Circutor MEG-1000 User manual

INSULATION GUARD

MEG-1000

(Code M15051)

INSTRUCTION MANUAL

(M98122001-20-19A)

(c) CIRCUTOR S.A.

MEG-1000

Page nº 1

Insulation guard MEG-1000

1.-BASIC INSTRUCTIONS

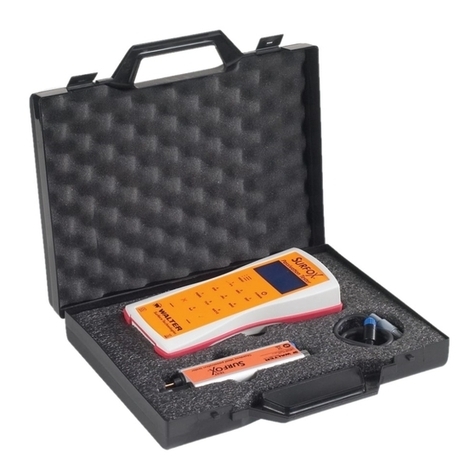

1.1.- Delivery spot check

This manual is issued to help all the MEG-1000 users to install and use it in order

to get the best from it. After receiving the unit please check the following points:

(a) Does this device corresponds to your order specifications?

(b) Check if any damage was done during the shipment process.

(c) Verify that it includes one instruction manual.

1.2.- Connection procedures

For the safe use of MEG-1000 is basic that people who install or handle it follow

the normal safety considerations and the diverse advises related in this manual.

Before connecting verify:

a. The power supply of the instrument (as default, 230 Va.c.

±

20 %)

corresponds to the rated voltage of the mains where you have to power it.

b. The voltage between phase and ground (points between which the insulating

level will be measured) have to be in normal conditions lower or equal than

600 Va.c.

c. Due to its operation mode, the device can only be used in A.C. networks.

MEG-1000

Page nº 2

2.- MAIN CHARACTERISTICS

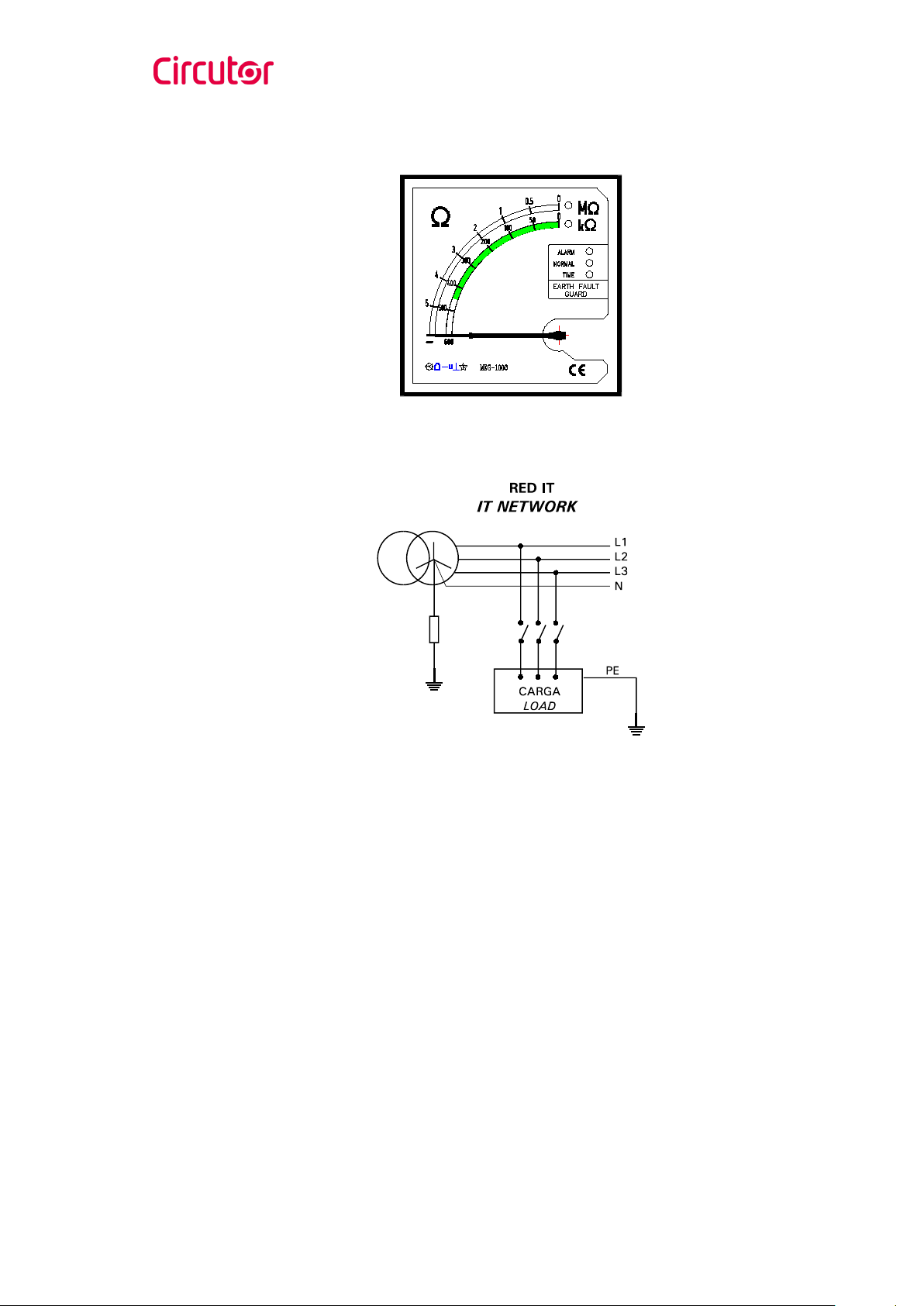

MEG-1000 is an electronic device that measures the insulating resistance between

the ground and one phase of an insulated neutral network (IT).

The insulating resistance value shows on a double scale galvanometer, which the

equipment selects automatically depending on the value.

MEG-1000

Page nº 3

Two output relays with temporisation adjustment are available: high resistance

relay (NORMAL) and low resistance relay (ALARM). The trip value and the delay

can be adjusted on each relay. The adjustment is done by means of three rear

push buttons (MODE,

↑

,

↓

). All adjustments are memorised even if the equipment

is not powered on.

The equipment has five led in the front plate, that indicate the measuring scale

and the output relays status in the operation mode; and the adjusted parameter in

the set-up mode.

Before operating the instrument read the INSTALLATION and ADJUST chapters

and choose the properly operation mode.

3.- INSTALLATION AND START-UP

The manual you hold in your hands contains information and warnings that the

user should respect in order to guarantee a proper operation of all the instrument

functions and keep its safety conditions.

The instrument must not be powered on and used until its definitive assembly on

the cabinet’s door.

If the instrument is not used as manufacturer’s specifications, the protection of

the instrument can be damaged.

When any protection failure is suspected to exist (for example, it presents external

visible damages), the instrument must be immediately powered off. In this case

contact a qualified service representative.

MEG-1000

Page nº 4

3.1.- INSTALLATION

Before applying AC power to the instrument, check the following points:

a.- Auxiliary voltage supply:230 Va.c. ±20 %

-Connection terminals: A1-A2.

-Instrument consumption: 2.8 VA.

b.-Measuring network structure: A.C. insulated or impedant neutral network (IT)

with phase-ground voltage ≤600 Va.c.

c.- Maximum permanent voltage between the measuring connection terminals

(E-R):1000 Va.c.*

-Connection terminals: E-R.

* This value allows the instrument to be protected from a phase fall on ground.

d.- Operation conditions:

- Working temperature: -20 to +50 ºC.

- Protection degree: Front plate: IP 52 / Connection terminals: IP 20.

- Indoor use.

e.-Safety: Designed to meet protection class I as per EN 61010.

Mounting:

The instrument is to be mounted on a panel. All connections keep inside the

cabinet.

MEG-1000

Page nº 5

Note that with the instrument powered on, the terminals could be dangerous to

touchi

ng and cover opening actions or elements removal may allow accessing

dangerous parts. Therefore, the instrument must not be used until this is

completely installed.

The instrument must be connected to a power supply circuit protected with gl

type (IEC 269 ) or M type fuses rated between 0.5 and 2 A. This circuit should be

provided with an automatic switch or any equivalent element to disconnect the

instrument from the power supply network. The supply and measuring voltage

circuits will be both connected through a wire with a minimum cross-section of 1

mm2.

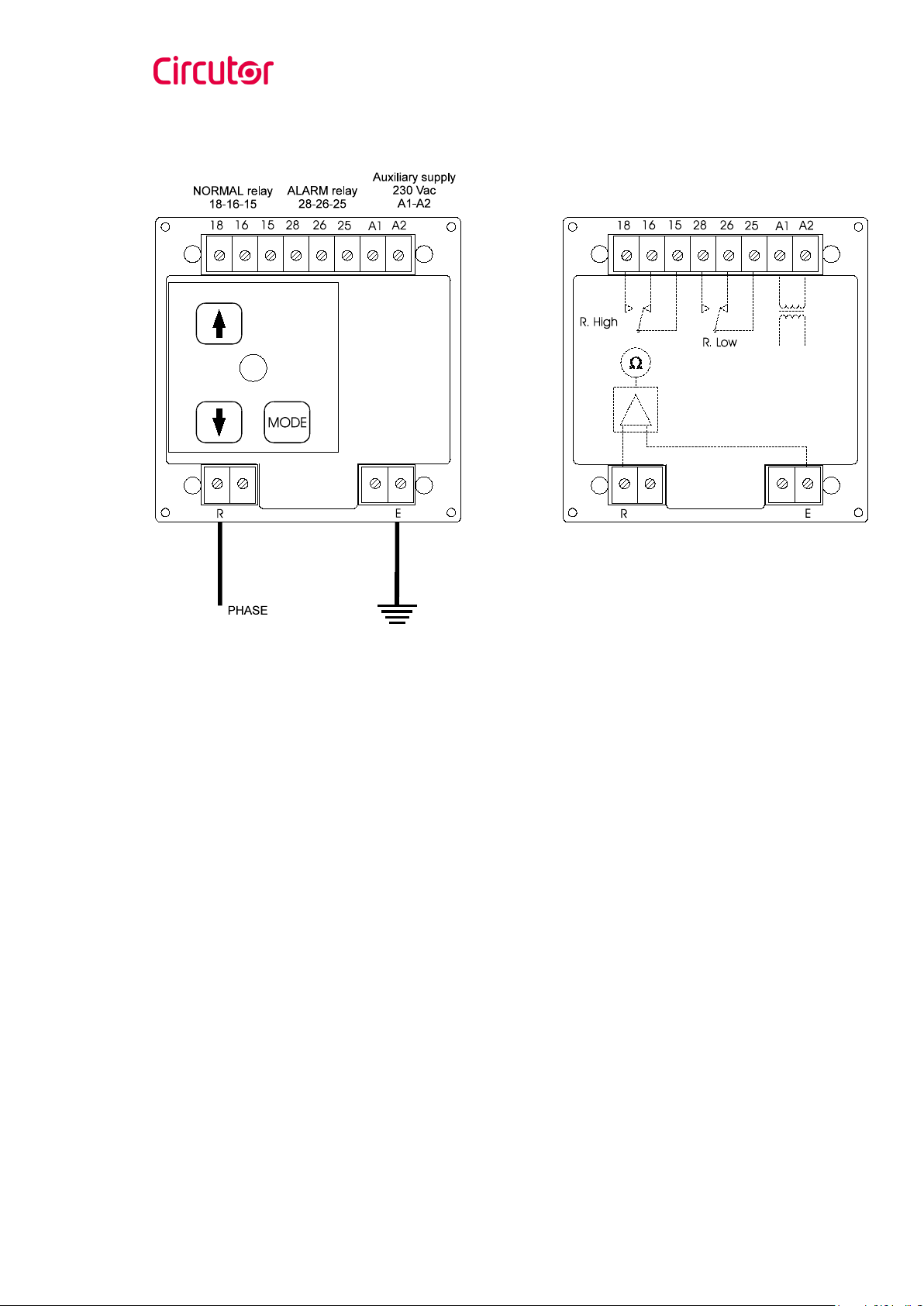

3.2.- MEG-1000 CONNECTION

3.2.1.- Connection terminals

Name

Concept

A1 -A2

Auxiliary supply of the device (230 Va.c. ±20 %)

E – R

Measuring of the insulation between a phase (R) and earth (E)

15 - 18 - 16

NORMAL relay with switchover contacts (free of voltage).

15-18: NO contact. 15-16: NC contact.

25 - 28 - 26 ALARM relay with switchover contacts (free of voltage).

25-28: NO contact. 25-26: NC contact.

MEG-1000

Page nº 6

3.2.2- Wiring diagram

MEG-1000

Page nº 7

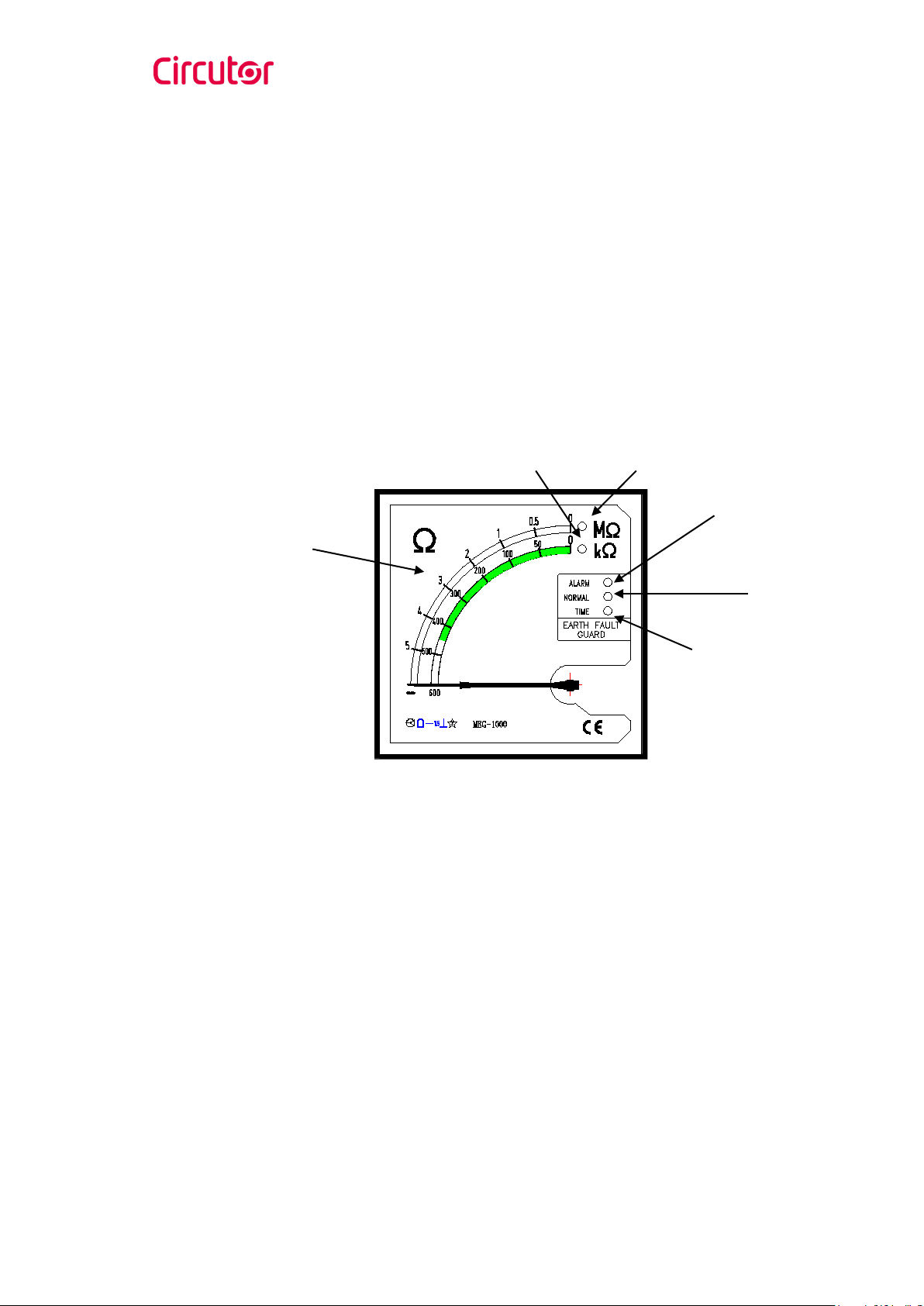

4.- OPERATION MODE

The user is informed about all the parameters by means of:

•Double scale galvanometer, that shows the value of the insulating resistance

(1).

•5 front plate leds:

-M

Ω

(2) and k

Ω

(3) leds indicate the measuring scale.

-ALARM (4) and NORMAL (5) leds indicate if the resistance is lower or

higher than the adjusted trip values.

-ALARM (4), NORMAL (5) and TIME (6) leds indicate the adjusted

parameter, when you are in adjusting mode.

(1)

(2)

(3)

(4)

(5)

(6)

MEG-1000

Page nº 8

The operation mode of the insulating guard is the following:

1. The device applies 24 Vd.c. voltage between the phase (R connection

terminal) and the ground (E connection terminal) and measures the

current.

2. The insulating resistance value, that is showed in the front plate

galvanometer (1), is obtained from the voltage and current values.

The instrument changes automatically the measuring scale, depending on the

value of the resistance. (2) and (3) yellow leds indicate whether the value is

referred to the MΩscale or to the kΩscale.

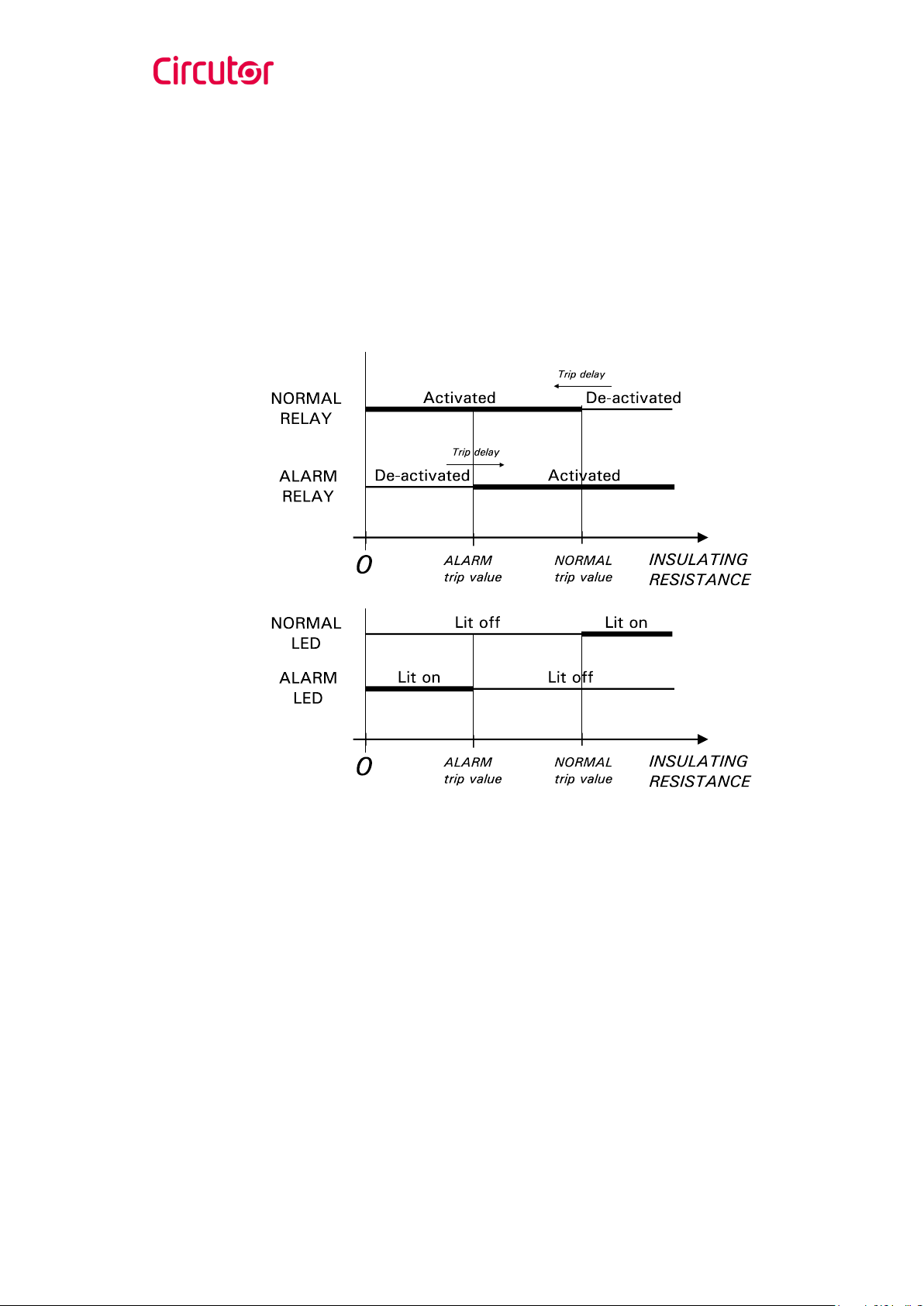

4.1.- OUTPUT RELAYS. OPERATION AND INDICATORS

Two output relays are available: ALARM relay and NORMAL relay. The trip value

and the delay time can be adjusted in each relay.

•NORMAL relay

While the insulating resistance is higher than the adjusted trip value the

NORMAL relay keeps de-activated. If the resistance being measured is lower

than the adjusted trip value the relay is activated after a set time.

Delay only takes place in relay activation; thus, when the resistance goes

beyond the relay trip value the relay is instantaneously de-activated.

NORMAL (5) green led lit on means that the insulating resistance is higher

than the NORMAL trip value.

MEG-1000

Page nº 9

•ALARM relay

While the insulating resistance is lower than the adjusted trip value the

ALARM relay keeps de-activated. If the resistance being measured is higher

than the adjusted trip value the relay is activated after a set time.

Delay only takes place in relay activation; thus, when the resistance lowers

under the relay trip value the relay is instantaneously de-activated.

ALARM (4) red led lit on means that the insulating resistance is lower than the

ALARM trip value.

In a chart:

MEG-1000

Page nº 10

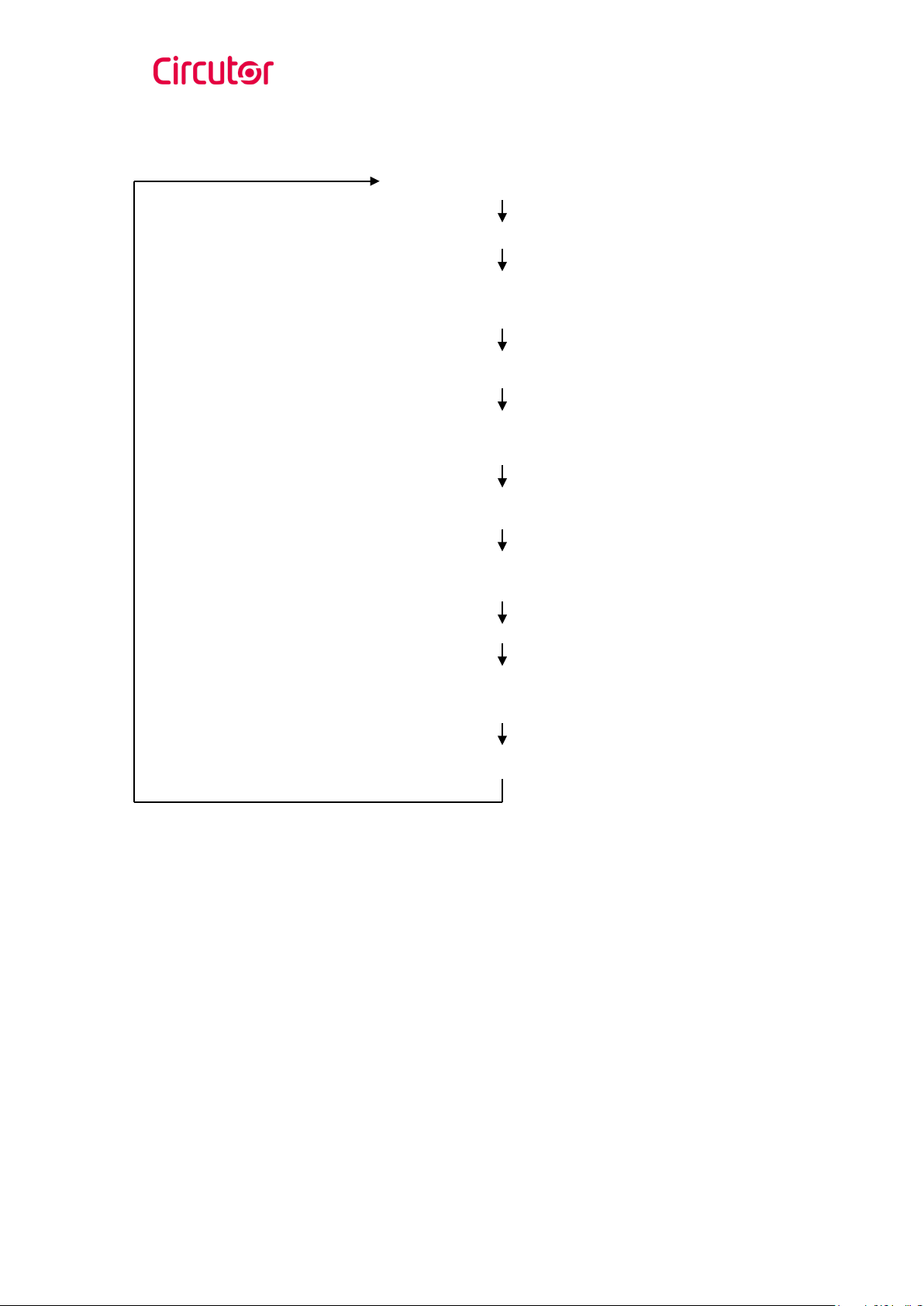

4.2.- EQUIPMENT ADJUSTMENT

The equipment has three rear push buttons in order to adjust the ALARM and

NORMAL values and their corresponding temporisation:

•MODE push button

MODE push button gives access to different adjustments and allows to pass

from one adjustment to the other.

•Upward

↑

and downward

↓

push buttons

These two buttons adjust the selected value through the indication needle on

the scale.

In the adjustment mode the equipment has a safety temporisation. After 10

seconds without pressing one of the push buttons, the equipment automatically

goes back to working mode, only updating the values entered pressing MODE (see

adjustment sequence in page 12).

The pointer and the scale leds (kΩ(2) and MΩ(3)) show the trip value when it is

being adjusted. Any value within the measuring range can be adjusted. For a

properly operation of the instrument, the NORMAL relay trip value should be

higher than the ALARM relay trip value.

MEG-1000

Page nº 11

The pointer and the scale leds (kΩ(2) and MΩ(3)) show the delay time when it is

being adjusted:

-ALARM relay temporisation. Each 100 kΩmeans a trip delay of 1

second. The active measuring scale is the kΩscale. The adjusting range

is within 0.1 and 3 s.

-NORMAL relay temporisation. If the active measuring scale is the kΩ

scale, each 100 kΩmeans a trip delay of 1 second. If the active

measuring scale is MΩ, each 1 MΩmeans a trip delay of 10 seconds.

The adjusting range is within 0.1 and 30 s.

Adjustment push buttons give access to different adjustments according to the

following sequence:

MEG-1000

Page nº 12

OPERATION MODE

Press MODE

ADJUST OF THE “ALARM” RELAY TRIP VALUE

ALARM led blinks. Adjust the value by means of

↑

and

↓

Press MODE

ADJUST OF THE “ALARM” RELAY DELAY TIME

ALARM and TIME leds blink. Adjust the value by means of

↑

and

↓

Press MODE

ADJUST OF THE “NORMAL” RELAY TRIP VALUE

NORMAL led blinks. Adjust the value by means of

↑

and

↓

Press MODE

ADJUST OF THE “NORMAL” RELAY DELAY TIME

NORMAL and TIME leds blink. Adjust the value by means of

↑

and

↓

Press MODE

MEG-1000

Page nº 13

•Quick adjustment mode

Besides of the explained adjusting mode, the instrument has a “quick

adjustment” where the next default values are loaded:

ALARM relay trip value ................... 440 kΩ

ALARM relay delay time ................. 0.5 s

NORMAL relay trip value ................ 3 MΩ

NORMAL relay delay time ............... 3 s

In order to load these values all three push buttons (MODE,

↑

and

↓

) must be

pressed at the same time for a minimum of 2 seconds; during that time all led

blink simultaneously. When the leds are off the equipment returns to working

mode.

NOTICE: When pressing the three push buttons do not press MODE button first, otherwise

the equipment will go to adjustment mode.

5.- TECHNICAL CHARACTERISTICS

Auxiliary supply

Voltage: 230 V ±20% 50...60 Hz.

Consumption: 2.8 VA.

Measuring circuit

Measuring range: within 0 and 500 kΩ, in kΩmeasuring scale.

within 0.5 and 5 MΩ, in MΩmeasuring scale.

Accuracy:1.5 class

Maximum permanent voltage between E and R connection terminals: 1000 Va.c.

Voltage applied by the equipment between E and R connection terminals in order

to measure the insulating resistance: 24 Vd.c.

MEG-1000

Page nº 14

Output relays

Relays: ALARM (15-16-18) and NORMAL (25-26-28).

Type: mechanical, 3 terminals, free of voltage.

Use: AC11 250 V/8 A

Isolation between contacts: 1000 Va.c.

between coil and contacts: 4000 Va.c.

Relays temporisation adjustment

ALARM relay: from 0.1 to 3 s.

NORMAL relay: from 0.1 to 30 s.

Accuracy: ±10 %.

Isolation

Between any connection terminal and the case: 2.5 kV 50 Hz for 1 min.

Insulating resistance between the inputs, the outputs and the power supply:

1 GΩ.

Insulating resistance between any connection terminal and the case: 1 GΩ.

Working conditions

Working temperature: -20 / +50ºC.

Use: indoor.

Constructive characteristics

Case material: ABS self-extinguishing (as per UL 94 V1) and high resistance

against impacts.

Protection degree: Case: IP 52 / Terminals: IP 20

Screwed transparent cover for the adjustment push buttons.

Safety

Category I , EN-61010.

Standards

IEC 255-5, IEC 1010-1, EN 61010-1, IEC 801-2, IEC 801-3, IEC 801-4.

MEG-1000

Page nº 15

Dimensions:

Panel hole: 92 mm+0.8 x 92 mm+0.8

7.-SAFETY CONSIDERATIONS

All installation specification described at the previous chapters named

INSTALLATION AND STARTUP and SPECIFICATIONS.

Note that with the instrument powered on, the terminals could be dangerous to

touching and cover opening actions or elements removal may allow accessing

dangerous parts. This instrument is factory-shipped at proper operation condition.

MEG-1000

Page nº 16

8.- MAINTENANCE

The MEG-1000 does not require any special maintenance. No adjustment,

maintenance or repairing action should be done over the instrument open and

powered and, should those actions are essential, high-qualified operators must

perform them.

Before any adjustment, replacement, maintenance or repairing operation is carried

out, the instrument must be disconnected from any power supply source.

When any protection failure is suspected to exist, the instrument must be

immediately put out of service. The instrument’s design allow a quick replacement

in case of any failure.

9.- TECHNICAL SERVICE

For any inquiry about the instrument performance or whether any failure happens,

contact to CIRCUTOR’s technical service.

CIRCUTOR S.A. - After sales service :902 449 459 (SPAIN) / (+34) 937 452 919

Vial Sant Jordi, s/n

08232 - Viladecavalls (Barcelona) - España

Tel: (+34) 973 452 000

Fax:(+34) 973 452 914

e-mail: sat@circutor.com–

This manual suits for next models

1

Table of contents

Other Circutor Test Equipment manuals