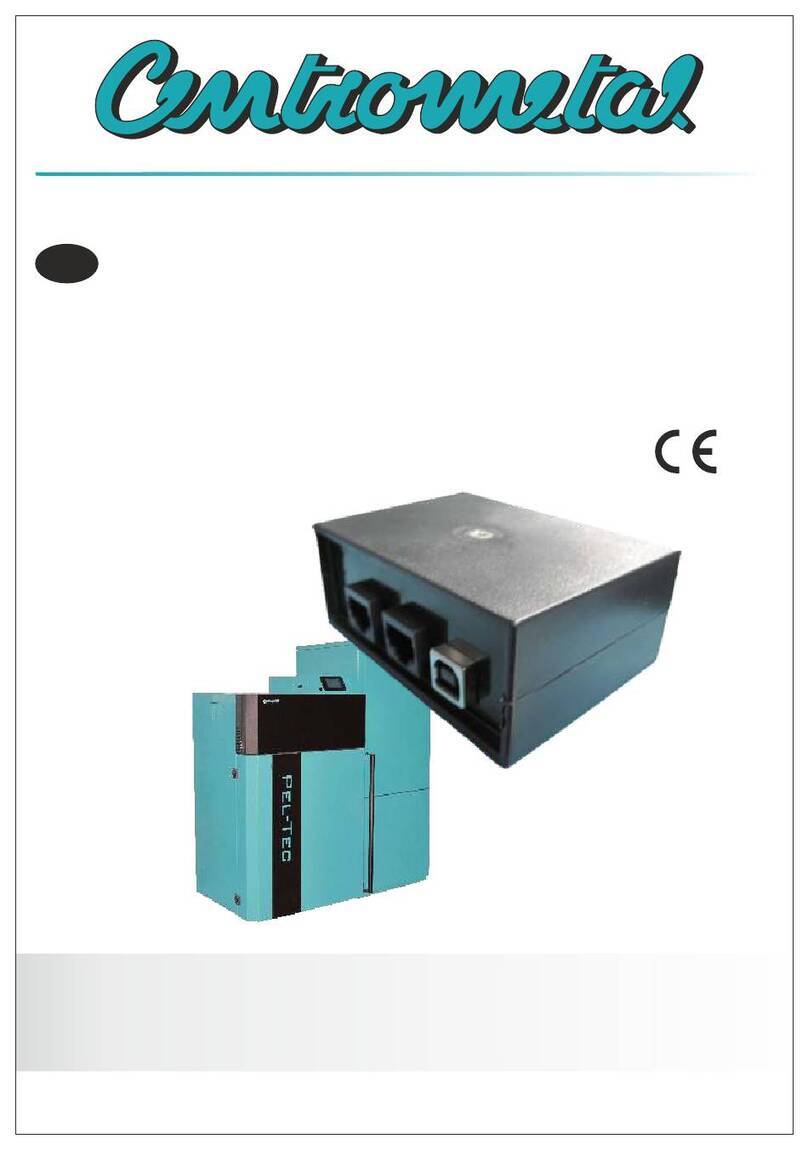

Technical instructions for the commissioning and adjustment

c) Drill 2 holes at the distance of 358 mm on the top side of boiler plating, and using enclosed

screws 3.9 x 9.5 mm fix boiler control unit CPREG, insert the safety thermostat sensor and

control unit sensor into the sleeve on the boiler (on the top side on EKO-CK P boiler) and

connect wires by 4-poles and 6-poles connectors onto the burner and then fix the connectors

to the burner body. Fix wire cable between the control unit and burner to the boiler casing by

supplied plastic cable holder (fix cable holder onto boiler casing with tapping screws 3.9 x 16

mm).

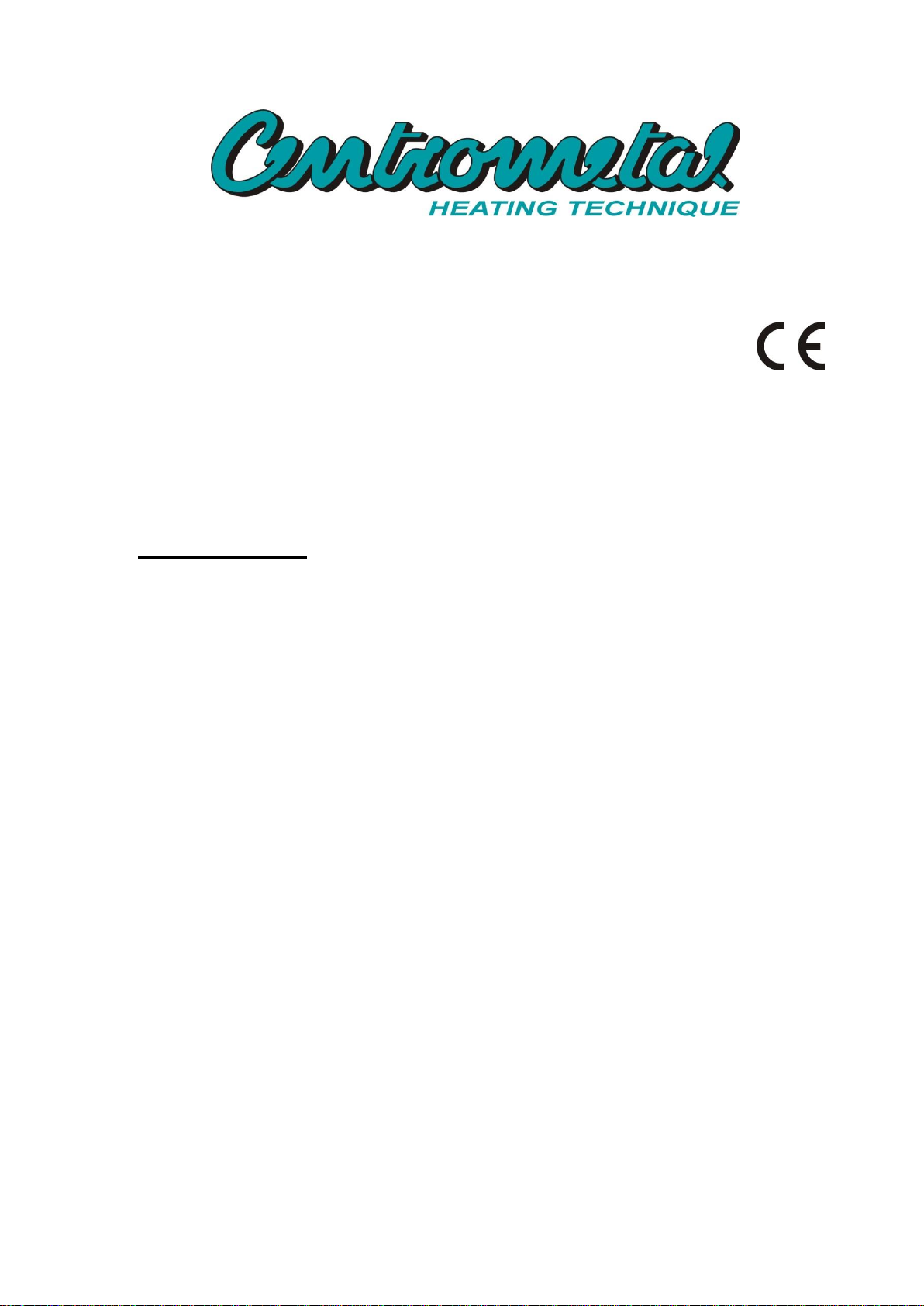

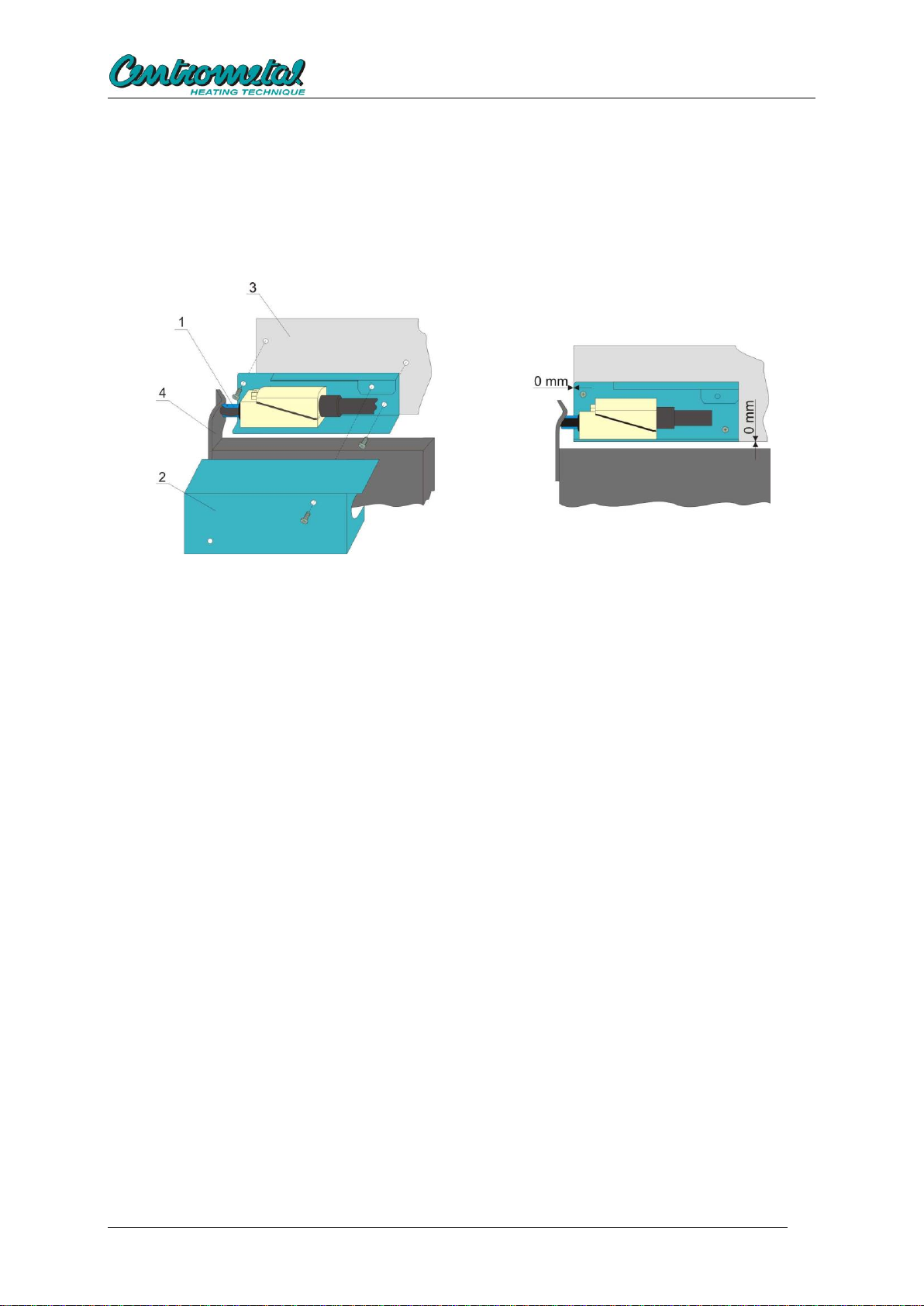

Mounting of the micro switch for lower boiler door

d) Set the micro switch (1) in lower left corner of the lower front casing of the boiler (3) using 2

screws, put the cover (2) according to the picture on micro switch and fasten it with the screw.

Check if lower boiler door, when they are closed, push the micro switch.

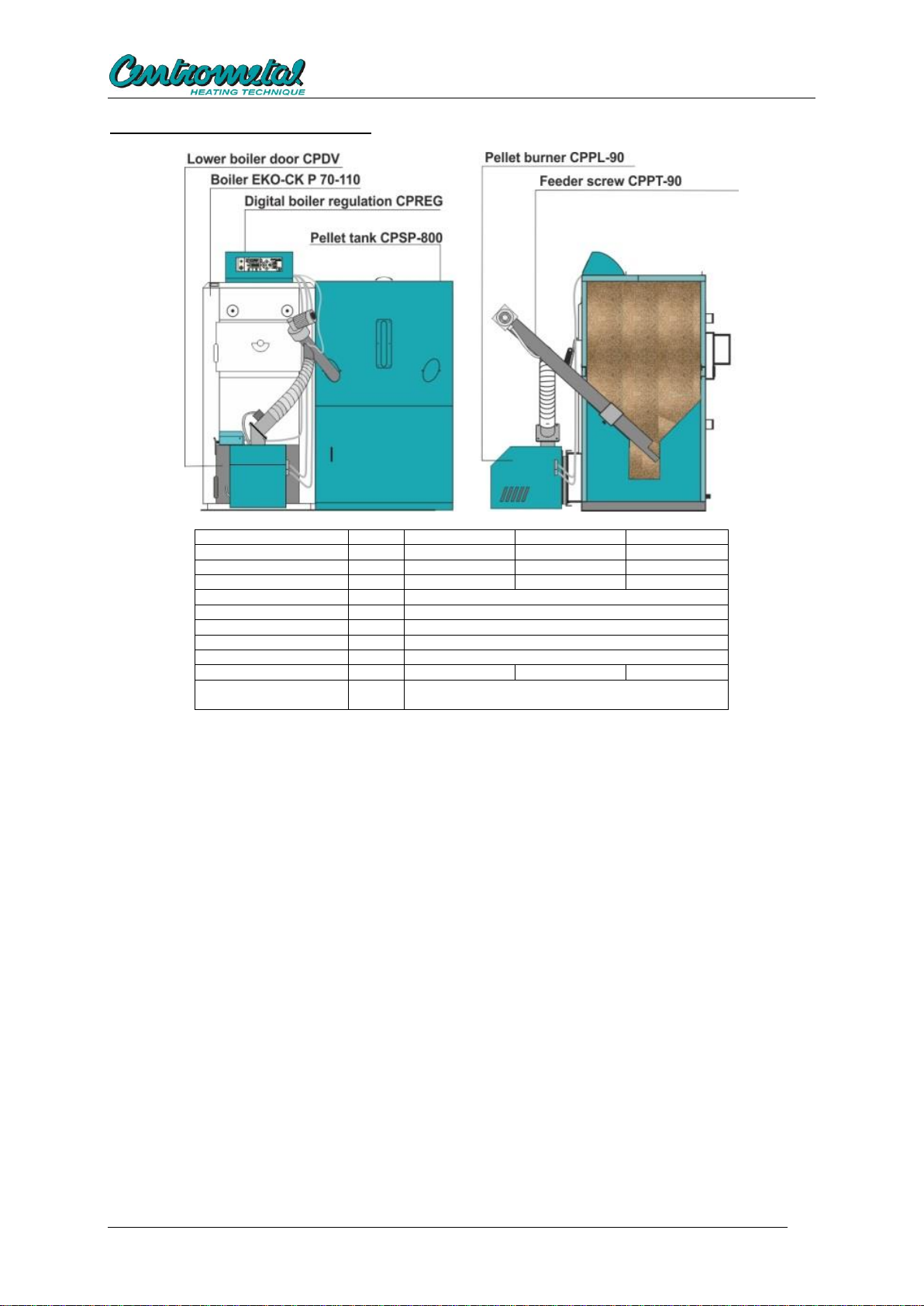

e) Assembly the pellet tank CPSP-800 according to technical instructions and position it next to

the right or left boiler side onto horizontal surface. Align tank bottom with the boiler bottom and

align the front tank side with the front side of boiler plating.

f) Place the feeder CPPT-90 into tank and connect it by a transparent flexible tube with a pellet

burner CPPL-90. Fix one end of transparent flexible tube to the burner (onto the feeding tube)

to backfilling sensor / temperature gauge on inlet tube, and other end should be fixed to the

feeder so that the tube will not become loosen. Transparent tube between the feeder and

burner must be as straight as possible so that pellets can fall smoothly from the feeder into the

burner (if pellets remain in the tube, it should be straighten and shorten, if necessary).

g) Connect a wire for power supply to the screw feeder CPPT-90 to the connector (2) on the

back side of the control unit CPREG.

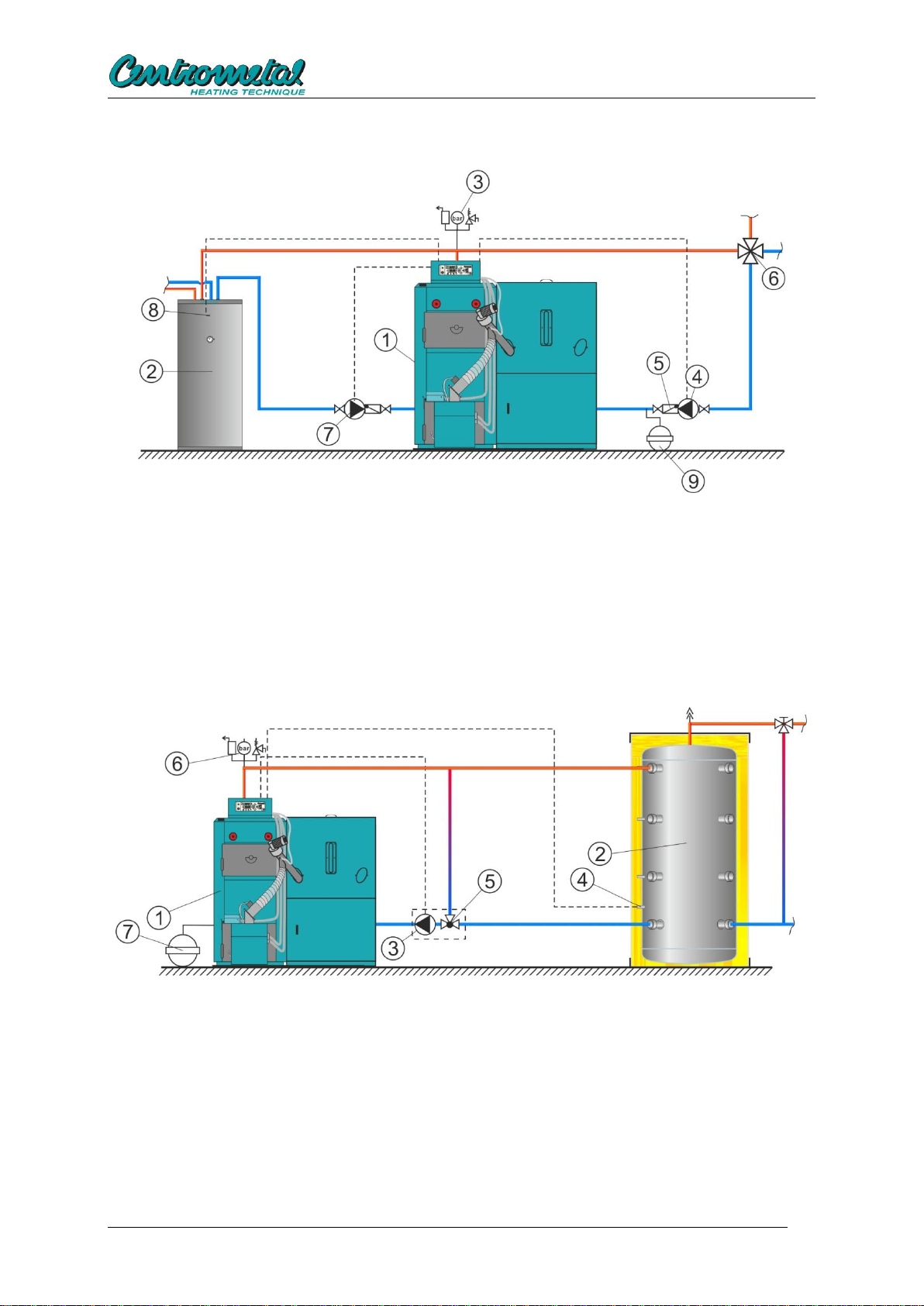

h) If sanitary water is prepared by using the boiler control unit, or the system installed one or

more accumulation tank (CAS) a sanitary water sensor should be fixed to connector 4 instead

of a jumper wire.

h1) If the sanitary water is prepared with the help of boiler control unit, sensor should

be placed in domestic hot water tank (Figure 1a).

h2) if it is installed one or more accumulation tanks (CAS) it is necessary to set the

domestic hot water sensor at the lowest sensor sleeve on the last accumulation

tank (CAS) or in a sensor tube below the water level we want to warm up (see

Figure 1b). In this case the hot water sensor has no direct connection with the

preparation of hot water (Figure 1b).

i) If used Telecontrol or cascade manager they is connected in place of a room thermostat

(Connector 3).

j) A jumper wire is factory installed in the place of room thermostat (connector (3). If an adapter

is used for ‘’more zones’’ control (optional equipment), a jumper wire in the connector (3) must

be put.

k) Do not connect boiler control unit to power supply via a built in thermostat on the boiler (if

there is a thermostat on the upper side of EKO-CK P boiler).