3

CLEARSPAN™END PANEL INSTALLATION

Revision date: 04.10.08

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all the

necessary parts before you begin.

Unpack the contents of the shipment and place where

you can easily inventory the parts. Refer to the Bill of

Materials/Spec Sheets.

Verify that all parts listed on the Bill of Materials/Spec

Sheets are present. If anything is missing or you have

questions, consult diagrams for clarification or contact

customer service.

NOTE: At this time, you do not need to open the plastic

bags containing smaller parts such as fasteners and

clamps (if present).

1.

2.

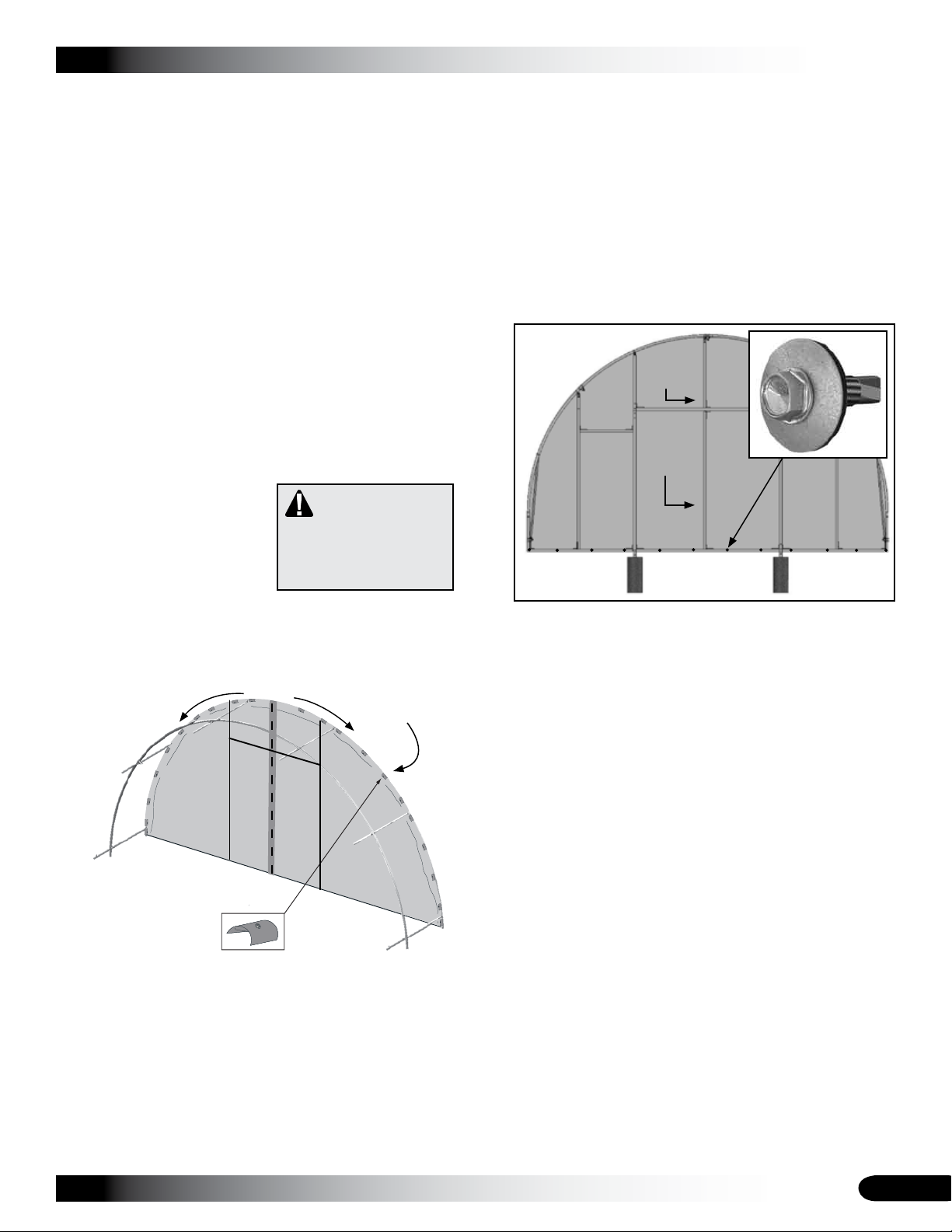

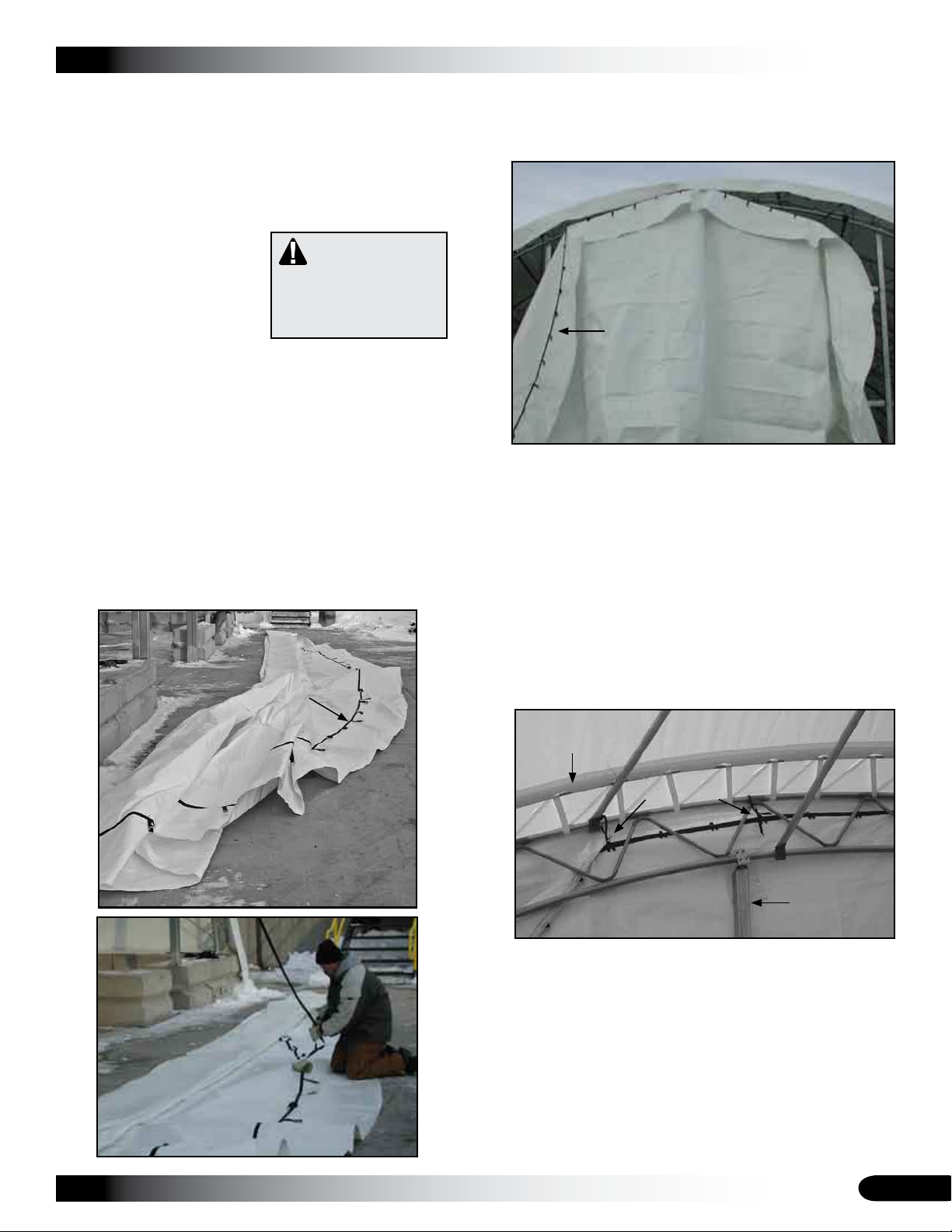

END FRAME: Final Check

Before you attach the end panel, inspect the end frame for

sharp edges or fasteners that could damage the panel.

Verify that all end frame members are properly

secured.

Verify that all bolts and clamps are tight.

Recheck the end frame assembly for sharp edges or

clamps and bolts that may interfere with the installation

of the end panel. File or tape sharp edges as needed.

Reposition clamps and bolts as needed and tape all

rafter pipe joints with duct tape to protect the panel.

Verify that the main building frame is properly and

adequately anchored.

DO NOT ATTACH AN END PANEL TO AN

UNANCHORED FRAME.

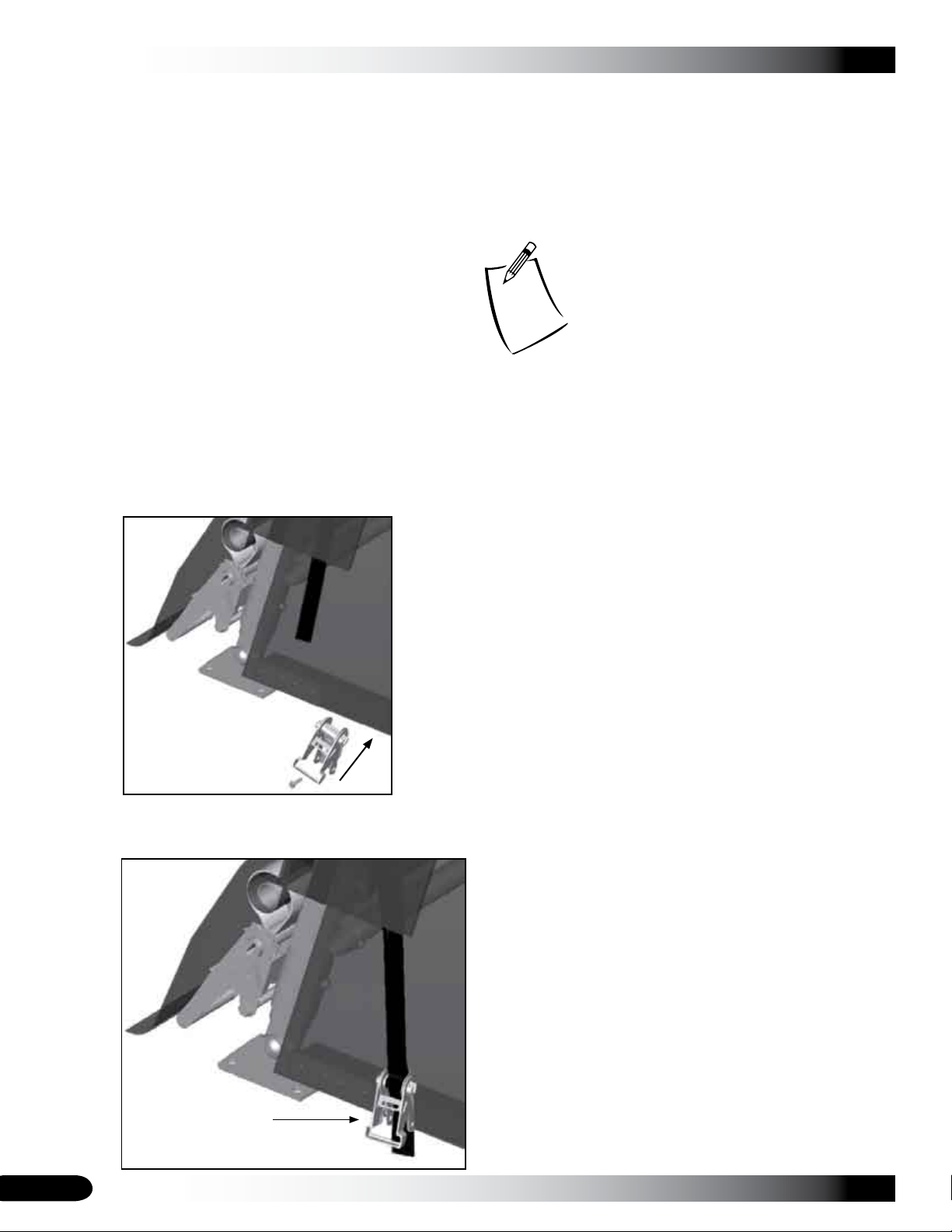

Remove the ratchets that secure the bonnet portion of

the main cover at each end of the original shelter. (This

step may not apply to all applications.) See Page 8 for

additional ratchet information.

Continue by attaching the end panel.

1.

2.

3.

4.

5.

6.

7.

Custom End Panels

The procedures presented in this guide describe attaching

a typical end panel to a typical end frame of a ClearSpan™

building. If you are attaching a custom panel or a typical

panel to an end frame that differs from what is shown,

some steps may not apply.

It is the responsibility of the owner/contractor to review the

steps in this guide and to adapt the procedures as needed

to account for differences.

If you have questions, consult the services of a qualified,

professional contractor familiar with the installation of

similar covers and panels.

Installation Kit Components and Typical End Panels

The design and size of the end panel determines which

components are included in each installation kit. For the

purpose of this installation guide, the following conditions

apply:

End panels (20', 26', and some 30' wide) are secured

to the end rafter and end frame using Tek screws,

washers, and fabric clips. These are the components

typically included with the installation kits for these end

panels. No 1" strapping or pipe are included.

EXCEPTION: In some instances for a 30' wide end

panel, PVC or metal conduit pipe or both are included

in the kit in addition to ratchets and 1" strapping.

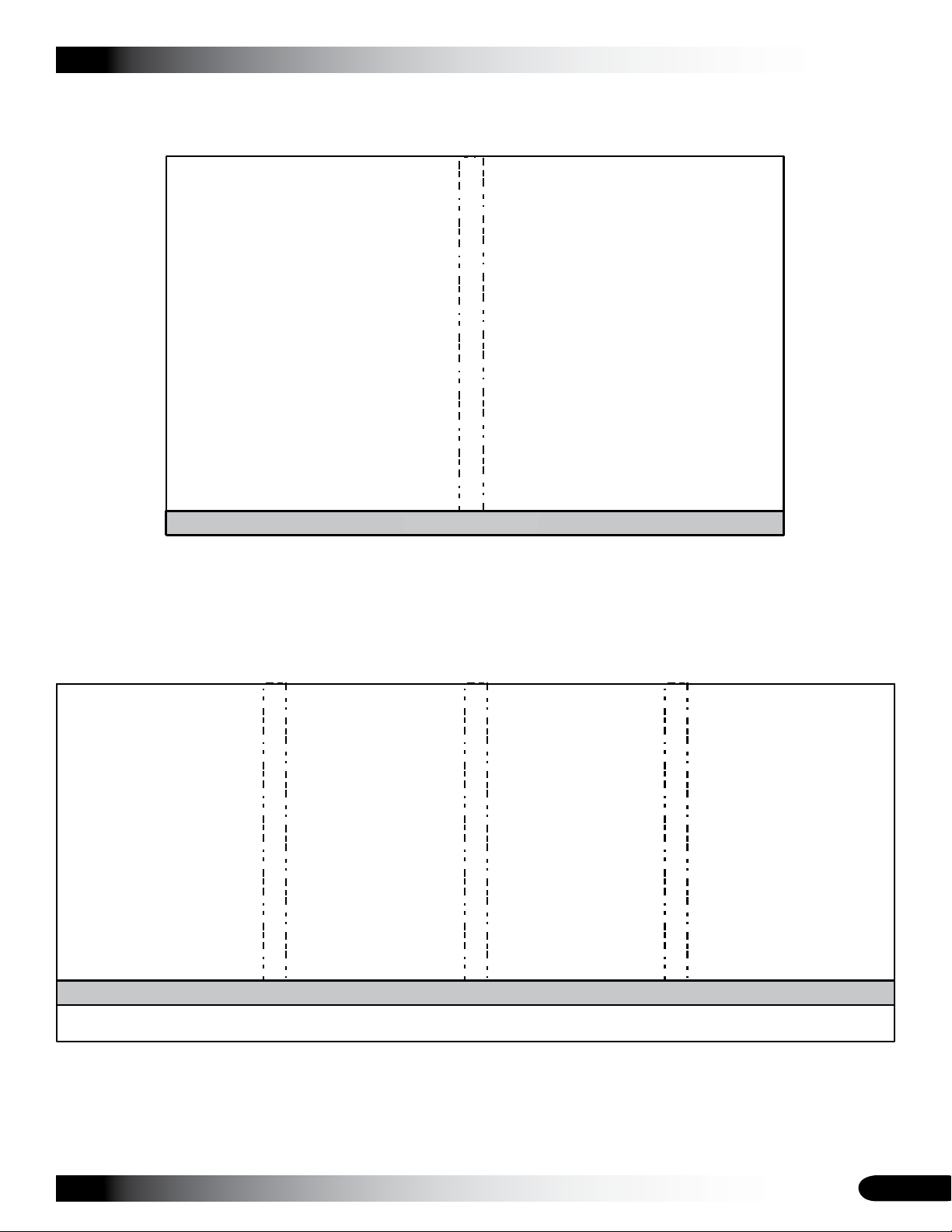

Consult Panel A and Panel B on Page 5 to view typical

end panel designs.

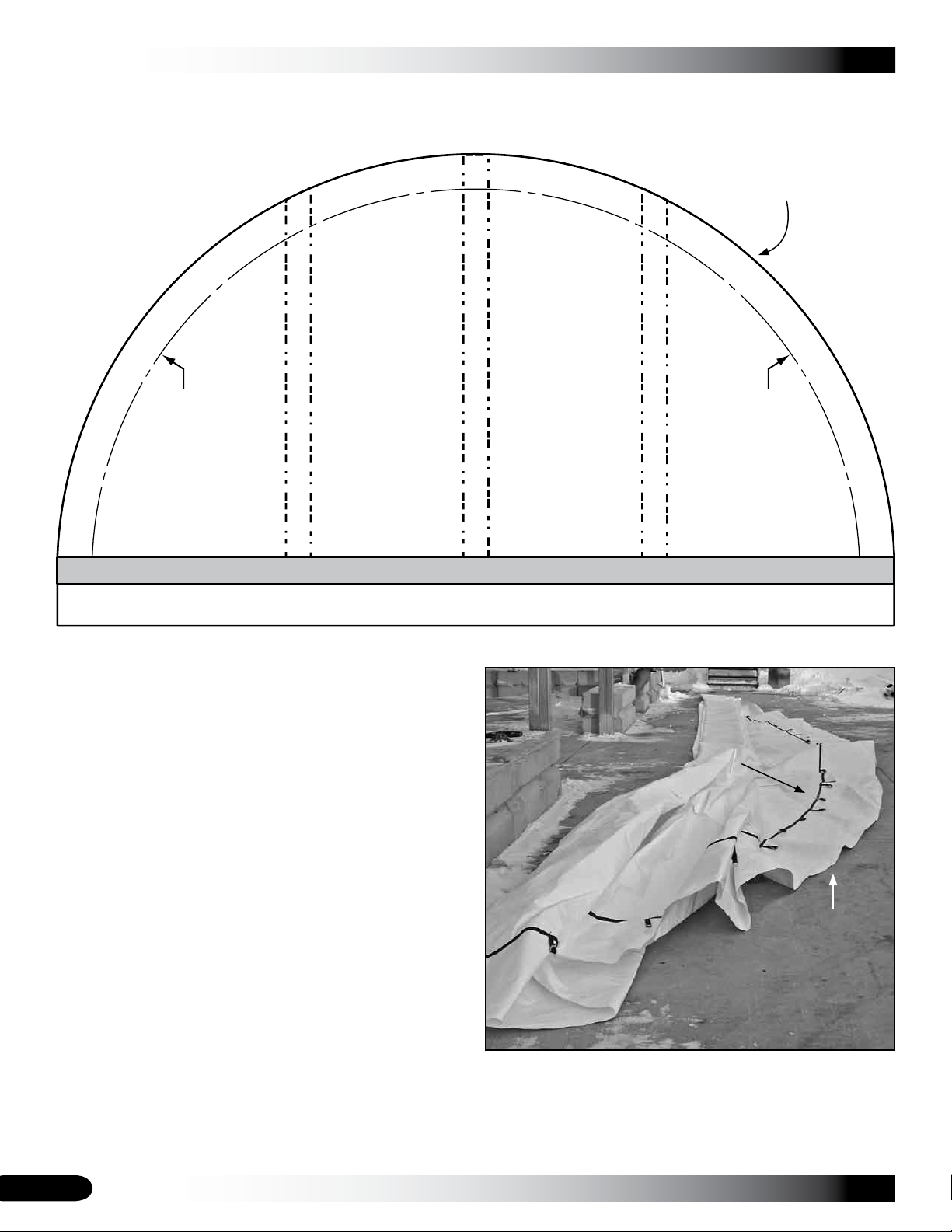

End panels that are 30' wide or wider typically include

D-rings along the upper radius and are secured to the

end rafter using 1" strap. Tek screws, washers, PVC

and metal conduit, and additional 1" strap are included.

No fabric clips are included.

EXCEPTION: In some instances, a 30' wide panel may

be designed without D-rings. In those cases, fabric

clips are included with the kit for that panel.

Consult Panel B and Panel C on Pages 5-6 to view

typical end panel designs.

For end panel widths not indicated above and for

customer end panels, the installation kits may include

a combination of all components mentioned above to

adequately secure the panel to the end frame.

This guide does not address the installation of custom

end panels or the installation of a typical end panel on

an atypical building frame or end frame. The customer

can, however, review the information and steps

presented in this guide to determine the best and safest

way to attach an end panel of a similar design.

Always consult the services of a qualied and

experienced contractor if you are not familiar with the

installation of similar covers panels.

•

•

•

•