CITC Super Foam Dome 100216 User manual

SUPER FOAM DOMETM

Operating Instructions

P/N 100216 (120 VAC)

1

Thank you for purchasing this SUPER FOAM DOMETM

As you will notice from the table of contents, the manual for your new

product is quite extensive.

To guarantee perfect and successful work with this machine, please

take some time to read the manual carefully.

And finally, we believe you will enjoy years of great foam effects if you

care for and maintain your SUPER FOAM DOMETM.

CITC

1420 80th St. SW #D

Everett, WA 98203

(888) 786-CITC

www.citcfx.com

2

Contents

1. Set of Equipment Supplied 3

2. Accessories 3

3. Description 3

4. Safety Instructions 4

5. Operating the Super Foam DomeTM 5

5.1 Selecting the location

5.2 Electrical Power Requirements

5.3 Hooking things up

5.4 Operating the machine

5.5 Cleanup

5.6 Troubleshooting

6. Service and Maintenance 9

6.1 Super Foam DomeTM Pump Information

6.2 Getting the most from your Super

Foam DomeTM Pump

7. Technical Data 10

8. Limited Warranty Conditions 11

3

1. Set of Equipment Supplied

1 Super Foam DomeTM Unit

1 Super Foam DomeTM pump with fittings

4’ garden hose with male end for pump intake

GFI Box Assembly

25’ plastic tubing w/2ea push-con fittings

Kit: Gloves, safety goggles and bolts

Instruction booklet, catalog, warranty card

Shield set

Note: you will need to provide a 55 gal. plastic barrel with at

least a 2” opening

2. Accessories

Foam DomeTM Extra-Dry Fluid Concentrate P/N 150135

Note: mix 1 gal. concentrate with 50 gallons water

Please check whether all the products you ordered are supplied.

3. Description of the Super Foam DomeTM

The Super Foam DomeTM makes massive amounts of foam (500 cubic feet per minute

(14m3/min)) quickly and harmlessly with its high-powered quiet fan. It will actually fill a

20’ x 20’ x 6’ pit in less than 5 minutes. The Super Foam DomeTM uses a clean, harmless

and biodegradable fluid to make foam, which will last 5 to 10 minutes in dry conditions

and dry in six to eight hours. The white modulator produces a thick, high volume output

of foam. You can dance in it, ride through it and make clouds and snow effects with it.

The Super Foam DomeTM is great for nightclubs, amusement park rides and special

events. It works well in combination with colored lighting.

4

4. Safety instructions

WARNING: FAILURE TO FOLLOW ALL SAFETY RULES AND INSTRUCTIONS LISTED

BELOW MAY RESULT IN SERIOUS INJURY TO YOURSELF OR OTHER

PARTICIPANTS OF THIS EFFECT.

o RISK OF ELECTRICAL SHOCK:

1. Keep all electrical appliances away from the foam area.

2. Do not touch Super Foam DomeTM or GFI switching device when wet.

3. This device is to be used on normal distribution systems 120 VAC/60Hz/20A. This

device is designed to be used with the supplied Ground Fault Interrupter (GFI), which

has a grounding conductor. To reduce risk of electrical shock, connect only to a

properly grounded, grounding type receptacle. Never remove the third prong from the

plug on the GFI, the pump or the Super Foam DomeTM unit (fan).

4. Be aware of foam accumulations near the Super Foam DomeTM electrical

source/power box. Since the Super Foam DomeTM is a very high output unit capable

of extreme volumes of foam, place in an area that allows full release of foam from

nozzle (front outlet) in all directions.

o NOTES ON GROUND FAULT INTERRUPTER (GFI):

1. This GFI is a safety device; do not use the test and reset buttons as an on/off switch.

2. Ground Fault Circuit Interrupters (GFI) do not protect against electrical shock resulting

from contact with both current-carrying conductors of an electrical circuit.

3. Do not connect an extension cord longer than 100 feet to the GFI output to avoid the

possibility of nuisance tripping.

4. Test frequently and before each use to ensure proper operation, by following

operating instructions in section 3.2.

5. DO NOT USE where water may enter GFI case.

6. DO NOT MODIFY OR IMMERSE this device.

7. DO NOT EXCEED electrical rating.

oSLIP HAZARD: The accumulation of foam on a slick floor can create a dangerous

environment, which could cause someone to fall. For safety reasons, the makers of the

Super Foam DomeTM require using this machine or Foam DomeTM Fluid on a non-slip

surface such as indoor/outdoor carpeting, turf, or asphalt.

o GLASS: Do not allow glassware or breakables in foam area. If glass breaks in foam

area, evacuate all persons immediately until cleaned up.

o SUPERVISION: No pushing, shoving or horseplay allowed. No diving, running or body

bowling. Intoxicated individuals should leave foam area.

o EXPOSURE TO FOAM: Avoid prolonged eye contact. Wash eyes with water if irritated.

Always rinse body after having contact with foam just as you would after contact with

soap, to prevent excess drying of skin. If irritation or allergic reaction occurs, individual

should leave foam area immediately and wash irritated area. Do not wear soaked

clothing for more than 4 hours without rinsing.

5

5. Operating the Super Foam DomeTM

5.1 Selecting the location

1. Make sure unit is in a well-supported and secure location before supplying power and

fluid to unit.

2. The height of the machine above the drum decides how fast it will pump fluid. The higher

the machine, the slower the fluid will flow through to the Super Foam DomeTM. This unit

is designed to be suspended 12’ to 16’ above the floor with the fluid drum on the floor.

Never place fluid reservoir level with or higher than the Super Foam DomeTM, as this will

cause siphoning and dripping and will not stop fluid when turned off.

5.2 Electrical Power Requirements

1. This machine requires a grounded 120VAC/20A circuit for operation. The Super Foam

DomeTM draws approximately 13 amps at 120 VAC. During Super Foam DomeTM

operation this circuit should be dedicated to the Super Foam DomeTM. If you have any

doubts about the capacity or grounding of your existing circuits, consult a qualified

electrician.

2. You must have both units connected through the Ground Fault Interrupter (GFI) in

order to use this device.

1. Plug GFI into a well-grounded 120VAC/20A circuit. If you have any doubt about the

circuit’s safety ground, plug-in testers are available to test the outlet. If in doubt,

discontinue trying to power this unit until the outlet can be checked by an electrician.

2. With the power switch in the OFF position, verify that the red LED in the plug turns on.

3. Press the test button, and verify that the red LED in the plug turns off.

4. Press and release the reset button, and verify that the red LED indicator turns on.

5. The GFI is now ready for use.

WARNING: If the GFI fails to trip (turn off) when the test button is pressed, or fails to

reset (turn on), the device is defective and should be replaced.

o NOTE: If the GFI tests properly without the Super Foam Dome™ turned on, but trips

each time the unit is powered up, then the Super Foam Dome™ has a ground fault

condition and needs to be repaired or replaced. DO NOT BYPASS THE GFI IF THIS

CONDITION OCCURS, A REAL SHOCK HAZARD MAY EXIST.

6

5.3 Hooking things up

1. Unpack crate and remove packing materials. Inspect Super Foam DomeTM, pump and

GFI for any damage and notify CITC immediately if any problems occurred during

shipping.

2. Hanging clamp is located behind the handle in the back. The safety cable is for properly

hanging the unit. Locate in open area for foam to drop to the floor. Before hanging, test

the fan in the Super Foam DomeTM unit to check for quiet operation. Hang vertically so

the fluid nozzle is facing down toward the floor. The fan unit should spin freely without

rubbing.

3. Mix fluid according to instructions. Never use concentrated fluid in this machine! Use

either a plastic 50-55 gal. drum (metal will rust) or a clean trash container heavy enough

to hold that much water. Note: Water weight is 500 lbs! While using eye protection and

rubber gloves, clean container if necessary and fill with 50-55 gals. of warm water first,

then add the 1 gallon of concentrate (use 12.8 oz of concentrate for 5 gal test) to the

warm water. Mix by stirring without agitating. See warning statement (below) about

proper safety features.

WARNING when mixing Concentrate: USE ONLY AS DIRECTED.

Handle concentrate with care. Avoid contact with eyes. Concentrate is an irritant

to eyes. Wear eye protection and gloves when mixing. If concentrate contacts eyes,

immediately wash with plenty of water for 15 minutes, while lifting eyelids. Consult a

physician. Prolonged contact with skin may cause irritation. Wash with water. If clothing

is wet with material, change to clean clothes and wash affected skin. Not food quality.

Do not digest. If digested, treat as dish soap. Odor from this product may be irritating to

some individuals. Discontinue use and remove to fresh air. As with all surfactants, care

must be used at all times. Contact CITC for further questions or copies of the MSDS at 1-

888-786-CITC or see it posted on our website at www.citcfx.com under MSDS.

4. Attach the ¾” garden hose to the pump and lower the opposite end of the hose into

drum full of Super Foam DomeTM Fluid. Be sure rubber washers are always in place

inside the hose connection before connecting. DO NOT SUBMERGE THIS PUMP.

5. Run the tubing from the pump to the Super Foam DomeTM.The pump and the Super

Foam DomeTM should then both be plugged into the GFI. Be sure the power switch is in

the OFF position before plugging in the pump. When powering up the Super Foam

DomeTM unit (fan), note that the fluid will take some time to travel out before foam is

produced. Never plug the pump into a wall outlet. It must be plugged into the outlet on

the GFI to insure that the pump does not come on unless the fan is on.

7

6. It is important to deploy the plastic shield

enclosed in the unit. This plastic shield

prevents most of the foam or bubbles

from being sucked back inside the Super

Foam DomeTM fan intake. Slide the

shield half #1 onto the fan outlet, behind

the modulator (sock) and under the tip of

the molded handle located on the blower

and molded strip under machine. Slide

the shield half #2 onto the other side so

that they come together. A hole lines up

with hole from the other shield. Place the

small bolt through the hole to connect the

washer and nut. Tighten the nut securely,

locking the shield in place.

7. Make sure unit is supported and secure before supplying power and fluid to unit. Shield

should be facing the floor with the modulator (sock) pointing straight down. Never point

modulator upward as this would cause electrical damage and ruin your unit.

5.4 Operating the machine

1. Review electrical connections: The red power switch should be OFF. The GFI should be

plugged into a properly grounded outlet. Plug both the Super Foam DomeTM and the

pump from the barrel into the GFI. Both units need to always come on at the same time.

o Never turn on the pump without the Super Foam DomeTM fan. This will cause

fluid to pour from fan area to floor. Unplug the pump if you need to test only the fan.

When done, switch GFI off and plug the pump back in to GFI to operate the system.

Never operate without all lines and hoses attached.

2. The Super Foam DomeTM and the pump will both turn on when you switch on the red

power switch on the GFI. The machine will slowly start spraying small amounts of fluid,

saturating the modulator with fluid. Once saturated, large volumes of foam will appear

and continue to increase in size all around the modulator.

3. Do not run pump if fluid is unavailable. This may damage the pump.

4. The pump uses 5 gallons in about 5 minutes. A 55-gallon drum of fluid will last about 55

minutes. The Super Foam DomeTM will produce 500 cubic feet (14m3) per minute of

foam, filling a 20’ x 20’ x 6’ volume in less than five minutes.

8

5.5 Clean up

1 Place a bucket under the modulator to catch falling water, and run 1-gallon fresh water

through system each night to clean and freshen equipment. Unplug GFI from power

source. Wipe off output end and any excess foam. Make sure no fluid has dripped or

splashed on the electrical components. Blow-dry with an air hose if necessary.

2 Clean up of the foam is easy. Some water may need to be mopped and removed. Use of

a wet/dry vacuum may be needed.

3 Foam DomeTM Fluid is non-toxic, clean, easy to use and can be very fluffy. Fluid will not

damage clothing.

5.6 Troubleshooting

o If unit does not start: Check electrical power for properly grounded outlet. Check

GFCI box (see instructions in section 3.2). Check power cord going to GFCI box for

cuts or separation.

o If the fan is not operating: Check Fan separately by disconnecting the pump from

the GFCI. Does the fan rotate? If foam has gotten inside the unit, disconnect the

hose and blow out the unit with an air line. If not available, discontinue use until

completely dry.

o If the fan rotates, but is not very fast: Power loss will cause this unit to not function

properly. Verify that any extension cords are 12 awg or larger and less than 100 feet

long. Unplug other equipment that is on the same circuit.

o If you are not getting fluid to the Super Foam DomeTM unit: Check pump

separately by disconnecting from the hose and by disconnecting the fan from the

GFCI and turning on the unit for a short time. If pump does not work, check another

power outlet. If it still does not work, replace unit by calling for assistance.

o If the unit was foaming, then stops:

o Check the intake hose of the pump in the bottom of the barrel. Certify that there is

sufficient fluid. Keep the barrel clean and occasionally check to be sure dirt is not

getting inside the barrel, as this will clog the pump. Shut off all power, disconnect

the pump from the GFCI and remove the pump from the barrel. Disconnect the

hoses and check for debris or dirt that may be clogging the unit. Connect the

suction hose to the pump and plug in the pump separately to see the output,

catching the output in a bucket. The output should be open and free.

o Check the nylon tubing going to the Super Foam DomeTM unit. If it is crimped or

bent in a 90 degree angle, change the tubing.

o Check the connection to the Super Foam DomeTM unit. There is a screen that will

capture dirt from entering the nozzle. Disconnect the tubing and clean the screen

at the connection. Reconnect and try again.

9

o If still clogged at the nozzle, remove unit to outside location and connect a high

pressure hose to the nozzle connection. While holding the unit in its hung position

so the water will run down and out of the unit, (not up or in the unit), turn on the

water to pressurize the nozzle inside and clean the nozzle. You should have

plenty of pressure and volume to remove any clogged item. If still clogged, send

the unit back to be serviced.

o If the modulator appears to yellow or change color: Dark areas that are warm are

easy for bacteria to grow. Rinse and let the fan blow out the modulator after each

use. Never leave the modulator (sock) wet or dripping with solution.

6. Service and Maintenance

6.1 Super Foam DomeTM Pump Information

The Super Foam DomeTM pump has built-in thermal overload protection, which means

the unit will automatically shut-off when it overheats. Once cooled down, it will reset and

is ready to pump again.

Power cord must always be plugged into the GFI. NEVER place pump in fluid!

Unplug or switch off the unit when fluid has drained to 1/8". Running the pump dry may

damage the pump.

6.2 Getting the most from your Super Foam DomeTM Pump

Optimum performance is reached at a maximum 25' tubing length, although the pump

continues to work at longer lengths.

10

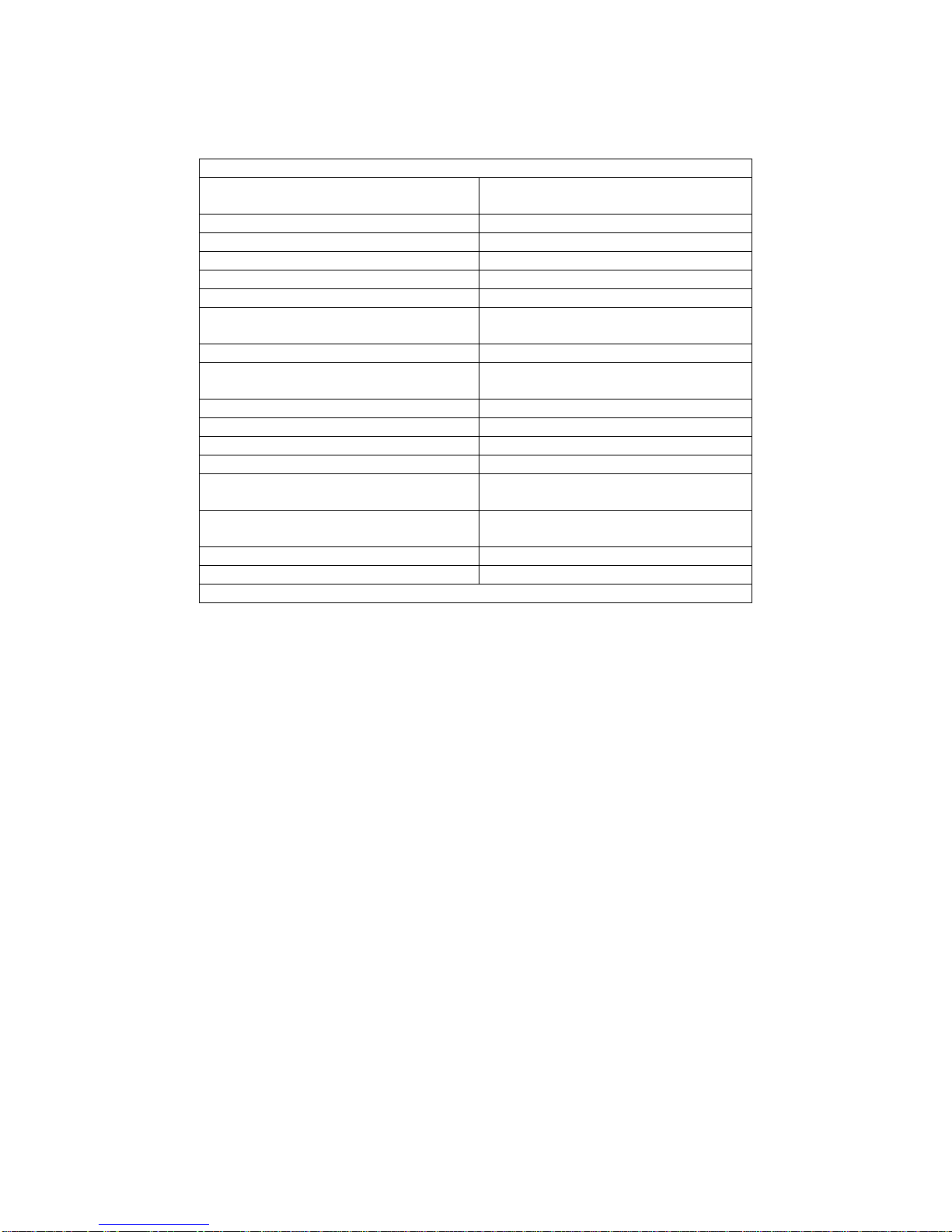

7. Technical Data

Super Foam DomeTM 120V Technical Data P/N 100216

Super Foam DomeTM Dimensions

19” x 19” x 19” (48cm x 48cm x

48cm)

Super Foam DomeTM Weight

56 lbs (25.5 kg) (including pump)

Shipping Dimensions

25” x 25” x 25” (63 x 63 x 63cm)

Shipping Weight

65 lbs (29.5 kg)

Super Foam DomeTM Power

1 hp: 120 VAC, 60 Hz, 13 A

Super Foam DomeTM Power Cord

6’ (1.9 m)

GFI Switch Box

Four outlets with lighted power

switch

GFI Power Cord

6’ (1.9m)

Fluid pump

High-pressure diaphragm pump

45 psi (3.1 bar) / 1.4gpm (5.3 lpm)

Pump Power

120 VAC, 60 Hz, 0.7 A

Pump Power Cord

6ft (1.9 m)

Type of Fluid

Super Foam DomeTM fluid/water mix

Output

500 cubic feet per minute (14m3/min)

Fluid Consumption

Approx 1 gallon per minute (3.8

l/min)

Hose

¾” x 4’ (1.4cm x 1.2m) pump hose

5/8” x 25’ (1cm x 7.6m) plastic tubing

Barrel supplied by user

55 gallon (209 liter) plastic

Limited Warranty

One year

Rev: 03/19/2018

11

8. One Year Limited Warranty

Model: ________________ Purchased on (date): ________________

Serial number: ________________ Purchased from: ________________

Congratulations!

You can now look forward to many years of reliable operation and outstanding performance.

Thank you for making CITC your personal choice in special effects equipment. Please take

a moment to fill out the top of this warranty, and then keep it – with the receipt – in a safe

place.

If you would like to receive information about specials, sales, and new products, please log

on to www.citcfx.com and click on the “Contact Us” link.

We appreciate your business, and wish to provide you with a quality product that will serve

you for many years to come. Once again, thank you for choosing CITC, and enjoy your new

entertainment product!

LIMITED WARRANTY CONDITIONS

This limited warranty guarantees to the original purchaser that this product shall be free of

defects in material and workmanship, under normal use, for a period of one year from the

date of purchase shown on the sales receipt. This warranty covers parts and labor providing

the product is returned to CITC in the original shipping carton and packaging. The warranty

for electrical is a (90) NINETY DAY limited warranty.

Damage resulting from shipping, accidents, misuse, negligence, unauthorized repairs or

modification is not covered by this warranty. Using any fluid other than what is

recommended for this machine will void warranty. No liability is accepted for injury or for

loss, damage or expense resulting from any interruption whatsoever in the operation of the

product or from any consequential loss arising there from. No liability is accepted for normal

wear and tear.

We wish to satisfy YOU, our customer, and have implemented many measures to prevent

problems and assure customer satisfaction. However, should you need a missing part or

have a functional problem with your product, please call:

(888) 786-CITC, from 7:30 am – 4:00 pm (Pacific Time), Monday – Friday, except for

holidays. Our customer service department will respond to your problems immediately.

Subject to the following conditions, CITC will repair any defect or fault in the unit if it is

caused by a proven factory defect within one year of delivery to the end user.

Insignificant deviations of the regular product quality does not guarantee replacement

rights, nor do faults or defects caused by water, by generally abnormal environment

conditions or Force Majeure:

1. Faulty parts or equipment will be repaired or replaced (manufacturer’s choice) with

correct parts. Faulty units must be shipped to CITC at customer’s expense. Call for

an RMA# - AN RMA# MUST COME WITH THE UNIT. Payment arrangements for

repair must be made before receiving your RMA#, in case the unit is not covered

under this limited warranty.

2. Repairs/replacements will only be made with the approval of the customer.

12

3. Exposure to outside elements voids Warranty. Unit cannot be used outdoors or in wet

weather without complete protection against the elements. Even then, high salty or

humid conditions will cause instant corrosion of connectors and will void Warranty.

4. The customer loses all rights for limited warranty services if any repairs or

adjustments are done to the units by unauthorized persons, and/or if spare parts are

used, which are not approved by CITC. The right of limited warranty service is also

lost if a fluid other than appropriate CITC fluid has been used or if units are sent in

without first emptying the equipment of fluid.

5. Freight costs to and from CITC, when under the limited warranty services, are the

responsibility of the customer. Customer must place appropriate insurance on return

of product. However, if product is returned due to factory defect within the first year,

CITC will cover the cost of returning the repaired unit to the customer.

6. Limited warranty services do not cause an extension of the limited warranty period or

the start of a new limited warranty period. The warranty of replaced parts ends with

the limited warranty period of the whole unit.

7. Further claims, especially for damages, losses etc. outside the unit are excluded.

Send unit to: CITC

RMA # XXXXXXX

1420 80th St. SW #D

Everett, WA 98203

Tel: (888) 786-CITC or (425) 776-4950

Fax: (425) 776-5129

Website: www.citcfx.com

E-mail: info@citcfx.com

Find us on Facebook!

www.facebook.com/CITCFX

March 19, 2018

Table of contents

Other CITC Dj Equipment manuals

CITC

CITC Bubble-Max X2 User manual

CITC

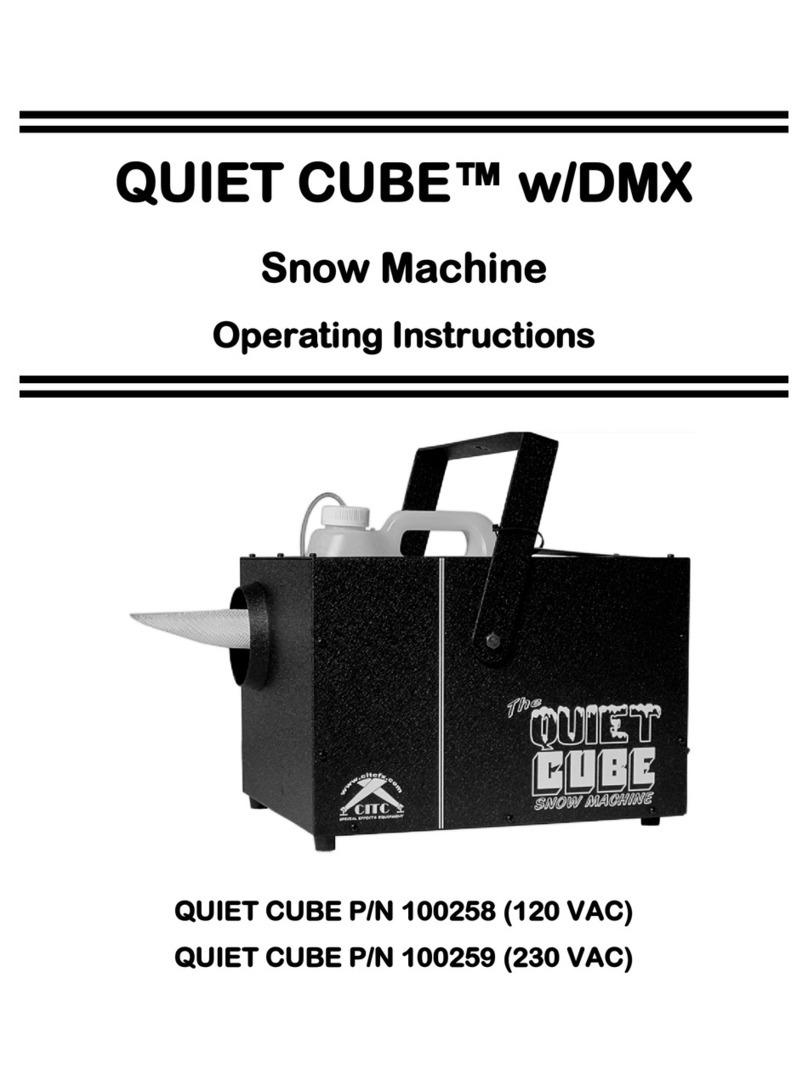

CITC QUIET CUBE 100258 User manual

CITC

CITC BUBBLE-MAX-SYSTEM User manual

CITC

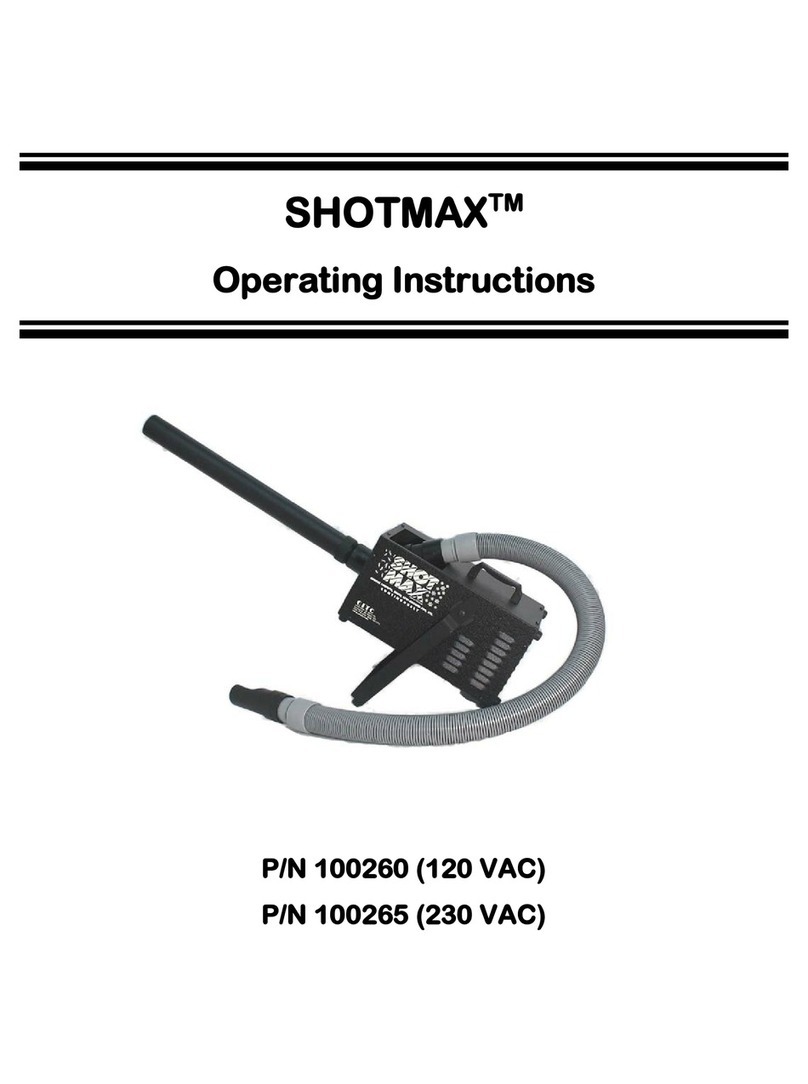

CITC ShotMax 100260 User manual

CITC

CITC Super Foam Dome 100217 User manual

CITC

CITC LITTLE BLIZZARD User manual

CITC

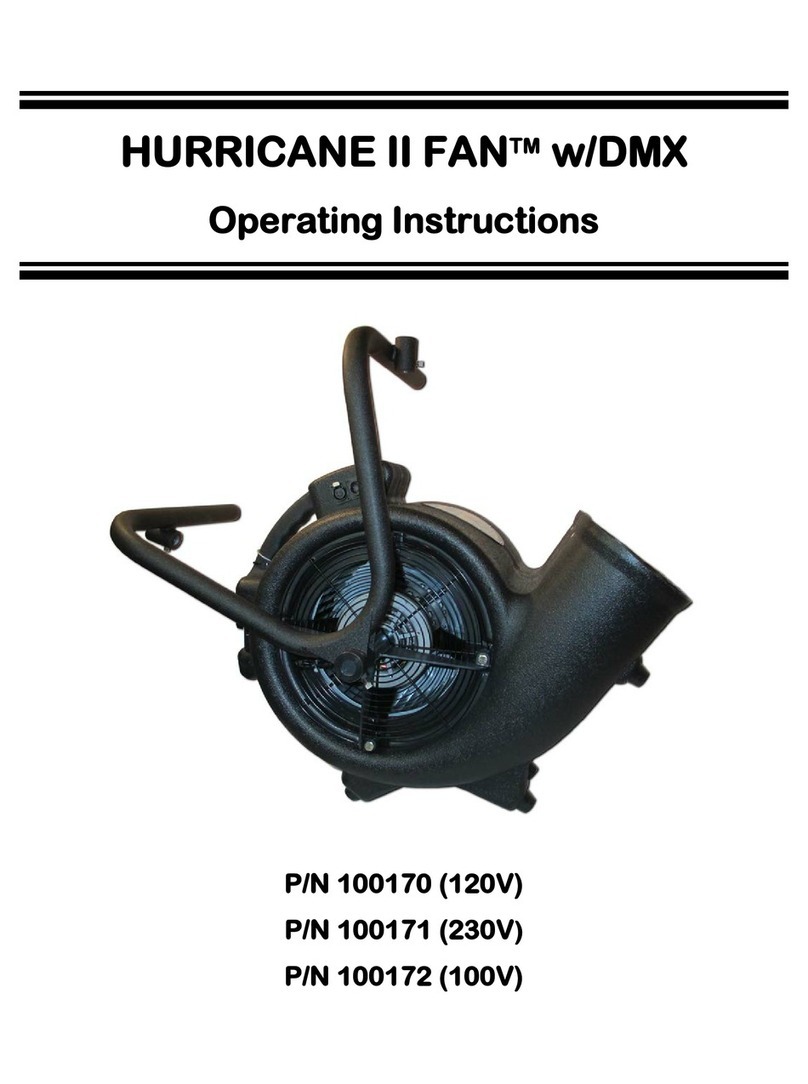

CITC Hurricane II Fan 100170 User manual

CITC

CITC LITTLE BLIZZARD XT 100256 User manual

CITC

CITC LITTLE BLIZZARD XT 100255 User manual

CITC

CITC BUBBLE BUDDY User manual

Popular Dj Equipment manuals by other brands

Beamz

Beamz SHOWBAR FREE user manual

Show Atelier

Show Atelier DIAPro ColorWash Magic manual

Martin

Martin THRILL Compact PAR 64 LED user guide

Coemar

Coemar Reflection LEDko FullSpectrum 6 instruction manual

Robe

Robe Robin Tarrantula TW user manual

Nightowl Stage Lighting

Nightowl Stage Lighting JT2410RGBW manual