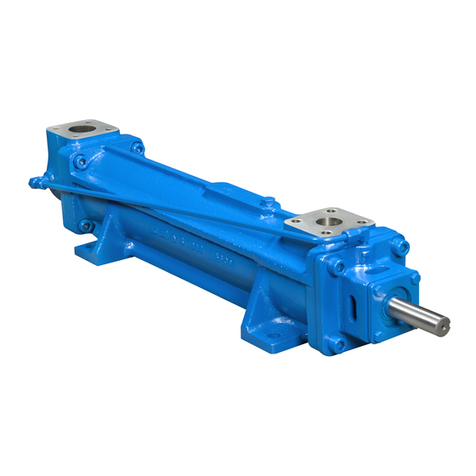

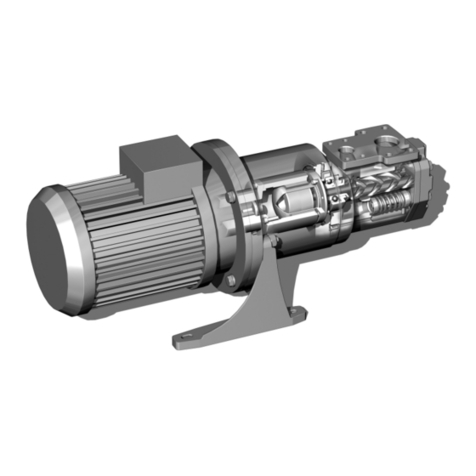

J. PUMP ASSEMBLY PROCEDURE

Notes: Prior to reassembly of pump, all parts should be cleaned and inspected for nicks and burrs.

Replace all worn or damaged parts. Imo Pump recommends automatic replacement of

gaskets, O-rings, bearings and mechanical seal when these parts are disturbed from their

previously installed positions. Coat all parts with light lubricating oil to assist in assembly.

Pump model covered in this instruction manual is provided with a Chesterton 180 cartridge type

mechanical seal equipped with Kalrez elastomers. Imo Pump recommends coating all pump

components with a silicone based lubricant during pump assembly.

If new rotor housings (8 & 10) are installed when performing Step 1, new anti-rotations pins (11) must

be installed. Anti-rotation pins are to be field fitted to each new housing to ensure housing maintains

alignment with pump case and opposite housing. If housing anti-rotation pins are not snugly fitted to

one housing, opposite housing may rotate out of position during pump operation and damage rotors.

To fit new anti-rotation pins, file or grind one or both pins flat surfaces until pin fits snugly into housing

slot. Do not over grind flats.

Step 1. Install jam nuts (25) and adjusting screws (19) to rotor housings (8 & 10). Install nuts and

screws loosely, do not tighten at this time.

Step 2. Install spacer (12) to pump case (1) bore, align opening in spacer with discharge port

opening. Align anti-rotation pin slot in housing to pin hole on side of case flange. Slide drive

end rotor housing (8) into pump case (1) inboard end. Repeat for non drive end rotor

housing (10) assuring that rotor housing end faces are fully seated against spacer (12)

faces. To assist in aligning housing bores, install idler rotors (14) into idler bores. Rotate

rotor housings until idlers slide back and forth freely without binding. When rotor housing

bores are aligned, install anti-rotation pins (11) per above note. Slide idler rotors back and

forth again ensure no binding exists. Install pipe plugs (7).

Step 3. Install shaft bushing (18) to inboard cover (17). Using anti-rotation stop pin (23) as a pilot

hole, drill a 7/16 – inch hole through the bushing. Make sure the bushing flange remains

seated against the inboard cover counter-bore when drilling. Remove the bushing from the

inboard cover and de-burr the drilling. Install bushing insert (57) and install bushing (18) in

inboard cover (17). Install stop pin (23) in inboard cover (17).

Step 4. Set the rotor housing adjusting screws by the following directions: Rotor housing adjusting

screws (19) at inboard and outboard ends of the pump should be set following the directions

outlined in Figures 2 and 3. To verify correct setting of adjusting screws (19), wipe bluing or

place fuse wire on adjusting screw heads and install inboard end cover (17) with gasket (4)

and bolts (2). Torque bolts to 50 ft-lbs. (67 Nm). Remove inboard end cover and verify

adjusting screw contact with inboard end cover.

DO NOT exceed .003” (.08 mm) squeeze on adjusting screws

When correct adjustment is confirmed, re-install gasket (4) and inboard cover (17) using bolts (2).

Torque bolts (2) to 155 + 10 ft-lbs. (189 + 13 Nm).

Repeat above procedure for outboard end cover (15) following directions outlined in Figure 3. When

correct adjustment is confirmed for the outboard end cover, proceed to Step 5 before final installation

of outboard cover (15).