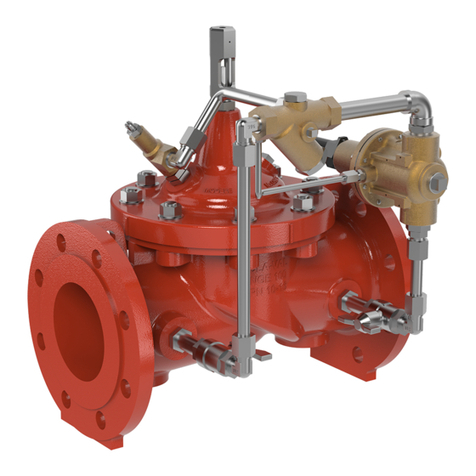

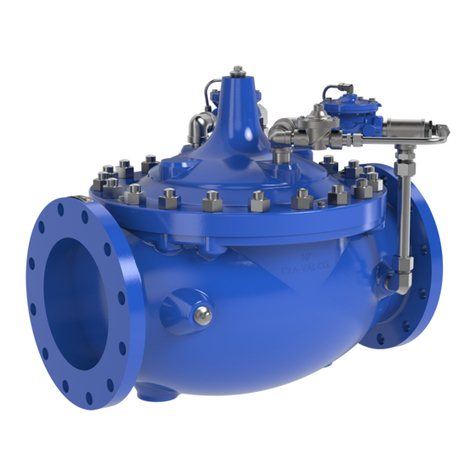

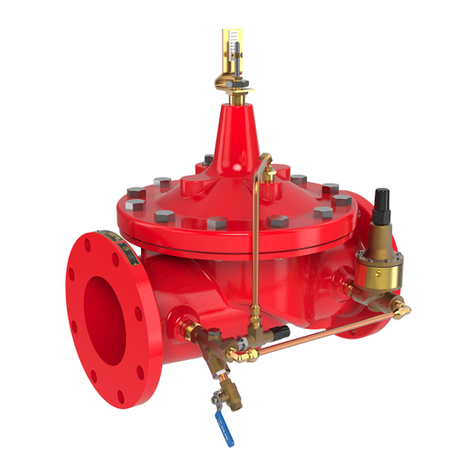

Seawater Service Pressure Relief Valve

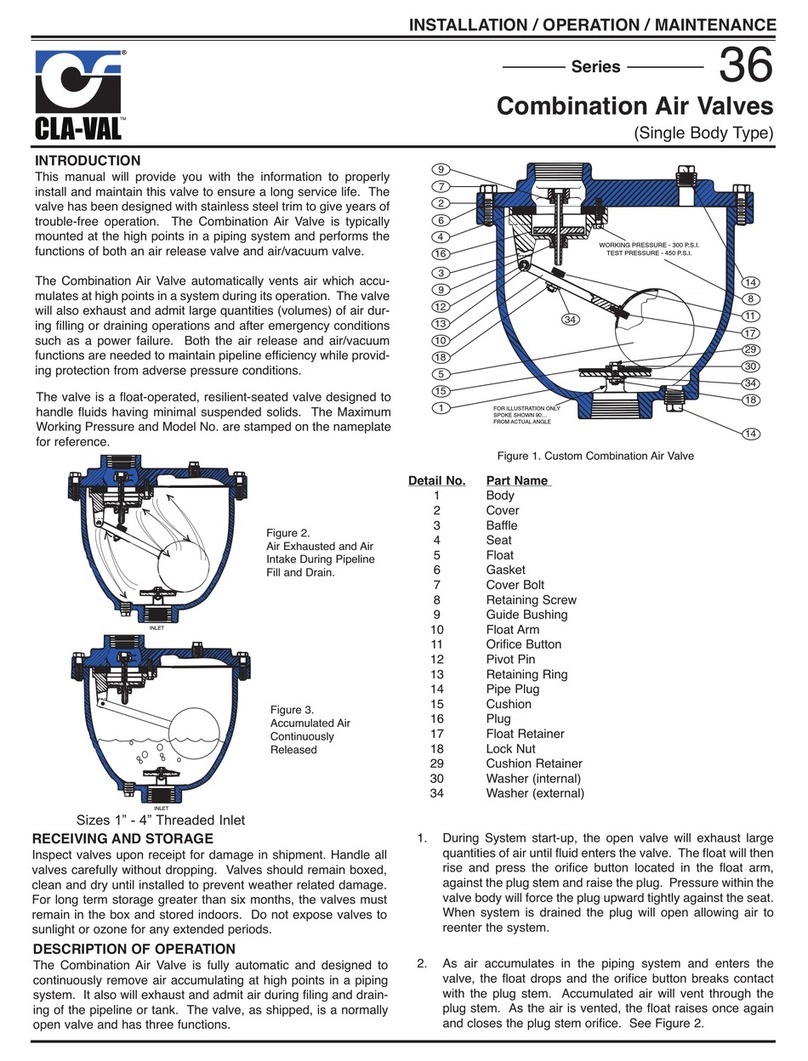

INTRODUCTION

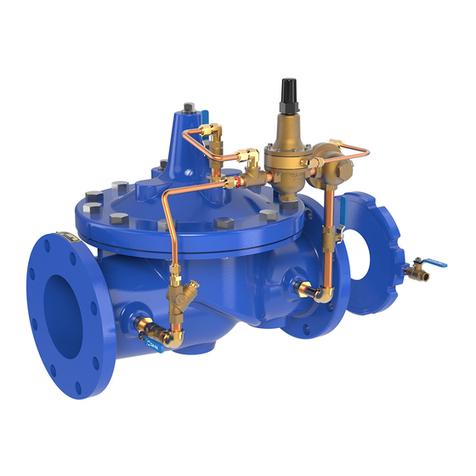

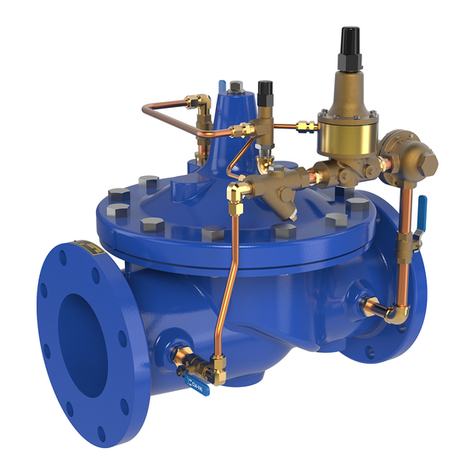

The Cla-Val 50-20/650-20 is an automatic control valve designed

to maintain constant upstream pressure to close limits. It is a

hydraulically operated, pilot controlled, modulating type valve.

The valve is actuated by inlet line pressure, opening to maintain

a steady line pressure and closing gradually to prevent surges.

When inlet pressure is below the pressure setting CRL pilot control,

the main valve and pilot are closed drip tight. Pressure setting

adjustment is made with single adjusting screw that has a protective

cap to discourage tampering.

INSTALLATION

1. Allow sufficient room around the valve assembly to make

adjustments and for servicing.

2. lt is recommended that gate or block valves be installed to

facilitate isolating valve for preventative maintenance. When used

as a surge control or pressure relief valve where valve outlet dis-

charge is to atmosphere, then a gate or block valve is needed at

valve inlet.

NOTE: BEFORE THE VALVE IS INSTALLED, PIPE LINES

SHOULD BE FLUSHED OF ALL FOREIGN MATTER.

3. Place valve in line with flow through valve in direction indicated

on inlet plate or flow arrows. Check all fittings and hardware for

proper makeup and verify that no apparent damage is evident.

4. Cla-Val Valves operate with maximum efficiency when mounted

in horizontal piping with the cover UP; however, other positions

are acceptable. Due to size and weight of cover and internal com-

ponents on six inch and larger valves, installation with the cover

up is advisable. This makes periodic inspection of internal parts

readily accessible.

5.Caution must be taken in the installation of this valve to insure that

galvanic and/or electrolytic action does not take place. The proper

use of dielectric fittings and gaskets are required in all systems using

dissimilar metals.

OPERATION AND START-UP

1. Prior to pressurizing the valve assembly make sure the nec-

essary gauges to measure pressure in the system, are installed

as required by the system engineer. CAUTION: During start-up

and test a large volume of water may be discharged down-

stream. Check that the downstream venting is adequate to pre-

vent damage to personnel and equipment. All pilot adjustments

should be made slowly in small increments. If the main valve

closes too rapidly it may cause surging in upstream piping.

2. If isolation valves (B) are installed in pilot system open these

valves (see schematic).

3. Remove cap on the CRL Pressure Relief Control, loosen jam

nut and turn adjusting screw clockwise until spring is fully com-

pressed. This puts the control in full closed mode and will cause

the main valve to close when system is pressurized.

4. If a downstream block valve is installed, slowly open this valve.

5. Partially open upstream block valve. The main valve should

close.

6. Carefully loosen the plug at top of indicator assembly.

Bleed air from cover and tighten plug or bleed valve.Carefully

loosen tubing fittings at highest points and bleed air from system.

Retighten fittings.

7. Open fully the upstream block valve and turn the CRL adjust-

ing screw slowly counterclockwise until you begin to hear a flow

through the control. The main valve should start to open. If the

pressure is below the required relief setting, refer to the spring

chart and turn the adjusting screw clockwise the number of turns

required for the proper setting. Lock the jam nut and replace

cover. An observation of the pressure relief setting should be made

during usage. The controls can be readjusted as required.

MAINTENANCE

1. Cla-Val Valves and Controls require no lubrication or packing

and a minimum of maintenance. However, a periodic inspection

schedule should be established to determine how the fluid is

affecting the efficiency of the valve assembly. Minimum of once

per year.

2. Repair and maintenance procedures of the Hytrol Main Valve

and control components are included in a more detailed IOM

manual. It can be downloaded from our web site (www.cla-val.com)

or obtained by contacting a Cla-Val Regional Sales Office.

3. When ordering parts always refer to the catalog number

and stock number on the valve nameplate.

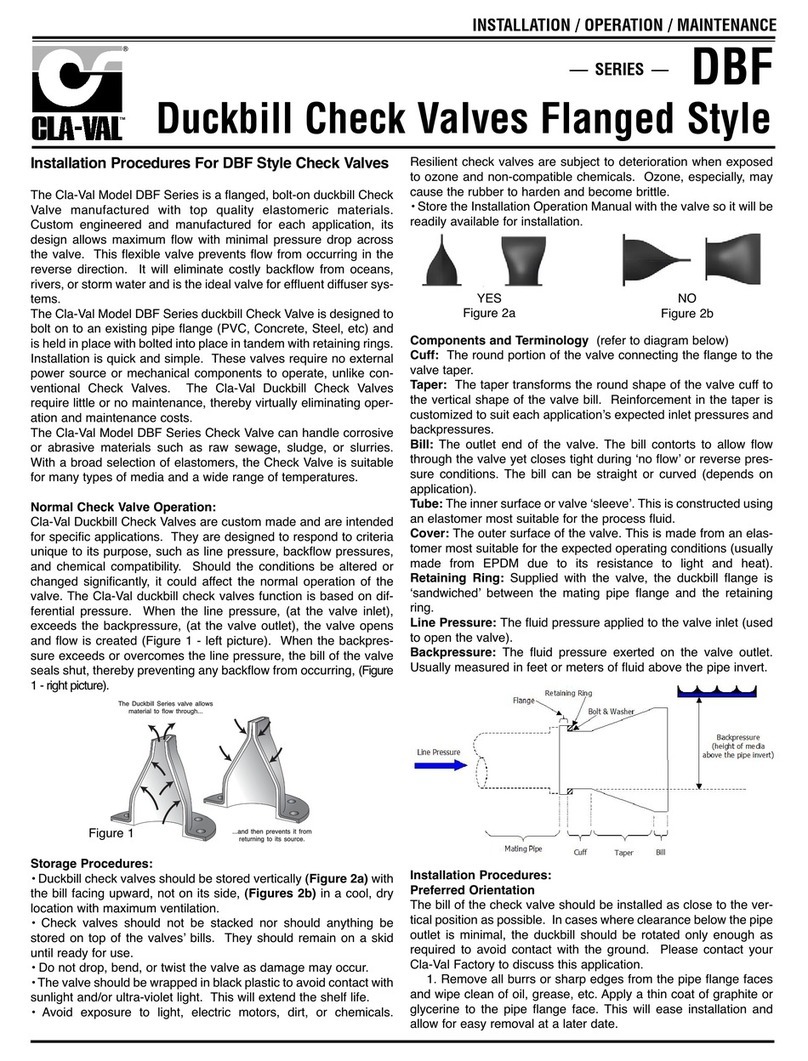

INSTALLATION / OPERATION / MAINTENANCE

50-20/650-20

MODEL

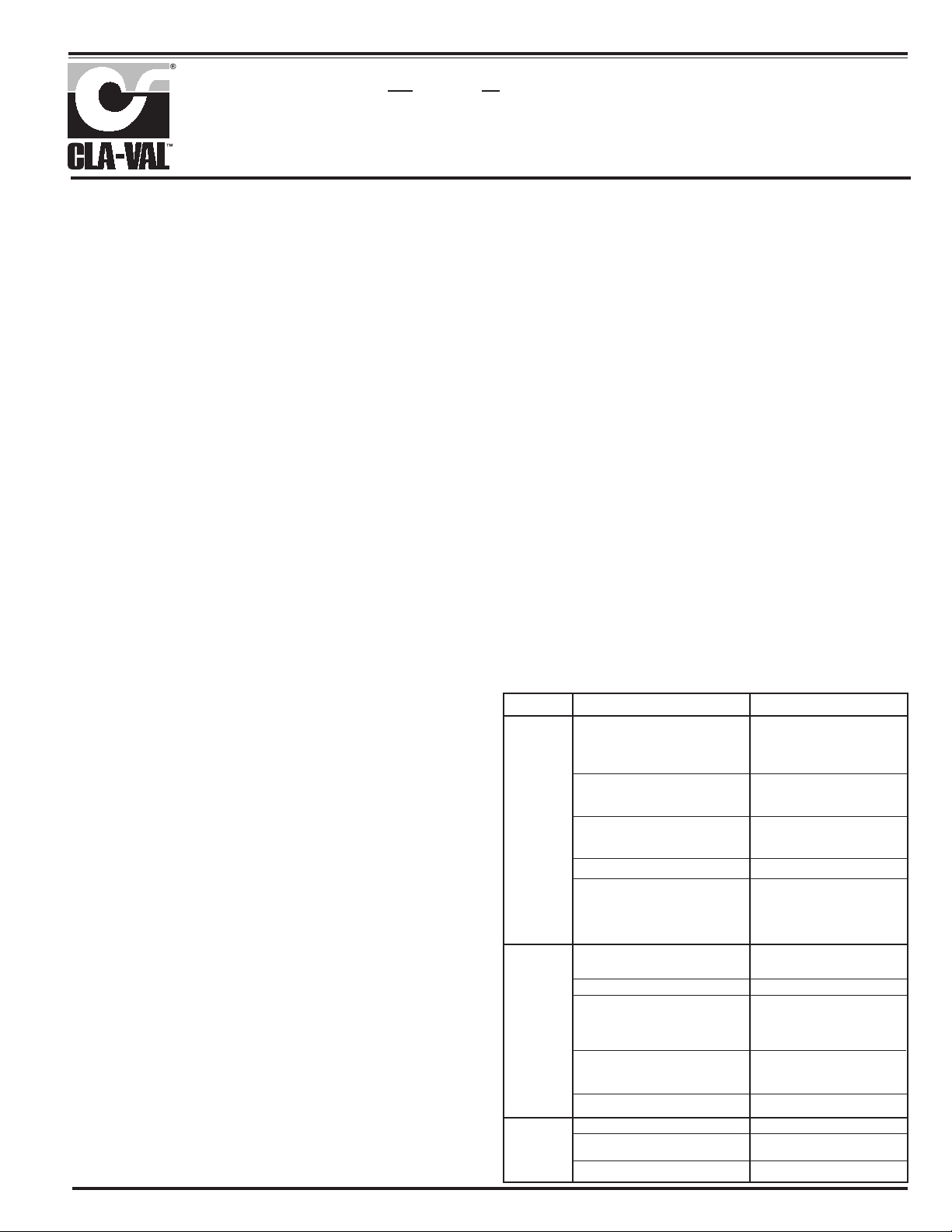

SYMPTOM PROBABLE CAUSE REMEDY

Main valve Inlet pressure below setting of Reset pilot valve. If change

won’t open pilot valve in setting is from tampering,

seal cap with wire and

lead seal

Pilot valve stuck closed Mineral Disassemble control and clean

deposit or foreign material between

disc retainer and power unit body

Pilot valve diaphragm ruptured or Disassemble and replace

diaphragm nut loose. Water coming diaphragm Tighten nut

out of the vent hole in cover

Main valve stuck closed Disassemble main valve,

clean

Mineral buildup on stem parts and/or replace damaged

Stem damaged part. Check downstream

and cover CK2 isolation

valves are open

Main valve Inlet pressure above setting of Reset pilot valve

won’t close pilot valve

Clogged needle valve or strainer Disassemble and clean

Pilot valve stuck open. Mineral Disassemble and clean

deposit or foreign material under

disc retainer or under diaphragm

assembly

Main valve stuck open. Mineral Disassemble and clean

buildup on stem. Foreign material

between seat and disc assembly

Main valve diaphragm worn Disassemble and replace

Valve leaks Pilot valve disc worn out Disassemble and replace

Continuously Main valve disc worn or small Disassemble and replace

pin hole in main valve diaphragm

Set point too close to inlet pressure Reset CRL Pilot