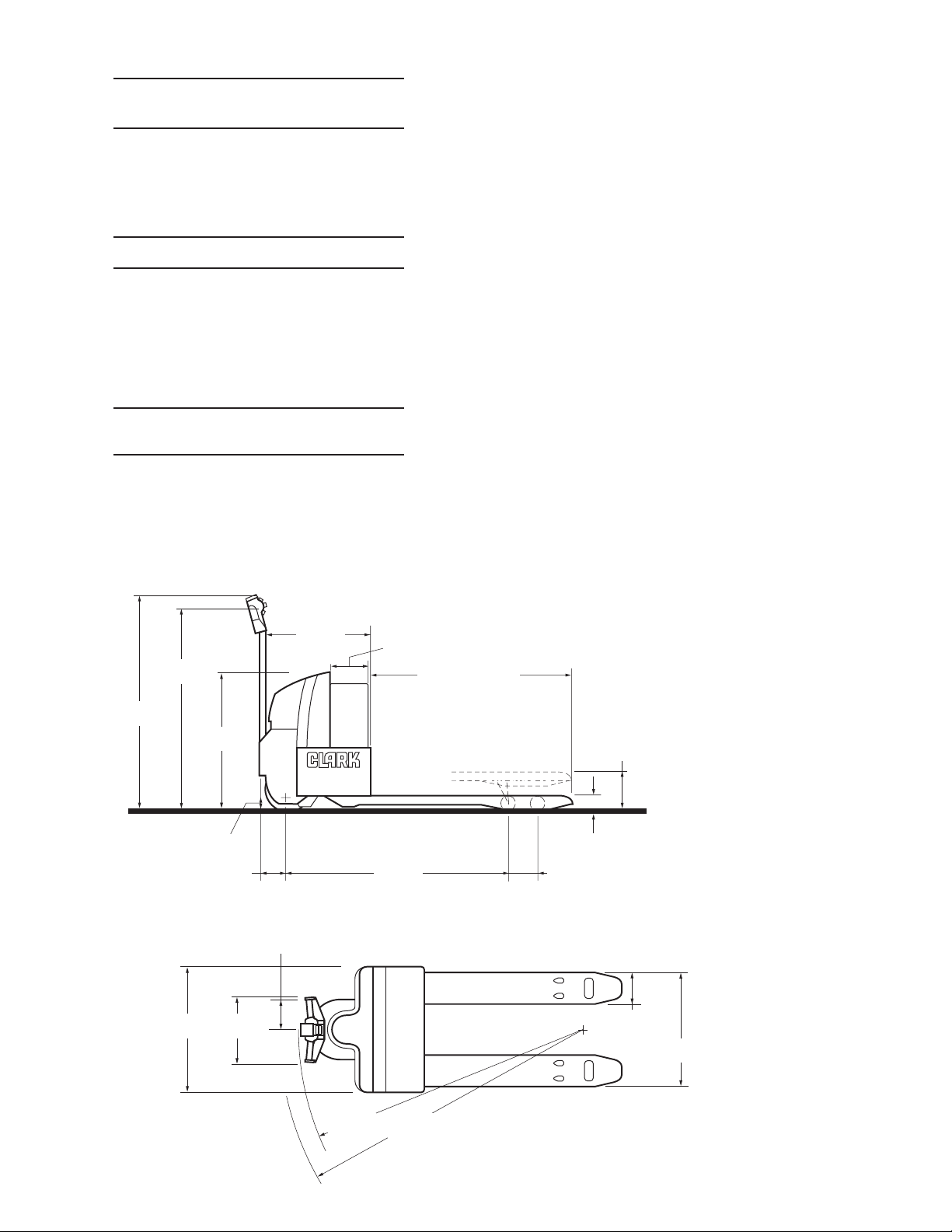

Clark WP 45 electric low-lift pallet trucks are ideal for moderate duty

cycles. Their quiet operation, and clean self-contained hydraulic

systems make them ideal for most indoor work areas. Their low initial

cost, ease of maintenance and 24-volt electrical system make

them an economical alternative to hand pallet jacks.

Operator Comfort/Convenience

•Formed steel handle with closed loop design

•All controls at operator’s fingertips

•International symbols identify functions

•Smooth, stepless speed control in forward and reverse

•Reversing switch in handle

The enclosed handle with designed-in hand guards is especially

convenient in tight workspaces. It allows control from either side of the

truck and provides excellent hand protection. The smooth

contours help prevent snagging on clothes, posts, doorways,

machinery or adjacent loads.

Direction, speed, lift/lower and horn controls are located on the

handle, marked with international symbols.

Reversing switch at the end of the handle is spring-loaded and

designed to override the directional control, automatically reversing

the truck on contact.

The directional control is thumb actuated and designed for left or right

hand operation.

Motors

Drive motor is 6.6 in. diameter, fan cooled and has class “H” insulation

for increased protection from heat damage. 24-volt drive motor is

separately excited (shunt wound).

Hydraulic motor is 4.5 in. diameter with class “H” insulation and

vertically mounted.

Electrical Systems

•Infinitely variable, separately excited transistor drive control

•24-volt operation

•Utilizes convenient battery pack with built in charger or

industrial battery (neither included in truck price)

•100 amp contactors

•Automatic resetting circuit breakers

•Easy access for inspection and testing

The separately excited control allows elimination of the forward and

reverse contactors. This control has many features designed to

improve productivity and serviceability including: programmable

neutral braking, creep and top speeds, variable plugging and

diagnostics to facilitate troubleshooting.

Wiring through the handle is contained in a heavy-duty harness

designed to last without undue binding, chafing or twisting.

A battery pack is optional and eliminates the need for special charging

equipment. It consists of a steel tray that holds four 6-volt, deep cycle,

heavy-duty batteries and a built-in charger. The charger plugs into any

grounded 110 volt AC outlet for quick, economical recharging of

batteries. The steel tray features hinged, swing-out top batteries for

easy bottom battery maintenance. Maintenance free batteries are also

available. Units equipped with either battery pack cannot carry UL

label.

•Battery pack provides 3.52 kwh with a 152 amp hour rating

(maintenance free battery pack provides 4.6 kwh with 195 amp

hour rating) and is equipped with a SB-175 red connector.

•Industrial battery - 12 cell 7 plate, 25.7 in. x 8.9 in. x 23.3 in. (653

mm x 226 mm x 592 mm) battery provides up to 7.6 kwh.

Drive Line

•Double reduction helical and spur gears

•Totally enclosed

•Protected location

Power from the horizontally mounted drive motor is transmitted

through 22 to 1 double reduction helical and spur gears to the drive

wheel axle. The gears are mounted on ball and tapered roller bearings

and operate totally enclosed in a bath of oil. Drive wheel is mounted

on a spline type axle and secured with a single, heavy duty lock nut for

quick change in the field.

Brakes

•Double acting

•Self adjusting

Brake is actuated by positioning the handle up or down. In either

position, the motor shuts off as the brakes are applied. When the

handle is released a heavy spring and chain return it to the vertical

position which applies the brake for parking. Brake pads are self-

adjusting and easily replaced.

Hydraulic System

•Integral pump and motor

•Simple hosing

•Serviceable cylinder

Hydraulic pump, motor, fluid reservoir, relief valves and inlet filter are

completely integrated, eliminating most of the connections associated

with hydraulic fluid leaks. Plumbing consists of a single, non-flexing

hose from the pump to the lift cylinder. The cylinder is a single acting,

ram type with an easily removable wire ring retainer for easy seal

replacement.

Steering

•Handle rotates drive unit 180°

•Design assures positive control

Long steer handle with low pivot point provides increased leverage to

reduce steering effort. Rectangular tubular design prevents handle

flexing and improves control.

Frame and Chassis

•Formed, unitized steel

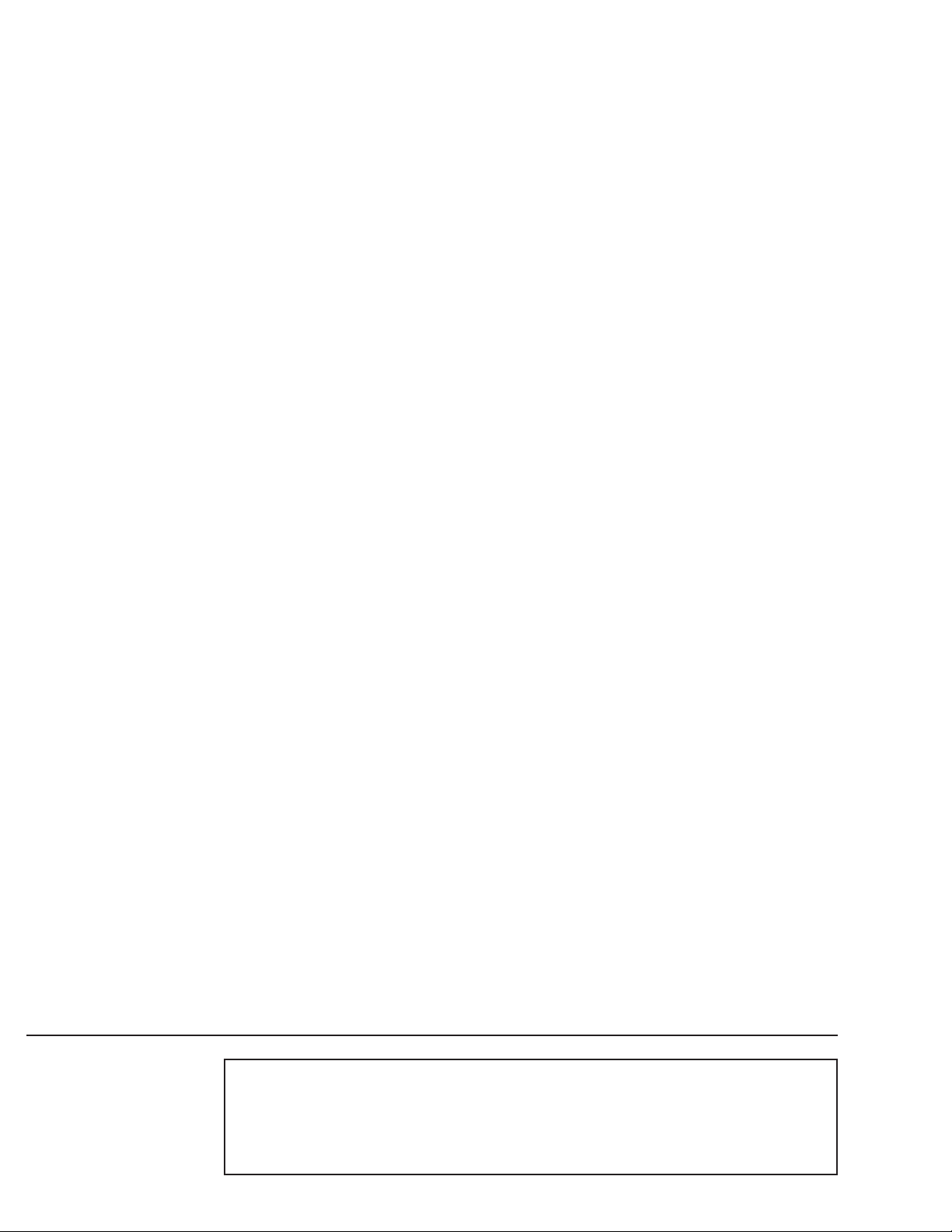

•Uniquely tooled fork design

Major components of the truck frame are formed steel, resulting in

superior strength at reduced weight. Forks are one piece steel

sections designed for added rigidity to increase service life. Frame

provides single point mounting of hydraulic cylinder and drive unit,

absorbs stress of lifting/lowering and travel. All exposed surfaces are

covered with a highly durable powder coat, free of chromium and lead.

This finish is smooth, easy to clean and resistant to chipping, rust and

corrosion.

Standard Equipment

Full 6” lift; 24-volt separately excited transistor control, rubber drive

tire with string guard; poly load wheels; poly skid stabilizers; horn; key

switch; BDI and 27 in. x 48 in. (686 x 1220 mm) forks. Finish is high-

visibility Clark green with black.

Options

Battery pack (standard or maintenance free batteries); poly drive tire;

various fork lengths from 32” (813 mm) to 60” (1524 mm) and widths

from 18” (457 mm) to 27” (686 mm), 48 in. (1220 mm) and 60 in. (1525

mm) load backrests; hour meter/BDI combination; cold

storage/corrosion conditioning, UL “E” and“EE” construction (“E”

requires industrial battery; “EE” requires “EE” rated industrial battery).

WP45 Specification Sheet

59-894-2041 Printed in USA CCIrev0305

your authorized CLARK dealer is:

■North America CMHC

Worldwide Headquarters

700 Enterprise Drive

Lexington, KY 40510

866-252-5275

www.clarkmhc.com

WP45_598942041v5.qxd 3/21/05 15:57 Page 2