CD3 Products Manual

CD3, General Benefit Corporation | www.cd3station.com | stopais@cd3station.com | 612.467.9441

Patent Pending | Made in USA | © 2019

3.6 Lights.....................................................................................................................................24

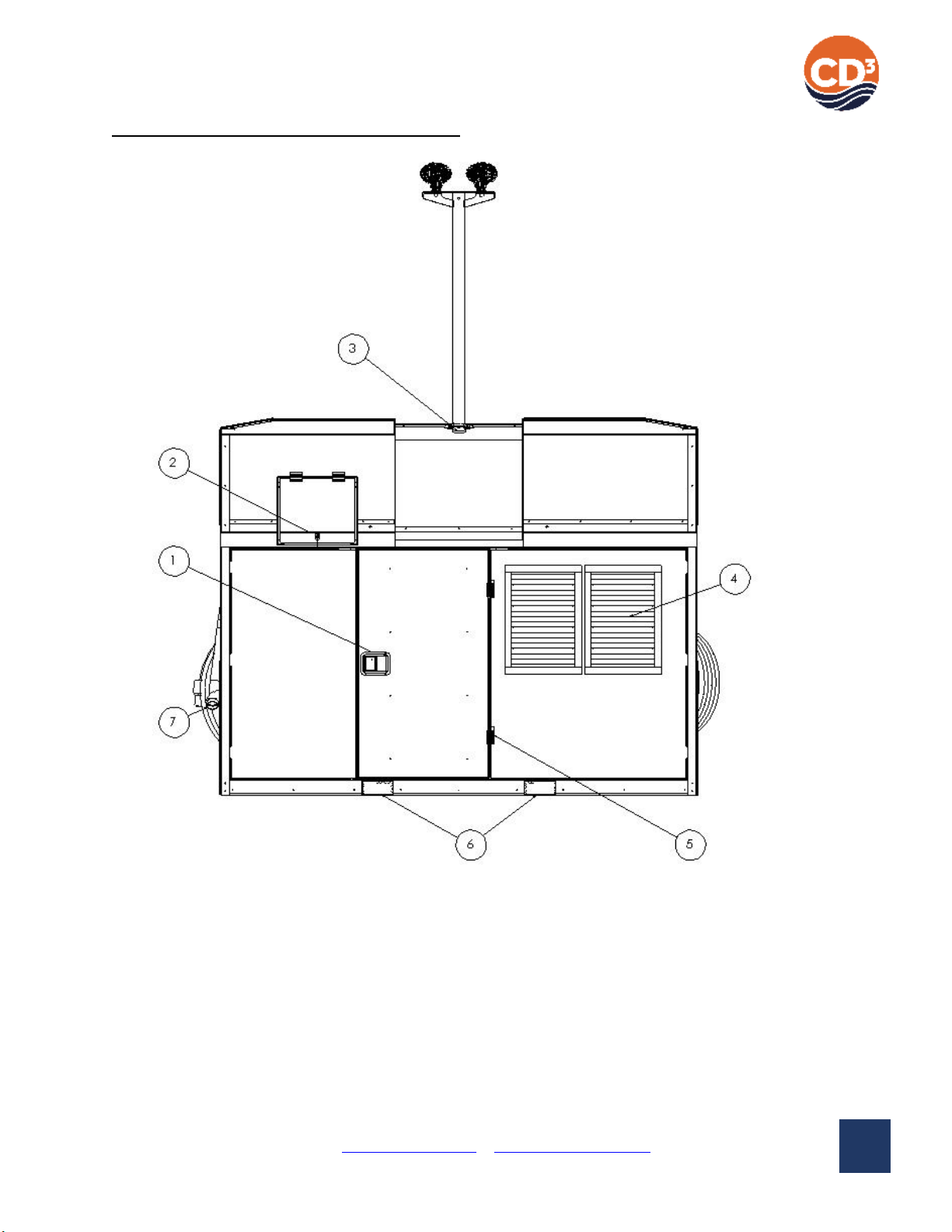

3.7 Trailer (Wayside 120V and Wayside Solar Only) ......................................................................25

3.7.1 Trailer Intended Use..................................................................................................................................25

3.7.2 Trailer Safety Information .........................................................................................................................26

3.7.3 Trailer Lowering/Crank Down Procedure..................................................................................................28

3.7.4 Solar Panel Tie Down (Trailered Wayside Solar Only)...............................................................................29

3.8 Battery Charging (Trailered Wayside Units Only).....................................................................31

3.8.1 Charging Procedure...................................................................................................................................31

3.8.2 Charger Safety Information.......................................................................................................................32

3.8.3 Extension Cord Requirements...................................................................................................................32

3.8.4 Partial Recharging .....................................................................................................................................32

3.8.5 Charge Time ..............................................................................................................................................32

3.8.6 Battery Break-In ........................................................................................................................................33

3.8.7 Depth of Discharge....................................................................................................................................33

Section 4 –Maintenance and Care ....................................................................................... 33

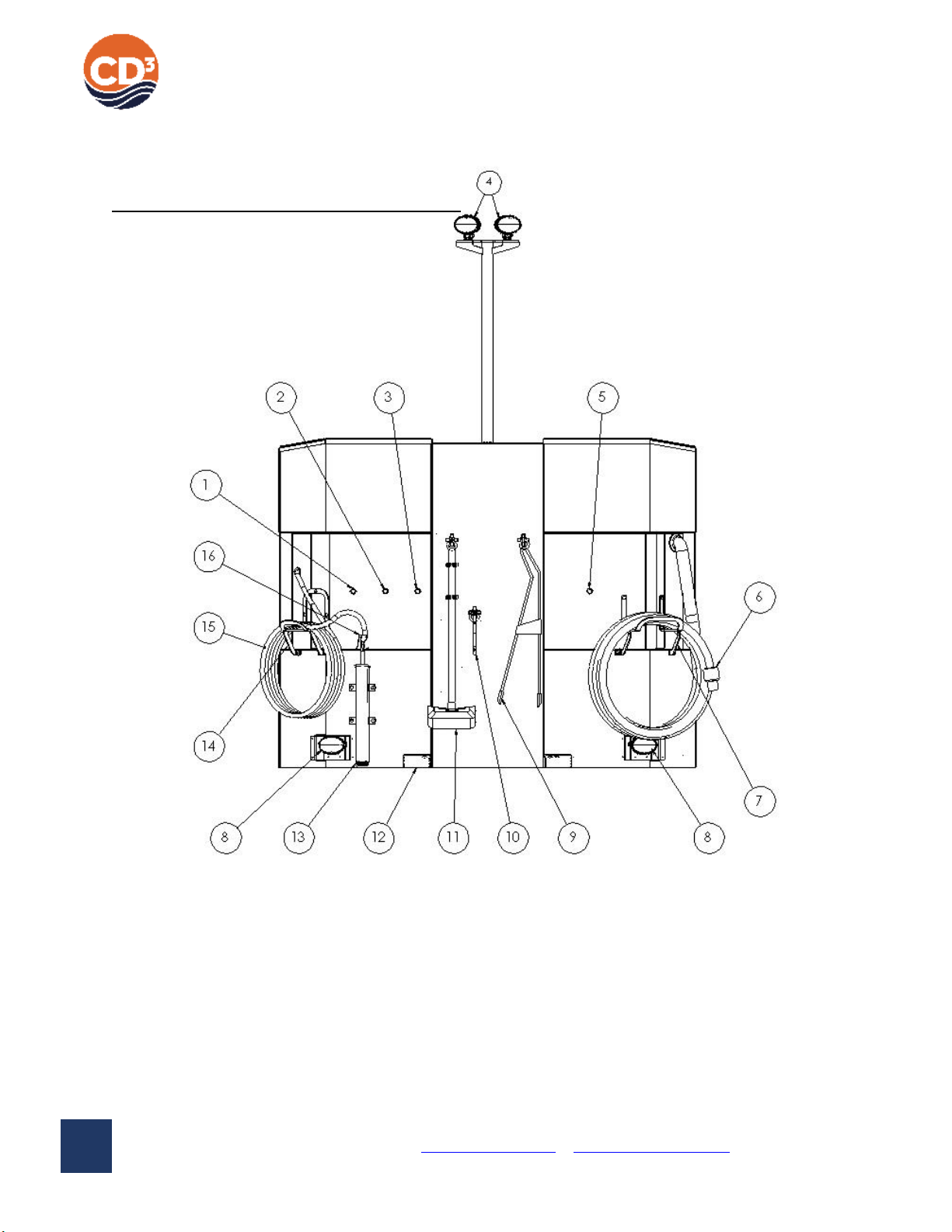

4.1 Vacuum System (Station/Wayside Only).................................................................................34

4.1.1 Tank Emptying...........................................................................................................................................34

4.1.2 Vacuum Pressure Relief Valve...................................................................................................................35

4.1.3 Inspect Hose..............................................................................................................................................35

4.2 Blower/Compressor (Station/Wayside Only) ..........................................................................36

4.2.1 Blower/Compressor Maintenance Safety .................................................................................................36

4.2.2 Air Pressure Regulator ..............................................................................................................................37

4.2.3 Relief Valve................................................................................................................................................37

4.2.4 Air Filter.....................................................................................................................................................38

4.2.5 Air Leaks ....................................................................................................................................................38

4.2.6 Compressor Oil..........................................................................................................................................38

4.2.7 Compressor Belts (Station Only) ...............................................................................................................39

4.3 Tool Reels .........................................................................................................................40

4.3.1 Reel Lubrication ........................................................................................................................................40

4.3.2 Cable Inspection........................................................................................................................................40

4.3.3 Tension Adjustment ..................................................................................................................................40

4.3.4 Spring Replacement ..................................................................................................................................40

4.3.5 Reel Sensors ..............................................................................................................................................40

4.3.6 Tool Replacement .....................................................................................................................................41

4.4 Batteries (Wayside/Outpost Only)..........................................................................................41

4.4.1 Battery Safety Precautions........................................................................................................................41

4.4.2 Battery Pack Inspection.............................................................................................................................42

4.4.3 Battery Cleaning........................................................................................................................................43

4.4.4 Battery Disposal ........................................................................................................................................43

4.5 Fuses .....................................................................................................................................43

4.6 Trailer (Wayside120V and Wayside Solar Units Only) ..............................................................44

4.6.1 Greasing Wheel Bearings ..........................................................................................................................44

4.6.2 Tire Pressure .............................................................................................................................................45

4.6.3 Lift System Inspection ...............................................................................................................................45