Prometha™Installation

750-441

3

4 - Installation Procedure - Hawk Panel, Master Panel, or PT Panel

4.1 - Power Supply

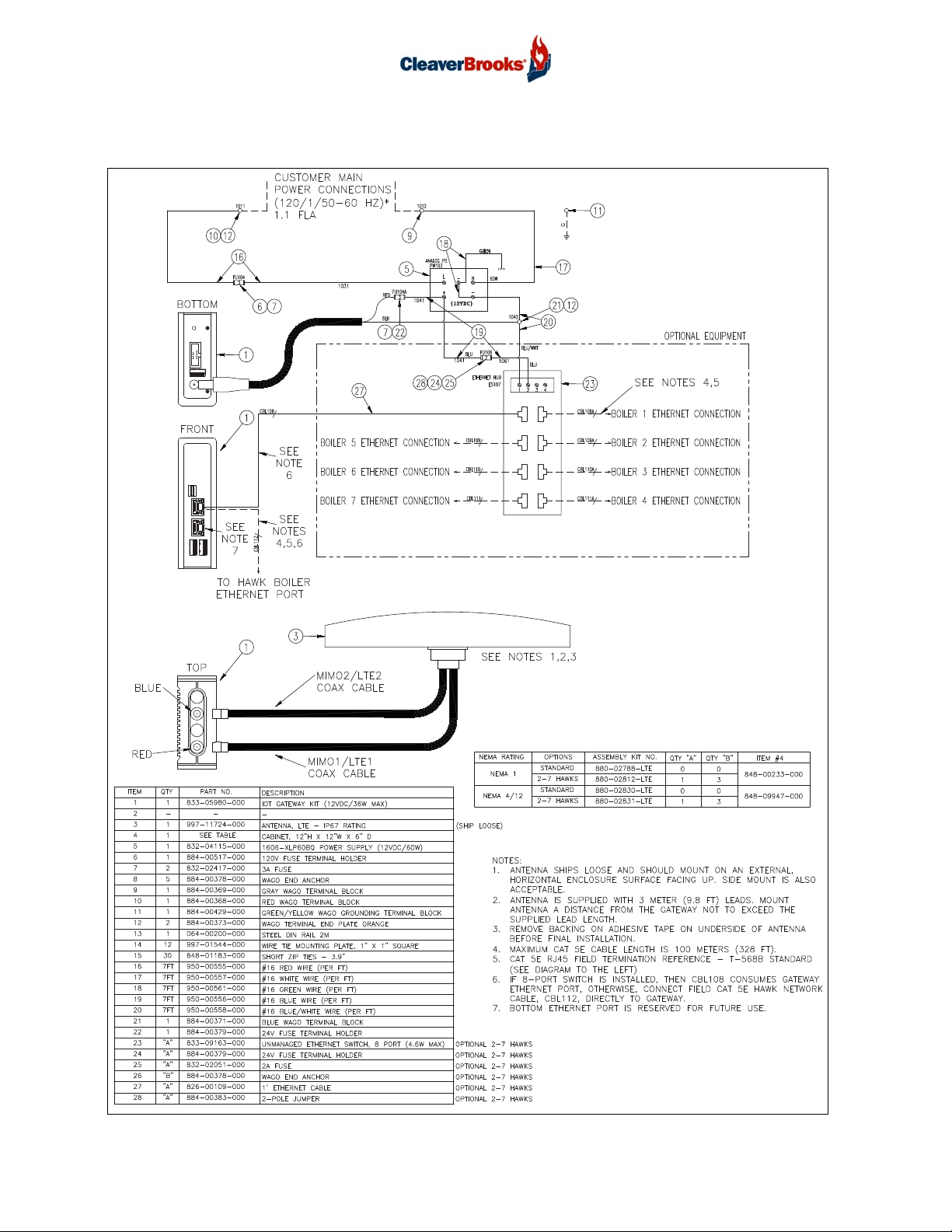

Mount the power supply on the DIN rail with the 12VDC output terminal on

top and the 120VAC input terminals on the bottom. See dimensions and

clearances below.

Install the gateway and power supply fuseblocks with 3A fuses and the ter-

minal block with end barrier installed. Install end anchors as needed. The

Supplemental Installation Kit (see Parts List) includes all required fuses and

mounting hardware.

Wire the power supply terminals as described below, referring to the wiring diagram if necessary. All

wiring is 16 gauge (see additional wiring specifications below).

1. Connect a green (ground) wire from the (-) terminal on the top of the power supply to the ground

terminal on the bottom. Insert an additional green wire into the bottom terminal and tighten.

Connect the second wire to an available ground lug or grounded terminal inside the panel.

2. Connect a red wire between the top, load side terminal of the 120V fuse holder and the L (load)

terminal at the bottom of the power supply.

3. Connect a white wire between the N terminal at the bottom of the power supply to the Neutral

terminal strip in the control panel.

4. Use a screwdriver to open the port directly above the terminal on the 120V fuse holder. Connect

a red wire to the bottom, line side terminal. Terminate the other end at a 120VAC power source

in the control panel.

5. Connect a blue wire to either of the two (+) terminals at the top of the power supply and termi-

nate the other end at the bottom, line side terminal of the 24V fuse holder.

6. Connect a blue-and-white wire to either of the two (-) terminals located on the top of the power

supply and connect the other end to the bottom terminal of the blue terminal block.

POWER SUPPLY DIMENSIONS 1.75"W x 3"H x 3.6"D

INSTALLATION CLEARANCES No minimum side clearance (5/8" each side if adjacent device is a heat source).

1.5" top

.75" bottom

TEMPERATURE RANGE 14degF to 158degF

FUSING 3A input fuse for isolation purposes

WIRING SPECIFICATIONS 16AWG Stranded Wire

~1/4" Stripping Length

9 lb.in Tightening Torque

OUTPUT 12VDC

INPUT 120VAC

POWER SUPPLY

WARNING

!

Disconnect power and follow all applicable

lockout/tagout procedures before beginning

installation.