14. Remove balance piston housing (022 or 045) with O-ring (028) from case (001). Remove O-ring (028)

from balance piston housing (022 or 045).

15. Remove oil balance tube (026 or 036) with O-rings (027 or 038) from rotor housing (024) or balance

piston housing (022 or 045) or inboard cover (046 or 008). Remove O-rings (027 or 038) form oil

balance tube (026 or 036).

16. Remove stop pin (006) and Dyna Seal (007) from case (001). Remove rotor housing (024) with O-ring

(028) from case (001). Remove O-ring (028) from groove of rotor housing (024).

17. Disassemble power rotor (044 or 063), removed in Step 10 as follows:

(Figures 3, 7, 8, 9) Remove outer truarc ring (042). Press ball bearing (049) off power rotor (063).

Remove inner truarc ring (042).

(Figures 3, 7, 8, 9) If seal is J seat type, remove spacer (048 or 014) and mechanical seal stationary

seat. If seal is O-ring type, remove seal seat adapter (048 or 014) with stationary seat from power

rotor (044 or 063). Remove stationary seat from seal seat adapter (048 or 014)

NOTE: Refer to Figure 2 for Mechanical Seal Types for proper disassembly.

(Figures 3, 7, 8, 9) Remove mechanical seal rotating assembly from power rotor (044 or 063).

NOTE: Refer to Figure 2 for Mechanical Seal Types for proper disassembly.

(Figures 7, 8, 9) Remove sleeve (038 or 037) from power rotor (044 or 063).

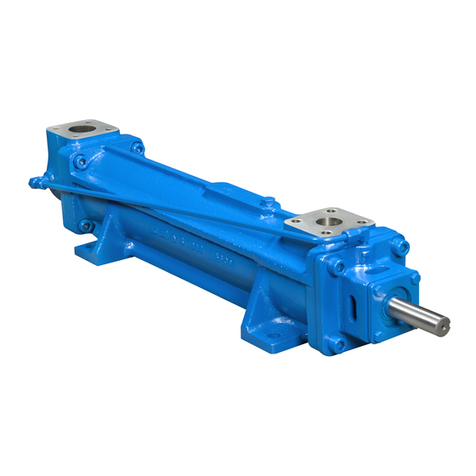

Assembly Procedures (Figures 3, 7, 8, 9 and 11)

NOTE: Prior to pump assembly, all parts should be cleaned and inspected for nicks and burrs.

Replace all worn or damaged parts. Imo Pump Division recommends automatic replacement

of O-rings (027, 028 and 038), gaskets (009), Dyna seal (007), ball bearing (049 or 015) and

mechanical seal (025) when these parts are disturbed from their previously installed position.

Refer to pump assembly drawings (Figures 3, 7, 8, 9), and List of Material (Table 4), during

assembly. Coat all parts with light lubricating oil to assist in assembly. Assembly procedures

for all A3D pumps equipped with mechanical seals are identical except when specifically

noted.

WARNING

When inspecting/servicing shaft seal and/or bearing, power rotor can be removed as a

subassembly with these components installed. Remove four (4) bearing retainer plate bolts

and retainer plate, and then remove power rotor sub-assembly. If for any reason pump is

disassembled further than this, it is possible idler rotor balance piston housings may fall off.

These idler rotor balance piston housings MUST be properly in place at reassembly. If idler

rotor balance piston housings are not properly installed on idler rotors, pump WILL

experience catastrophic failure.

Figures 3, 7, 8, 9 are basic pump assembly figures. For variations that may apply to your pump, see

Figure 10 for seal installation variations.

1. Install O-ring (028) in groove of rotor housing (024). (Figures 3, 7, 8, 9 and 11) Install O-rings (027) on

oil balance tube (026), and install oil balance tube (026) in suction end of rotor housing (024).

2. (Figures 3, 7, 8 and 11) Install O-rings (027 or 038) on oil balance tube (026 or 036), and install oil

balance tube (026 or 036) in discharge end of rotor housing (024).