INTRODUCTION

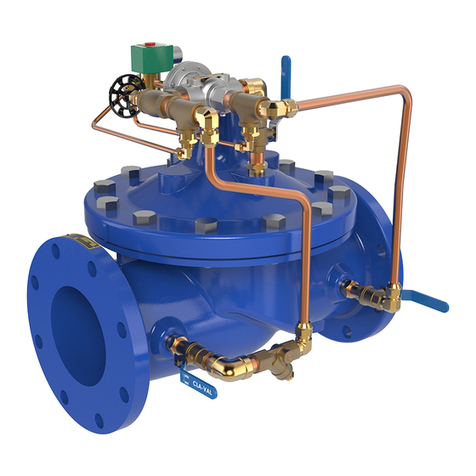

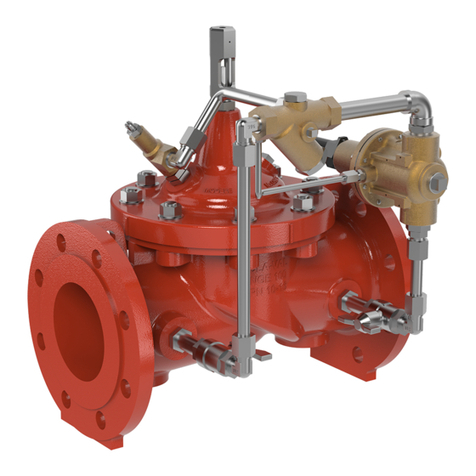

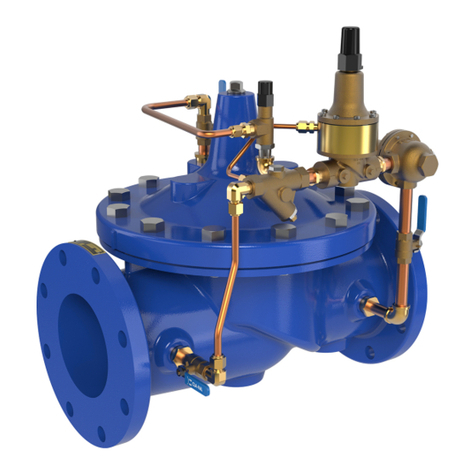

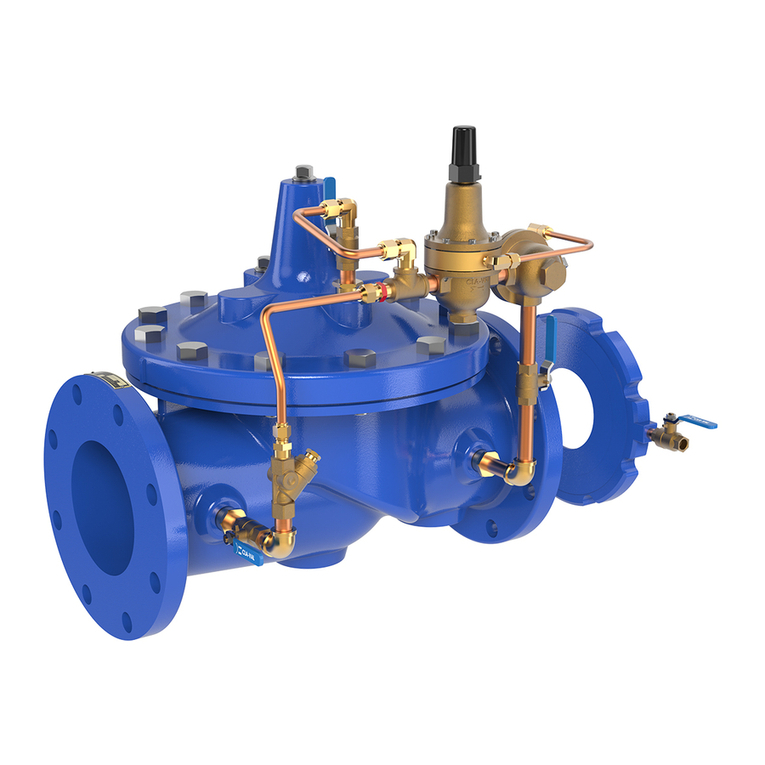

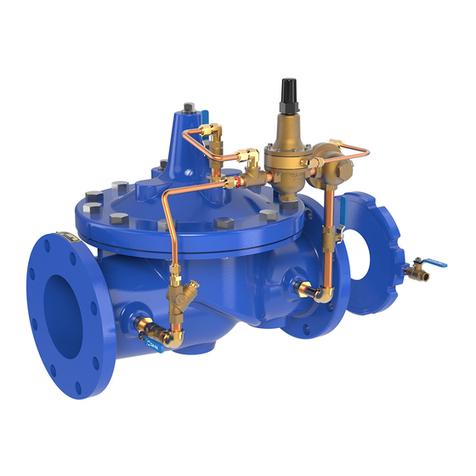

The Cla-Val Model 81-02/681-02 Check Valve is an automatic

valve designed to close drip tight when outlet pressure exceeds

inlet pressure. It is a hydraulically operated, pilot controlled,

diaphragm type globe or angle valve. When a pressure reversal

occurs, higher downstream pressure is applied to the cover cham-

ber through one control tube line and valve closes tightly. Upon

resumption of normal pressure, cover chamber pressure is relieved

through the other control tube line. The valve opens for flow. This

valve is equipped with adjustable opening and closing speed con-

trols.

INSTALLATION

1. Allow sufficient room around the valve to make adjustments, and

for disassembly.

2. It is recommended that gate or block valves be installed on both

ends of the 81-02/681-02 to facilitate isolating the valve for pre-

ventive maintenance.

NOTE: BEFORE VALVE ASSEMBLY IS INSTALLED, PIPE

LINES SHOULD BE FLUSHED OF ALL CHIPS, SCALE AND

FOREIGN MATTER.

3. Place the valve in the line with flow through the valve in the

direction indicated on the inlet nameplate or by flow arrows. Check

all fittings and hardware for proper makeup and that no apparent

damage is evident. Be sure main valve cover nuts/bolts are tight.

4. Cla-Val valves operate with maximum efficiency when mounted

in horizontal piping with the cover UP; however, other positions are

acceptable. Due to size and weight of cover and internal compo-

nents of six inch and larger valves, installation with the cover up is

advisable. This makes periodic inspection of internal parts readily

accessible.

OPERATION AND START-UP

1. A Cla-Val X101 Valve Position Indicator may be installed in the

center cover port to provide a visual indication of the valve stem

during start-up.

2. Close the two speed control valves by turning full clockwise.

Open both valves 1/4 to 1/2 turn counterclockwise for an initial

setting.

3. With pressure in the piping, slowly open the gate or block valves

on both ends of the Cla-Val 81-02/681-02 Check Valve. Carefully

loosen the center cover plug of the Hytrol Valve, or the vent valve

of X101 Valve Position Indicator (if installed), and bleed air from

valve. Retighten cover plug or vent after all air is expelled.

4.To check the operation of the valve lower the pressure at the

valve inlet and the valve will close. Return the inlet pressure to a

higher pressure than the outlet pressure and the valve will open.

5. The opening and closing speed of the main valve is controlled

by the speed control valves. The opening control will be on the

smaller of the two control lines.

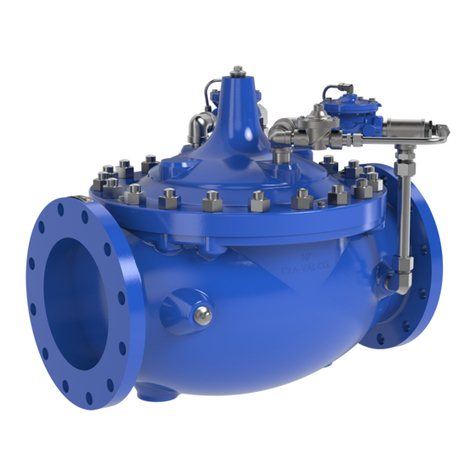

MAINTENANCE

1.Cla-Val Valves and Controls require no lubrication or packing

and a minimum of maintenance. However, a periodic inspection

schedule should be established to determine how the fluid handled

is affecting the operation of the valve assembly. Minimum of once

per year.

2. Repair and adjustment procedures of the Cla-Val Hytrol valve

and control components are included in a more detailed IOM

manual. It can be downloaded from our web site (www.cla-

val.com) or by contacting a Cla-Val Regional Sales Office.

3. When ordering parts always refer to the catalog number and

stock number on the valve nameplate.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

81-02/681-02

Check Valve

Lack of cover chamber

pressure

Diaphragm damaged

Diaphragm assembly

inoperative Corrosion

or excessive scale build

up on valve stem

Mechanical obstruction

Object lodged in valve

Worn disc

Badly scored seat

Closing speed control closed

Insufficient line pressure

Diaphragm assembly

in-operative Corrosion

on valve stem

Diaphragm damaged

Opening speed control

closed

Check upstream and

downstream pressure,

tubing for restrictions

Replace diaphragm

Clean and polish stem

Replace any defective

part damaged, badly

eroded

Remove obstruction

Replace disc

Replace seat

Open speed control1/4 turn

Check pressure

Clean and polish stem

Replace any defective part

damaged, badly eroded

Replace diaphragm

Open 1/4 turn

SYMPTOM PROBABLE CAUSE REMEDY

Fails to close

Fails to open

(Valve is

designed to

fail closed

on a

diaphragm

failure)