Table of contents:

1. PRECAUTIONS AND SAFETY MEASURES............................................................................3

1.1. PRELIMINARY INSTRUCTIONS........................................................................................3

1.2. DURING USE .....................................................................................................................4

1.3. AFTER USE........................................................................................................................4

1.4. DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY..................................4

2. GENERAL DESCRIPTION........................................................................................................5

2.1. INTRODUCTION ................................................................................................................5

2.2. INSTRUMENT FUNCTIONS...............................................................................................5

3. PREPARATION FOR USE........................................................................................................6

3.1. INITIAL CHECKS................................................................................................................6

3.2. INSTRUMENT POWER SUPPLY.......................................................................................6

3.3. CALIBRATION....................................................................................................................6

3.4. STORAGE ..........................................................................................................................6

4. NOMENCLATURE ....................................................................................................................7

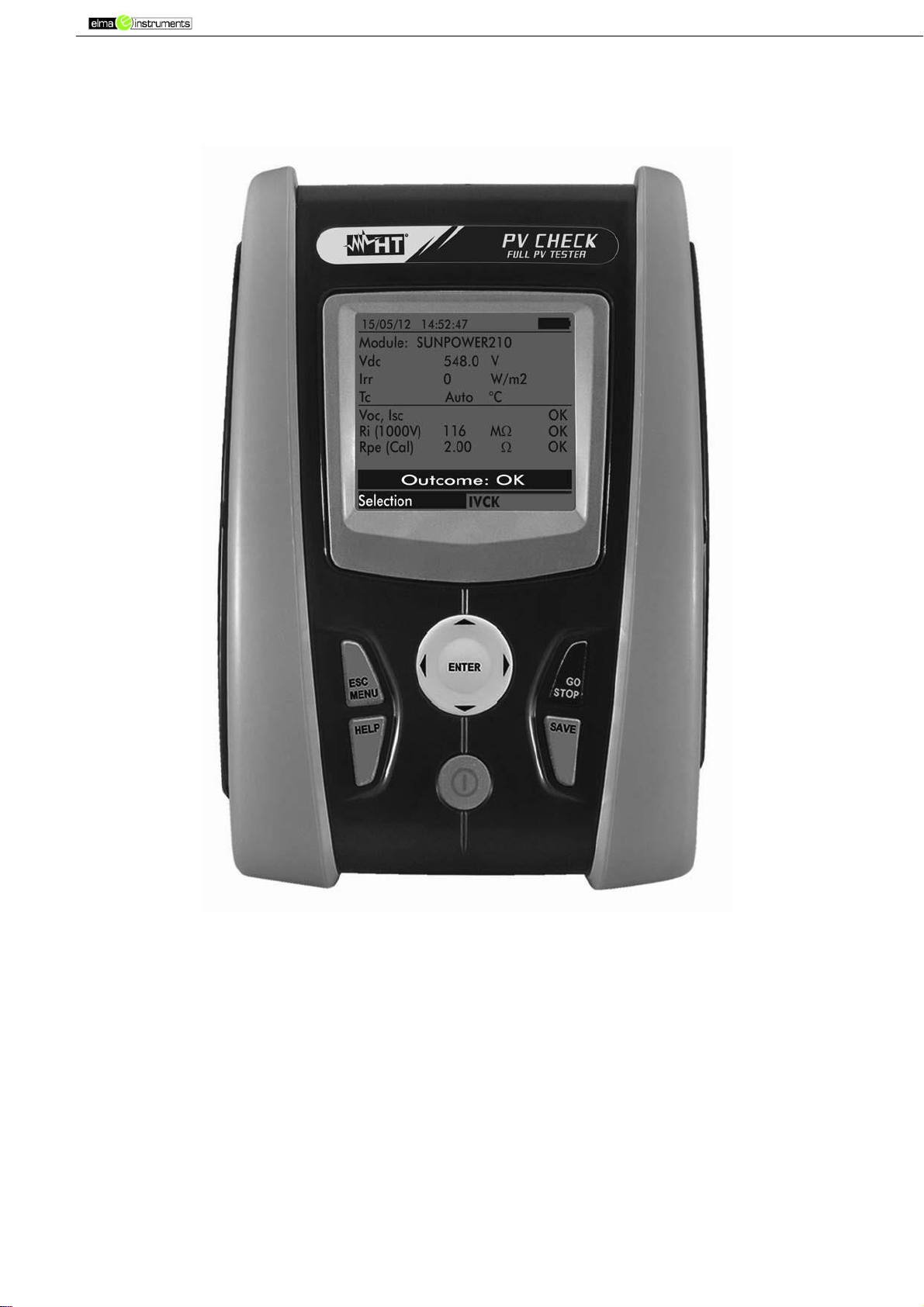

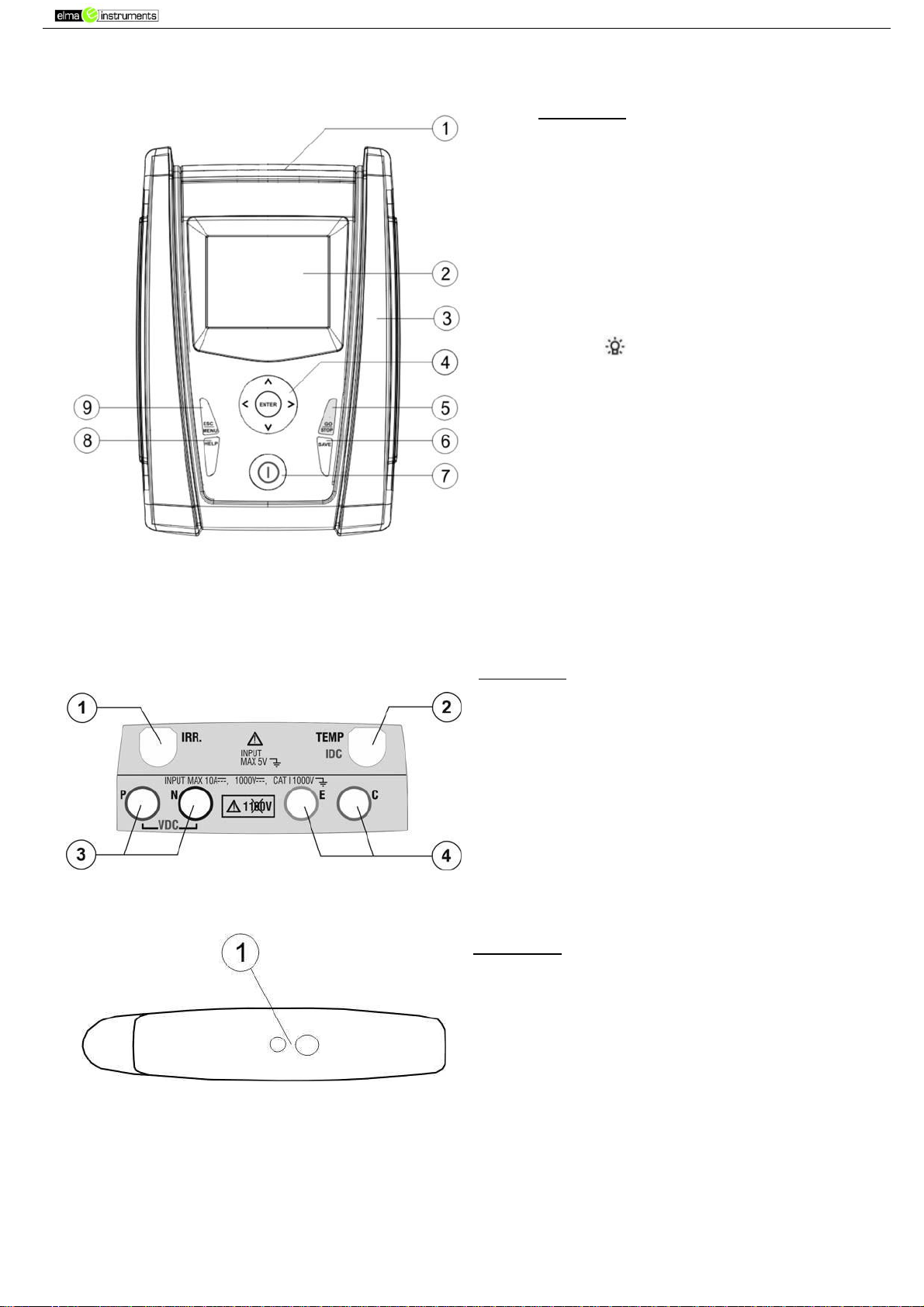

4.1. INSTRUMENT DESCRIPTION...........................................................................................7

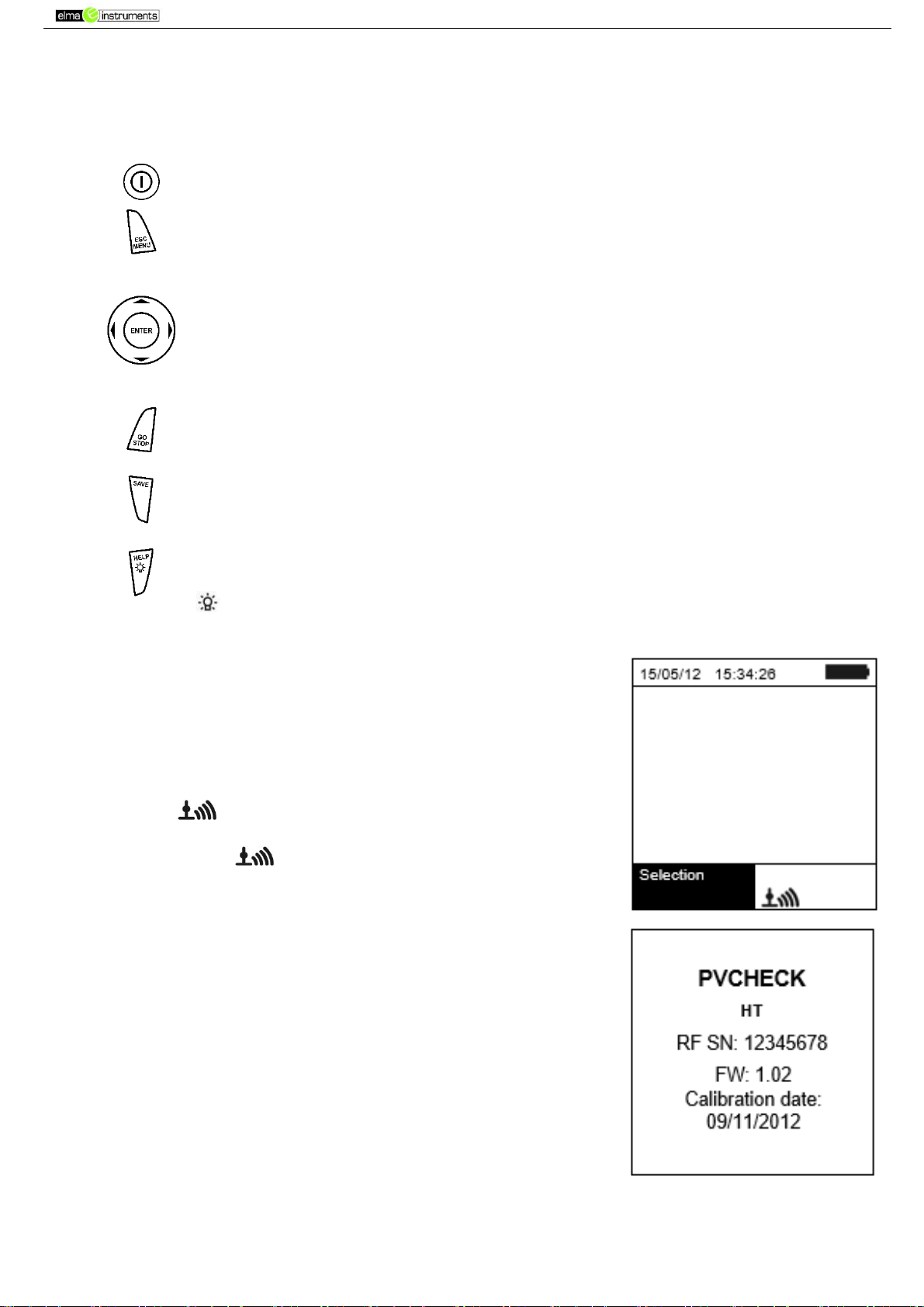

4.2. KEYBOARD DESCRIPTION...............................................................................................8

4.3. DISPLAY DESCRIPTION ...................................................................................................8

4.4. INITIAL SCREEN................................................................................................................8

5. GENERAL MENU......................................................................................................................9

5.1. SET –INSTRUMENT SETTINGS.......................................................................................9

5.1.1. General.........................................................................................................................9

5.1.2. Measuring unit............................................................................................................10

5.1.3. Date and time.............................................................................................................10

5.1.4. Remote unit/Pyranometer...........................................................................................10

5.1.5. Irradiance ...................................................................................................................11

5.1.6. DC Clamp...................................................................................................................11

5.2. EFF –EFFICIENCY TEST SETTINGS FOR PV INSTALLATIONS..................................12

5.2.1. Instrument settings.....................................................................................................12

5.2.2. System parameters ....................................................................................................13

5.2.3. Selection of the compensation relationship of temperature effects ............................14

5.3. LOWΩ–SETTINGS FOR CONTINUITY TEST WITH 200MA .........................................15

5.3.1. Instrument settings.....................................................................................................15

5.4. MΩ – SETTINGS FOR INSULATION MEASUREMENT...................................................15

5.4.1. Instrument settings.....................................................................................................15

5.5. IVCK –SETTINGS FOR IVCK QUICK TEST ...................................................................16

5.5.1. Instrument settings.....................................................................................................16

5.6. DB –DATABASE MODULE MANAGEMENT...................................................................18

5.6.1. How to define a new PV module.................................................................................19

5.6.2. How to modify an existing PV module........................................................................20

5.6.3. How to delete an existing PV module.........................................................................20

6. OPERATING INSTRUCTIONS................................................................................................21

6.1. MEASURING EFFICIENCY PV PLANTS BY USING REMOTE UNIT SOLAR-02 ...........21

6.2. MEASURING PARAMETERS ON PV PLANT WITHOUT USING SOLAR-02..................24