2

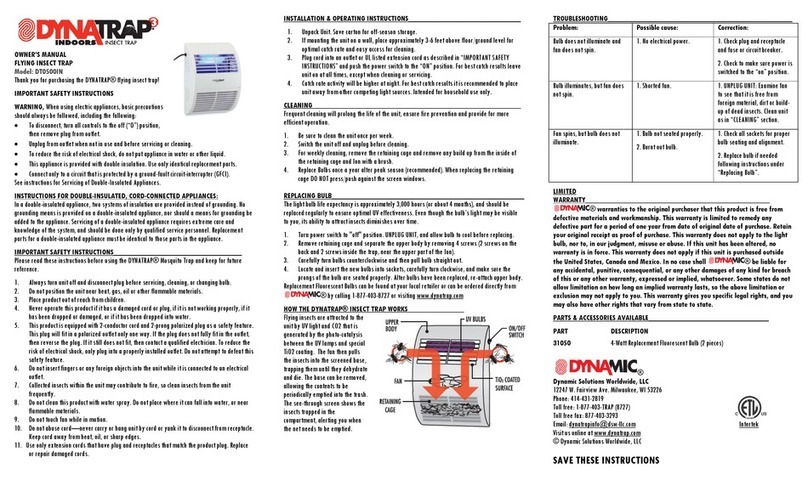

PRO-MIST DURA® ULV

Important Notes to Help You Get the Most

out of Your Sprayer and Maintain the Warranty

1. Read and understand this instruction booklet before

operating your sprayer. If you have questions about

operating the sprayer, proper applications, or

insecticides, call Clarke and ask for technical support.

2. Use only insecticides that are specifically registered

by the appropriate state and federal agencies for

ultra-low-volume (ULV) adult mosquito and/or

fly control.

3. Read and follow the insecticide label. It is a federal

oense to use any pesticide in a manner not in

accordance with its labeling. This includes

directives on the use of protective clothing and

safety equipment.

4. To obtain the best results with a ULV sprayer, the

operator must be knowledgeable of space spraying

concepts. Many insecticide labels list specific training

and/or certification requirements for users. Consult

Clarke or your nearest cooperative extension agent

for information.

5. Operate the sprayer only when:

• The vehicle is moving in a forward direction.

• Winds are less than 8 m.p.h.

• Insects are exposed to spray (evening or early

morning is the best time for most species).

6. Operate the sprayer only when the safety guard is

in place. If the sleeve assembly becomes damaged

and flies apart while the safety guard is not in place.

Serious physical injury could result. Always wear

safety glasses as well as ear protection when

working near a running sprayer.

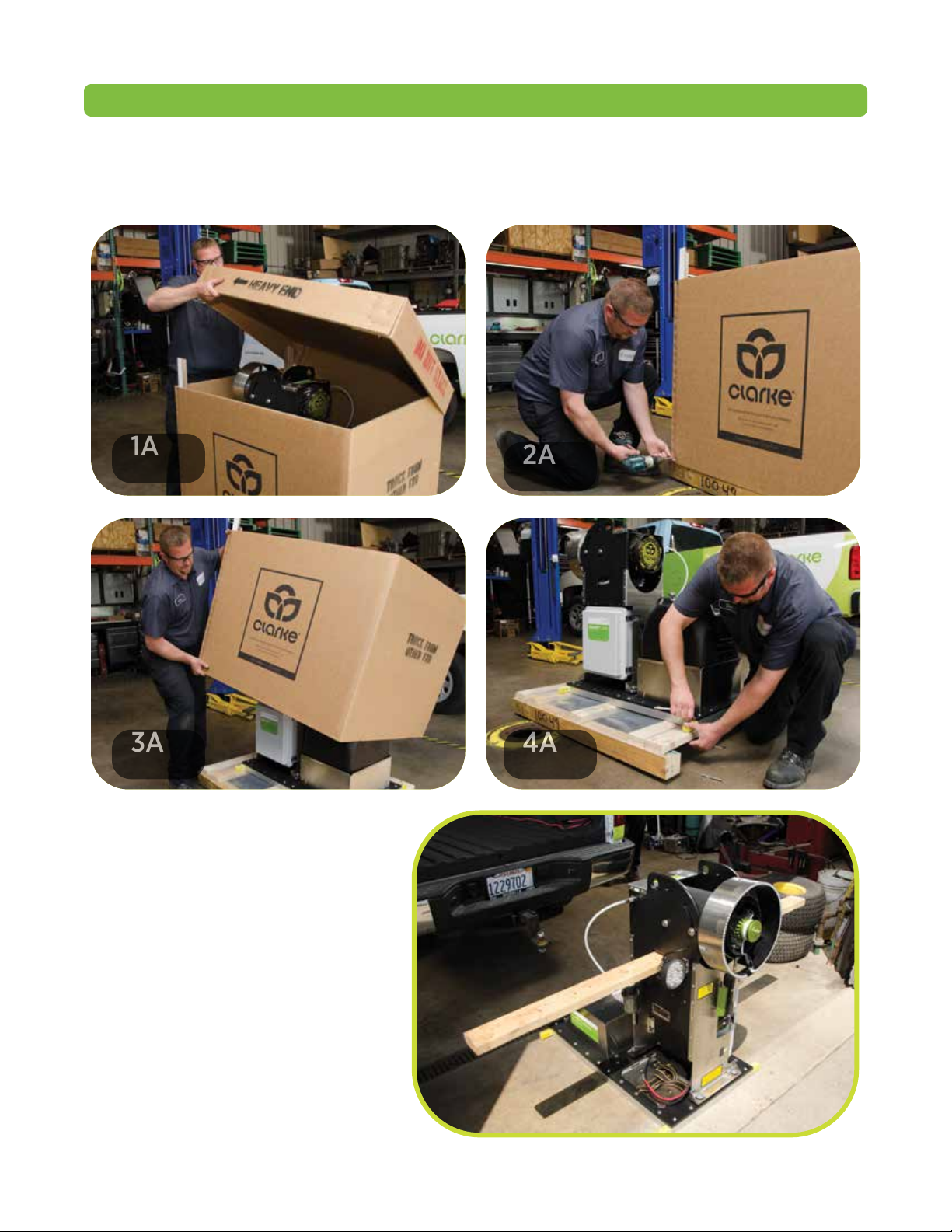

7. Using the Special Spanner puller tool, remove Hub

and Sleeve Assembly from Spray Head Assembly

before storing sprayer for extended periods of time.

Failure to follow this instruction may result in sprayer

damage. Clean Hub and Sleeve Assembly and store

in a sealed bag or container.

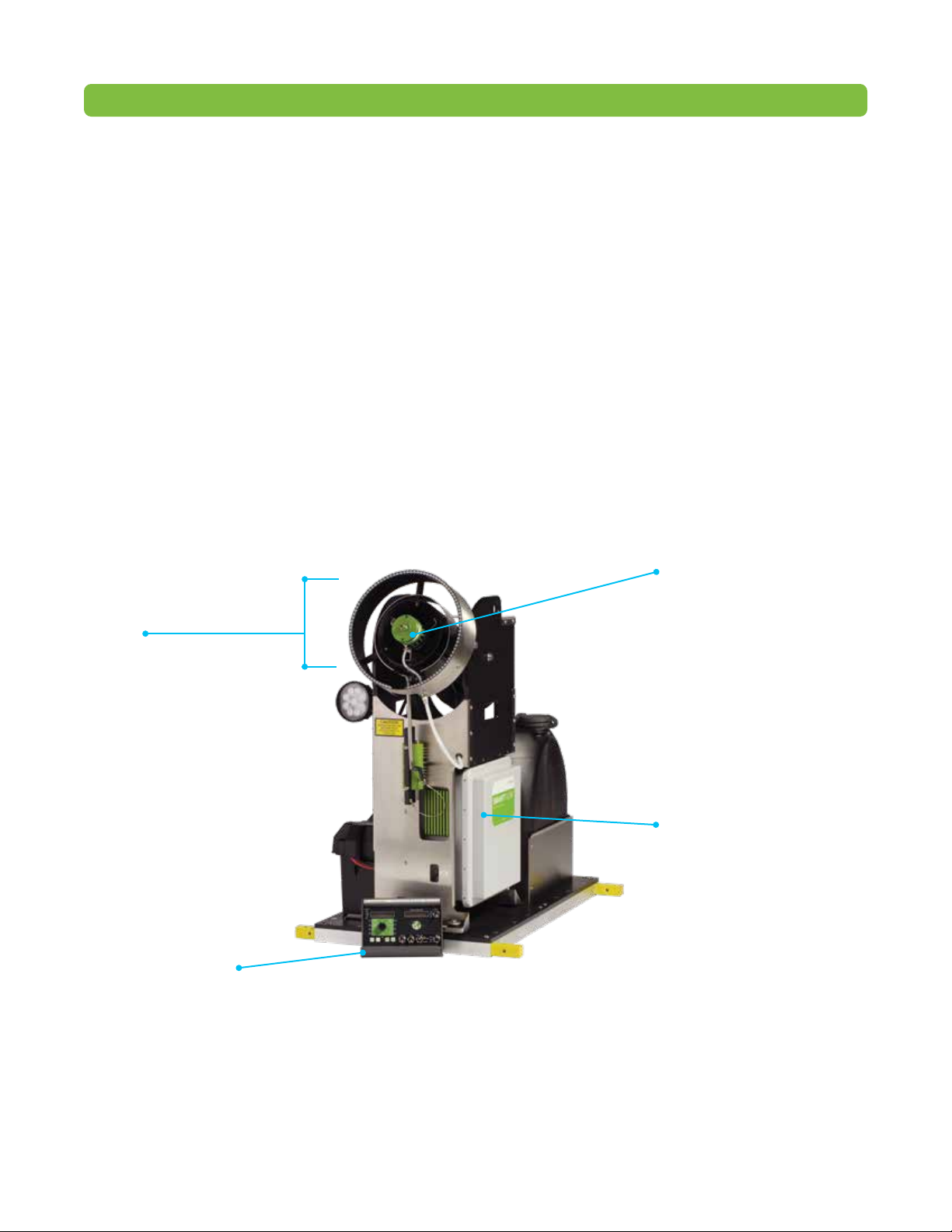

8. The spray head motor is a precision high speed

device. Pay special attention to avoid any forceful

impacts or stress on the spray head motor shaft.

Use a small amount of common automotive type

of anti-seize grease on the threads of the motor

shaft, hub and retaining ring. Always use the

Spanner Puller Tool as described in the sleeve

removal and replacement section.

9. Maintaining the Disposable Sleeve is a key part

of insuring proper machine performance as well as

extending spray head motor life. Sleeve life can vary

dramatically depending on type of formulation and

dispensing rate. Always monitor the condition of the

sleeve. The Maintenance Alert is a programmable

countdown timer that can assist in managing this

required maintenance interval. See the Maintenance

Alert Count Down timer section for details on

this feature.

FOREWARD