9

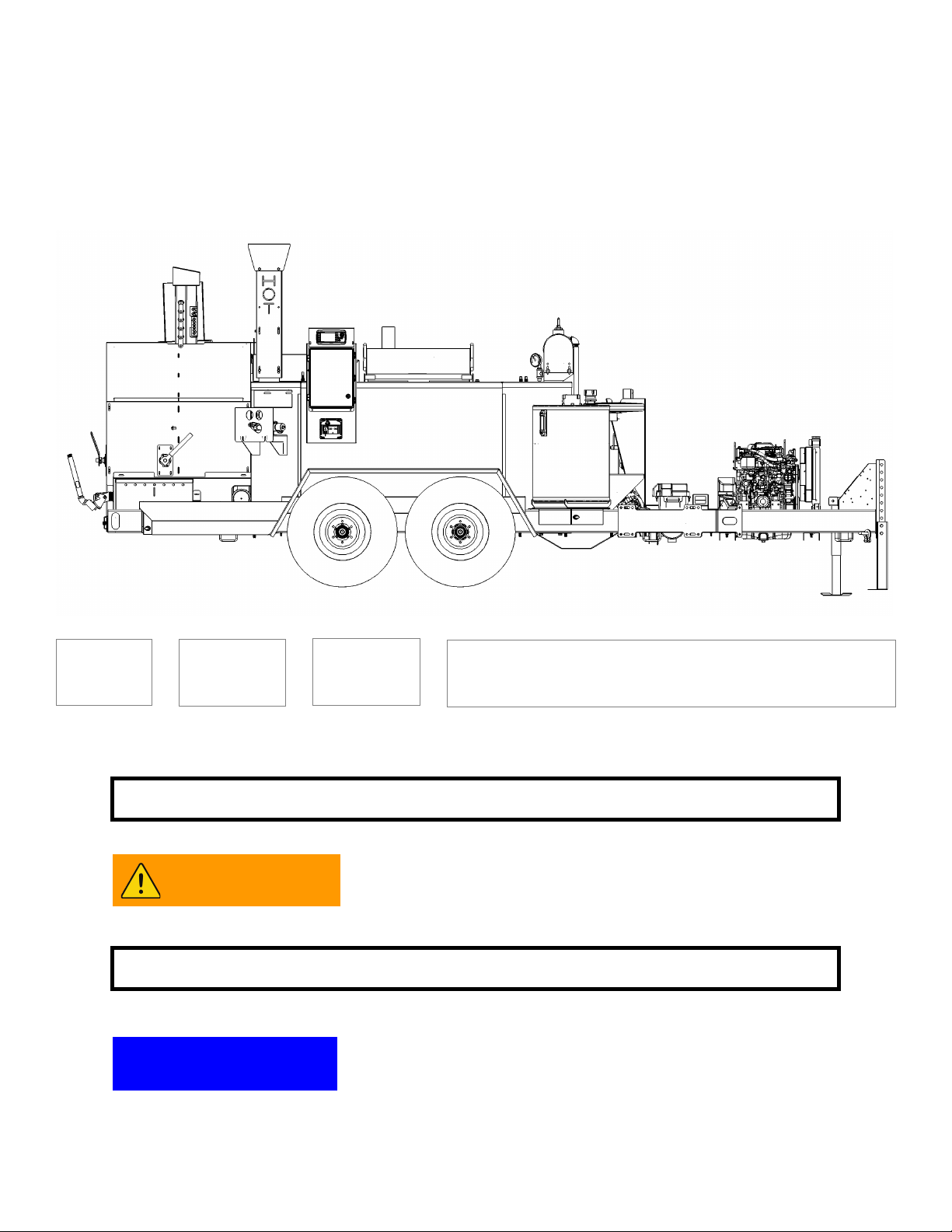

NOTE: This general outline will familiarize you with this machine dependent on model,

location and style and may vary with options installed. Read through the entire manual before

putting this machine into operation.

1) Main Control Panel: The main control panel is used to control the primary functions of the melter,

including simple automated user controls for Off / Run / Clean Out / Cool Down as well as manual control

of the sealant material pump direction and tank agitator. You can also monitor or adjust the temperature of

the sealant material and heat transfer oil on the control sub panel. See page 10 for more information on

the main control panel.

2) MA4 Applicator Electronic Control Display: This computerized panel will allow you to set your

application rate and calibrate the output rate of the sealant material through the application bar. See page

11 for more information on the electronic control unit.

3) Loading Door: Place the sealant material block or biscuit on the open door to load the melting

tank. See page 14 for more information on safely loading sealant material into the melter.

4) Heat Transfer Oil Level Dipstick: Allows you to monitor the amount of heat transfer oil in the

melter oil tank. See page 25 for more information on using the heat transfer oil dipstick.

5) Heat Transfer Oil Temperature Gauge: Displays the heat transfer oil temperature.

6) Ignition Switch: Engine key “ Start” / “ On” / “ Off” and also displays engine running hours, glow

plug status, alternator charge, engine oil pressure and engine coolant warnings.

7) Main Tank Valve: “ Open” / “ Shut” allows sealant material to enter pump from sealant material

tank.

8) Control Handles (Qty. 2): Controls flow from “ Circulation” re-circulation back to sealant material tank

and “Spray Bar Circulate” circulation through application bar and back to sealant material tank.

9) Bulk Loading Plug: This 3 inch Cam and Groove fitting allows for liquefied bulk sealant material to

be pumped directly into the MA4 sealant material tank from an external source.

10) Secondary Tank Valve: Allows sealant material to enter the Draw Off / Sample system out to the

Draw Off / Sample Valve.

11) Draw Off / Sample Valve: Allows sealant material to gravity pour into a pour pot for manual

application on areas unreachable by the application bar, or can be used for drawing off sealant material

samples for testing purposes.

12) Pour Pot Storage: Two pour pots can be stored in this external box. Items in this box must be tied

down properly while in transport.

13) Control Lights: These lights are visible to the driver and indicate when the system is ready to

begin application and that the vehicle is driving an appropriate speed for the application rate. See page 16

for more information on the control lights.

14) Ground Speed Encoding Wheel: This sensor folds up / down for storage and reports trailer speed

to the computerized control system. The control system communicates with the pump to apply the

appropriate amount of sealant material based on the speed reported by this wheel. See page 16 for more

information on the ground speed encoding wheel.

15) Application Bar: The application bar folds up / down for storage. When the control valves are

opened to “Spray Bar Circulate” hot sealant material circulates through the application bar until the system

is activated and senses movement, dispensing sealant material as directed by the control system.

16) Tip Control Keypad: You can manually control and engage the application tips from this keypad

(or with the key fob remote). See page 20 for more information on the tip control keypad

17) Key Fob Remote Transmitter: The MA4 comes with 1 wireless remote to activate the application of

sealant material from the application bar. The key fob remote transmitter also can control which of the 5

spray tips are actively applying sealant material. Note: Only one remote can be actively powered on at a

time. See page 16 for more information on the key fob remote transmitter. See page 20 for information on

pairing the key fob remote transmitter.

MA4 Feature Overview