7

TECHNICAL DATA

CONSTRUCTION FEATURES

Safety devices

•

Power supply shuts off automati-

cally in the event of overheating or

cooling system failure.

•

Power shuts off automatically when

cover is opened.

Cooling

Forced ventilation cooling system

using axial flow fans.

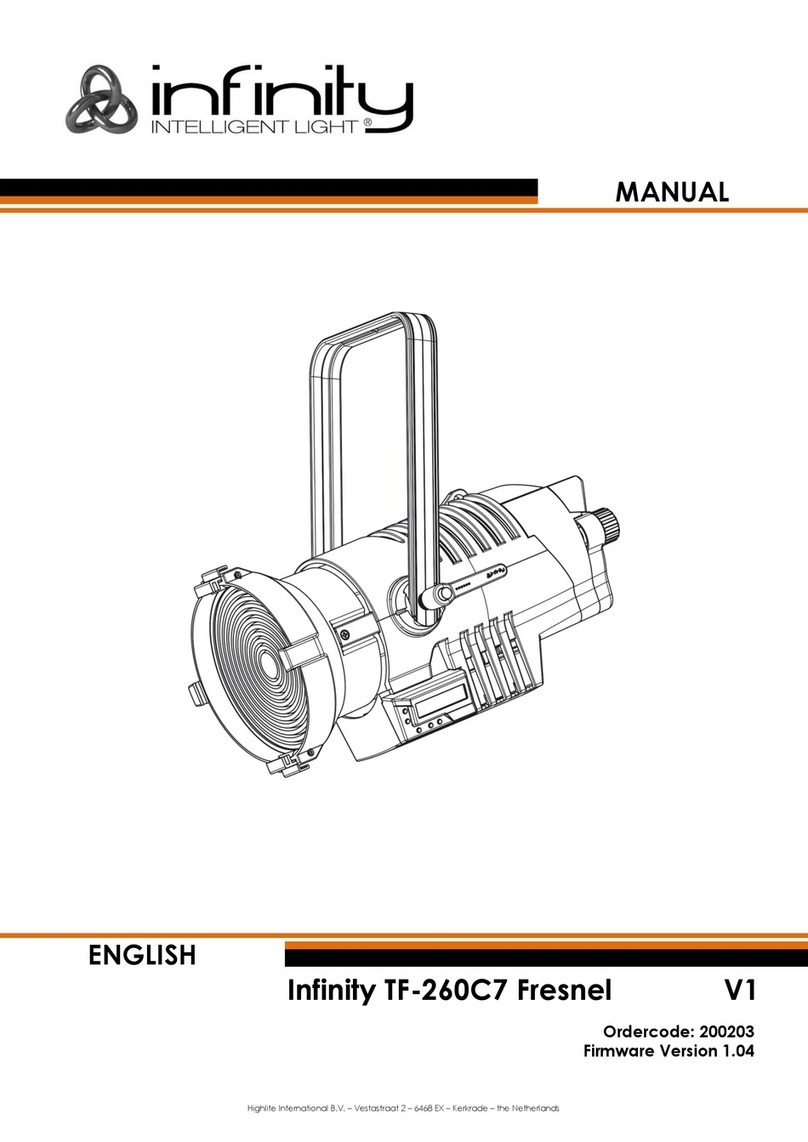

Housing

In steel sheet with epoxy powder coat-

ed finish.

Mounting

•

Steel bracket with epoxy powder

coated finish.

•

Bracket adjustable through 95°.

Operating position

Will function in any position.

Weights and dimensions

Weight: 35 kg (77 lbs)

ELECTRICAL / MECHANICAL

SPECIFICATIONS

Power supply

•

220 - 240V 50Hz

•

200 - 220V 60Hz

Lamp

Metal halide type with special built-in

power supply unit.

•

Type HMI 575W

•

- Cap SFc 10-4

•

- Colour temperature 6000 K

•

- Luminous flux 49000 lm

•

- Average life 750 h

Power consumption

1500 VA at 230V 50Hz

Motors

N. 14 microstepping motors with full

microprocessor control.

CONTROL SYSTEMS

Channels

N. 8 control channels.

Inputs

TORNADO is set up to accept digital

control signals from controllers or

computers.

•

Digital serial input

RS232/423(PMX) or DMX 512

MIRROR HEADS

•

In diecast aluminium with epoxy

powder coating.

•

Very high luminous efficiency

mirrors.

Movement

•

Produced by two microprocessor

controlled microstepping motors.

•

Infinitely variable speed of rotation;

maximum values:

- PAN = 0.4 sec (150°)

- TILT = 0.3 sec (110°)

•

Continuous and uniform movement.

Resolution:

- PAN = ±0.3° (150°)

- TILT = ±0.2° (110°)

7

ENGLISH

IMPORTANT: do not use solvents or

alcohol

Parts that need cleaning frequently

Parts that need cleaning monthly

Internal components should be

cleaned once a year by dislodging

dust and dirt with a brush and remov-

ing it simultaneously with a vacuum

cleaner.

IMPORTANT: isolate the projector from the electrical power supply before com-

mencing maintenance work of any description.

The maximum temperature on the outer surface of the projector under normal

operating conditions is 80° C (176° F).

After switching off, do not remove any part of the projector for at least 7 minutes,

as indicated on the lamp change label (2).

Once this time has elapsed, the risk of a lamp exploding is practically zero.

If the lamp needs changing, wait a further 15 minutes to avoid the risk of burns.

In the event of a lamp exploding, the projector is designed to prevent fragments of

glass from being scattered. The lenses supplied with the projector must be fitted

at all times, and if visibly damaged, must be replaced with genuine spares.

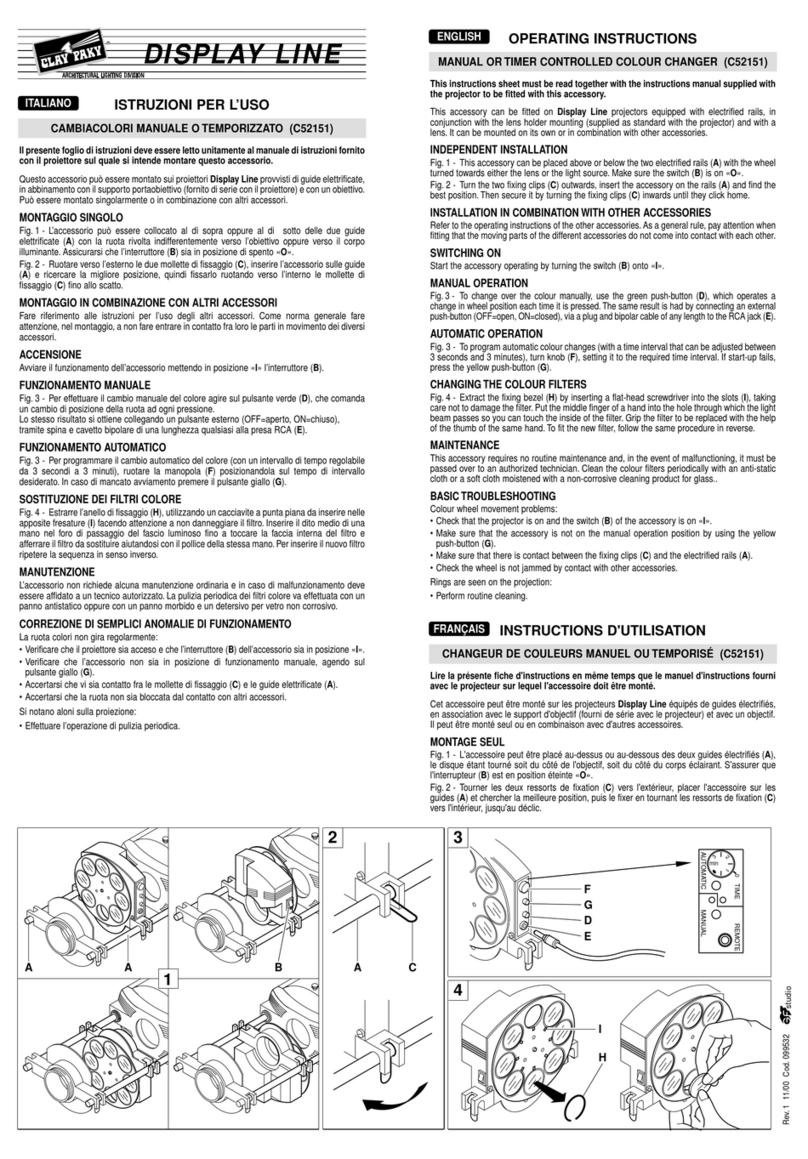

• Changing the lamp

Unscrew the two knobs (9) and

remove the lamp change cover (10).

Loosen the nut (11) of the lamp to be

replaced and remove it from plate

(12) gripping it by attachment (13).

Remove the new lamp from its box,

remove the nut (14) and loosen the

other nut (11).

Screw the lamp directly into plate

(12) gripping it by attachment (13).

Fit metal strip (15) onto attachment

(16) and fully tighten nut (11).

Refit cover (10) tightening knobs (9)

fully.

CAUTION: The projector uses a high pressure lamp with external starter.

- When fitting a new lamp, read the manufacturer's instructions carefully.

- The lamp must always be changed without delay if damaged or deformed by

heat.

• Replacing fuses

To replace the fuses, press the tab

(18) and pull out the fuse holder

(19). Replace any blown fuse with

one of the same type and rating as

indicated on the label (20) attached

to the holder (19).

Insert the fuse holder and push in to

engage the tab (18).

IMPORTANT: for uniform distribution of the light beam, the lamp must be posi-

tioned so that the glass pip (17) on the bulb does not coincide with any of the six

optical axes of the projector.

MAINTENANCE

5

910

11

14 13

17

11

16

15

17

16

12

13

20 19 18

TROUBLESHOOTING

6

No electrical power supply. Check that the power supply is

available at the mains socket

and/or that the fuses are intact.

THE PROJECTOR DOES NOT LIGHT UP

ANOMALIES

ELECTRONICS NOT WORKING

PROJECTION FAULTY FAULTS

REDUCED BRIGHTNESS

POSSIBLE CAUSES CHECKS AND REMEDIES

•

••

•

••

••

•

Lamp expended or faulty. Change lamp (see instructions).

Signal transmission cable short-

circuiting or disconnected. Change cables.

Address codes incorrect. See projector coding instructions.

Defect in electronic circuits. Contact an authorized technician.

Lenses broken. Contact an authorized technician.

Deposit of dust or grease. Clean (see instructions).

• Routine cleaning

To maintain the light output of the projector undiminished, parts that tend to

accumulate dust and grease must be cleaned periodically.

The projector will give long and trouble-free service if these simple guidelines are

followed.

To remove dirt from the lenses and filters, use a soft cloth moistened with any

liquid detergent suitable for cleaning glass.

(39.4”)

1.000

(19.7”)

500