SAFETY PRECAUTIONS

IMPORTANT

Failure to follow these precautions could result in

personal injury, and/or damage to property.

1. ALWAYS wear approved impact resistant safety

goggles. (Eye glasses are NOT safety glasses).

2. ALWAYS disconnect the tool when not in use,

before changing accessories and before carrying

out any maintenance

3. ALWAYS have trigger in the OFF position when

connecting to an air supply.

4. ALWAYS keep a safe distance between yourself

and other people when using the tool.

5. Maintain the tool with care. Keep it clean for

best and safest performance.

6. Quick change couplings should not be

located at the tool. They add weight and

could fail due to vibration.

7. DO NOT over-reach. Keep your proper footing

and balance at all times.

8. DO NOT force or misuse the tool. It will do a

better and safer job at the rate for which

it was designed.

9. DO NOT abuse hoses or connectors. NEVER

carry a tool by the hose, or yank it to

disconnect from the air supply. Keep hoses

away from heat, oil and sharp edges.

Check hoses for weak or worn condition

before use, and ensure that all connections

are secure.

10. DO NOT exceed 90 PSI at the tool.

11. DO NOT modify the tool in any way.

AIR SUPPLY

Tools of this type, operate on a wide range

of air pressures. It is recommended that

air pressure to this tool does not exceed

90 PSI, at the tool when running. Higher

pressure and unclean air, will shorten the

tools’ life because of faster wear, and

could be a safety hazard.

Water in the air line will cause damage to

the tool, ensure it is properly maintained

at all times.

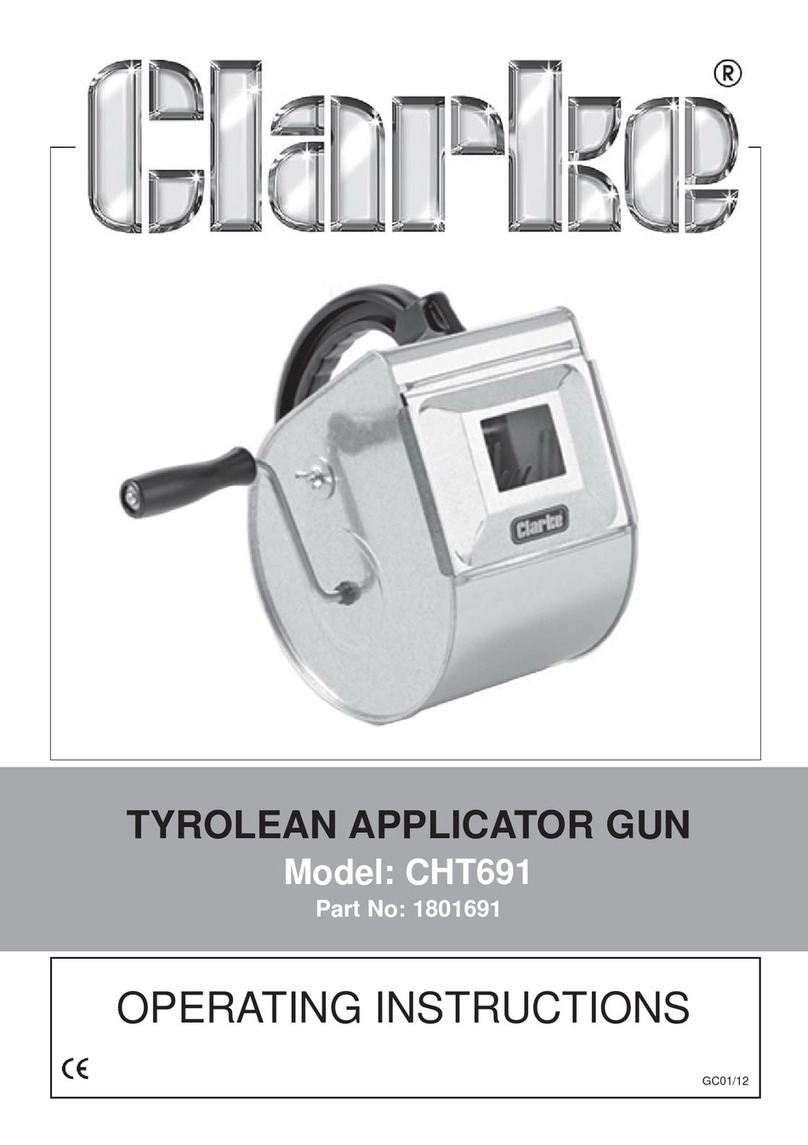

The recommended procedure to connect

this tool to an air supply, is shown at fig. 1.

The air inlet used for connecting air supply,

has a standard ¼” BSP thread.

Line pressure, or hose inside diameter, should be increased to compensate for unusually long air hoses

(over 25 feet). Minimum hose diameter should be 5/16" (8mm) ID., and fittings should have the same

inside dimen.sions.

OPERATION

Ensure the air supply is disconnected before filling the grease chamber.

1. Unscrew and remove the grease chamber complete.

2. Enter a grease cartridge (available from your Clarke dealer), into the open end of the grease chamber,

then gently and progressively pull the piston rod (19) out fully, against spring pressure, whilst guiding the

cartridge into the chamber. Lock the piston Rod in place using the locking plate (21).

3. Clean the edge of the chamber before screwing back on to the body of the gun.

4. Release the piston rod by pressing the locking plate.

5. Open the Air vent valve (10) to expel any air in the chamber, and close again when solid grease is

expelled.