2

Table of Contents

Shipping Papers and Information…………………….…….…3

Safety Notes……………………………………………….………4

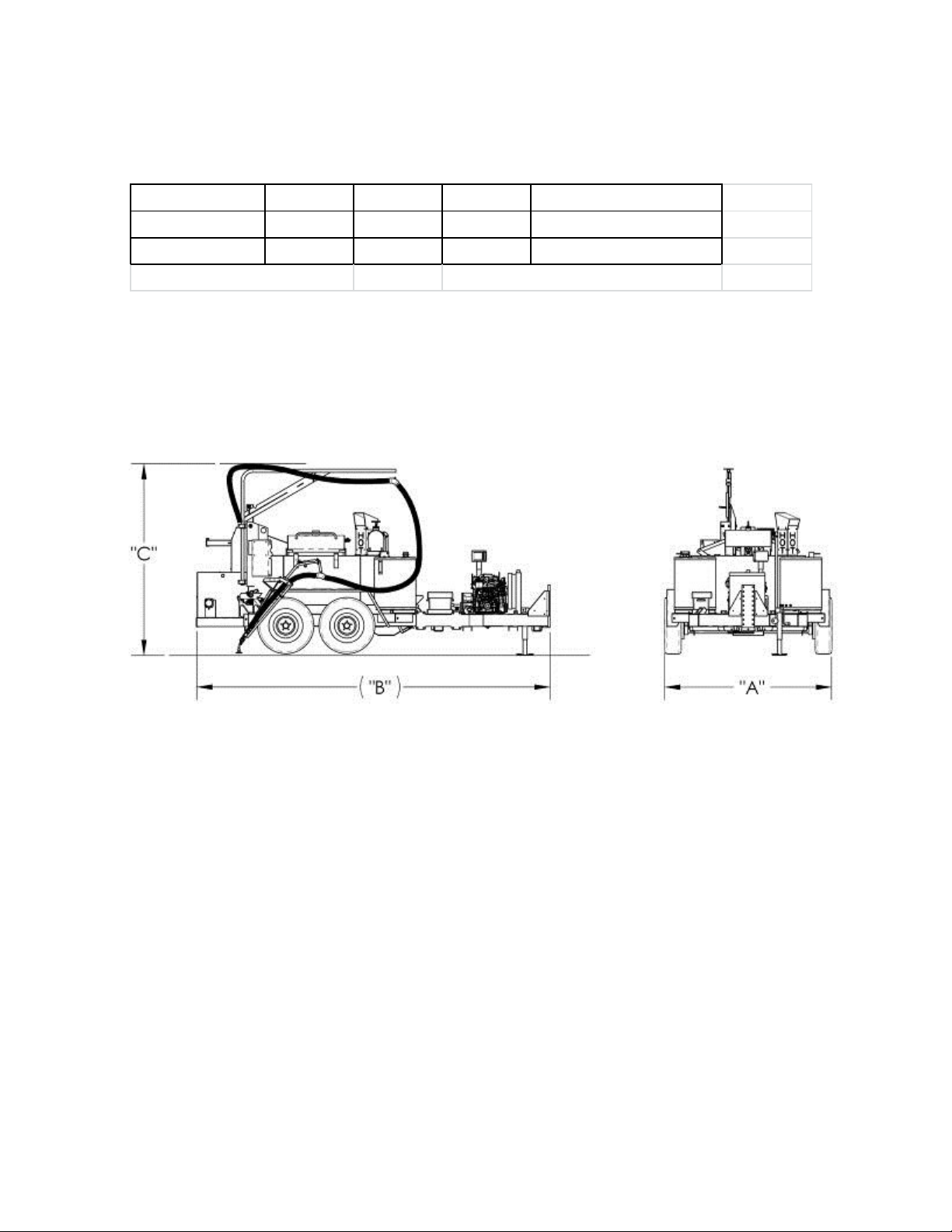

Weights and Dimensions………………………………….……5

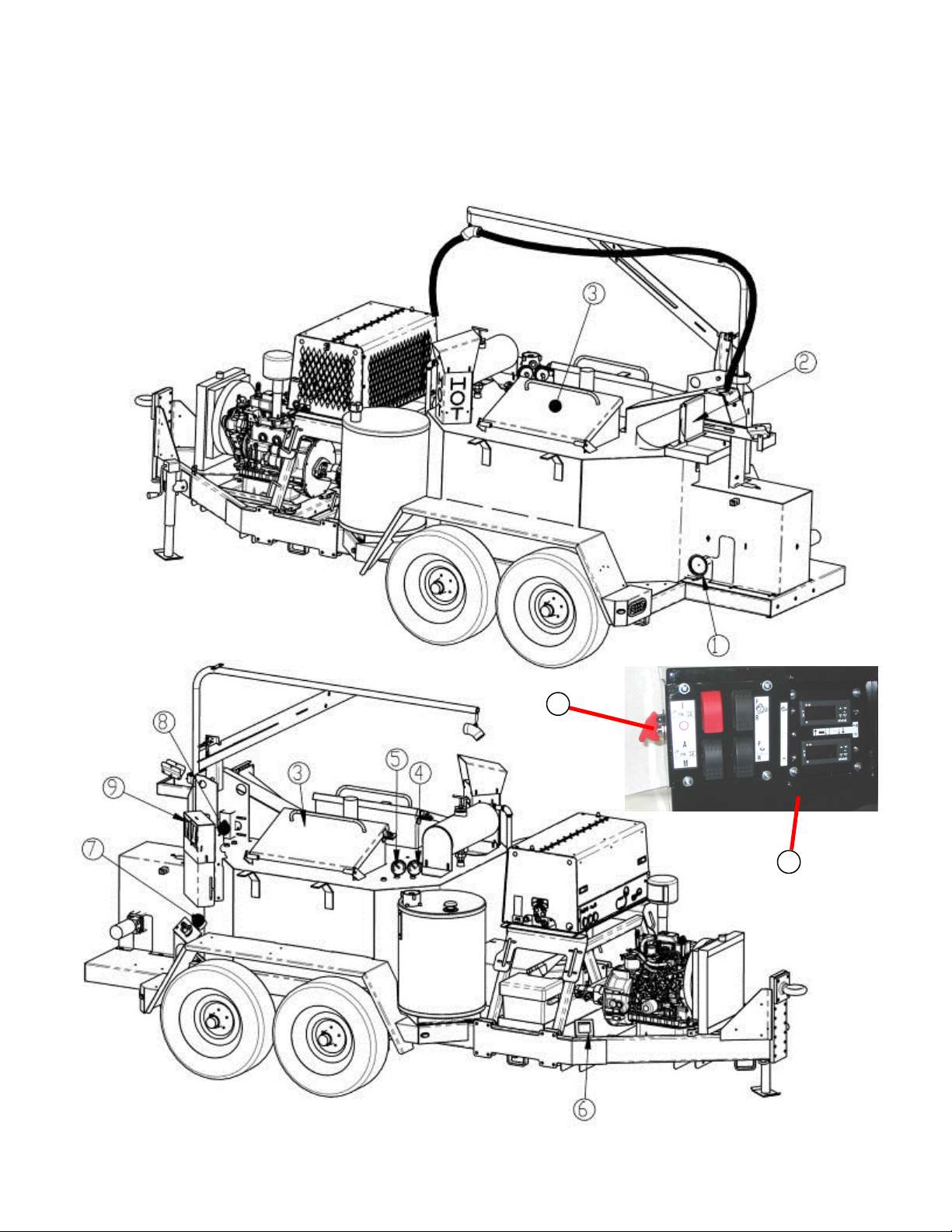

Controls and Their Functions………………………………..6-7

Start Up…………………………………………………………..8-9

Automatic Temperature Control Setting…………………….10

Loading Empty Tank…………………………………………….11

Cleanout Procedure……………………………………………..12

Cleanout Procedure (Optional Air Cleanout)………………..13

Maintenance…………………………………………………...14-15

Fluid and Components Specs…………………………………16

Heat Transfer Oil Specs………………………………………...17

Material Tank Capacity………………………………………….18

Trouble Shooting Guide………………………………………..19

Parts Section

Wiring Diagrams……………………………………………..21-27

Complete Wiring Diagram………………………………….21

Engine and Burner Wiring Harness………………..……..22

Switch Panel…………………………………………………..23

Temperature Control Wiring Diagram………………..…..24

Relay Panel ………………………………………………...…25

Main Supply Harness………………………………………..26

Primary Control…………………………………….………...27

Hydraulic Schematic……………………………..……………..28

Hydraulic Manifold Parts List………………………………….29

Electrical Components…………………………..……………..30

Isuzu Diesel Engine and Pump Parts List

(See supplement for compressor models)………………31

Plumbing System Parts List………………………………..32-33

Material Pump Parts List……………...…………………….34-35

Sealing Hose and Wand……...…...………….………………...36

Sealing Tips……………………………………………….……....37

Agitation System Parts List…………………………………….38

Oil Burner Parts List……………………………………………..39

Combustion Chamber Parts List and Tank Insulation.…....40

Fuel and Hydraulic Tank Components ..……………………..41

Miscellaneous Parts………………………………………….42-43

Spare Parts Kit……………………………………………………44

Compressor Option……………………………………………...45