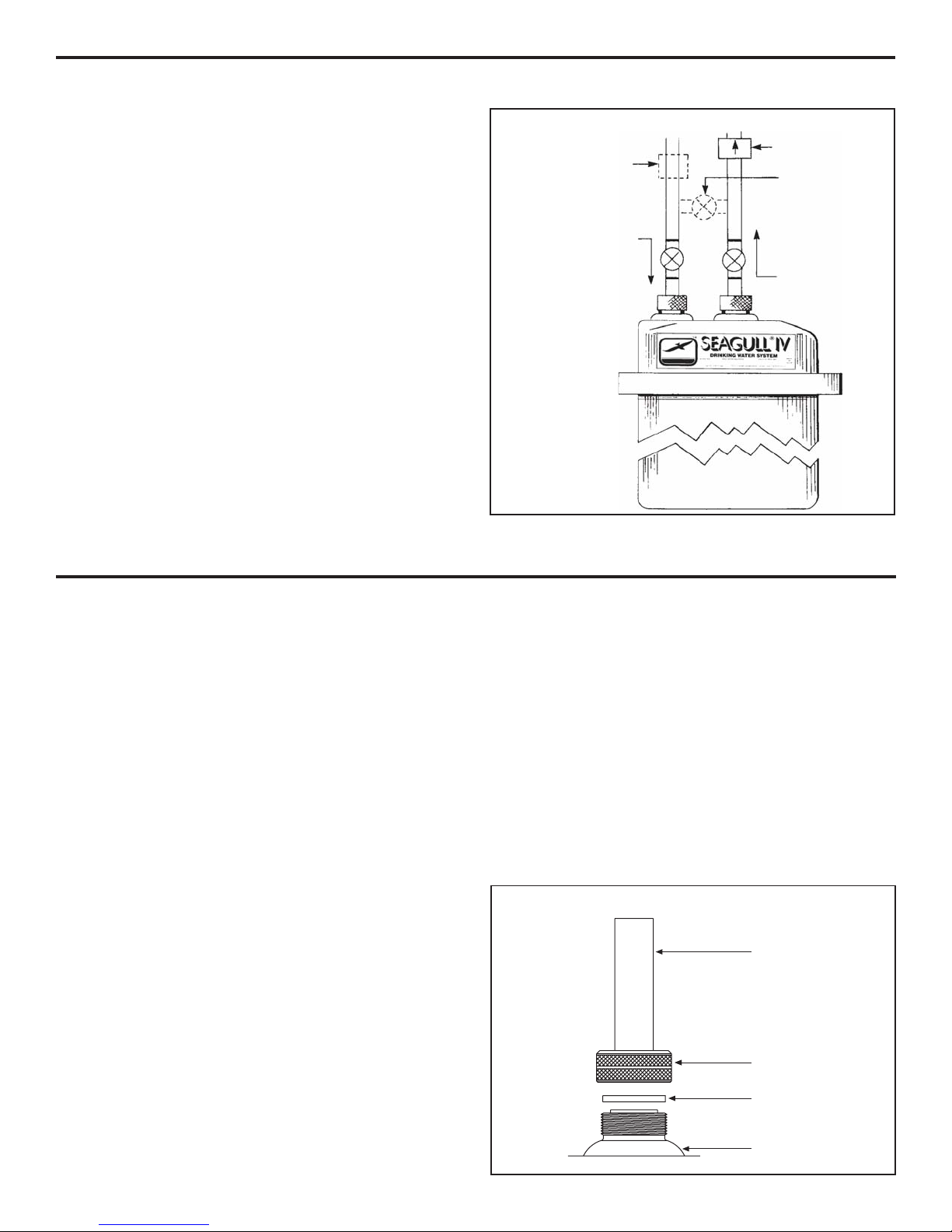

SEAGULL®IV X-6 Parts List and Dimensions

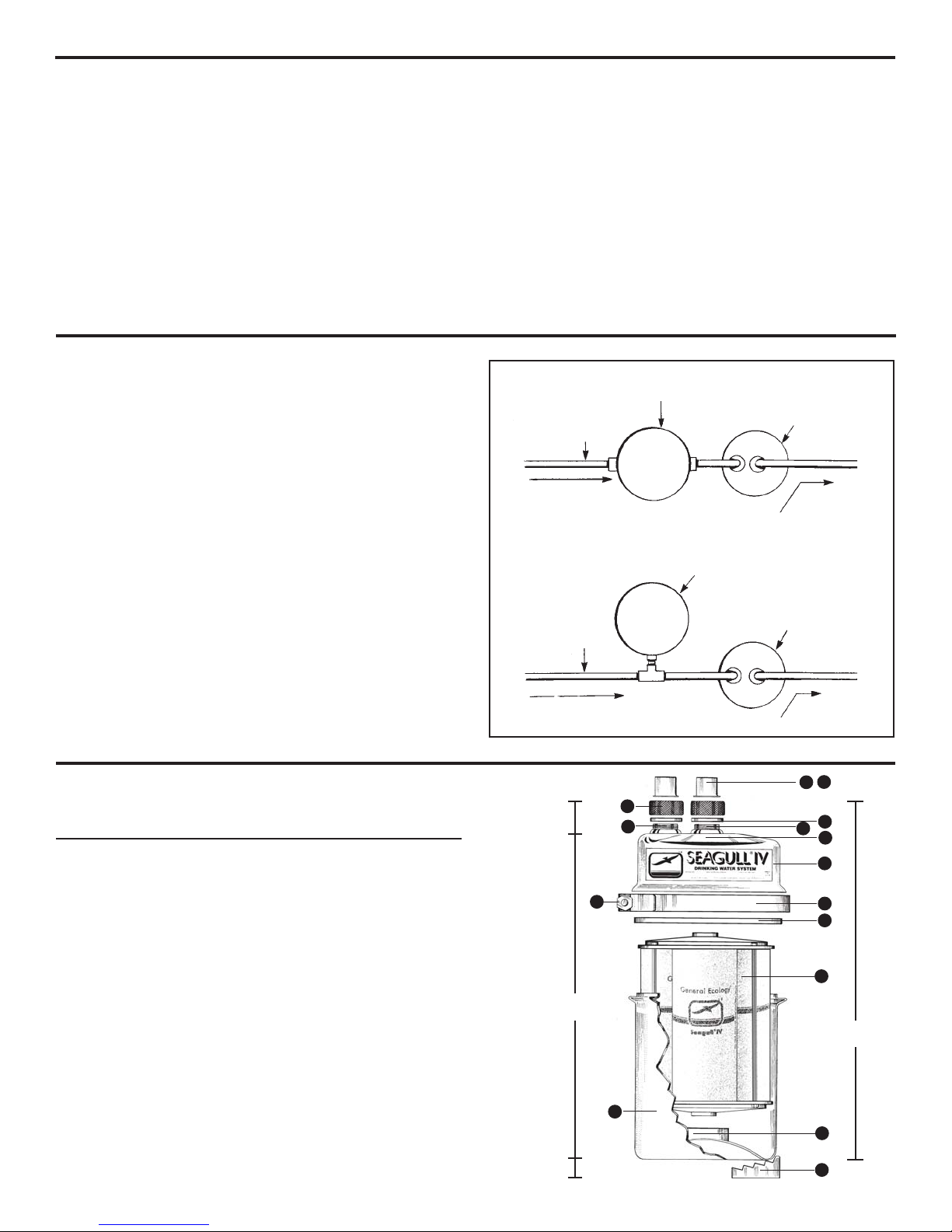

AssemblyInstructions

should be applied to center Port O-Rings of Housing Cover

before aligning it with the Cartridge Module.

7. Center the Cover on the Module while aligning it with the

Bowl Flange and press down into position.

8. Install V-clamp and tighten while lightly tapping the outside

of the V-clamp outside the bolt. A light coating of petroleum

jelly applied to the insides of the V segments will ease

the Clamp installation.

9. Note the Unit Cover’s Supply (INLET) Port and Service

(OUTLET) Port. On all General Ecology stainless steel

Units the Port closest to the side is the Supply (INLET)

Port and the center Port is the Service (OUTLET) Port.

1. Remove the stainless steel Housing and the Cartridge

Module from the package.

2. Remove the V-band that secures the Housing Cover and

Bowl by removing ½" Nut with a wrench or ½" deep socket.

3. Carefully raise the Cover, being careful not to dent or cut

the Bowl Flange, nor allow dirt on any of the Gaskets.

4. Lower the Cartridge Module into the Bowl until it sits on

top of the Rubber Pedestal.

5. Be sure Gaskets are clean and free of cuts and other

potential leak paths.

6. For ease of installation, a light coating of petroleum jelly

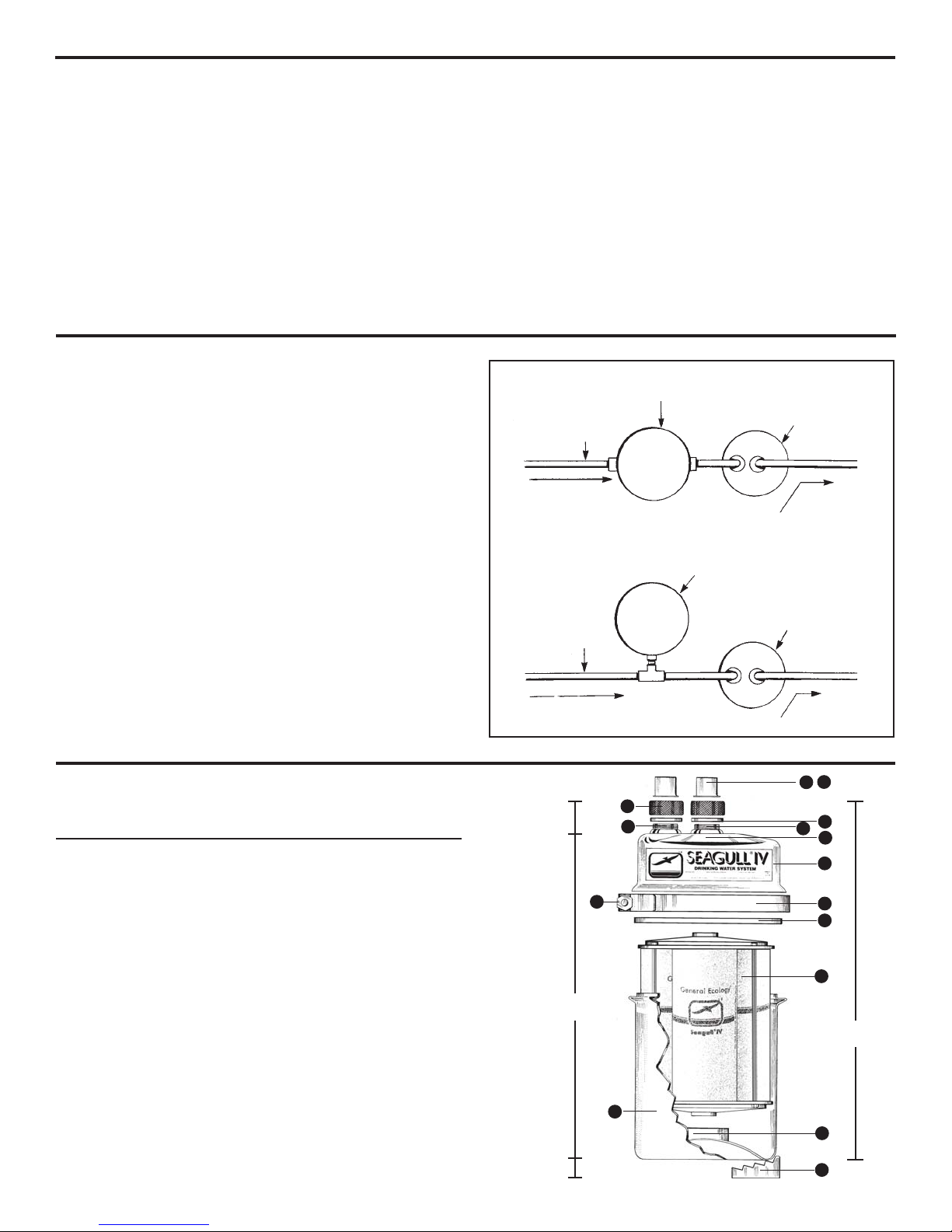

EquipmentPlacement

The SEAGULL®IV X-6 Unit should be level and should have

adequate vertical clearance to permit the three (3) Dielectric

Positioning Pads to be positioned under each Unit.It is important

to use these Pads to allow vertical clearance for the Unit to

clear the Inlet and Outlet Connectors during servicing.

Additionally, the Pads eliminate potential electrical interface

between the Unit and the floor.

The Unit should always be placed on the Service (OUTLET)

side, rather than the Supply (INLET) side, of the air pressure

tanks used with on-site water supplies. See

Figure 2

.

After deciding on placement of the Unit, it is recommended

that appropriate fittings such as valves, nipples, elbows, etc.,

be “dry fit” to be sure of proper positioning, and to double-

check the routing, proper lengths and other factors that will

assure a workmanlike job. Do not strap copper tubing rigidly in

place near the Unit. Allowing tubing to flex slightly will reduce

possibilities of uneven strain at the Inlet and Outlet Connections.

Because of the special Inlet and Outlet Connectors, union joints

usually are not needed.

SERVICE

(OUT)

1 Cover 1 100200

2 Bowl 1 100300

3 V-Clamp 1 100400

4 Housing Gasket 1 100401

5 Inlet Port 1 100411

6 Outlet Port 1 100412

7 Module Seal O-Rings (Internal) 2 100414

8 Knurled Closure Nuts 2 100415

9 Closure Nut Gaskets 2 100416

10 3/4" Sweat Adapters 2 100417

11 1" Sweat Adapters 2 100418

12 Pedestal Assembly 1 100424

13 Dielectric Positioning Pads 3 100421

14 V-Clamp Hex Nut 1 100402

15 RS-6SG Module 1 100501

No. Description Qty. Part No.

SPARK-L-PURE®

METERING

PUMP

(If Required)

SUPPLY (IN)

"TEE" Pressure Tank Installation

SPARK-L-PURE®

METERING

PUMP

(If Required)

SUPPLY (IN)

Figure 2

SERVICE

(OUT)

SERVICE

(OUT)

IN/OUT Pressure Tank Installation

9

6

1

3

4

12

13

7

10 11

8

5

15

16.25" *

(38.1 cm)

1.25" *

(3.2 cm)

15" *

(38.1 cm)

1.25" *

(3.2 cm) * Assembled Dimensions

14

2