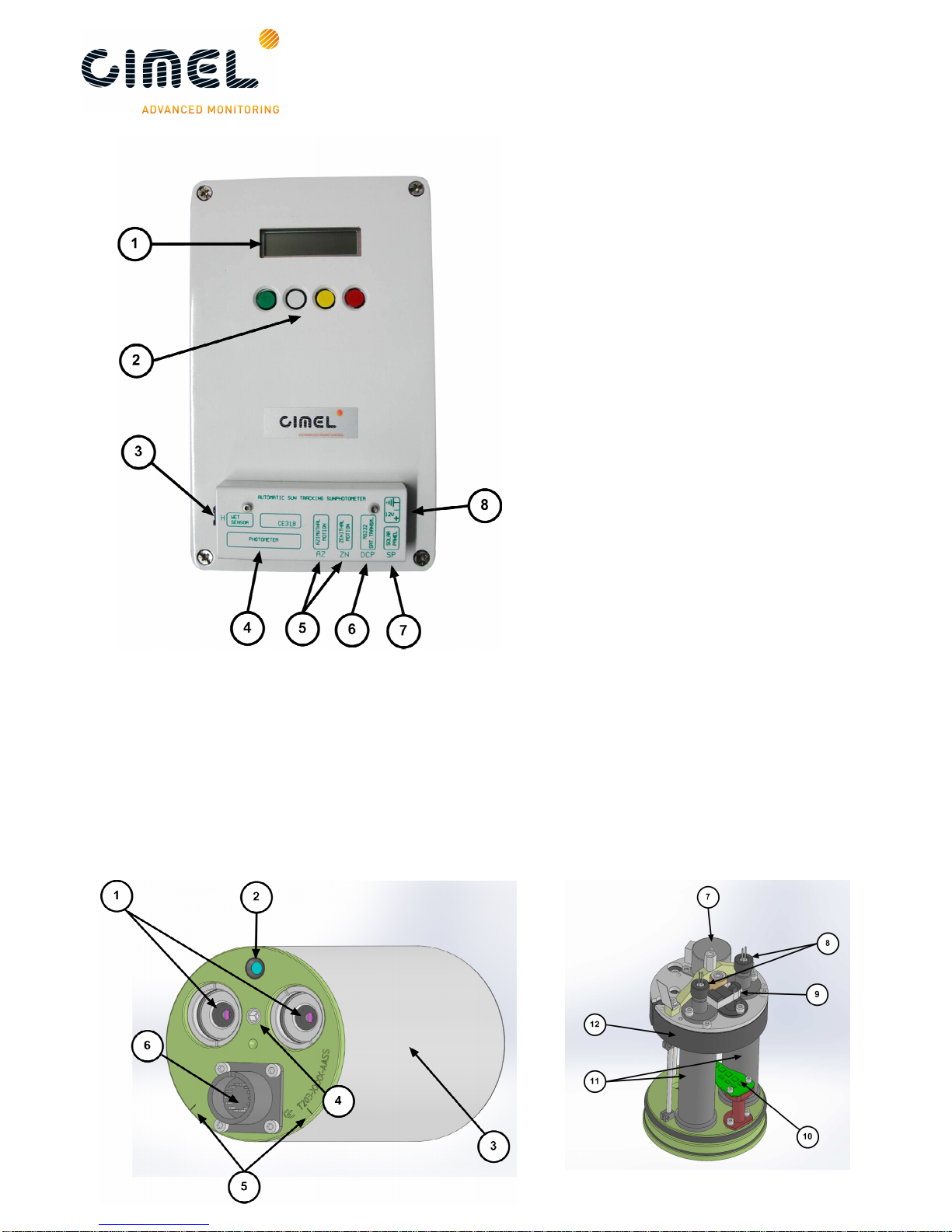

1. Control Unit (CU)

The Control Unit is the component where all the data acquired by the optical head

are sent and it is used as the user interface to parameterize the whole system

running.

The CU gets four colored buttons and a screen display which enable the users to

navigate through the menus.

The features and the menus are described more precisely in chapter 3.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 5/70

User interface:

1: Graphic display.

2: Coloured buttons.

Removable terminal block:

3: Wet sensor.

4: Sensor head.

5: Robot azimuth and zenith

motion.

6: DCP / Serial communication.

7: Solar panel.

8: External battery.

2. Sensor head and collimator

a. The sensor head

The sensor head measures the received signal from the sun, sky, soil or sea. Then it

is sent and recorded to the CU.

Detectors can be either silicon and InGaAs or silicon only for the SEAPRISM sensor

head type. InGaAs detector is used for near-infrared wavelengths.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 6/70

1: Front plate lenses and optical chambers entrance 7: Step by step motor

2: 4 quadrant detector lens 8: Detectors

3: Cover 9: Filter wheel detector

4: Threaded hole for collimator 10: 4 quadrant

5: Positioning notches 11: Optical chambers

6: Head sensor cord connector 12: Filter wheel carter

b. Collimator

The collimator is a component that enables the light to be guided correctly to the

sensor head outside lenses. The collimator helps to reduce the stray light.

1: notch 2: tightening screw 3: alignment hole 4: spot

3. Robot

The robot is the component on which the sensor head is attached. Its mechanical

design enables it to point on whole directions of the sky on the azimuthal and zenithal

angles with a very high accuracy.

It is controlled through 2 cables (with RJ11 connectors), one for each axis.

1: Adjustment wheel (X2)

2: Robot base

3: Strap

4: V-shaped part

5: Spirit level

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 7/70

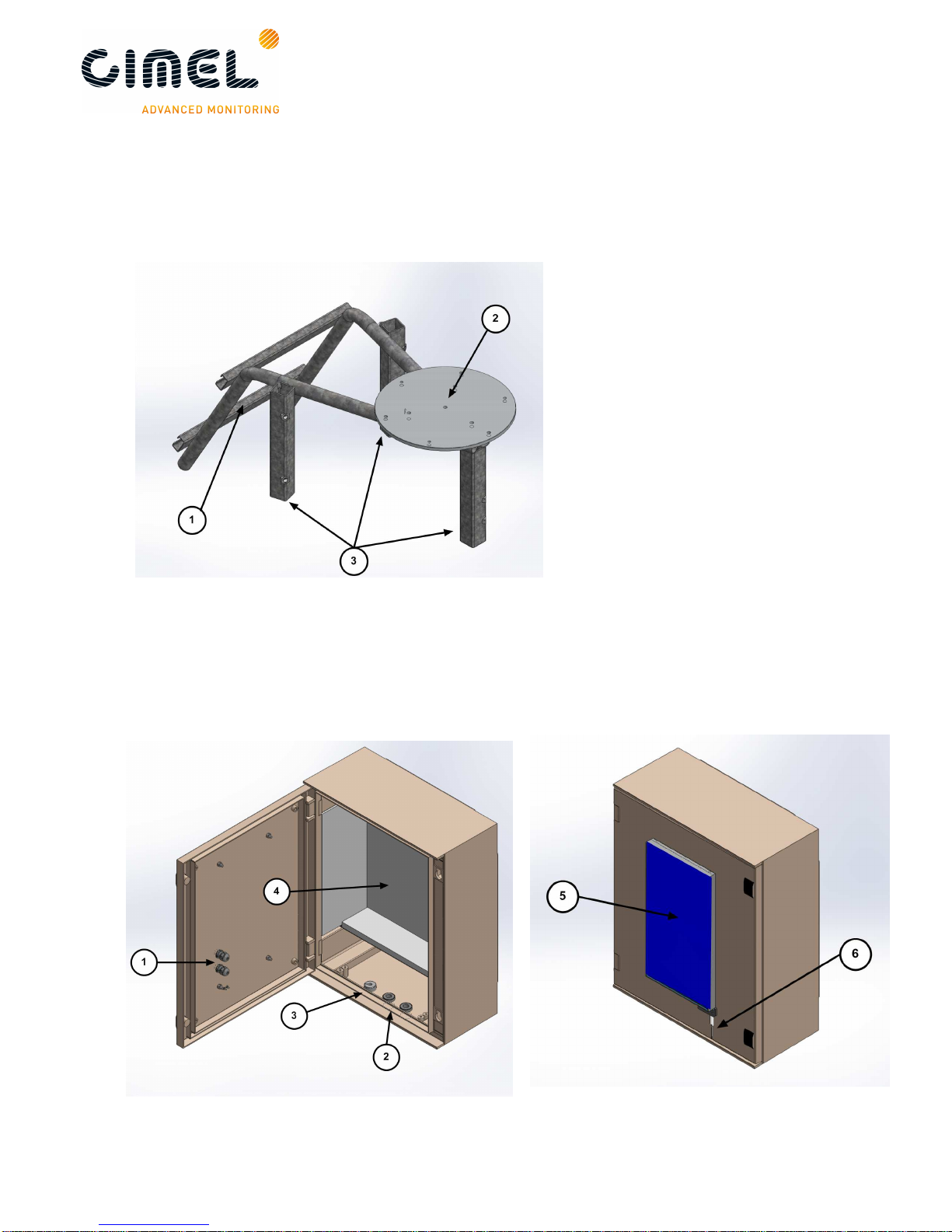

4. Tripod and tray

The tripod is the supplied infrastructure where the protection case and the robot are

fixed and that enables the whole system to be stably fixed on the ground.

The tray is a part fixed horizontally on the tripod and where the robot will be fixed on.

1: Emplacement for the

protection case

2: Tray

3: Tripod feet

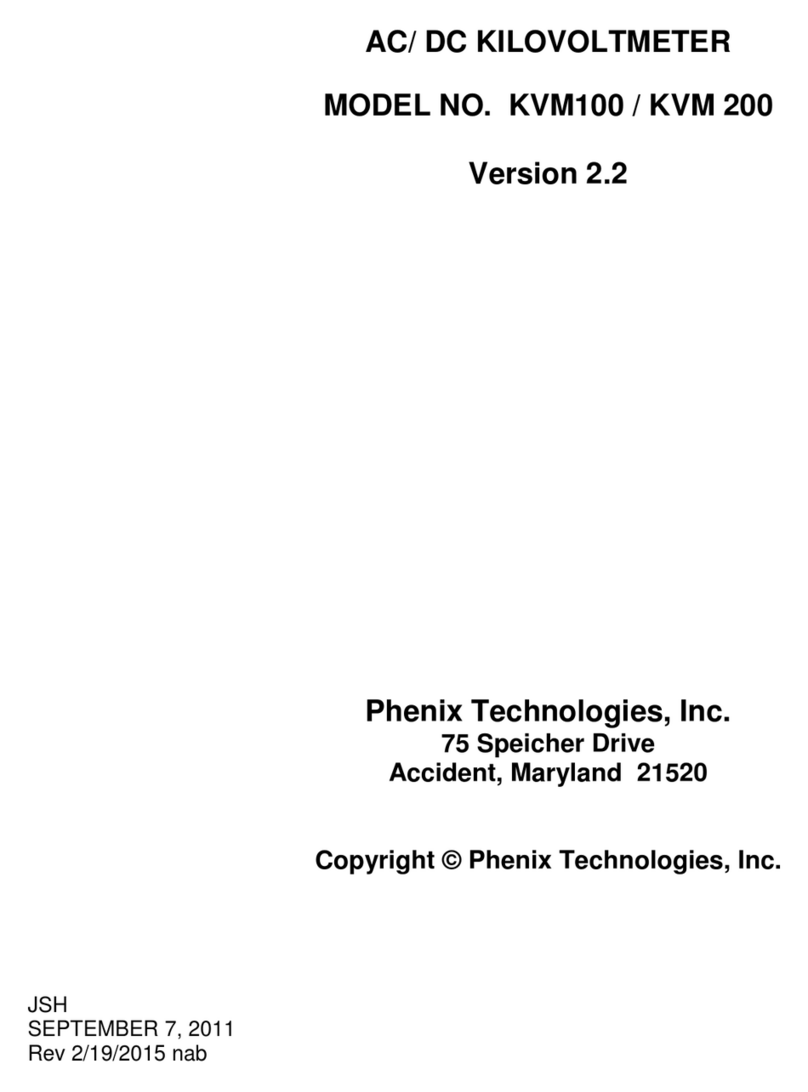

5. Protection case with solar panel

The pair of batteries and the CU are placed into the case. The solar panel that

powers the system is incorporated in the case.

The output plug of the solar panel is a RJ11 connector.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 8/70

1: Cable gland. The wet sensor and solar panel wires will go through.

2: Cable gland. The robot and computer wires will go through

3: Cap. The sensor head cord will go through

4: Foam

5: Solar Panel

6: Wet sensor

6. Wet sensor

The wet sensor detects rain in order to stop measurements and protect the sensor

head from water when it is raining. The output plug of the sensor is a RJ11

connector. Standard length of the wire is 3m.

7. Sensor head cord

The sensor head cord connects the CU and the sensor head. The standard length is

3 meters. One side connector is DB25 (male) type and this other side is Jupiter type

with 22 pins (female)

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 9/70

8. Batteries and battery charger

The black batteries supply power to the CU. The battery is 8AH.

The YUASA battery is furnished when the satellite transmitter is used. The battery is

24AH.

The battery charger is used only in case of solar panel breakdown.

9. Flycase

10.Acquisition PC

The acquisition PC (not supplied) receives the data transmitted by the CU either via

RS232.

11.ASTPWin software

ASTPWin is the software used to communicate from the acquisition PC to the CU.

ASTPwin is not used when having a data transfer by satellite communication

protocol.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 10/70

12.Satellite transmitter (optional)

The satellite transmitter is useful in remote places where no reliable PC is available.

It enables to send the data directly to an appropriate geostationary satellite which has

a dedicated transmission channel for the CIMEL photometers.

1: Solar Panel Solartek

2: IAGI antenna

3: Mast

1.3.

Sensor head types

5 different sensor head types exist:

•Standard: It uses 340, 380, 440, 500, 675, 870, 937, 1020 and 1640 nm filters

•Polarized: A filter wheel containing 3 sets of 3 polarizers operating in infrared

(POL1), Ultraviolet (POL2), and visible (POL3) and which are orientated with a

120° angles is added on top of the wheel containing the Standard filters.

Additional information about the aerosols nature and shapes can then be

retrieved.

•Seaprism: It is designed for Ocean Color application. It uses only silicon

detectors. It uses 412, 440, 500, 531, 550, 675, 870, 937, 1020 nm filters.

•BRDF: it uses 380, 440, 550, 675, 740, 870, 937, 1020 and 1640 nm filters

•BRDF 12 filters: It is designed for satellite calibration. It uses 412, 440, 500,

555, 675, 702, 740, 782, 870, 937, 1020, 1640 nm filters.

The sensor head types differs in the presence of an additional wheel filter containing

polarisers for the Polarized type, the filters wavelengths mounted in the head sensor,

the and the scenario sequence established.

Filters wavelengths are defined in the UV-visible-IR spectrum according to scientific

retrieval purposes.

The filters and polarizers curves are delivered with the photometer.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 11/70

1.4.

Data transmission

The photometer can use 2 different communication protocols to send its data from

the CU.

•PC data transfer using a RS232 link to an acquisition PC. (default data

transmission)

•Satellite data transfer using a DCP transmitter module. The proper way to set

the module is explained in the Installation chapter.

Figure

3

: STANDARD option

Figure

1

: BRDF

option

Figure

5

: BRDF 12 filters option

Figure

4

: POLARISED option

Figure

2

: SEAPRISM option

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 12/70

2 Installation

2.1.

Installation site recommendations

The site should be chosen carefully in order to comply with the following conditions:

•Easy access to facilitate the weekly maintenance of the device.

•The device should be installed in a clear area where it has the largest field of

view as possible so that it can track the sun from sunrise to sunset (no

buildings, trees…).

•Less than 100m cable length to a PC (RS232 link mode).

•A support where it can be strongly fixed so that the system is stable

(preferably the tripod).

2.2.

Hardware installation and setup

In this description, notions on how to manually control the photometer via the CU are

necessary, it is recommended to read chapter 3 and 4 to have a better overview of

what is done when installing the system.

However the following instructions are detailed enough so that it is not mandatory to

read the 2 chapters cited above.

If the tripod system is not used, skip to part 2.2.4.

2.2.1. Needed tools

To install the system, the following tools are needed:

•Open-end wrench size 10.

•Open wrench size 13.

If possible, a tubular spirit level will be used in addition of the robot spirit level to

make the installation easier (0.4mm/m accuracy).

2.2.2. Tripod mounting

The tripod mounting system is designed for easy installation of the photometers in

most site conditions.

1. Insert the three photometer tripod feet into the metallic frame.

2. Tight the 3 screws on the tripod feet.

3. Insert the ribs into the slides designed for this.

4. Insert the screw into the tray.

5. Tight strongly the screw into the rib with the tray in between.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 13/70

6. Attach the tripod feet to the ground with appropriate screws.

Note: Orientate the protection case emplacement South if the location is in the

Northern hemisphere or North if the location is in the Southern Hemisphere.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 14/70

2.2.3. Case mounting

7. Insert the 4 ribs into the metallic frame in order to fix the case.

8. Tight strongly the screw into the ribs with the inside of the case in

between.

9. Put the foam at the bottom of the case and on the sides, place the

batteries and the CU as shown on the picture below.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 15/70

2.2.4. Robot and sensor head mounting

10.Put the screws into white plastic part.

11. Put the screws on the holes trough the robot base but don’t tight them

to the end, let a 2 or 3 cm backlash so that the leveling that is done in

the next part is easier to do.

12.Connect AZ (robot AZimuthal motor), ZN (robot ZeNithal motor), solar

panel, wet sensor and battery wires to the removable terminal block of

the CU passing them going through the cable glands of the protection

case.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 16/70

13.Launch a Park scenario in the CU menu. The robot will find its zero

position.

14.Set the horizontal robot axis in the East-West direction by manually

turning the whole base of the robot.

15. Assemble the collimator to the sensor head front plates by tightening

the long central threaded rod. The notch must face the 4 quadrants lens

on the sensor head frontplate.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 17/70

Note: Watch out that the collimator and the sensor head are completely

interdependent. There should be no slack while trying to move the collimator after

having tightened it.

16.Strap the sensor head on the V-shaped support of the robot. Two

things are to be checked. First align the sensor head front plate with the

upper surface of the V-shaped support. Then use the notches present

both on the robot and the sensor head as a visual indicator to position

the sensor head correctly. Notches have to be aligned.

17.Plug the sensor head cord from the CU to the sensor head passing it

through the cap and attaching it to the pig tail. Connect the computer or

the transmitter to the DCP input on the removable terminal block via a

RS232 to RJ11 cable.

Note: A sufficient slack has to be maintained so that the head sensor cord will not be

too much extended while the device is operating, which can lead to the

malfunctioning of the photometer.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 18/70

18.Level the robot up so that it’s perfectly horizontal by playing on both

precision wheels until the spirit level on the top of the robot is centered.

This part is a little tricky and may take few trials. Using an additional

tubular sprit level may facilitate this step.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 19/70

19.Setting the date and the time UT in the AU menu

Important note 1: the time set is UT. If you are not sure about it, please visit this

website to get it:

http://fr.thetimenow.com/utc/universal_coordinated_time

Important note 2: seconds can not be set, wait until a whole minute is coming and

validate the time at this point more or less 2 seconds. For instance, validate the time

when it’s 14:05:00 or 17:18:00.

20.Set the GPS coordinates in the CU menu

Important note: the coordinates are entered in hours, minutes and seconds.

Therefore you may have to convert your GPS position if not into the good units.

This conversion can be done in ASTPWin software. Refer to part 5.

CE318 Photometer

User's Operation Manual

Revision 5.0 April 2015 20/70

21.Launch a Park scenario in the CU menu. The photometer head will find

its PARK position which is the nadir on the zenithal angle (head

orientated down).

If the head is pointing to zenith (orientated up), unstrap the sensor

head, reposition it in the opposite sense in the straps and do step 13

again.

Note: Place the spirit level on the robot V-shaped part after the PARK scenario. It

should be perfectly horizontal, if not refer to part 5.2.2.

22.Launch a GoSun scenario in the CU menu. The optical head is going to

point the sun.

After a GOSUN scenario the sun spot may not be centered on the target.

Table of contents

Other Cimel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

iZ Technology

iZ Technology RADAR I Upgrade manual

Phenix Technologies

Phenix Technologies KVM100 manual

Horstmann

Horstmann ComPass B Instructions for use

Minebea

Minebea CSD-903-73 instruction manual

Direct Scientific

Direct Scientific DSM-502 Operation & maintenance manual

DeFelsko

DeFelsko PosiTector 200 instruction manual