4www.scanmaskin.com

TABLE OF CONTENTS

1 Specications ...................................................................................................................................5

1.1 Power specications ........................................................................................................................5

1.2 Mechanical specications...............................................................................................................5

1.3 Water tank.........................................................................................................................................6

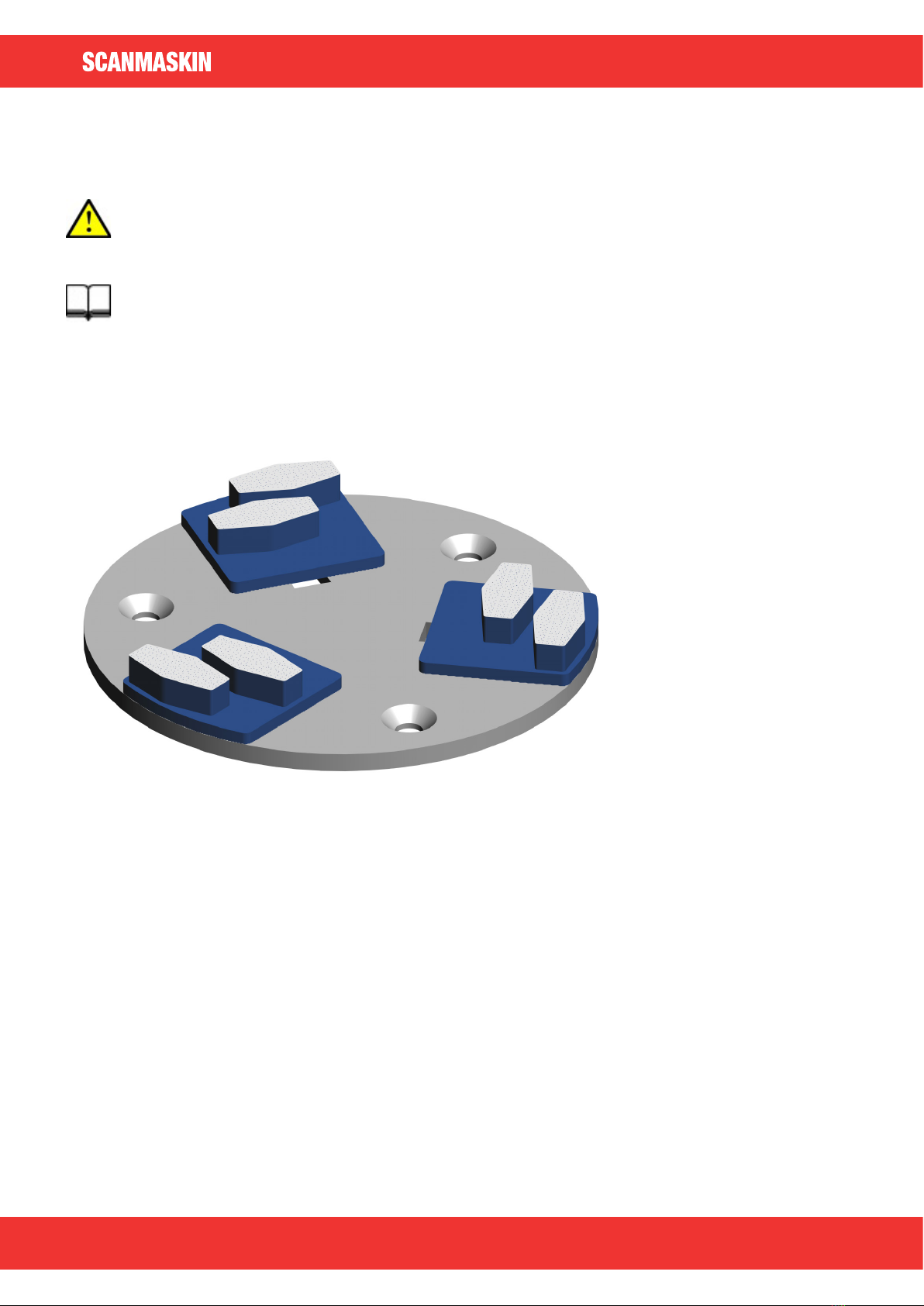

1.4 Tools ..................................................................................................................................................7

1.5 Range of application .......................................................................................................................8

1.6 Scope of supply ...............................................................................................................................8

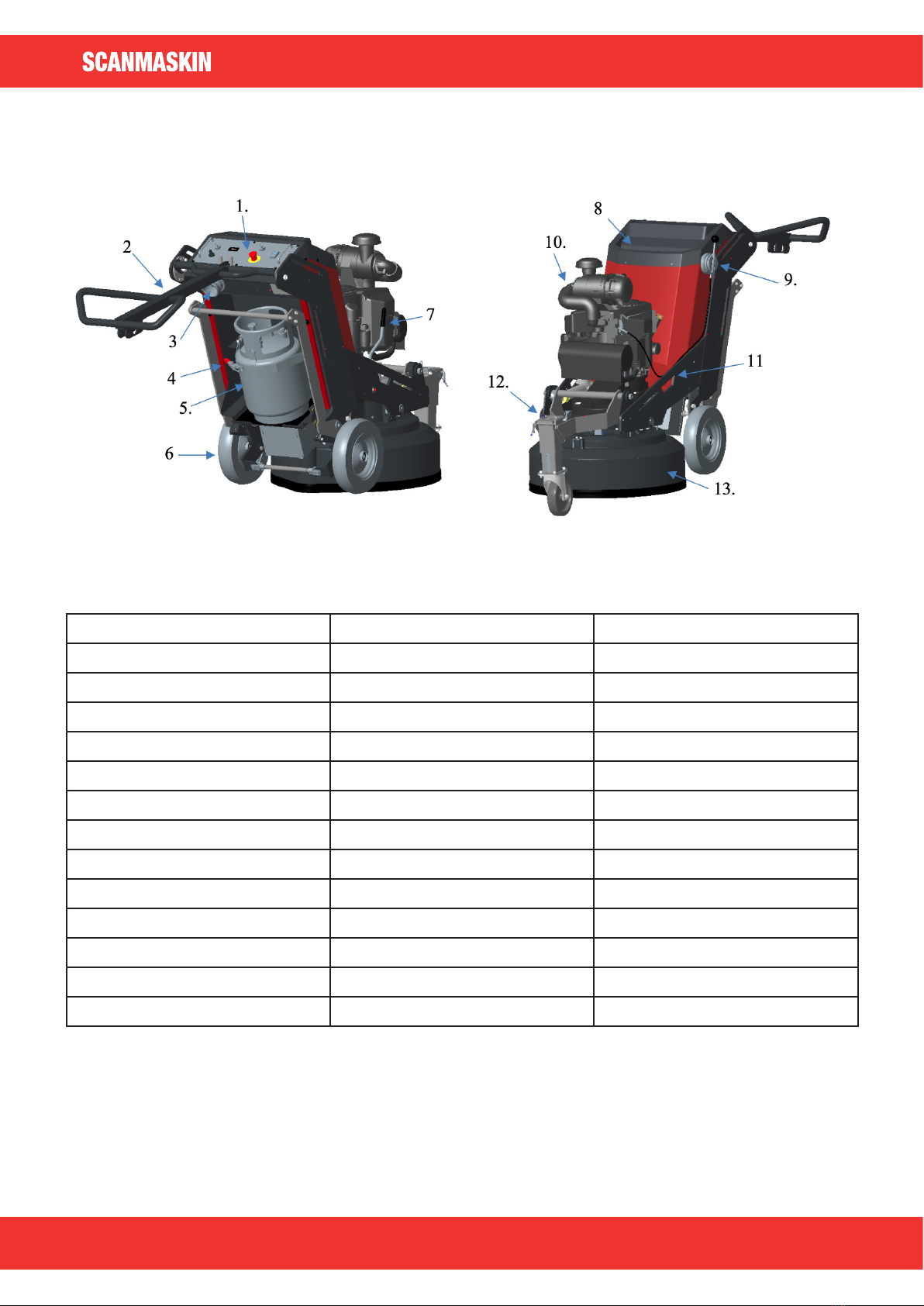

1.7 Overview ...........................................................................................................................................9

2 Safety Regulations .........................................................................................................................10

2.1 Legend ............................................................................................................................................10

2.2 Safety precautions .........................................................................................................................10

2.3 Propane safety................................................................................................................................11

2.4 Fire Safety........................................................................................................................................11

2.5 Emissions ........................................................................................................................................11

2.6 Hazard Communication ................................................................................................................11

2.7 Local agencies and regulations....................................................................................................12

2.7.1 • NFPA .............................................................................................................................................12

2.8 Organizational measures ..............................................................................................................13

2.9 Personnel qualication ..................................................................................................................15

2.10 Safety regarding operation of machine .....................................................................................15

2.11 Propane tanks ...............................................................................................................................16

2.12 Relling propane tanks.................................................................................................................16

2.13 Storage propane tanks.................................................................................................................17

2.14 Denition of the “Safety off position”.........................................................................................17

2.15 Safety regarding maintenance ....................................................................................................17

2.16 Safety regarding transport..............................................................................................................18

2.16.1 Manual transport...........................................................................................................................18

2.16.2 Lifting..............................................................................................................................................18

2.16.3 Inside vehicles ...............................................................................................................................18

2.16.4 Inside vehicles ...............................................................................................................................18

3 Transport .........................................................................................................................................19

3.1 Precautions .....................................................................................................................................19

3.2 Manual transport............................................................................................................................19

3.3 Lifting...............................................................................................................................................19

3.4 Inside vehicles ................................................................................................................................19

3.5 Transporting propane tanks .........................................................................................................20

4 Operation........................................................................................................................................20

4.1 Preparation ....................................................................................................................................20

4.2 Precautions .....................................................................................................................................20

4.3 Operation of machine ...................................................................................................................21

4.4 Control panel..................................................................................................................................21

4.5 Throttle ...........................................................................................................................................22

4.7 Stop.................................................................................................................................................23

4.8 Emergency Stop ...........................................................................................................................23

4.9 Adjusting grinding speed............................................................................................................23

4.10 Safety off position .........................................................................................................................24