citerm

HEATING SYSTEMS

9

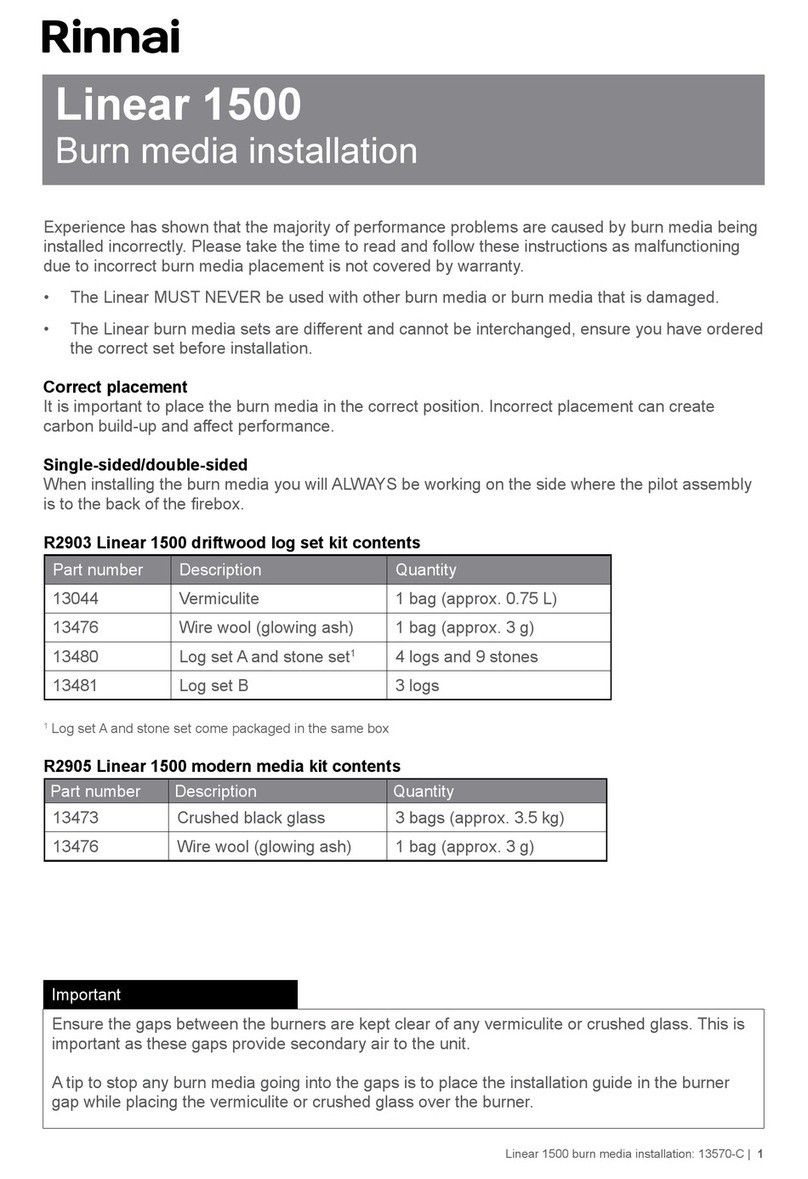

Malfunction Possible Cause Remedy

Burner does not ignite

or Flame interrups and

stops

AHeating oil is not combustible due to

sludge or water contamination

b Oil tank empty

c Oil level in burn tank too high

d Oil level in burner tank too low

e Filter, feeding pump lter clloged, oil or

air pipes defective

fSolenold valve feedingpump defective

gNozzle clogged or defective

hFeeding pump blocked

iNo current

jMotor defective

k Overheat thermostat has triggered

l Overheat thermostat continues triggering

mPhoto cell dirty or not pluggend in cor

rectly

nBurner control defective

oNo ignition

pNo comresed air

qCompresed air too iow

rSolenoid valve defective

sCompressor or air pipe defective

t Oil too viscous from frost

uDistance between storage tank and

burner to long

vBurner too big or set too high

APoen drain tap of burner tank. Drain

sludge and water or use better heating

oil

b Rell with oil

cCorrect oil level by draining through

drain tap and readjust if necessary.

Float-switch leve setting

d Correct oil level (rell) Clean feeding

pump lter

e Clean lter, feeding pump lter and

pipes or repair

fCheck or raplace solenoid valve

feedingpump

gClean or replace nozzle

h Remove feeding pumpand clean gear

wheel

iSwitch on plug coupling at burner to

heater

k Unlok overheat thermostat

iChange temperature regulator

mClean photo cell, plug it in correctly,

replace if defective

n Replace burner control

oAdjust ignition electrodes and replace

if necessary. Check transformer and

ignition leads

pConect compressed air and adjust

pressure

qVerify the compressed air at Compres

sor (not below 2 bar)

rCheck solenoid valve and replace if

necessary

sCheck compressor and air pipe and

repair it

tInsulate tank and oil tubes

uMount an additional feeding pump

v Replace oveheat thermostat at heater

and reduce heat load of burner

Burner ignites to late

aCartrige heater and thermocouple in

burner tank incrused or defective aClean catridge feeding and at thermo

couple in burner tank or replace

No oil supply to the

burner tank

aFeeding pump dirty

bFilter at the suction line is clogged aClean feeding pump strainer

b Clean lter

Nozzle clogged or

carbonized

aFlame ring falsely set

bToo muchor too less compressed air

cToo little ventilation in the heating room

a Correct measuring of the ame ring

bCorrect gauge pressure

cMake ventilation openings big enough

Each readjustment of quantity, primary or secondary air requires an exaust measuring and adjust-

ment to optimum values- see at „factory setting“

Malfunction- Possible cause - Remedy