4

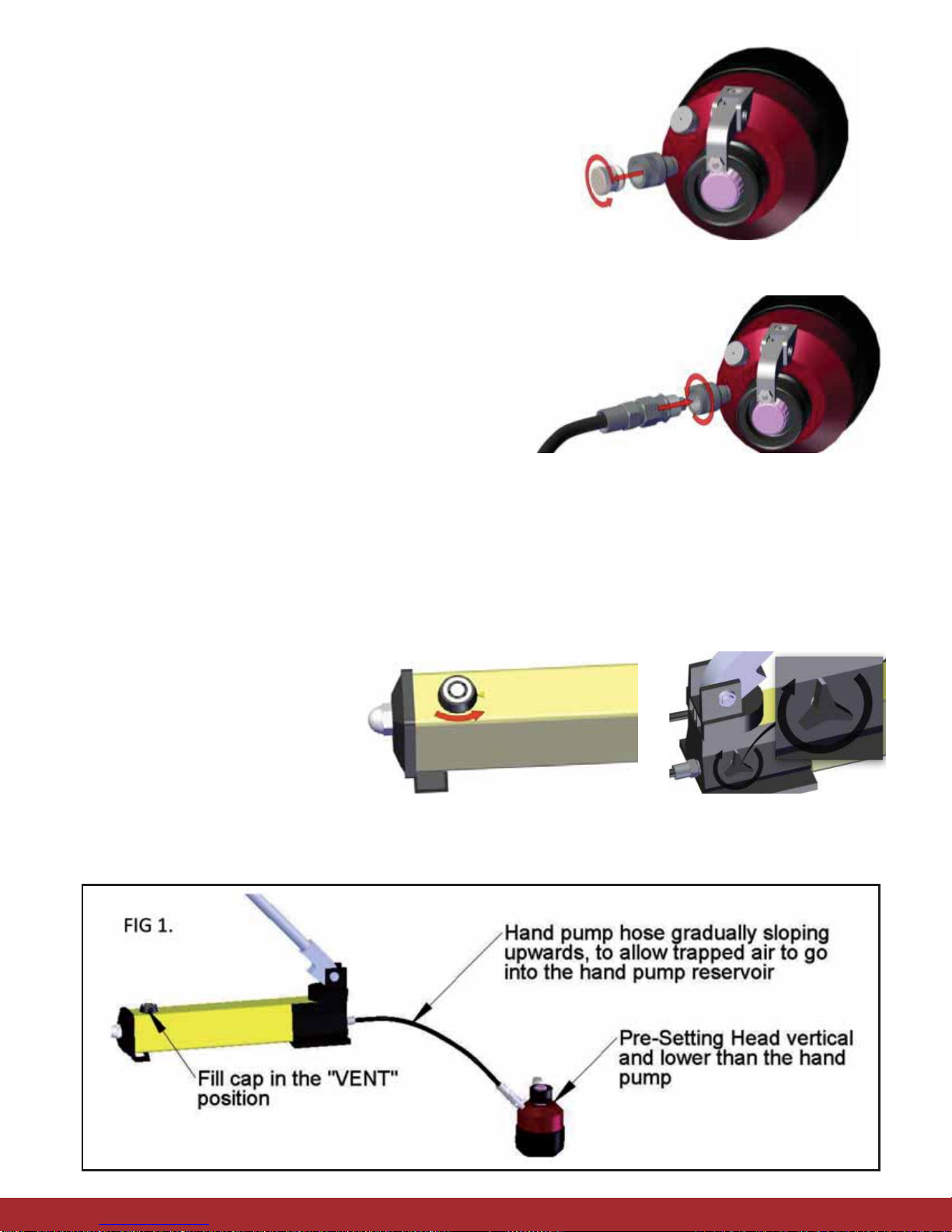

2.4 Operate the hand pump (pump the handle) until the piston in

the Pre-Setting head if fully extended. This is achieved when

the pump handle is hard to push. Do not try to pump the handle

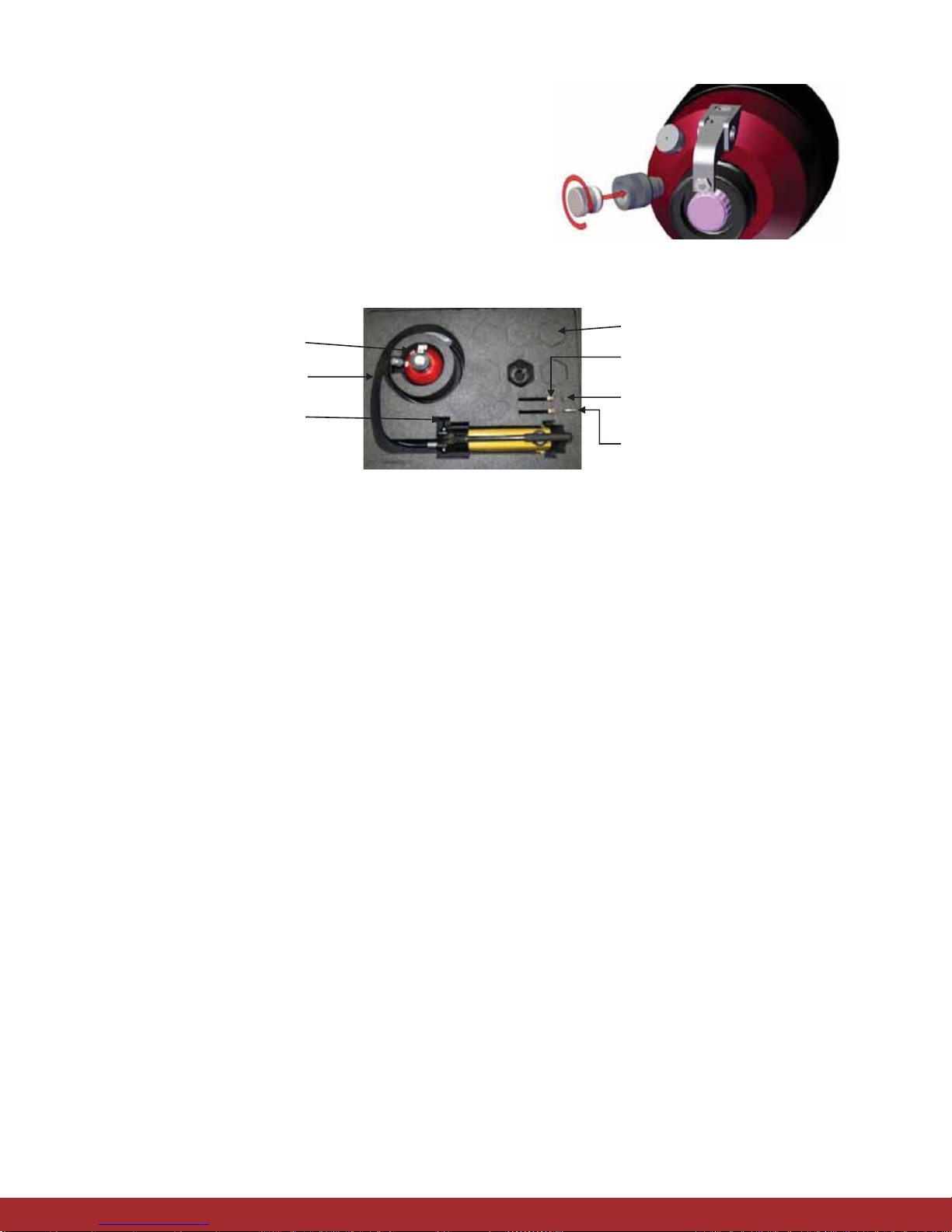

any further. Pre-Setting head, turn counter-clockwise. Keep

the plug in a safe place, such as in theblack case.

2.5 Open the release valve on the hand pump to retract

the Pre-Setting head piston. This action will force

any trapped air to move up into the hand pump reservoir.

2.6 Repeat the above step as necessary.

2.7 Add oil to the hand pump reservoir, if necessary.

Reference hand pump manufacturer’s manual

for instructions.

2.8 Return fill cap to the operating position (“CLOSE”).

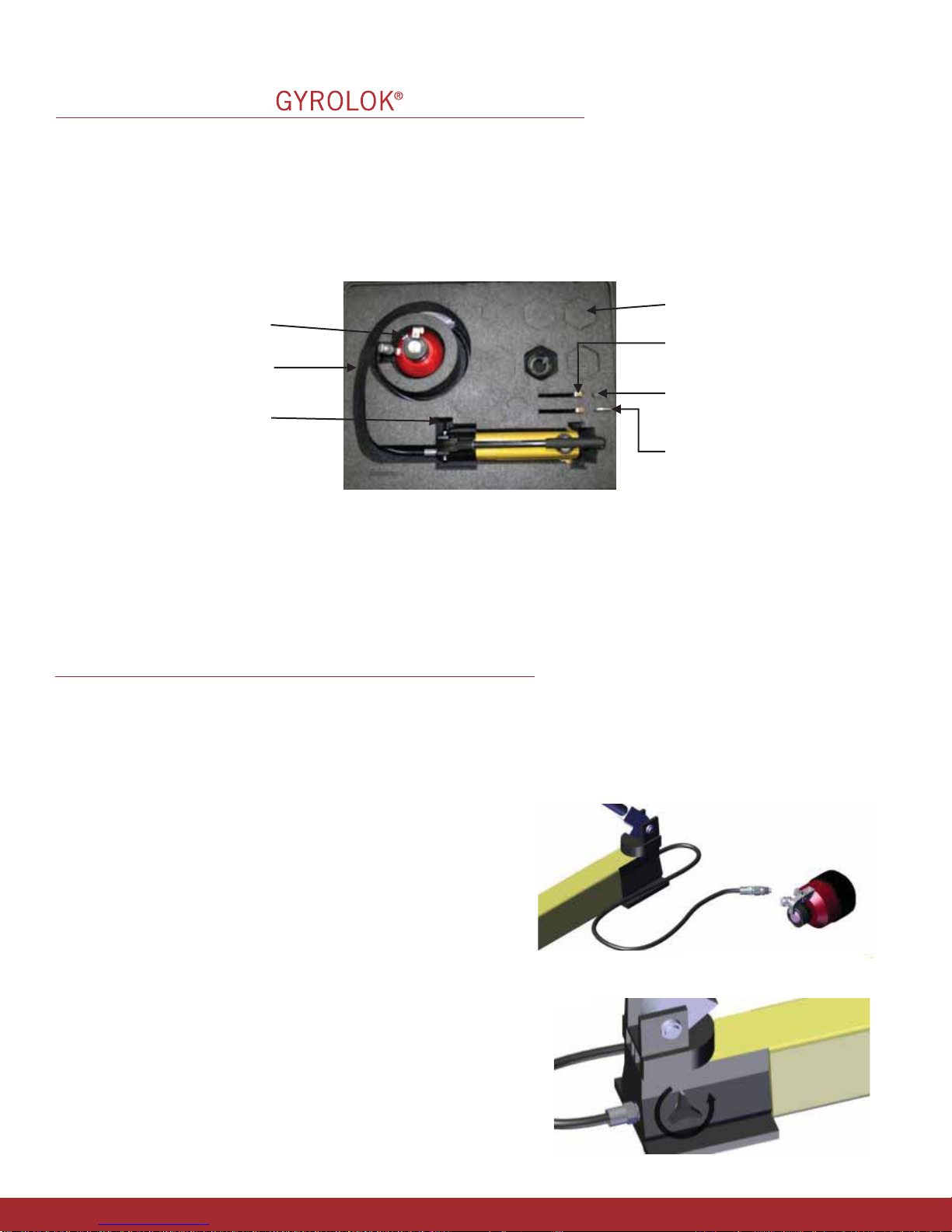

3. Die and Jig Installation

Always keep the Die and Jig as a matched pair and stored in the black

case when not in use.

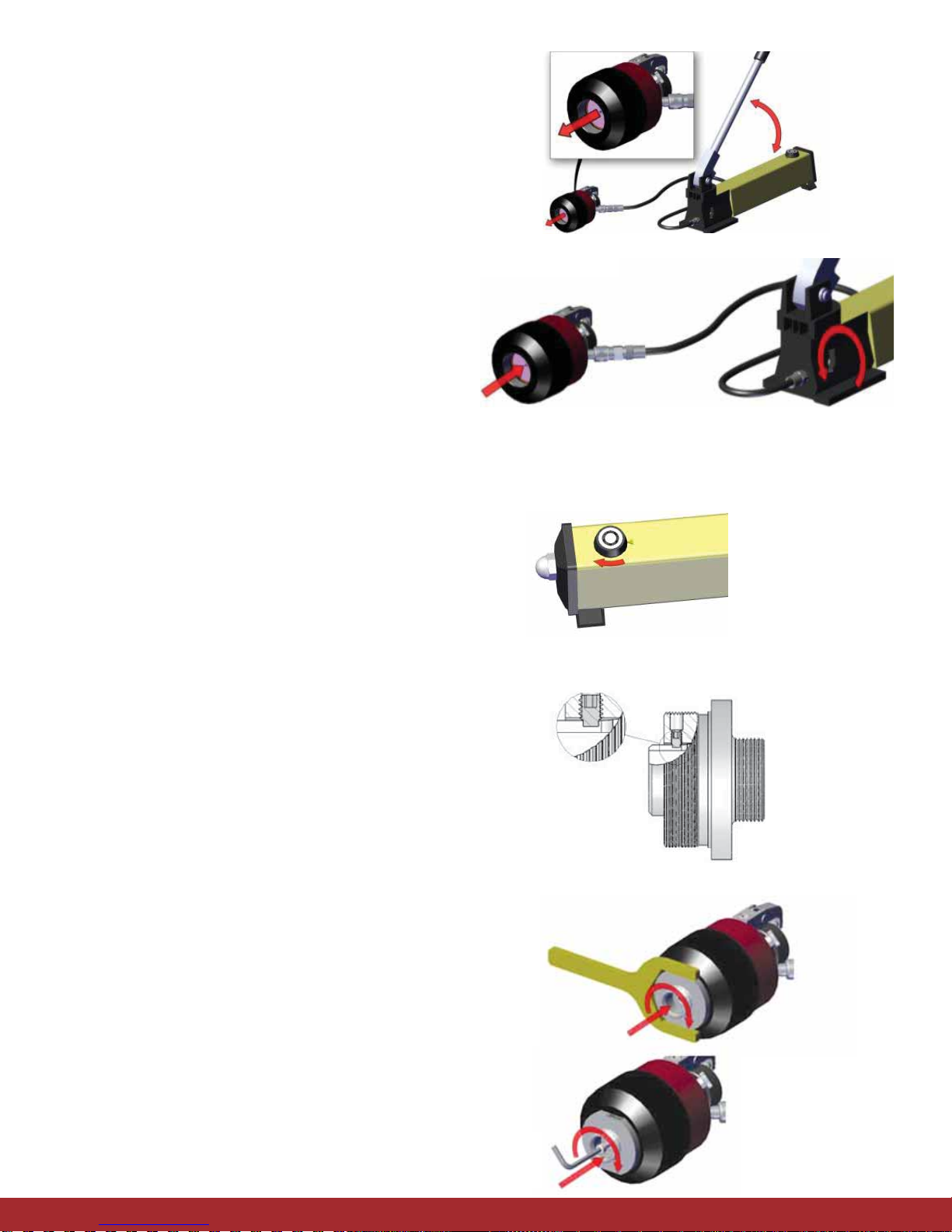

3.1 Select the corresponding Die and Jig set to the desired tube

size you wish to pre-set. Make sure the Die and Jig is a matched

pair. Use a 3/32 Allen Wrench to loosen the set screw located on

the large end of the jig (See adjacent figure). This ensures that

the Die moves freely prior to installing the Die and Jig assembly

into the Pre-Setting head unit.

3.2 Maintaining the Jig key in the Die slot, install the Jig and Die

by screwing the Jig into the Pre-Setting head and tighten

completely, turning clockwise. Do not over-tighten. Use ONLY

open-end wrenches provided.

3.3. Screw the Die-Fixing bolt to secure the Die onto the Pre-Setting

head’s piston, use the 5mm hex wrench, provided. Apply

a small amount of lube, provided with the fitting, to the

Jig threads. Do this on the first and every 5th use of the

tool thereafter.