cleanAIR 0723-10 User manual

Table of Contents

Heated Sample Line

1

IMPORTANT!!!................................................................................................................. 2

Customer Feedback......................................................................................................... 3

1 Safety .......................................................................................................................... 4

1.1 Temperature........................................................................................................ 4

1.2 Electrical Shock.................................................................................................. 4

1 Principles of Operation............................................................................................... 5

1.3 Lengths, Voltages, Watts.................................................................................... 5

2.2 System Components............................................................................................ 5

2.3 System Operation................................................................................................ 6

3 Maintenance and Inspection ....................................................................................... 7

3.1 External maintenance.......................................................................................... 7

3.2 Maintenance Issues............................................................................................. 7

4 Troubleshooting.......................................................................................................... 8

IMPORTANT!!!

Heated Sample Line

2

IMPORTANT!!!

BEFORE YOU BEGIN READ THIS!!!

READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE USING THIS

SYSTEM! SAVE THESE INSTRUCTIONS!!!

To Avoid Accidents…

Keep your work area clean and well lit.

Keep bystanders away.

Exercise common sense.

Electrical Safety…

Do not operate in combustible environments.

DO NOT operate these products when wet or in water.

ALWAYS be sure that the components of this system are running with the

correct voltage (see section 1.1).

Never remove a grounding prong or modify a plug.

Do not cut or alter the heated sample line in any way.

Do not abuse the power cord or plug. Remove by handling plug only.

Personal Safety…

The parts of this system are heated in excess of 500 degrees Fahrenheit.

Use caution when handling your equipment during and after a test.

Stay alert and watch what you are doing.

Dress appropriately. Wear the appropriate personal safety devices.

BE SURE to read all tags and stickers attached to the line.

Equipment Maintenance…

Clean Air Express can not ensure that our Heated Sample Line is

compatible with any other temperature controllers but our own. It is

HIGHLY recommended that one of Clean Air Express’s digital temperature

controllers (0725RNT, 0725PM, 0725R) be used with this product. See

http://www.cleanair.com or call (800) 223-3977 for more information

Maintenance and repairs should be performed by one of Clean Air

Express’s trained technicians.

When removing the hose from its spool take care that the hose does not

kink. This may cause damage to the core.

While the line is hot or heating up it SHOULD NEVER come in contact

with itself. This can possibly result in permanent damage to the line.

Avoid wrapping the hose with tape or other insulating materials.

Customer Feedback

Heated Sample Line

3

Customer Feedback

Clean Air Engineering takes pride in our quality products and services. We strive

to provide the highest quality products and services in the industry. We realize

the importance of end user input in the continual improvement of our products

and services. Customer feedback is of paramount importance. We encourage

your feedback with any suggestions or problems that can help us improve

our performance. A customer feedback form is available online at

http://www.cleanair.com/About/feedback.html. To emphasize our commitment to

quality products and complete customer satisfaction, Clean Air Engineering’s

manufacturing division, CAE Express, offers what we feel is the best and most

comprehensive warranty in the environmental industry.

Safety

Heated Sample Line

4

1 Safety

Safety should always be considered first, and proper safety procedures should

be followed.

1.1 Temperature

Clean Air Express’s temperature controllers are capable of heating lines to very

high temperatures. Exercise caution around the exterior of the box, lines, and

probes as they can all become very hot when the assembly is on.

1.2 Electrical Shock

The Heated Sample Line is powered by a standard 120 VAC line, meaning

potentially fatal shocks are possible. It is no more dangerous than many

household appliances in this regard; however, care must be taken to avoid

shock. Before performing any maintenance on this or an assembly containing it,

turn off and unplug all devices from the 120 VAC line.

Principles of Operation

Heated Sample Line

5

1 Principles of Operation

Maintaining a steady temperature around 250°F is important so that moisture,

acid gas, and other constituents of the gas stream do not condense within the

sample lines. This can result in the damage of equipment as well as the loss of

important data. The Heated Sample Line helps to ensure the accuracy of gas

samples by providing a heated route for the gas in order to help prevent

scrubbing.

1.3 Lengths, Voltages, Watts

Part Number

Voltage

Watts

Length

0723-10

120

300

10

0723-25

120

750

25

0723-50

120

1500

50

0723-100

120

2500

100

0723-100HD*

120

3000

100

*NOTE: The HD model is manufactured to operate at a temperature of 400

degrees Fahrenheit.

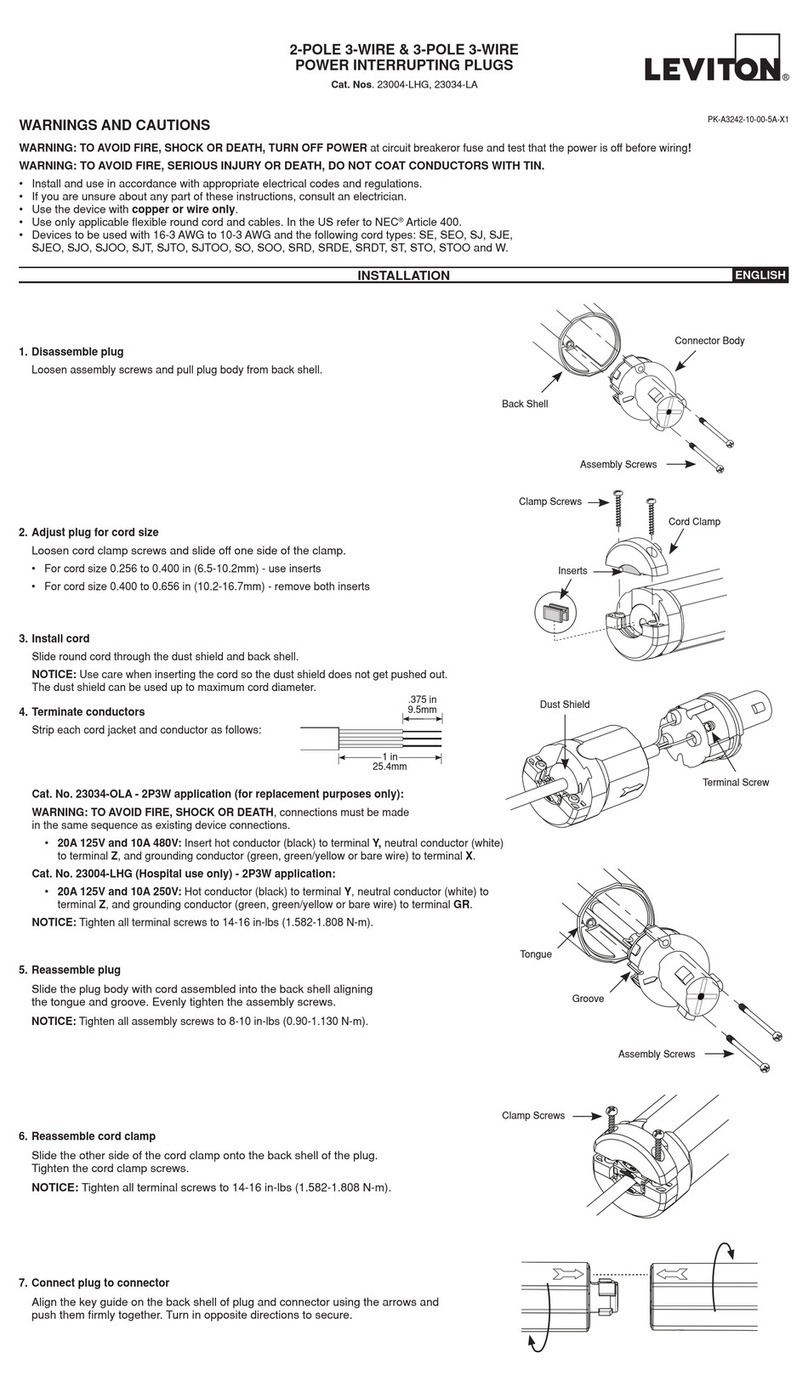

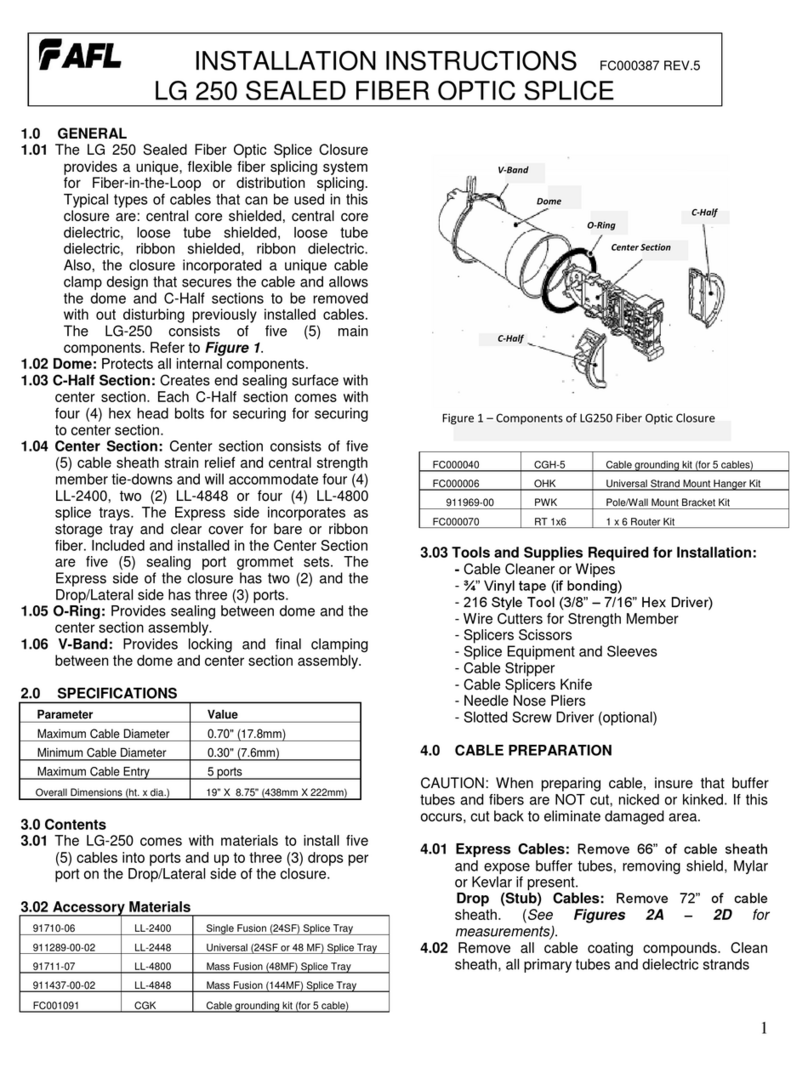

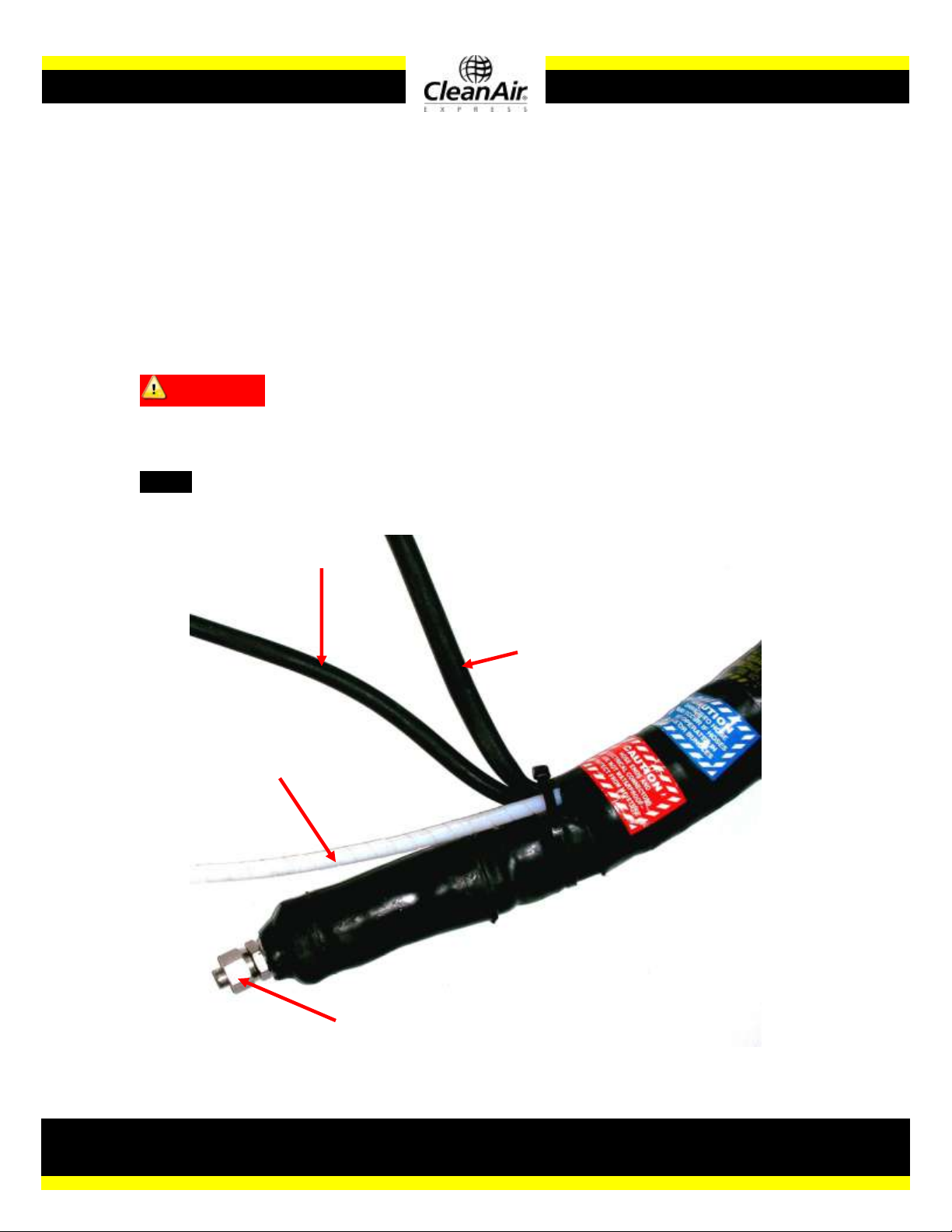

2.2 System Components

The Heated Sample Line consists of a Teflon sample line (which can also be

ordered as stainless steel), a smaller Teflon calibration gas line, a power cord,

and two type K thermocouples (3) located 1/3 of the way from each end. The

second thermocouple is a spare in case of breakage. The lines are heated by

coils throughout the length of the line (see figure 2). They are very durable as

well as flexible.

(3)

Type K

Thermocouple

Heating Coil

Figure 1

Figure 2

Principles of Operation

Heated Sample Line

6

2.3 System Operation

See below for pictures.

Insert one of the thermocouples (3, Figure 1)into the corresponding input on the

temperature controller; the second is simply a spare. It is unnecessary to plug

the second thermocouple into anything. Connect the calibration gas line (2) and

the sample line (1). Plug in the temperature controller and the heated sample

line (4), as well as any other equipment (120V). Select the desired temperature.

Allow 10-15 minutes for the system to warm up then begin sampling.

CAUTION!! –If the light on the temperature controller does not blink when it

gets near the target temperature, overheating is very likely! The most likely

cause is a bad relay in the temperature controller.

NOTE –In the event of an overload, the circuit breaker on the temperature

controlling device will pop out. Simply push it in to reset.

(4) Power

Cord

(3)

Thermocouple

Wire

(2) Calibration

Gas Line

(1) Sample

Line

Connection

Figure 3

Maintenance

Heated Sample Line

7

3 Maintenance and Inspection

CAUTION!! –Do NOT disassemble this product! For internal maintenance

contact Clean Air Express.

3.1 External maintenance

If dirty, the outside of the lines can be cleaned with mild soap. Thermocouple

plugs can also be damaged relatively easily, but are simple to replace. Order

part number 0316M from Clean Air Express.

3.2 Maintenance Issues

For any other maintenance issues, concerns, or questions, please contact

Clean Air Express at (800)-223-3977. Clean Air Express can also be reached by

mail at 212 N. Woodwork Lane Palatine, IL 60067; by fax at (847)-991-8924 or

on the web at http://www.cleanair.com/equipment/Express/main.html

Troubleshooting

Heated Sample Line

8

4 Troubleshooting

Heated Sample Line Controller not heating the sample lines

There is no easy way to repair/replace a burned-out probe heater or

heated sample line in the field. However, often the source of failure is not

a burned-out heater, but a bad connector. Check the connectors for a

broken or bent pin, and repair/replace as necessary. If the connectors

and pins are fine, check to make sure the breaker is not tripped. Reset

the breaker if it has tripped. If resetting the breaker fails, or immediately

trips again, unplug the assembly and look for shorts in the circuit. Do NOT

disassemble the controller; contact Clean Air Express for maintenance.

Overheating

The overheating of this product or the assembly it is contained in is most

often a result of either a thermocouple or temperature controller problem.

If a thermocouple’s insulation is compromised and the bare wires allowed

to come in contact with a surface, it will report the temperature at that

point, rather than at its tip. This can fool at temperature controller into

keeping a heater on continuously. Try using the spare thermocouple

instead. If none of the thermocouples has failed, it means that the

temperature controller itself has failed and needs to be replaced. This

could be due to disengagement of the temperature sensor, a locked

switch, or a bad relay.

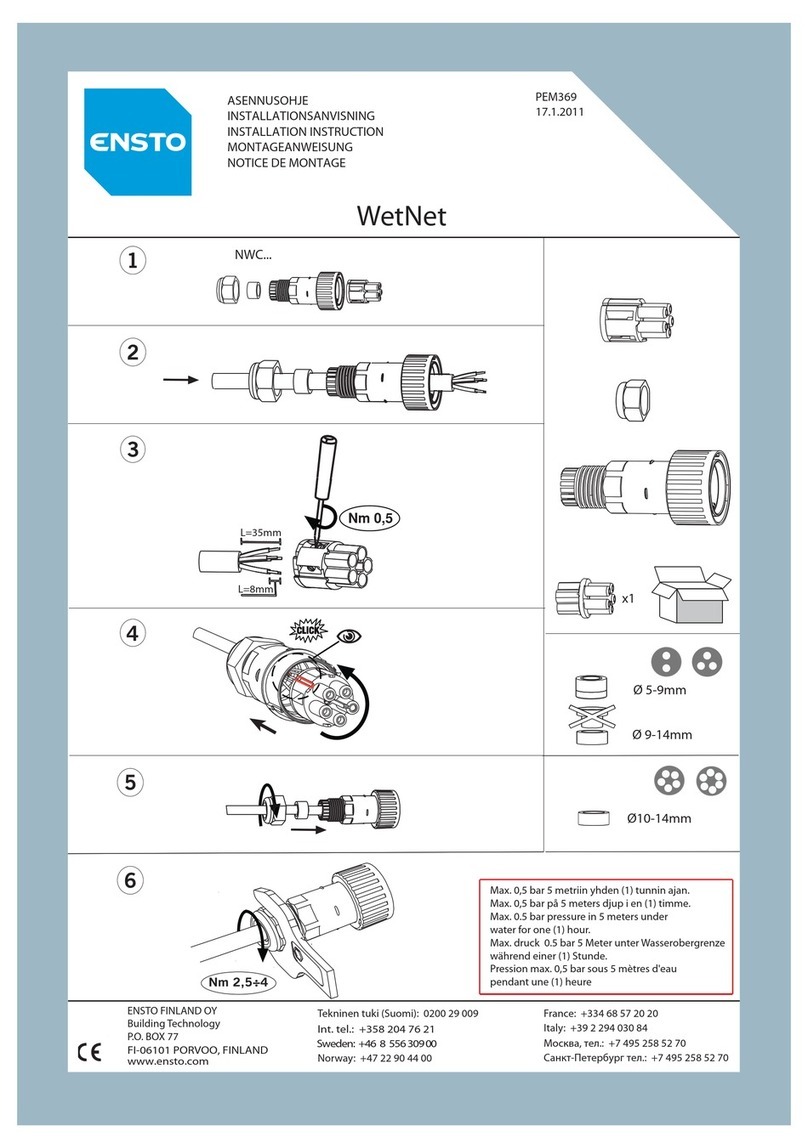

Cross Sectional View

Heated Sample Line

9

Electrical

(Thermo-

couples,

Power

cord)

Sample

Line

Calibra-

tion

Line

Parts List

Heated Sample Line

10

CLEAN AIR ENGINEERING

PARTS LIST

HEATED SAMPLE LINE

May 22, 2008

Parent Part #: 0723-* Type: F

*dependent on length

COMPONENT DESCRIPTION QTY UM TYPE

------------------- --------------------- ------- ----- --------

0723G HEATED SAMPLE LINE GUARD 2.0 EA R

SAFETY YELLOW

9801100 HEATED SAMPLE LINE 100' 1.0 EA R

0419SRU UNION 3/8"T-1/4"T S.S. 2.0 EA R

0316M STD MALE THERMOCOUPLE PLUG 2.0 EA R

TYPE K

94032 3 PIN CABLE CLAMP 1.0 EA R

94031 3 PIN AMPHENOL MALE INSERT 1.0 EA R

9403 3 PIN CABLE PLUG 1.0 EA R

(SHELL ONLY)

Our Guarantee

Heated Sample Line

11

Our Guarantee

Clean Air Engineering warrants products to be free from defects and

workmanship for a period of one year after delivery date. The sole and exclusive

remedy for defective goods shall be repair or replacement of defective parts or

payment price of the goods for which damages are claimed, at Clean Air

Engineering’s option.

© Clean Air Engineering –June 2008

This manual suits for next models

4

Table of contents