Chapter 1 — General

1-4 Part No. 750-386

1.3-Two Tank System Description

Two Tank systems can control up to 4 boiler feed pumps and 3

transfer pumps (6 pumps total), all of which can be run by

contactors, combination starters, soft starters, or Variable

Frequency Drives. The pump control method selected must be the

same for all pumps on a tank, but the Tank 1 method can be

different from Tank 2. For example, Tank 1 may use Variable

Frequency Drives, but Tank 2 may use contactors.

Pumps on a common header can be alternated on a customer

defined schedule and be set up in a customer defined lead lag

format.

When lead lag operation is in use, a pressure transmitter mounted

in the common header sends a signal to the PLC. The customer sets

the pressure point via the touch screen. If the first pump cannot

achieve that set point, the PLC will start a second pump and so on.

If the pressure rises above the set point, the PLC will shed the last

pump and so on. During normal operation the lead pump will

always run.

Pumps on a “one pump per boiler” installation can be controlled by

the boiler. Variable Frequency Drives cannot be used in a one pump

per boiler configuration where each pump is hard piped to

individual boilers. VFDs are only available on common pump

discharge header configurations.

Standard system is capable of using discrete level alarm switches

(such as the McDonnell Miller 63 or 64) for fixed level alarms, or a

level transmitter which can be configured from the touch screen.

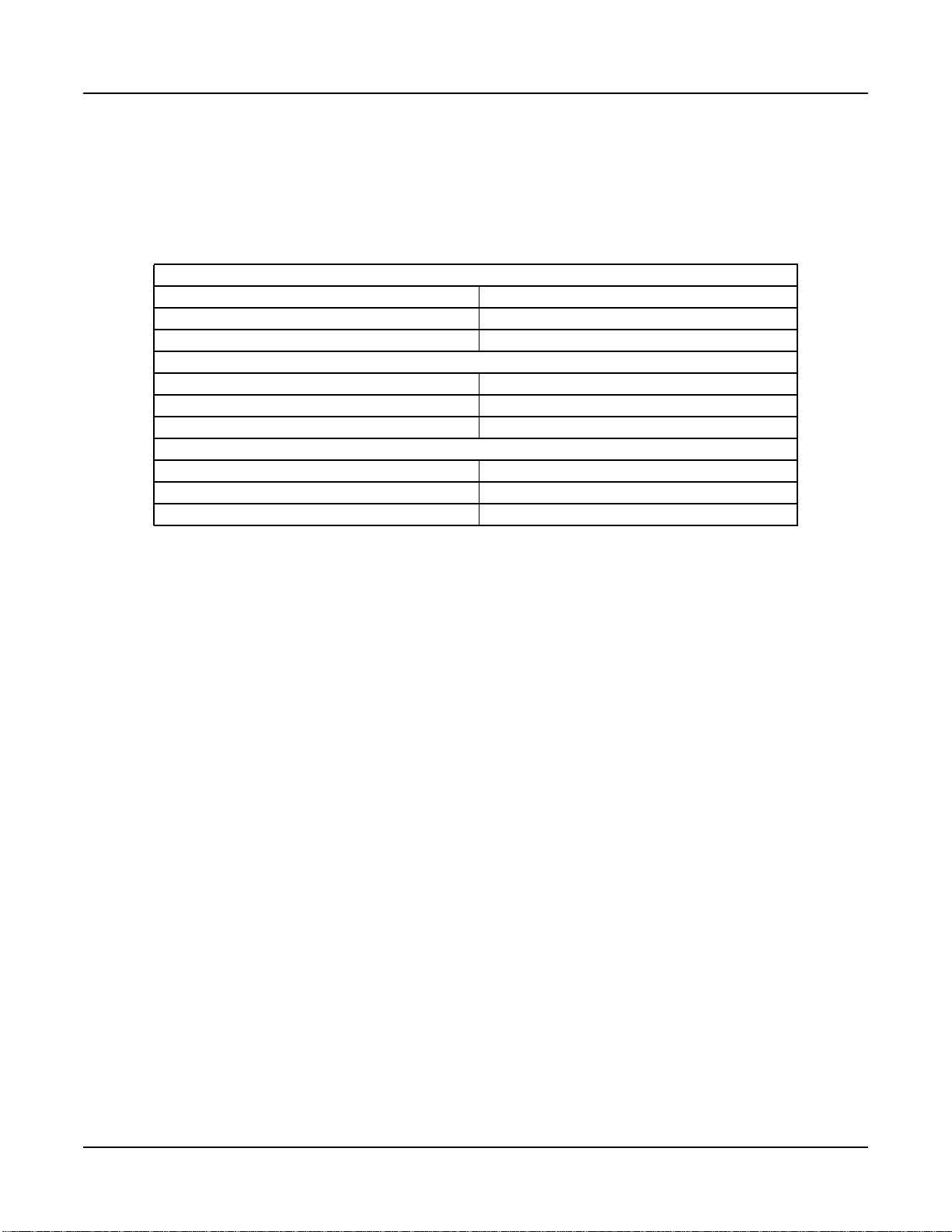

1.3.1 - Standard Equipment

7 inch color touch screen is standard.

A three module stack light is standard with a light for each mode.

Green for normal, Yellow for non critical alarms Red for critical

alarms. An audible alarm is standard, either a bell, horn or

electronic sounder

PLC based control system for a two tank starts with and includes a

base unit consisting of the processor and embedded I/O, power

supply, I/O cards, 7" color touch screen, and Nema 4 control panel

to provide the following functions

Level control can be an independent mechanical system, or by using

the above mentioned transmitter, control an electrical or I/P make-

up valve.

Tank Pressure is monitored by a transmitter in steam space. PRV

can be an independent mechanical system or an electrical or I/P

pressure reducing valve.

The second tank will be treated as an atmospheric pressure tank

and will not have a tank pressure sensor.