Clack WS CI Series Owner's manual

Installation, Operation

& Maintenance Guide

Clack WS CI

Simplex Regenerating Systems

Including:

Softener

Crystal Right

(Iron & Manganese Removal)

Nitrate Removal

Colour Removal

(Organic Scavenger)

AquaMulti

Manual 017.4

2

Contents

1. Unpacking Instructions

2. Installation

Pre-installation checks

Fitting the distribution system

Adding the media

Fitting the valve

Brine tank connections

Hydraulic connections

DLFC (drain line flow control)

Injector

Electrical Connections

Quickstart

Programming the valve

3. Your System

Identifying your system

Softener setting sheet

Crystal Right CR100 setting sheet

Crystal Right CR200 setting sheet

Nitrate Removal setting sheet

Colour Removal setting sheet

AquaMulti setting sheet

4. Commissioning

Introduction

Regeneration

Service

5. Routine Maintenance

Weekly

Monthly

Yearly

6. Troubleshooting

Accessories

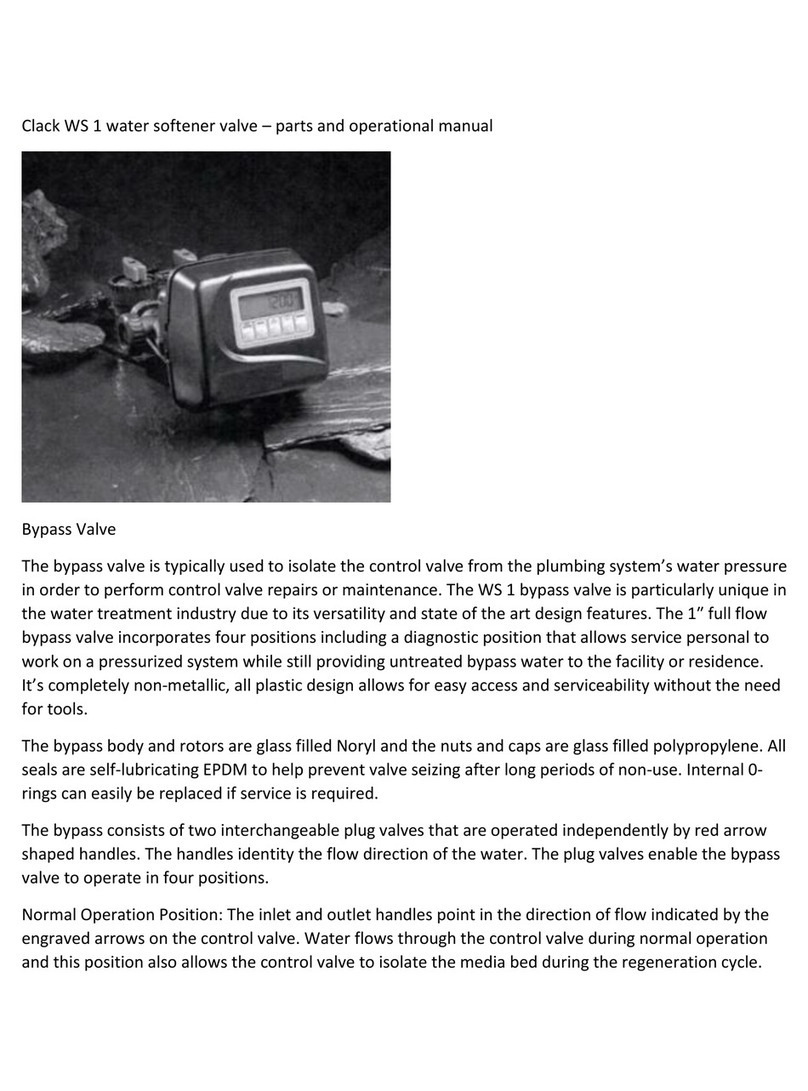

5303024075 Bypass (suitable for 1” connections)

5303024084 Auxiliary Micro Switch (for 1” & 1.¼” valves)

5303020005 Auxiliary Micro Switch (for 1.½” & 2” valves)

5303028632 Service Wrench

5303024087 Vertical Adaptor Assy (1” connections up to 14” vessel)

5303020765 No untreated water bypass 1” & 1. ¼” valves

5302036536 Motorised Alt Valve 1. ½” valve (can use as no untreated water bypass)

5303028622 Motorised Alt Valve 2” valve (can used as no untreated water bypass)

5303027234 2” Meter Assy

3

Thank you for purchasing this system. We are sure that it will provide you with trouble free

service for many years to come. Please use the following pages to assist you with the

assembly and installation of your new system.

1. Unpacking

PLEASE USE THE ACCOMPANYING PACKING DOCUMENTS TO CHECK THAT ALL

ITEMS ARE PRESENT AND CORRECT.

If any item is missing or damaged your carrier and supplier must be notified within 2 days of

receipt if a claim is to be made.

The main parts of the system include:

Salt

Brine tank

and lid

Brine elbow and bulkhead

connector

Drain line

Brine line

Overflow

Brine tube

and strainer

Brine Elbow

Valve

Upper

screen

Vessel

Riser

Lower

screen

Base

4

Note. Smaller Nitrate removal units are in self

contained cabinets, these have

been assembled in the factory

and do not require any assembly.

(see note after 2.1)

2. Installation

Please observe the local regulations concerning the installation of your system. Check that

you have allowed space for access to the unit for possible future maintenance. This

installation may require plumbing work and will require an electrical outlet to be fitted near the

system. Only attempt this if you have the necessary skills.

2.1 Pre-installation checks

The area needs to be level, frost free, have access to electricity and an open drain. Check the

incoming water quality is within any parameters specified for that media (contact your

supplier). In addition to this check the incoming water pressure is between 2 and 8 bar

(preferably approx. 4 bar) and the water temperature is between 3ºC and 45ºC.

If your system is a small cabinet unit proceed to section 2.6

2.2 Fitting the Distribution System

Fit the bottom distribution system into the vessel – the bottom screen should been pre glued

to the riser tube (fig A.1) (smaller systems). Alternatively if the system uses bottom laterals

these need to be assembled inside the vessel (fig A.2), Move the vessel in its final position as

it will be difficult to move once the media has been added.

Fig A.1 Fig A.2 Fig A.3

5

2.3 Adding the Media

Block the top of the riser tube to stop media getting down the tube.(see fig A.3). Add about

1/3 by volume of water to the vessel so when the media is poured in it doesn’t damage the

bottom distribution system. If you have been supplied gravel with your kit this should be

added first so it covers the bottom distribution system. Add the media supplied but make sure

there is approximately 30%. free space left above the media so when the system is

backwashed the media can expand into the space and allow any sediment or contaminants to

be backwashed away (there may be media left over). Unblock the riser tube.

2.4 Fitting the Valve

Add a small amount of silicone grease to the valve outer and inner o-rings (fig A.4 & 5).

Fig A.4 Fig A.5

If a top screen has been supplied this should be attached next.

Slide the valve onto the riser tube and gently push

it down onto the vessel treads. Screw the valve on

until you start to squeeze the main O ring and

then finally give the valve a final tighten by tapping

the rear side of the valve with the palm of your

hand (fig A.6)

Fig A.6

6

2.5 Brine Tank Connections.

Attach the brine line tubing to the brine tank and valve using the connectors fitted to the brine

tank (fig A.7), and valve (fig A.8).

Fig A.7 Fig A.8

Sizes may vary depending on the valve used, please note to use the poly insert if provided

with your specific valve.

2.6 Hydraulic Connections.

Connect your pipe work to the inlet / outlet connections; use the supplied tails provided for 1”

and 1.25” valves or direct BSP threaded connections on the 1.5” or 2” valves.

2.7 DLFC (drain line flow control)

This is possibly one of the most important components to check has been installed; this will

control the backwash flow rate and ensure the system will continue to function correctly. The

DLFC will either be fitted inside the drain line elbow, the 1” adaptor or in an external housing.

The larger external DLFC may have more than one flow controls fitted to gain the required

flow rate. See below pictures of the drain line housings.

¾” Elbow

Insert

1” External Straight 1.½” External

7

2.8 Injector

The injector is another important item in the

functioning of the system, please check that

it is fitted in the DN position and that the UP

position has been plugged. The injector colour

will vary depending on the size of the system,

this should be listed on the items list.

2.9 Electrical connections

To connect the power cable you need to firstly remove the

cover then remove the drive bracket assembly by pressing

up on the drive brackets release tabs and pulling towards

you, the drive bracket including software can now be lifted

away to reveal the back plate (fig A.9). Fig A.9

The power cable should be threaded through the back plate

And strain relief as shown in Fig A.9a

Fig A.9a

You can now re install the drive bracket into its original position.

Please make sure that this has been replaced correctly as this can cause problems at a

later date.

If fitting a MAV or NHBP locate the knock out on the back plate

Fig A.10 then remove the tabs at the bottom of the strain relief

on the back side of the back plate fig A.11 thread the cables

Fig A.12 and fit the cover Fig A13

Fig A.10

Fig A.11 Fig A.12 Fig A.13

8

You can now make connections to the PCB board.

Connect NHWB here marked Drive if used.

Connect power here marked 12V DC

When all connections have been made

the power can be turned on and

programming can take place.

Quick Start

2.10 Programming the Valves.

The valves are pre programmed with the exception of the time of day and the

hardness, Nitrate and Colour setting.

All adjustment should be made using the up and down arrows when the setting you

wish to adjust is displayed on screen.

Set Time of Day.

Press SET CLOCK.

Adjust the hours and press NEXT to adjust the minutes, press NEXT to return to the

normal TIME display.

Hardness setting / Nitrate / Colour setting.

Press NEXT and UP simultaneously for 3 seconds and release.

Set DISPLAY with ENGLISH flashing should appear.

HARDNESS with 340 should appear on screen.

Softener: Adjust as necessary to your incoming supply hardness in ppm CaCO3

this can be obtained by using a purchased hardness test kit or by

contacting your water supplier.

Crystal Right: Adjust as necessary to your incoming supply hardness in ppm CaCO3

+ 2 x Sodium level (ppm) if the Sodium level is unknown add 60 to the

total hardness + 1 x Fe Iron (ppm) & 1 x Mn Manganese (ppm).

Nitrate: Adjust as necessary to your incoming supply Nitrate reading in ppm.

Colour Removal: Set to regen on a timed basis (default every 2 days).

Press NEXT repeatedly until the display returns to the time of day.

9

2.11 Programming the Valves in case of memory loss.

Should the programming have been lost in transit the following instructions in

conjunction with the relevant setting sheet will allow you to re set them.

When the power has been connected the valve will display the software number and initialise

itself and then display TIME; you can then start to program the valve.

Selections are made using the UP and DOWN buttons until

the required setting is displayed: after each setting press

NEXT to continue.

Set Time of Day.

Press SET CLOCK.

Adjust the hours and press NEXT to adjust the minutes, press NEXT to return to the normal

TIME display.

Step 1: Cycle Sequence.

Press NEXT and DOWN simultaneously for 3 seconds and release.

The screen will display SOFTENING flashing!

Press NEXT and DOWN simultaneously for 3 seconds.

The screen should display SET 25, adjust as necessary (see setting sheet page?) Press

NEXT after each setting and set each setting accordingly until the display returns to TIME.

(See notes if fitting a untreated Water Bypass valve)

Step 2: System Setup.

Press NEXT and DOWN simultaneously for 3 seconds and release.

The screen will display SOFTENING flashing. Press NEXT.

The screen should display CYCLE 1, adjust as necessary (see setting sheet that corresponds

to your system!) Press NEXT and set each setting accordingly until the display returns to

TIME.

Step 3: Display Settings.

Press NEXT and UP simultaneously for 3 seconds and release.

HARDNESS with 340 should appear on screen. Adjust as necessary (see quick start section.

Press NEXT and set each setting accordingly. The Regen Time settings, have a factory

default of 02:00 am this can be adjusted if required the display will return to the time of day

after setting the regen time.

10

4202035013

Sno 03100137

Soft

1354-WS1CI

3. Your System.

3.1 Identifying your System.

Your System will have an identification label fixed to the control valve, this will look similar to

the picture shown here.

The information listed can be read as follows:

Stock Number: Manufacturers part number.

Serial No: Serial No.

Id Code: System type identification code (soft, CR100, CR200 Nitrate or

Colour).

Configuration: Vessel size, Valve type & Controller type.

Identify the settings from the chart in the programming section.

The valve is supplied pre programmed!

(excluding settings that need to be done on site)

The settings are listed in case there is a need to re

program the unit.

If you have any concerns or worries following the setting procedure please contact your

supplier who will help you through the set up procedures.

Using the above information to identify your system you can then select the

relevant setting sheet from the following pages.

11

Clack CI Valves Set up as SIMPLEX Softeners.

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Capacities calculated at 50g CaCO3 hardness removal per litre of resin,

Vessel Size 735 835 935 1035 1044 1054 1248 1354 1465 1465 1665 1865 2160 2469 3072 3672

Media Volume (litres) 14 20 25 30 40 50 60 75 100 125 150 200 250 350 500 700

Valve Size 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1.25" 1.25" 1.5" 2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.3 1.3 1.5 2 2 2

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Brine dn 54 54 54 68 60 70 62 64 86 86 71 84 61 66 81 72

Cycle 3 Rinse 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Cycle 4 Fill Kg 2 3 3.75 4.5 6 7.5 9 11.25 15 18.8 22.5 30 37.5 52.5 75 105

Cycle 4 Fill Mins 2" Only

7(4.2g) 10 (4.2g) 14 (4.2g) 16 (5.3g)

Cycle 5 End

Set Capacity Kg 0.7 1 1.25 1.5 2 2.5 3 3.8 5 6.25 7.5 10 12.5 17.5 25 35

Set Regen

Set Time Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Software version from 332.2

An additional screen will now show if 1.5 or 2 has been selected. Select " FLo1.5 for 1.5" or FLo2 for 2" valve"

PPM

or (See note 7 for use)

Off

Backwash

Brine Draw dn

Rinse

Fill (Salt required)

End

or (See note 4 for options)

NORMAL

or (see note 5 for options)

or (see note 6 for options)

Off

Off

Alt Off

or (See note 1 for options)

or (See note 2)

Off

or (See note 3 for options)

Auto (automatic reserve calculation)

If 1.5 has been selected above an extra screen will show (Fill) select Kg

Default 2:

Set on Site (if SET REGEN is set to AUTO)

0 (not used)

14

Default :00

3.2 Softener.

12

3.3 Crystal Right 100.

Clack CI Valves Set up as SIMPLEX CR100.

All figures based on a calculated hardness of 100ppm using CR100 Crystal-Right

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Vessel Size 1044 1054 1252 1354 1465 1665 1865 2160 2469 3072 3672

Media Volume (cft) 1 1.5 2 3 4 5 6 7 11 19 24

Valve Size 1" 1" 1" 1" 1" 1" 1" 2" 2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.0 1.0 2 2 2 2

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Brine dn 66 52 64 57 81 67 75 55 61 49 67

Cycle 3 Rinse 7 7 7 7 7 7 7 7 7 7 7

Cycle 4 Fill Kg 4 5 6.8 8.5 12 15.25 20.5 23.75 37.5 64.5 81.5

Cycle 4 Fill Mins 2" Only 9 14

12 (4.2g) 12 (5.3g)

Cycle 5

Set Capacity Kg 0.7 1.3 1.7 2.1 3 3.8 5.1 5.9 9.3 16.1 22.3

Set Regen

Set Time Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Calculation.

Hardness is calculated as follows: 1 x CaCO3 ppm + 2 x Na ppm + Fe ppm + Mn ppm 19/12/2018

End

Software version from 332.2

An additional screen will now show if 1.5 or 2 has been selected. Select " FLo1.5 for 1.5" or FLo2 for 2" valve"

Alt Off

or (see note 1 for options)

Off

or (see note 2 for options)

PPM

Backwash

Brine dn

Rinse

Fill

Off

or (see note 6 for options)

Off

or (See note 7 for use)

Normal

or (See note 4 for options)

Off

or (see note 5 for options)

If 1.5 has been selected above an extra screen will show (Fill) select Kg

5

2:

:00

Set on site (See calculation below)

NA

Auto (Automatic reserve calculation)

or (See note 3 for options)

13

3.4 Crystal Right 200.

Clack CI Valves Set up as SIMPLEX CR200

All figures based on a calculated hardness of 100ppm using CR200 Crystal-Right

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Vessel Size 1044 1054 1252 1354 1465 1665 1865 2160 2469 3072 3672

Media Volume (cft) 1 1.5 2 3 4 5 6 7 11 19 24

Valve Size 1" 1" 1" 1" 1" 1" 1" 2" 2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.0 1.0 2.0 2.0 2.0 2.0

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Brine dn 66 52 64 57 81 67 75 55 61 49 67

Cycle 3 Rinse 7 7 7 7 7 7 7 7 7 7 7

Cycle 4 Fill Kg 4 5 6.8 8.5 12 15.25 20.5 23.75 37.5 64.5 81.5

Cycle 4 Fill Mins 2" Only 9 14

12 (4.2g) 12 (5.3g)

Cycle 5

Set Capacity Kg 1.1 1.7 2.2 2.8 4 5 6.8 7.9 12.4 21.5 27.1

Set Regen

Set Time Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Calculation.

Hardness is calculated as follows: 1 x CaCO3 ppm + 2 x Na ppm + Fe ppm + Mn ppm 19/12/2018

End

Software version from 332.2

An additional screen will now show if 1.5 or 2 has been selected. Select " FLo1.5 for 1.5" or FLo2 for 2" valve"

Alt Off

or (see note 1 for options)

Off

or (see note 2 for options)

PPM

Backwash

Brine dn

Rinse

Fill

If 1.5 has been selected above an extra screen will show (Fill) select Kg

5

2:

:00

Off

or (see note 6 for options)

Off

or (see nonte 7 for use)

Set on site (see calculation below)

NA

Auto (Automatic reserve calculation)

or (see note 3 for options)

Normal

or (see note 4 for options)

Off

or (see note 5 for options)

14

Clack CI Valves Set up as SIMPLEX Nitrate Software version from 332.2

Capacities based on 20g No3 removal per litre of resin,

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Vessel Size 735 822 835 935 1035 1044 1054 1248/52 1354 1465 1665 1865 2160 2469 3072 3672 4278

Swan

Mistral

Swan Swan Swan

Media Volume (litres) 18 22 25 30 35 35 42 50 75 100 150 200 250 350 500 700 1000

Valve Size 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1.5" 2" 2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.5 2 2 2 2

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Brine dn 64 59 59 63 63 60 70 62 64 86 71 84 68 66 81 72 72

Cycle 3 Rinse 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Cycle 4 Fill Kg 3.05 3.7 4.3 5.1 5.1 6.05 7.1 5.5 12.8 17 25.5 34 42.5

Cycle 4 Fill Mins 2" Only

11 (4.2g) 16 (4.2g) 18 (5.3g) 25 (5.3g)

Cycle 5

Set Capacity Kg 0.36 0.44 0.5 0.6 0.7 0.7 0.84 1 1.5 2 3 4 5 7 10 14 20

Set Regen (Time Control)

Set Regen (Meter Control)

Set Time Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Note:

Brine Draw dn

See note below for information

An additional screen will now show if 1.5 or 2 has been selected. Select " FLo1.5 for 1.5" or FLo2 for 2" valve"

or (see note 4 for options)

Off

Alt Off

or (see note 1 for options)

or (see note 2 for options)

Off

or (see note 3 for options)

Off for Time Control

Normal

End

End

If 1.5 has been selected above an extra screen will show (Fill) select Kg

PPM

Backwash

Entering the Nitrate level as PPM will provide a volumetric capacity of the system, if you need to increase the

capacity you can lower the PPM setting or increase the PPM setting to reduce capacity.

Rinse

25/06/2019

Off

Off

or (see note 5 for options)

or (see note 6 for options)

or (see note 7 for use)

Default: 2:

Default: :00

0 (not used)

If a Time version set to 3, if Metered set to 14

Set on Site using the Nitrate reading in ppm "if SET REGEN is set to AUTO"

Fill

Auto for Metered (Enter Nitrate level as PPM)

3.5 Nitrate Removal.

15

Clack CI Valves Set up as SIMPLEX Colour Removal

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Capacities calculated at 50g CaCO3 hardness removal per litre of resin,

Vessel Size 1035 1054 1252 1354 1465 1665 1865 2160 2469 3072 3672

Swan

Media Volume (litres) 25 50 50 75 100 150 200 250 350 500 700

Valve Size 1" 1" 1" 1" 1" 1.25" 1.25" 1.5" 2" 2" 2"

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.3 1.3 1.5 2 2 2

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 5 5 5 5 5 5 5 5 5 5 5

Cycle 2 Brine dn 44 89 63 78 98 108 114 64 79 73 75

Cycle 3 Rinse 6 6 6 6 6 6 6 6 6 6 6

Cycle 4 Fill Kg 6.5 13 13 19.5 26 39 52 65 91 130 182

Cycle 4 Fill Mins 2" Only

17 (4.2g) 24 (4.2g) 27 (5.3g)

Cycle 5

Set Capacity Kg 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Set Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Software version from 332.2

Default :00

or (see note 6 for options)

or (see note 7 for use)

or (see note 5 for options)

Brine Draw DN

Rinse

Fill (salt required)

Default 2:

Alt Off

or (see note 1 for options)

Off

or (see note 2 for options)

Default 340 (Not used)

0 (not used)

PPM

Backwash

28/07/2015

End

if 1.5 has been selected above and extra screen will show (Fill) seleck Kg

2 Days

Off

Off

Off

Off

3.6 Colour Removal (Organic Scavenger).

16

Clack CI Valves Set up as SIMPLEX Aqua Multi

Capacity based on 37 grams per litre @ 300ppm CaCO3

Please apply the settings in the following sequence

Selections are made using the UP & DOWN buttons until the required setting is displayed,

After each setting press NEXT to continue or press REGEN to go back one stage.

Vessel Size 1044 1054 1252 1354 1465 1665 1865 2160 2469 3072 3672

Media Volume (Ltr) 37 37 50 62 75 100 125 150 300 450 650

Injector White White Blue Yellow Green Orange Lt Blue Lt Green Orange V3010-2D V3010-2E

DLFC usgpm 3.2 3.2 4.2 5.3 6.5 7.5 11 15 20 25 42

BLFC usgpm 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 2.2 2.2

Step 1, Cycle Sequence,

Press NEXT and DOWN simultaneously for 3 seconds and release.

Screen will display SOFTENING flashing

Press NEXT and DOWN simultaneously for three seconds, the screen should display SET 1, adjust to turbine setting below,

Set 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.5 1.5 2 2

Set (Alternating)

SET dp

Hardness

Set 1

Set 2

Set 3

Set 4

Set 5

Step 2. System Setup,

Press NEXT and DOWN simultaneously for 3 seconds and release.

SET with SOFTENING flashing should appear on screen.

Cycle 1 Backwash 12 15 15 15 15 15 15 15 15 20 20

Cycle 2 Brine dn 50 50 47 50 55 50 50 30 45 50 55

Cycle 3 Rinse 6 6 6 6 6 6 6 6 6 6 6

Cycle 4 Fill Kg 3.8 3.8 5 6.2 7.5 10 12.5 15 30 65

Cycle 4 Fill Mins 2" Only 16 24

Cycle 5

Set Capacity Kg 1.3 1.3 1.8 2.2 2.7 3.7 4.6 5.5 11.1 16.6 24

Set Regen

Set Time Regen

Set rLY 1 (Relay 1)

Set rLY 2 ( Relay 2)

Set Salt

Step 3, Display Settings.

Press NEXT & UP simultaneously for three seconds and release.

HARDNESS with 340 flashing should appear on screen,

Hardness

Hardness 2

Regen Day

Set Time Regen Hrs

Set Time Regen Min

Step 4, Set time of day,

Press SET CLOCK

Set hours using the up and down buttons.

Set minutes using the up and down buttons,

Software version from 332.2

An additional screen will now show if 1.5 or 2 has been selected. Select " FLo1.5 for 1.5" or FLo2 for 2" valve"

Alt Off

or (see note 1 for options)

Off

or (see note 2 for options)

PPM

Backwash

Brine dn

Rinse

Fill

End

If 1.5 has been selected above an extra screen will show (Fill) select Kg

Auto (Automatic reserve calculation)

or (See note 3 for options)

Normal

or (See note 4 for options)

Set on site

NA

6

Off

or (see note 5 for options)

Off

or (see note 6 for options)

03/12/2015

2:

:00

Off

or (See note 7 for use)

3.7 AquaMulti

17

Notes for CI valves software version 332.2

Starting a manual Regeneration Press and hold the REGEN button until the motor starts.

Set a delayed regeneration Press the REGEN button (REGEN TODAY) will flash on screen) press

the REGEN button again to clear.

Advancing through a regeneration Press the REGEN button to move to the next stage of regeneration.

Doing a soft reset Press & Hold REGEB & NEXT for 3 seconds. (resets valve in error).

Doing a total reset Press & Hold REGEB & NEXT for 3 seconds, then press & hold the

UP & DOWN buttons togeter for 3 seconds. (resets valves history).

Changing the service display Press NEXT to toggle to the next available display.

Note Options

1Off

ALT A

ALT B

SYS

SEPS

nHbP

2Off

dpon0

dPdEL

Hold

3Auto

OFF

M³

4NORMAL

On 0

Normal on 0

5OFF

Time on

L Softening on

6OFF

Time on

L Softening on

Error

7

8OFF

Delay

8a PrE

9PrE

depleted to 10%.

A pre sinse can be set to rinse the next cylinder before going into service (1" 2" & 1" TT)

A pre rinse can be set if required of up to 20 min duration.

Add the KG of salt added to the brine bin each fill, doe's not show for 1.5 & 2" valves.

L Softening Regen on

Standard setting.

The last two cycles can be delayed (Rinse & Fill) this delays untl the on line unit is

L Softening Regen on

Activates in service after a set number of litres for a set time and deactivates after

a set period of flow stops.

As above but during regeneration.

Activates whenever the valve enters an error mode.

Activates in service after a set number of litres for a set time and deactivates after

a set period of flow stops.

As above but during regeneration.

Feature not used.

Activates after a set time from the start of a regeneration for a set period of time.

Regenerations will occur immediately when capacity reaches zero.

Regeneration will occur at the preset time when volume is below the reserve or if

volume is below the reserve after 10 minutes of no water usage.

Feature not used.

Activates after a set time from the start of a regeneration for a set period of time.

Capacity is automatically calculated and a reserve will be estimated.

Regenerations will be controlled from the day override setting (user settings)

Regeneration will occur immediately when the set capacity has expired.

If off or M³ is selected the hardness setting will not display in settings.

Regenerations will occur at the pre set time. (not available on alternating duplex)

Feature not used (standard setting) If used the following options are available)

If the contact is closed it will initiate an immediate regeneration.

If the contact is closed it will initiate a delayed regeneration.

If the contact is closed a regeneration will be prevented.

Feature not used (standard setting)

Set on primary valve is using a standard duplex alternating systen (Duplex only)

Secondary valve if using a standard duplex alternating system (Duplex only)

If being used with a system controller.

Used if a separate source MAV is being fitted (requires 3 way Mav valve)

Used if a No Untreated Water valve is being fitted (no untreated water during regen)

Notes:

18

4. Commissioning the System

4.1 Introduction.

With the system fully plumbed and the valve programmed commissioning can start.

4.2 Regeneration.

When the system is fully functional the regeneration will happen at the pre-set time (see

programming the valve section). However, running a manual regeneration during

commissioning is the best way of removing air from the system, bedding in the resin and

flushing the system through.

Make sure the water inlet and outlet are closed. Press and hold the regeneration button for 3

seconds. The piston will move to the backwash position. Slowly half open the water inlet to

the system, and then slowly open the outlet to allow the air to be purged from the system.

Once this has been done you can fully open the inlet and outlet and allow the system to

continue through the regeneration cycle, this will allow you to check for leaks and also purge

any remaining air from the system. After a backwash the system will move through a brine

draw routine, rinse and fill before stopping in the service position.

For new systems or after a media change it maybe necessary to run two regenerations to fully

charge the media (check the water at the end of the backwash is running clear).

To initiate a delayed regeneration press the regeneration button once quickly this will start

flashing Regen Today in the bottom left corner of the screen and the system will regenerate at

the pre-set regeneration time. If you wish to cancel this just press the regeneration button

again and the display will disappear.

To initiate an immediate regeneration press and hold the regeneration button until the valve

motor starts to turn.

If during a regeneration cycle you need to skip through the cycle this can be done in the

following way. To skip to the next stage quickly press the regeneration button and this will

take it to the next stage of the regeneration, this can be repeated to get to the end of the

regeneration cycle.

4.3 Service.

Water flows into the valve at the top, down through the media and then up through the ‘riser’

tube in the middle of the vessel. As the water travels through the media the ion exchange

takes place. The controllers are set to automatically regenerate on capacity.

The display on the control can show either of the following; Time, current flow in litres per

minute or remaining capacity, this can be changed by pressing the NEXT button.

19

5.Routine Maintenance

Your system is designed to run with the minimum of maintenance and does not normally

require much adjustment.

Weekly

Check the salt level (this may need to be done more regularly dependant on

consumption) The salt level should always be above the water level.

Check there is no sign of damage or leaks,

Check the quality of the treated water.

Monthly

Check the quality of the incoming water to see if it has changed significantly.

Yearly

Check for leaks or damage.

Soda Ash Regeneration CR100 & CR200 units only )

Soda Ash Regeneration (CR100 & CR200 Only)

GUIDELINES FOR THE USE OF SODA ASH AS A REGENERANT IN

CRYSTAL –RIGHT INSTALLATIONS

Crystal Right is a well proven iron and manganese reduction media. Provided that the guidelines are followed

with regard to the water analysis and selecting the correct grade and volume of media, then problems are rare.

However there can be certain ground conditions where dissolved gases in the raw water may lead to a reduction

in operating capacity.

During the normal service run gases present in ground water will be absorbed by the Crystal Right, and most of

these gases are released during the standard brine regeneration. However some gases [especially CO2] may

not be and stay retained in the crystals. This leads to a small reduction in Crystal-Right’s exchange capacity per

cycle which after a while can lead to a significant decrease in the exchange capacity of the unit.

To reverse the loss of capacity we have to carry out a regeneration that will release the remaining elements

retained by the crystals that have not been removed by the standard brine regenerations. The way we can

achieve this is to do regeneration with Sodium Carbonate [Na2CO3] which is also known as Soda Ash.

To reverse capacity loss we would suggest ‘shock treatment’ regeneration with Soda Ash followed by further

routine regenerations at set intervals to prevent a further build up of problem elements on the crystals. It can also

be beneficial to periodically regenerate Crystal-Right units that are working satisfactorily with Soda Ash purely as

a preventative measure; it will be beneficial to the crystals.

Soda Ash Regeneration Procedure As a Routine Maintenance

Soda Ash is a powder which needs to be dissolved in water to make a liquid that can be drawn into the unit

during a regeneration cycle, warm water will dissolve the Soda Ash faster, stirring the mixture also helps to

dissolve it. Once the measured amount has been dissolved it is added to the brine solution in the brine tank and

regeneration is initiated, during the injection cycle the mixture of brine and liquid soda ash will be drawn into the

Crystal-Right bed in the normal way. If the brine tank is fitted with a brine well you can ensure the liquid soda

ash makes direct contact with the brine by introducing it via the top of the brine well.

20

Vessel Crystal Right Soda Ash Dissolved

Size Volume Ammount In Water

1044 1.0 CU,FT 400 Gramms 2 Ltrs

1054 1.5 CU,FT 600 Gramms 3 Ltrs

1252 2.0 CU,FT 800 Gramms 4 Ltrs

1354 2.5 CU,FT 1.0KG 5 Ltrs

1465 3.5 CU,FT 1.4KG 7 Ltrs

1665 4.5 CU,FT 1.8KG 9 Ltrs

1865 6.0 CU,FT 2.4KG 12 Ltrs

2160 7.0 CU,FT 2.8KG 14 ltrs

2469 11 CU,FT 4.4KG 22 Ltrs

3072 19 CU,FT 7.6KG 38 Ltrs

3672 26 CU,FT 10.4KG 52 Ltrs

CRYSTAL RIGHT SODA ASHREGENERATION CHART

Mixing theSoda Ash with warm waterwill dissolvethe granuals quicker

Soda Ash Shock Treatment

The Soda Ash is prepared in the same way and to the same strength as the routine procedure, the difference

being during the shock procedure it is drawn direct from the container it is prepared in. The easiest way to do

this is to disconnect the regular brine draw tube from the brine elbow, re-connect a piece of flexible tube to the

elbow the other end of which is put into the Soda Ash solution.

I. The first stage of the shock treatment is to backwash the unit for the standard length of time

II. After the backwash the liquid soda ash is drawn into the bed as per the above guidelines, immediately

all the soda ash solution has been drawn into the valve the original brine line is re attached to the brine

elbow and the brine draw initiated and the standard regeneration cycle allowed to run its course.

III. Important When using the shock method monitor the pH of the rinse water going to drain, if CO2 is

being released from the Crystal-Right the pH of the rinse water will drop, the lower the pH the more gas

is being released from the crystals.

What Concentration and how much Soda Ash

The correct solution strength is made by dissolving 200 grams of Soda Ash in 1 litre of water. Each cubic foot of

Crystal Right will require 2 Litres of Soda Ash solution for regeneration.

Other manuals for WS CI Series

1

This manual suits for next models

4

Table of contents

Other Clack Control Unit manuals

Clack

Clack Water Specialist 2H User manual

Clack

Clack V1CIDMF-03 Owner's manual

Clack

Clack Water Specialist CI Owner's manual

Clack

Clack WS1 Series Instruction manual

Clack

Clack WS1TC Series Guide

Clack

Clack Water Specialist WS1TC Guide

Clack

Clack WS 1 Quick start guide

Clack

Clack Water Specialist EI User manual

Clack

Clack Water specialist WS2H User manual

Clack

Clack WS15P Quick start guide