WS1TC & WS1.25 TC Manual

Table of Contents

Control Valve Function and Cycles of Operation Control Valve Function and Cycles of Operation 1 - 2

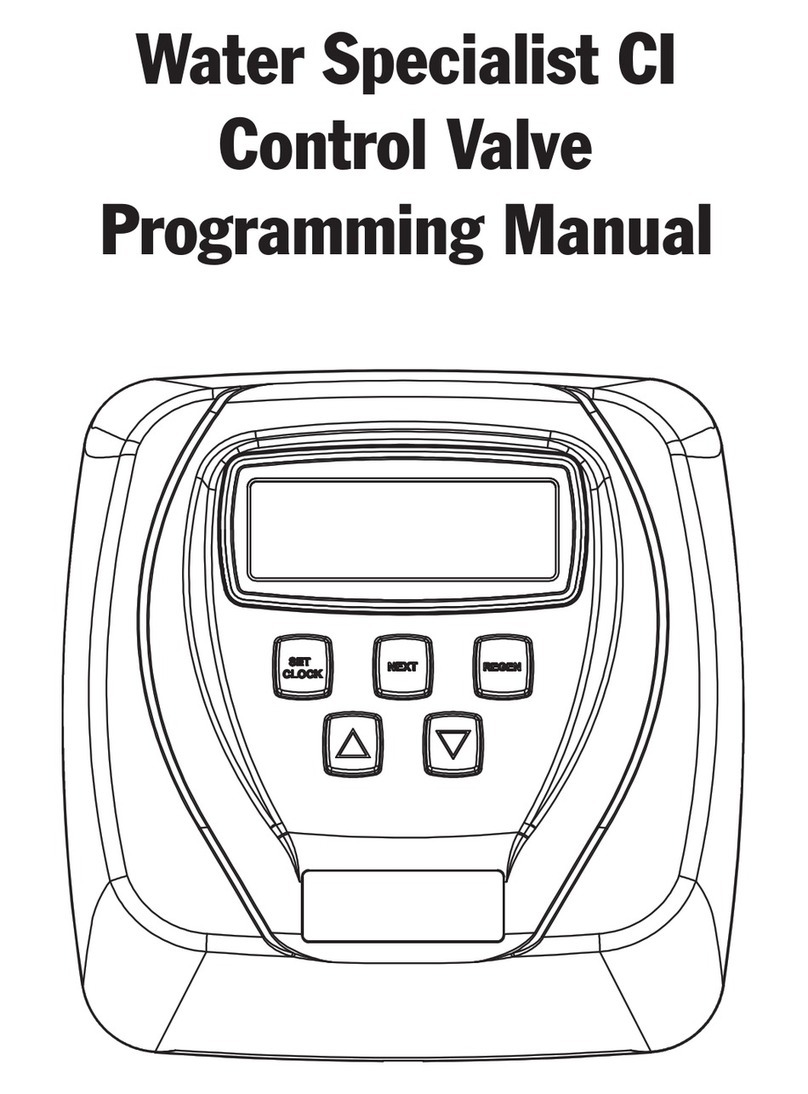

OEM General Programming Instructions Programming 1

OEM System Setup Programming 1

Installer Displays/Settings Programming 3

User Displays/Settings Programming 4

Drawings and Part Numbers

Front Cover and Drive Assembly Drawings and Part Numbers 1

WS1TC Drive Cap, Pistons and Spacer Stack Drawings and Part Numbers 2a

WS1.25TC Drive Cap, Pistons and Spacer Stack Drawings and Part Numbers 2b

WS1 & WS1.25 Identification Figure Drawings and Part Numbers 2c

FOR INFORMATION COMMON TOALL1” & 1.25” CONTROLVALVES REFER TO THE WS1&WS1.25 COMMON

INFORMATION MANUAL

The common manual contains the Table of Contents shown below

Other Drawings and Part Numbers

Compliance Table No page number

Injector Cap, Injector Screen, Injector, Plug and O-ring Drawings and Part Numbers 3a

Injector Order Information Drawings and Part Numbers 3b

Injector Graphs US Units: Injector Draw, Slow Rinse and Total Flow Rates Drawings and Part Numbers 3c-3d

Injector Graphs Metric Units: Injector Draw, Slow Rinse and Total Flow Rates Drawings and Part Numbers 3e-3f

Refill Flow Control Assembly and Refill Port Plug Drawings and Part Numbers 4

Drain Line – 3/4” Drawings and Part Numbers 5

Drain Line – 1” Drawings and Part Numbers 6

Water Meter, Meter Plug and Mixing Valve Drawings and Part Numbers 7

Installation Fitting Assemblies Drawings and Part Numbers 8a – 8b

Bypass Valve Drawings and Part Numbers 9

Flow Diagrams – Service and Backwash Drawings and Part Numbers 10

Flow Diagrams – Downflow and Upflow Drawings and Part Numbers 11

Flow Diagrams – Rinse and Fill Drawings and Part Numbers 12

WS1 Wrench Drawings and Part Numbers 13

General Information General Information 1

General Warnings (Must appear in OEM’s manual) General Information 1

Specifications which must be included in OEM’s Manual General Information 2

Quick Reference Specifications General Information 2

Drive Assembly General Information 3

Drive Cap Assembly, Main Piston and Regenerant Piston General Information 3

Spacer Stack Assembly General Information 4

Injector Cap, Screen, Injector Plug and Injector General Information 4

Refill Flow Control Assembly or Refill Port Plug General Information 4

Drain Line Flow Control and Fitting Assembly General Information 5

Water Meter or Meter Plug General Information 6

Mixing Valve General Information 6

Installation Fitting Assemblies General Information 6

Bypass Valve General Information 7 - 8

Installation Installation 1 - 2

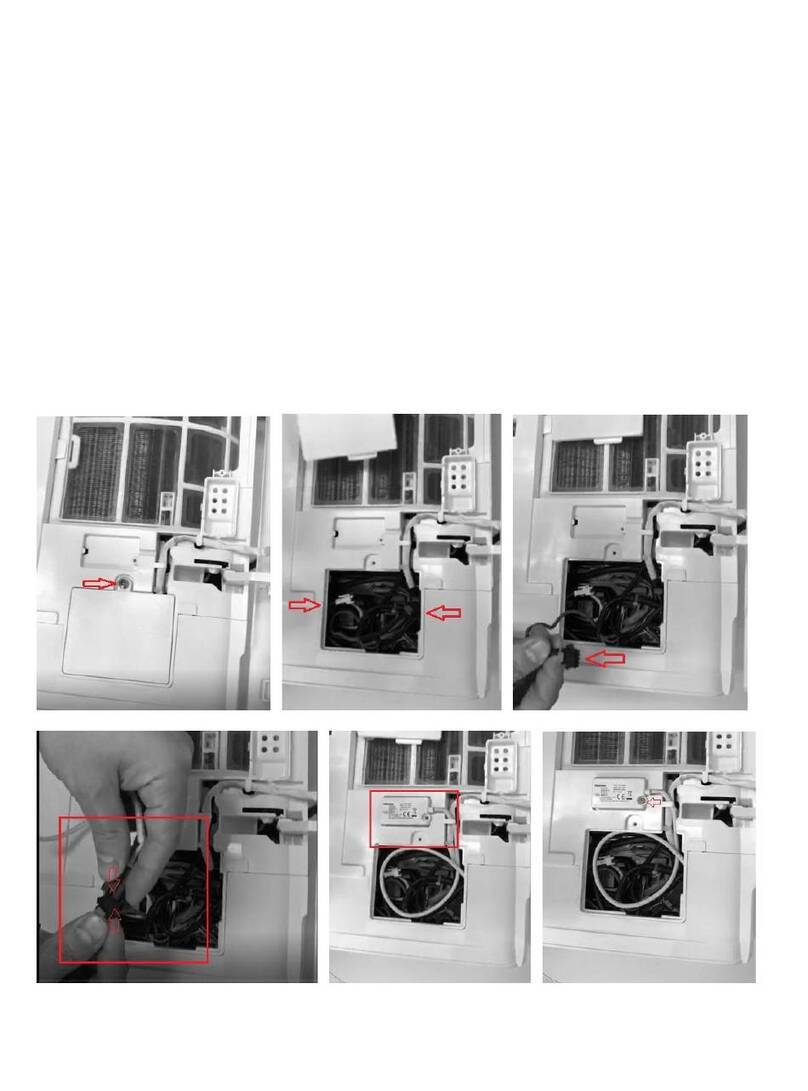

Service Instructions Service Instructions 1 - 5

Troubleshooting Troubleshooting 1 - 2

Limited Warranty Last Page