4

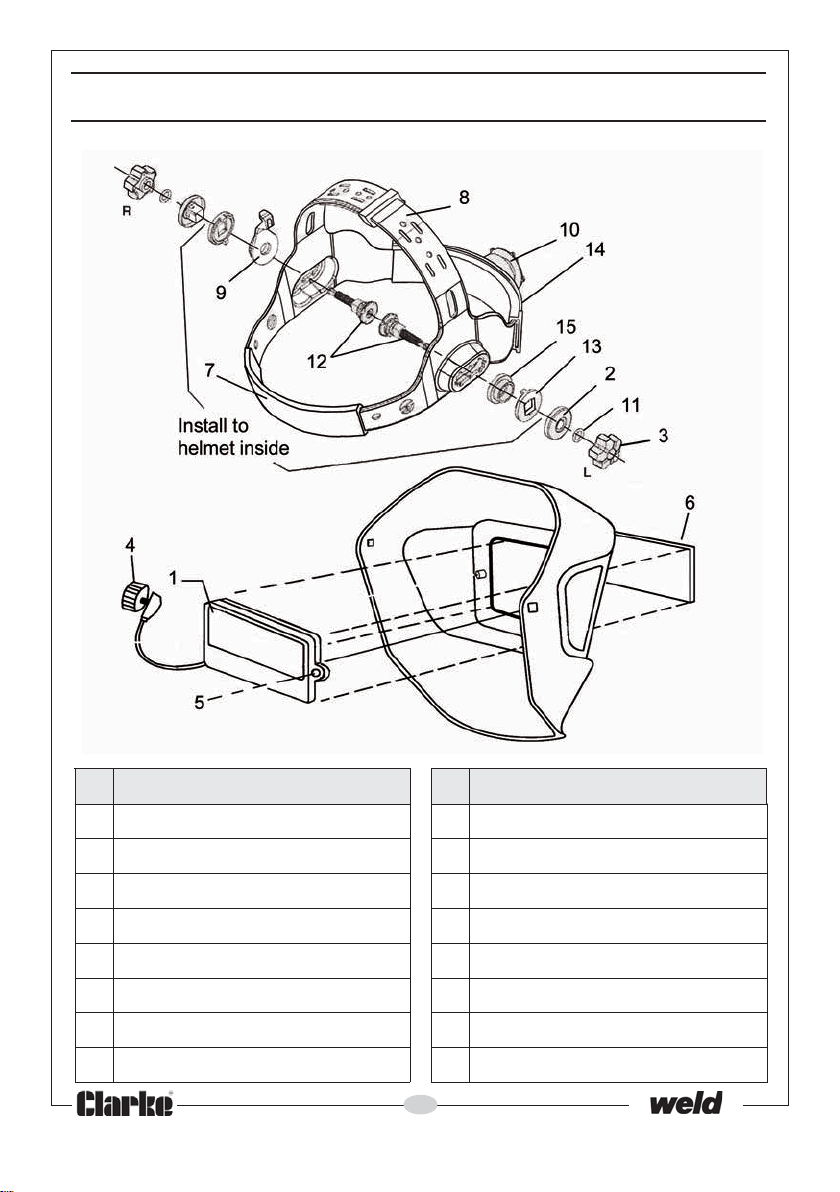

2. The top headband can be adjusted by bending the strap and positioning

the peg in the appropriate hole.

3. When the thumbscrews (3) are tight, the angle of tilt can be quickly and

repeatably adjusted using the adjusting tab (9), by placing it on the

chosen peg on the headband.

USING THE HEADSHIELD

1. Remove the protective film from both sides of the cartridge (1).

• The window will be set to Light DIN 4 state, and you will be able to see the

workpiece. The lens will automatically darken when an arc is struck.

2. Test the lens by striking an arc on the workpiece for the first time. Check

also that the outer screen and lens are clean and clear at all times.

3. Change the shade of setting as required using the shade adjustment knob

(4). Refer to the table opposite.

4. When the helmet is not used for 15 minutes, the power will automatically

shut off. There is no OFF switch.

SELECT THE SHADE SETTING

On striking an arc, the light created

will activate the solar cell and the

window will automatically darken to

a preset level. The lithium battery will

provide the necessary energy to

operate the head shield when there

is no arc light. Because the cartridge

assembly is a sealed unit, the battery

cannot be replaced. You can adjust

this shade level using the shade knob

(4) on the side of the headshield,

corresponding to the type of welding

process.

• There are five levels available;

9, 10, 11, 12 and 13. Check the

table to determine which value

you should select.

1. Set the shade selector (4) to the

required setting.

2. During the welding operation the

lens will automatically darken to

the pre-set shade. On removal of the arc, the lens will return to the light

state.

3. Adjust the ‘Sensitivity’ and ‘Delay Time’ as desired by using the adjustment

knob.