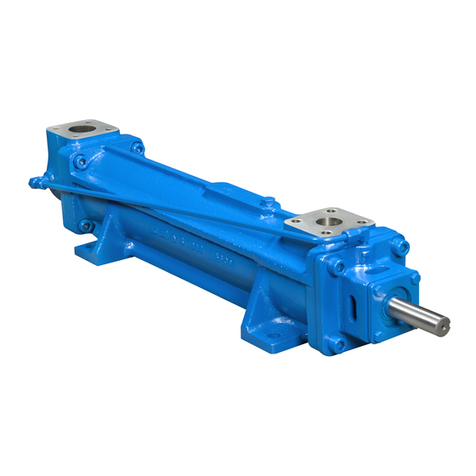

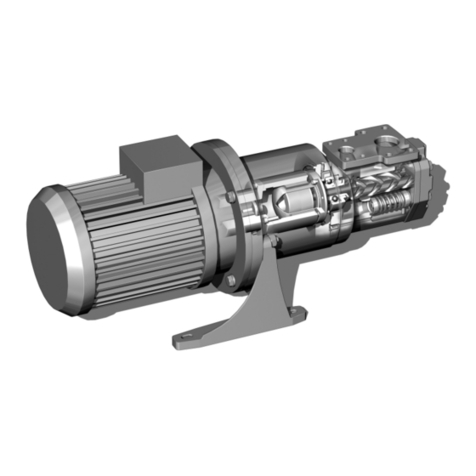

Pump Description

This instruction manual covers the D3EICS-162 pump.

The D3EICS-162 pump is a positive displacement, rotary screw pump consisting of a precision machined

housing that encloses a driven screw (power rotor) and two intermeshing following screws (idler rotors).

These screws, when rotating, form a succession of closures or cavities. As they rotate, the fluid is moved

axially from the inlet port to the outlet port in a continuous, uniform flow with minimum fluid pulsation and

pump noise. Fluid flowing through pump provides lubrication for moving parts. Normal rotation of pump is

clockwise as viewed from the shaft end. It is assumed by Imo that fluid this pump will be used on is not

hazardous in any way, nor is fluid considered flammable. Environmental or health risk associated with fluid

spillage or contact is not considered as part of Imo Pump's hazard analysis. Imo Pump must approve use

in any other service.

GENERAL INSTRUCTIONS

Instructions given herein cover generally operation and maintenance of subject equipment. Should any

questions arise which may not be answered specifically by these instructions, they should be referred to

Imo Pump for further detailed information and technical assistance.

This manual cannot possibly cover every situation connected with operation, adjustment, inspection, test,

overhaul and maintenance of equipment furnished. Every effort is made to prepare text of manual so that

engineering and design data is transformed into most easily understood wording. Imo Pump, in furnishing

this equipment and this manual, must presume that operating and maintenance personnel assigned

thereto have sufficient technical knowledge and experience to apply sound safety and operational

practices which may not be otherwise covered herein.

In applications where Imo Pump furnished equipment is to be integrated with a process or other

machinery, these instructions should be thoroughly reviewed to determine proper integration of equipment

into overall plant operational procedures. On critical or dangerous equipment, provide suitable safety and

emergency systems to protect personnel and property from injury due to pump malfunction. If pump

handles flammable, toxic, corrosive or explosive fluids, provide for safety in event of pump leakage or

malfunction.

WARNING

If installation, operation and maintenance instructions are not correctly and strictly followed and

observed, injury to personnel or serious damage to pump could result. Imo Pump cannot accept

responsibility for unsatisfactory performance or damage resulting from failure to comply with

instructions.

ORDERING INSTRUCTIONS

To order replacement pump, contact an Imo sales office or representative with pump model number and

serial number. This information can be found on pump nameplate and in this manual. Major and minor

kits are also available.

LIQUID LIMITATIONS

Never operate on water. Pump is designed for liquids having general characteristics of lubricating oil or

distillate fuel oils.

1