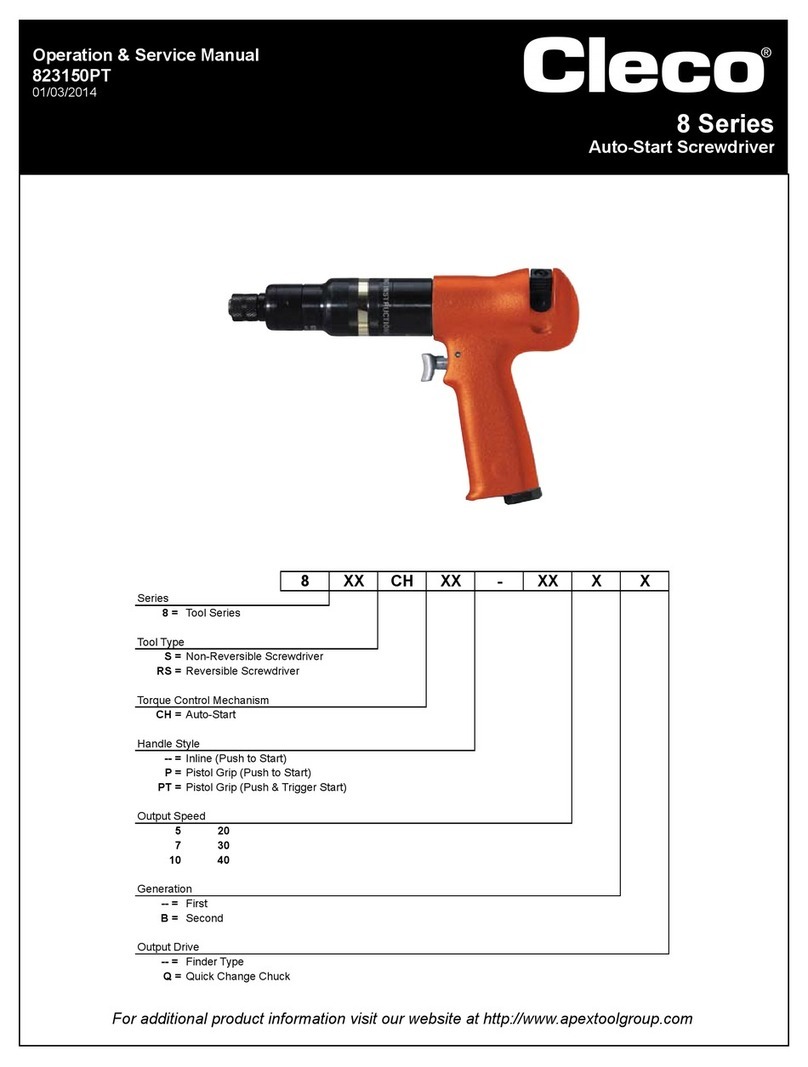

Cleco 8 Series User manual

For additional product information visit our website at http://www.apextoolgroup.com

Parts Manual

823126

04/07/2011

8 Series

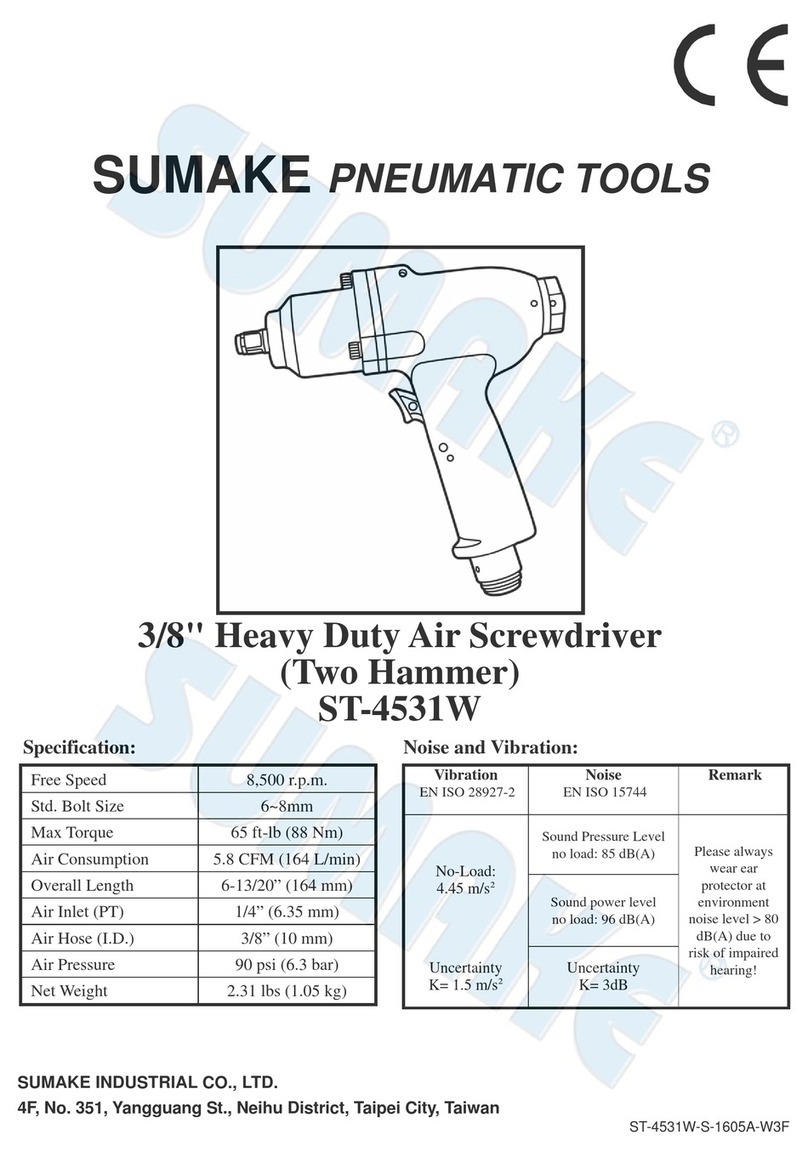

Rolling Impulse Clutch, Positive Clutch and Stall Screwdrivers

2

For your safety and the safety of others, read and under-

stand the safety recommendations and operating instruc-

tions before operating a screwdriver.

Always wear protective equipment:

For additional information on eye protection and face

protection, refer to Federal OSHA Regulations, 29 Code

ofFederalRegulations,Section1910.133.,EyeandFace

Protection, and American National Standards Institute,

ANSIZ87.1,OccupationalandEducationalEye andFace

Protection. Z87.1 is available from the American National

Standards Institute, Inc., 11 West 42nd Street, New York,

N.Y. 10036.

Hearing protection is recommended in high noise areas

85 dBA or greater. The operation of other tools and

equipmentinthearea,reflectivesurfaces,processnoises

and resonant structures can substantially contribute to,

and increase the noise level in the area. Excessive air

pressure above 90 PSIG or worn motor components can

also increase sound level emitted by tool. Proper hearing

conservation measures, including annual audiograms

andtrainingintheuseandfitofhearingprotectiondevices

may be necessary. For additional information on hearing

protection,refertoFederal Regulations,Section1910.95,

Occupational Noise Exposure, and American National

Standards Institute, ANSI S12.6, Hearing Protectors.

Cleco screwdrivers are designed to operate on 90 psig

(6.2 bar) maximum air pressure. If the tool is properly

sized and applied, higher air pressure is unnecessary.

Excessive air pressure increases the loads and stresses

onthetoolparts,sockets,andfastenersandmayresultin

breakage. Installation of a filter-regulator-lubricator in the

air supply line ahead of the tool is recommended.

Safety Recommendations

Before the tool is connected to the air supply, check the

throttleforproper operation(i.e.,throttlemovesfreelyand

returns to closed position). Being careful not to endanger

adjacent personnel, clear the air hose of accumulated

dustandmoisture.Beforeconnectingatooltotheairhose,

removing a tool from service or changing bits, make sure

the air line is shut off and drained of air. This will prevent

thetoolfromoperatingifthethrottleisaccidentlyengaged.

Tools with clutches can stall if adjusted over maximum

power output of tool, or if there is a drop in air pressure.

Operator must then resist stall torque until throttle is

released.

Higher torque screwdrivers can be equipped with grip

sleeves and dead handles. Tool balance arms are avail-

abletoabsorbthetorque reaction of the tool while balanc-

ing the weight of the tool for improved ergonomic applica-

tions.

Poor quality fasteners and bits can cause vibration during

run down. Use quality fasteners and bits.

Some individuals may be susceptible to disorders of the

hands and arms when performing tasks consisting of

highly repetitive motions and/or exposure to extended

vibration. Cumulative trauma disorders such as carpal

tunnel syndrome and tendonitis may be caused or aggra-

vated by repetitious, forceful exertions of the hands and

arms. Vibration may contribute to a condition called

Raynaud'sSyndrome.These disorders develop gradually

over periods of weeks, months, and years. It is presently

unknown to what extent exposure to vibrations or repeti-

tive motions may contribute to the disorders. Hereditary

factors, vasculatory or circulatory problems, exposure to

cold and dampness, diet, smoking and work practices are

thought to contribute to the conditions.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

CAUTION!

Repetitive work motions and/or vibration

may cause injury to hands and arms.

Use minimum hand grip force consistent

with proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

WARNING

!

Avoid repeated bending of wrists and hands.

3

Safety Recommendations

Work gloves with vibration reducing liners and wrist sup-

ports are available from some manufacturers of industrial

work gloves. Tool wraps and grips are also available from

anumber of different manufacturers.Thesegloves,wraps,

and wrist supports are designed to reduce and moderate

the effects of extended vibration exposure and repetitive

wrist trauma. Since they vary widely in design, material,

thickness, vibration reduction, and wrist support qualities,

itisrecommendedthattheglove,toolwrap,orwristsupport

manufacturer be consulted for items designed for your

specific application. WARNING! Proper fit of gloves is

important. Improperly fitted gloves may restrict blood

flow to the fingers and can substantially reduce grip

strength.

For more information on the safe use of portable air tools,

see the latest edition of ANSI B186.1, Safety Code for

Portable Air Tools, available from the American National

Standards Institute, Inc. 11 West 42nd Street, New York,

N.Y. 10036.

Thisinformationisacompilationofgeneralsafetypractices

obtained from various sources available at the date of

production.However,ourcompanydoesnotrepresentthat

every acceptable safety practice is offered herein, or that

abnormal or unusual circumstances may not warrant or

require additional procedures. Your work may require

additional specific safety procedures. Follow these proce-

dures as required by your company.

Warning Labels

The warning labels found on these tools are an essential

part of this product. Labels should not be removed. Labels

should be checked periodically for ligibility. Replace warn-

ing labels when missing or when the information can no

longerberead.Replacementlabelscanbeorderedasany

spare part.

Anytool operator should be awareof the following warning

signs and symptoms so that a problem can be addressed

before it becomes a debilitating injury. Any user suffering

prolonged symptoms of tingling, numbness, blanching of

fingers,clumsiness orweakenedgrip, nocturnalpaininthe

hand, or any other disorder of the shoulders, arms, wrists,

or fingers is advised to consult a physician. If it is deter-

mined that the symptoms are job related or aggravated by

movementsand postures dictated bythejobdesign, it may

be necessary for the employer to take steps to prevent

furtheroccurrences.Thesestepsmightinclude,butarenot

limited to, repositioning the workpiece or redesigning the

workstation, reassigning workers to other jobs, rotating

jobs, changing work pace, and/or changing the type of tool

used so as to minimize stress on the operator. Some tasks

may require more than one type of tool to obtain the

optimum operator/tool/task relationship.

Thefollowing suggestionswillhelp reduceormoderatethe

effectsofrepetitiveworkmotionsand/orextendedvibration

exposure:

• Use a minimum hand grip force consistent with proper

control and safe operation

• Keep body and hands warm and dry (cold weather is

reported to be a major factor contributing to Raynaud's

Syndrome)

• Avoid anything that inhibits blood circulation

—Smoking Tobacco (another contributing

factor)

—Cold Temperatures

—Certain Drugs

• Tasks should be performed in such a manner that the

wrists are maintained in a neutral position, which is not

flexed, hyperextended, or turned side to side.

• Stressful postures should be avoided — select a tool

appropriate for the job and work location

• Avoid highly repetitive movements of hands and wrists,

and continuous vibration exposure (after each period of

operation, exercise to increase blood circulation)

• Keep tool well maintained and replace worn parts

OVER

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

Read Operating Instructions carefully. Follow

the Safety Recommendations for your safety

and the safety of others.

Hearing protection is recommended in high noise

areas (above 85 dBA). Close proximity of other

tools, reflective surfaces, process noises, and

resonant structures can substantially contribute

to the sound level experienced by the user.

WARNING

!

Repetitive work motions and/or vibration

can cause injury to hands and arms.

Use minimum hand grip force consistent with

proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

Avoid repeated bending of wrists and hands.

Do not remove this tag until

the operator of this tool has

read these safety precautions.

203288

203185-4

READ

OPERATING

INSTRUCTIONS

203185

Extension Neutral Flexion Radial Deviation Neutral Ulnar Deviation

Avoid Avoid Avoid

OK Avoid OK

4

OPERATING INSTRUCTIONS

ROLLING IMPULSE CLUTCH

Torque control in this clutch does not depend on air pres-

sure,butisachievedbypresettingtheclutchtothedesired

torque.

CLUTCH ADJUSTMENT

Unscrew (left hand threads) the clutch housing from the

gear case. Tighten the adjustment nut (clockwise) to in-

crease torque and loosen (counterclockwise) to decrease

the torque output of the tool.

Note: If the clutch is adjusted over the maximum power

outputofthetool,theclutchwillnotfunctionandthetoolwill

operate like a stall-type tool. Also, if the tool is being

operated at its upper torque limits, a drop in air pressure

couldcausetheclutchnottofunctionduetoalossofmotor

power and the tool will function like a stall-type tool and

operator must be prepared to counteract stall torque.

OPERATIONAL CHECK: Grip tool securely and be pre-

paredtocounteractstalltorqueincaseclutchisimproperly

adjusted.

POSITIVE CLUTCH

Twoclutchjawswithangledengagingedgesareheldapart

by a light spring. The amount of pressure exerted by the

operators, and consequently the amount of jaw engage-

ment, controls torque output of the tool.

STALL TYPE

Torquemaybecontrolledbytheuseofapressureregulator

to change the stall torque of the tool.

AIR SUPPLY

Thetoolisdesignedtooperateat90psigairpressure.The

air pressure should be checked at the tool's air inlet while

the tool is running.

For maximum performance, use a 1/4" I.D. air hose up to

8' in length. If additional length is required, a 3/8" I.D. or

largerhoseshould beconnected tothe 1/4"I.D.hose.The

air hose should be cleared of accumulated dirt and mois-

ture.

LUBRICATION

An automatic in-line filter-lubricator is recommended as it

increasestoollifeandkeepsthetoolinsustainedoperation.

Thein-linelubricatorshouldberegularlycheckedandfilled

with a good grade of 10W machine oil. Proper adjustment

of the in-line lubricator is performed by placing a sheet of

paper next to the exhaust ports and holding the throttle

openforapproximately30seconds.Thelubricatorisprop-

erly set when a very light stain of oil collects on the paper.

Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous amount of lubrication at that

timeandagainwhenreturnedtoservice.Thetoolshouldbe

stored in a clean and dry environment.

Application of the tool should govern how frequently it is

greased. It is recommended that the idler gears receive a

generous amount of NLGI 2-EP grease after every 40

hours of operation. The clutch housing (left hand threads)

and clutch must be removed and the grease applied

through the hex in the spider.

READ SAFETY RECOMMENDATIONS ON PAGES 2 AND 3 BEFORE CONNECTING TOOL.

5

If replacement of the idler gear pins is necessary, they

should be pressed out the rear of the spider See Fig. 1 for

replacement pin height.

Fig. 1 - SINGLE REDUCTION SPIDER

B. Double Reduction

Both spiders should be removed from the rear of the gear

case, No. 867907. Remove the retainer ring, No. 844364,

andpressthebearing,No.847147,outthefrontofthegear

case.

If replacement of the idler gear pins is necessary, they

should be pressed out the rear of the spider See Fig. 2 for

replacement pin height.

1st Reduction Spider 2nd Reduction Spider

Fig. 2 -- DOUBLE REDUCTION SPIDERS

MOTOR DISASSEMBLY

Slip the front bearing plate and bearing off the front of the

rotorandremovethecylinderandfour(4)rotorblades,No.

863738.Settherearbearingplateontheviselawswiththe

rotorhangingdown.Usea7/32"punchtodrivetherotorout

of the rear rotor bearing.

DISASSEMBLY — GENERAL

(ALL MODELS)

Clampthebackheadina soft-jawedviseandunscrew(left

hand threads) the clutch housing and remove the clutch

assembly. Unscrew and remove the gear case assembly.

The trip rod and motor unit may now be removed from the

front of the backhead. See the following paragraphs for

complete disassembly instructions on the various sub-

assemblies.

QUICK CHANGE CHUCK

DISASSEMBLY

Remove retainer ring, No. 833688. This will release the

washer, No. 864249; spring, No. 202842; release sleeve,

No. 202833, and ball, No. 844265. Remove retainer ring,

No. 619524. This releases the remainder of the clutch.

ROLLING IMPULSE CLUTCH

DISASSEMBLY

Remove the retainer ring, No. 412055, and unscrew the

adjustmentnut,No.867875.Thiswillallowtheadjustment

lock plate, No. 867876; bearing race, No. 863455; thrust

bearing, No. 847104; bearing race, No. 863455; torque

spring, No. 867938, ball retainer, No. 867881, and six (6)

steel balls, No. 842162, to be removed from the clutch

spindleassembly.Washthespindleassemblyinkerosene.

Removetheballretainerring,No.867923,andballretainer

plug,No.867908.Rotatetheclutchspindle,No.867867,to

allowthesixteen(16)steelballs,No.844265,todropoutof

theballloadingholelocatedintheclutchface,No.867869.

QUICK CHANGE CHUCK GEAR CASE

DISASSEMBLY

For double reduction gear cases the first reduction spider

should be removed from rear of gear case. Remove re-

tainer ring, No. 833688. This will release the washer, No.

864249; spring, No. 202842; release sleeve, No. 202833,

and ball, No. 844265. Remove retainer ring, No. 619524.

Thiswillallowyoutoremovewasher,No.864249.Unscrew

(left hand threads) bearing retainer, No. 202031. Press

spindle out of bearings.

GEAR CASE DlSASSEMBLY

A. Single Reduction

Thespidershouldbepressedouttherearofthegearcase,

No. 867871. Remove the retainer ring, No. 844364, and

press the bearing, No. 847147, out the front of the gear

case.

SERVICE INSTRUCTIONS

.240

.255

Front Rear

.360

.375

Front Rear

.240

.255

Front Rear

6

BACKHEADDISASSEMBLY

Lever

For inspecion or replaement of the throttle valve seal, No.

847426, unscrew and remove the throttle valve cap, No.

832207.

Unscrew the air inlet bushing, No. 867882, for inspection

and cleaning of the air inlet screen, No. 833300, and the

muffler, No. 869510. If either the screen or muffler is

clogged or torn, it should be replaced .

On reversible tools, the reversing valve, No. 869253, may

be removed by unscrewing the reversing valve retainer

screw, No. 867878.

Offset

For inspection or replacement of the throttle valve, No.

867055,unscrewtheairinletbushing,No.867916.Theair

inlet screen, No. 412775, should also be inspected at this

time. Replace the screen if clogged or torn.

Themuffler,No.869200,mayberemovedforcleaningand

inspection by removing the muffler screen retainer, No.

847033.

The reversing valve, No. 869253, may be removed by

unscrewingthereversingvalveretainerscrew,No.867878.

Pistol Grip

For inspection or replacement of the throttle valve, No.

202828,andthrottlevalvesealNo.202782,unscrewtheair

inletbushing,No.867929.Theairinletscreen,No.412775,

should also be inspected at this time. Replace the screen

if clogged or torn.

Themuffler,No.867933,mayberemovedforcleaningand

inspection by removing the muffler screen retainer, No

847033.

The reversing valve, No 867898, can be removed by

unscrewing the reversing knob screw, No. 613749.

Removetheairinletbushing,No.867929,forinspectionof

the throttle valve, No. 202828, seal, No. 202782, and air

inletscreen,No.412775.Thescreenshould bewashed in

a solvent and blown out in the reverse of normal air flow.

Replace the screen if clogged or torn.

SERVICE INSTRUCTIONS

REASSEMBLY - GENERAL

Reassembly of all of the various sub-assemblies is in the

reverseorderofdisassembly;however,thefollowingpara-

graphslist some of the more important reassembly proce-

dures.

All parts should be washed in a solvent and inspected for

damageorwear.Particularattention shouldbe givento all

bearings, gears, gear pins, and rotor blades as failure of

theseparts couldcause damageto more expensiveparts.

Rotor blades should be replaced at every repair cycle or if

they measure less than 3/16" (4.7mm) on either end.

Inspectand replace any "O"ringsor seals that showsigns

of wear or deterioration. All gears, gear pins, and open

bearingsshould receivea generousamountof NLGI2-EP

grease during reassembly. When assembling the gear

case to the backhead, the gear case should be torqued to

300/325 in. lbs. (33.9/36.7 Nm). Reassembly of all of the

varioussubassembliesisinthereverseorderofdisassem-

bly; however, the following paragraphs list some of the

more important reassembly procedures.

CLUTCH REASSEMBLY

During reassembly of the clutch, all parts should receive a

thincoatingofamixtureof10WmachineoilandNLGI2-EP

grease. Allpartsinstalledintotheclutchspindleandclutch

cam should be checked for smooth operation before com-

plete assembly of the clutch.

MOTOR REASSEMBLY

Install the rear rotor bearing, No. 847609, into the rear

bearing plate. Press the bearing plate assembly (press on

thebearing'sinnerrace)ontotherearrotorshaftuntilthere

is approximately .0015" clearance between the rear bear-

ing plate and rotor. Install the cylinder with the slotted end

toward the front bearing plate.

Must be replaced if less than

3/16" (4.7mm) on either end.

7

SERVICE INSTRUCTIONS

PISTOL GRIP AND OFFSET HANDLE

Wheninstallingthethrottlelinkpin,No.867939,thenotched

end should be installed into the backhead in a vertical

position to engage the throttle valve stem.

TRIP ROD SIZING

Old Trip Rod

Thetoolshouldbereassembledcompletelessthetriprod,

clutch,andclutchhousing.Withtheairon,installthetriprod

andclutchintothetool andmeasurethedistancebetween

therearface of the ball retainer, No. 867881, and the front

faceofthegearcase.Turntheairoffanddepresstheclutch

assemblyandmeasureclutchtravel.Clutchtravelmustbe

at least 3/16". If not, the trip rod should be replaced.

New Trip Rod

Assemblethetoolcompletely,lesstheclutchhousing,and

connectthetooltotheairsupply.Screw(lefthandthreads)

the clutch housing onto the gear case until air exhausts

from the backhead. Measure the gap between the clutch

housingandgearcase.Grindthisamountplus5/64"offthe

trip rod.

.0015" (.038mm)

Clearance

SAFETY CHECK

Afterrepairorreplacementofparts,toolsequippedwithan

automatic shut-off device should be tested at low torque

and 90 p.s.i.g. to verify that the device is functioning

properly.

8

202819

202820

202823

202833

202839

202842

412055

619524

833688

841284

842162

842320

844247

844265

Quick Change Clutch Housing*

Spindle Bushing

Spindle

Release Sleeve

Adjustment Cover*

Spring

Retainer Ring

Retainer Ring

Retainer Ring

FinderRetainer*

Steel Ball (1/4")

Pin

Spring

Steel Ball (1/8")

847104

847114

863455

864249

867867

867869

867870

867875

867876

867881

867908

867923

867938

869952

Thrust Bearing

Bit Ball Retainer

Thrust Race

Washer

Clutch Spindle

Clutch Face

Clutch Driver (incl. 842320)

Adjustment Nut

Adjustment Lock Plate

Ball Retainer

Ball Retainer Plug

Ball Retainer Ring

Torque Spring (Green)

Finder Clutch Housing (incl. 202839 & 841284)*

FINDER ROLLING IMPULSE CLUTCH QUICK-CHANGE ROLLING IMPULSE

CLUTCH

867867 867869 867870

842320844247

867881

867923

842162

844265

847104

863455 863455

867938

867875 867876

867908

844265

847114

412055

869952 202839 841284

FINDER SPRING

PART NO. FORCE WIRE DIA.

865728 LIGHT .020"

844000 MEDIUM .033"

867869 867870

842320844247

867881

867923

842162

844265

847104

863455 863455

867938

867875 867876

867908

202823

844265

202820

202833

619524

833688

864249

202842

202819 202839

PART NO. NAME OF PART QTY. PART NO. NAME OF PART QTY.

1

1

1

1

1

1

1

1

1

1

6

1

1

17

1

1

2

1

1

1

1

1

1

1

1

1

1

1

The complete clutches can be purchased as subassemblies using part numbers 861574 for Finder Type and 201226 for Quick Change. * Not included in subassem-

blies.

202820

202826

202825

202833

202839

202842

619524

833688

Spindle Bushing

Spindle

Positive Quick Change Clutch Housing (incl. 202839)*

Release Sleeve

Adjustment Cover*

Spring

Retainer Ring

Retainer Ring

841284

844265

847114

864249

865191

867917

867918

869970

FinderRetainer*

Steel Ball (1/8")

Bit Ball Retainer

Washer

Pin

Finder Type Clutch Spindle

Clutch Driver

Finder Clutch Housing (incl. 202839)*

FINDER POSITIVE CLUTCH QUICK-CHANGE POSITIVE CLUTCH

867917 867918

865191 843252

869970 202839

844265

847114

202826 867918

865191 843252

844265

202820

202833

619524

833688

864249

202842

202825

PART NO. NAME OF PART QTY. PART NO. NAME OF PART QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

The complete clutches can be purchased as subassemblies using part numbers 861591 for Finder Type and 201227 for Quick Change. * Not included in subassem-

blies.

9

PARTS LIST —- 20, - 30, & - 40 GEAR TRAINS

PART NO. NAME OF PART QTY.

844364 Bearing Retainer Ring 1

847147 Spider Bearing 1

865862 Pinion 40 Model Only (12T) 1

867866 20 Idler Gear (18T) (incl. 867921) 3

867871 Gear Case 1

867872 20 Spider (incl. 867922) 1

867921 20 & 30 Idler Gear Bearing 3

867922 Idler Gear Pin 3

869181 30 Idler Gear (16T) (incl. 867921) 3

869182 30 Spider (incl. 867922) 1

869554 40 Idler Gear (15T) 3

869584 Pinion Spacer 0 Model Only 1

869945 40 Spider (incl. 867922) 1

869949 Thrust Washer 40 Model Only 1

The complete gear cases can be purchased as a subassembly

using Part No. 20 - 861573, 30 - 861680, 40 - 861928.

-20, -30, & -40 GEAR TRAINS

PART NO.

832128

844364

847147

867902

867903

867904

867905

867906

867907

867921

PART NO.

867922

867925

869258

869259

869584

884125

QTY.

3

1

1

1

3

3

1

1

1

3

QTY.

3

3

3

1

1

3

NAME OF PART

7 & 10 2nd Red. Gear Pin

Retainer Ring

Spider Bearing

10 Rotor Pinion (15T)

10 1st Red.Gear (l5T) - incl. 867925

7 & 10 2nd Red. Gear (15T)

10 1st Red. Spider - incl. 884125

7 & 10 2nd Red. Spider - incl. 832128

Gear Case (45T)

7 1st Red. Gear Bearing

NAME OF PART

7 1st Red. Gear Pin

10 1st Red. Gear Bushing

7 1st Red. Gear (17T) - incl. 867921

7 1st Red. Spider - incl. 867922

10 Pinion Spacer

10 1st Red. Gear Pin

The complete gear cases can be purchased as a subassembly using Part No. 7 - 861719, 10 - 861578.

PARTS LIST —- 7, & - 10 GEAR TRAINS

- 7, & - 10 GEAR TRAINS

847147

844364 867907 867906

832128 867904

203062

-7 & -10 GEAR TRAINS

-7 869259

-10 867905

867902

-10 ONLY

869584

-7 867922

-10 884125 -7 869258

-10 867903

-7 867921

-10 867925

847147

844364

867922

- 20 867866

- 30 869181

- 40 869554

865862

- 40 MODEL ONLY

869584

- 40 MODEL ONLY

867871

869949

- 40 MODEL ONLY

- 20 867921

- 30 867921

- 40 NONE

- 20 867872

- 30 869182

- 40 869945

10

QUICK-CHANGE CHUCK

STALL TYPE SCREWDRIVER

GEAR TRAINS

QTY.

1

1

1

1

1

1

1

1

1

1

1

3

2

1

1

3

1

1

3

1

QTY.

1

3

3

1

1

3

3

3

3

3

1

1

3

1

3

3

1

1

3

PART NO.

202031

202032

202312

202827

202833

202835

202836

202837

202842

202959

619524

832128

833688

843635

844265

846177

864249

865862

867866

867871

PART NO.

867902

867903

867904

867905

867907

867921

867922

867925

869181

869258

869259

869553

869554

869584

869637

869640

869643

869645

884125

NAME OF PART

10 Pinion (15T)

10 Idler Gear (15T) (incl. 867925)

7 & 10 Idler Gear (15T)

10 1st Red. Spider (15T) -Incl. 884125

7 & 10 Gear Case (45T)

Gear Bearing

Gear Pin

10 Gear Bushing

30 Idler Gear (16T) - Incl. 867921

7 Idler Gear (17T) - Incl. 867921

7 Spider (15T) - Incl. 867922

40 Pinion Spacer

40 Idler Gear (15T)

10 Pinion Spacer

50 Idler Gear (15T) - Incl. 846177

Gear Pin

50 Gear Case (48T)

50 Pinion (18T)

10 Gear Pin

NAME OF PART

Bearing Retainer

Spindle Bearing (Front)

Bearing Spacer

7, 10 Spindle

Release Collar

20 Spindle

30 Spindle

40 Spindle

Spring

50 Spindle

Retainer Ring

Gear Pin

Retainer Ring

Spindle Bearing (Rear)

Ball (1/8")

Gear Bushing

Washer

40 Pinion (12T)

20 Idler Gear (18T) - Incl. 867921

20, 30, & 40 Gear Case (42T)

PARTS LIST

The complete gear train can be purchased as a subassembly using part numbers below.

7 —201228 30 —201231

10*—201229 40 —201232

*Does not include pinion spacer 20 —201230 50 —201251

O

F

F

619524

864249

202842

202833 833688

864249

202031

202032

202312

843635

844265

867904

832128

869259 -7

867905 -10

869553

(-40 Only)

O

F

F

619524

864249

202842

202833 833688

864249

202031

202032

202312

843635 844265

833688

202827 -7, -10

202835 -20

202836 -30

202837 -40

202959 -50

867907

867922 -7

884125 -10

867921 -7

867925 -10

869258 -7

867903 -10

867902

(-10 Only)

869584

(-10 Only)

867922 -20

867922 -30

867922 -40

869640 -50

867921 -20

867921 -30

846177 -40

846177 -50

867866 -20

869181 -30

869554 -40

869637 -50

867871 -20

867871 -30

867871 -40

869643 -50

None -20

None -30

865862 -40

869645 -50

833688

11

REAR BEARING PLATE

Non-Rev. 867854

Rev. 867937

REAR CYLINDER PIN

Non-Rev. Lever 833718

Rev. Lever 812167

Rev. Offset 812167

Rev. Pistol 844234

847609

CYLINDER

Type Part No.

Non-Rev. 867853

Rev. 867936

863738

844234

847603

Pistol Models

Only

SPACER

Model Part No.

-7 869180

-30

-10 867873

-20

-40 867873

-50

FRONT BEARING

Model Part No.

-7 847095

-30

-10 847609

-20

-40

-50

ROTOR

Model Part No.

-7 869183

-30

-10 867880

-20

-40

-50

FRONT BEARING PLATE

Model Lever Pistol Offset

-7 869179 869179 869179

-10 867855 867935 867855

-20 867855 867935 867855

-30 869179 869179 869179

-40 867855 867855 867935

-50 867855 867935

MOTORS

NAME OF PART

Spacer

Rotor (6T)

Bearing Plate

Cylinder

Bearing Plate

Rotor (9T)

Bearing Plate

Spacer

Rotor (9T)

PART NO.

812167

833718

844234

847095

847603

847609

863738

867853

867854

867855

NAME OF PART

Cylinder Pin

Cyiinder Pin

Cylinder Pin (Rev. Pistol requires two (2))

Rotor Bearing

Alignment Pin

Rotor Bearing (7 & 30 require one (1 ) only)

Rotor Blade

Cylinder

Bearing Plate

Bearing Plate

QTY.

1

1

1

1

1

2

4

1

1

1

PART NO.

867873

867880

867935

867936

867937

869178

869179

869180

869183

QTY.

1

1

1

1

1

1

1

1

1

PARTS LIST —MOTORS

COMPLETE MOTOR SUBASSEMBLIES

HANDLE STYLE

MODEL LEVER OFFSET PISTOL GRIP

7

10

20

30

40

50

Non-Rev. Rev. Rev. Rev.

861684

861588

861684

861588

-

861686

861572

861686

861572

-

861686

861572

861686

861572

861572

861685

861595

861685

861595

861595

12

ROLLING IMPULSE AND STALL

LEVER HANDLE FOR RSCL AND SCL

Valve Block

Exhaust Deflector

Throttle Lever

Inlet Bushing (incl. 833300)

Reversing Valve Retainer Screw

Throttle Valve

Backhead

Reversible Backhead

Reversing Valve (Opt.)

Muffler

PART NO.

202410

202674

412603

832207

832636

833300

844060

847426

863454

865728

865770

NAME OF PART

Throttle Lever Pin

Reversing Valve (Non-locking Std.)

Bail

Throttle Valve Cap

Throttle Valve Cap Gasket

Inlet Screen

Throttle Valve Spring (incl. 847426)

Throttle Valve Seal

"O"-Ring 9/16" x 11/16"

Inlet Screen Spring

Reversing Valve Spring

QTY.

1

1

1

1

1

1

1

1

1

1

1

QTY.

1

1

1

1

1

1

1

1

1

1

PARTS LIST —ROLLING IMPULSE AND STALL LEVER HANDLE

PART NO. NAME OF PART

867857*

867874

867877

867882

867878

869036

869044

869045

869253

869510

The complete handles can be purchased as a subassembly using Part No. Non-Reversible - 861628, Reversible - 861629.

*Parts not included in sub-assembly.

863454

833300

865728 867882

867857

Non-Rev. Tools Only

Reversible Tools Only

Non-Rev. 869044

Rev. 869045

412603

869510

867874

202410

867877

844060

832636

832207

869036

847426

869253 Locking (Opt.)

202674 Non-locking (Std.)

865770

867878

13

REVERSIBLE OFFSET HANDLE

FOR RNO, RSO AND RSCO

201905

202020

202339

202674

412775

833303

847033

847411

847767

844787

865770

867878

867911

867915

867916

869200

869253

869350

Trigger Assembly

Drive Screw

3 Caution Label

Non-Locking Reversing Valve

Air Inlet Screen

Muffler Screen

Muffler Screen Retainer

O-Ring 11/16" X 13/16"

Throttle Valve Spring

Trigger Pin

Reversing Valve Spring

Reversing Valve Retainer Screw

Throttle Link Pin

Reversible Handle

Air Inlet Bushing

Muffler

Locking Reversing Valve

Throttle Valve

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Part No. Name of Part Qty. Part No. Name of Part Qty.

The complete Offset handle can be purchased as a subassembly using part no. 861581.

The handle includes non-locking reversing valve 202674.

844787

867911

847033

833303869200 869350 412775

847767

847272

847411 867916

867915

202339 202020

869253 Locking

202674 Non-locking

865770

867878

201905

14

PART NO.

201905

202773

202782

202828

202951

412775

613749

833303

843572

844787

847033

847272

847411

QTY.

1

1

1

1

1

1

1

1

1

1

1

2

1

QTY.

1

1

1

1

1

1

1

PART NO.

867898

867899

867926

867929

867933

867939

869852

NAME OF PART

Reversing Valve

Motor Block

"O"-Ring 1/16" x 1/16"

Air Inlet Bushing

Muffler

Throttle Link Pin

Reversing Knob

The complete handle can be purchased as a subassembly using Part No. 861582.

NAME OF PART

Trigger Assembly

Backhead Reversible

Valve Seal

Throttle Valve

Throttle Valve Spring

Air Inlet Screen

Reversing Knob Screw

MufflerScreen

Plug

Trigger Pin

Retainer Ring

"O"-Ring 5/8" x 3/4"

"O"-Ring 11/16" x 13/16"

R

867898 867926617290

613749

869852

844787

867939

847033

833303 867933

202782

202828 412775

202951 847272

847411 867929

202760 847272 843572

202773

201905

PARTS LIST —PISTOL HANDLE WITH TRIGGER

PISTOL HANDLE WITH

TRIGGER FOR RSCP,

RSP AND RNP

15

NOTES

Sales & Service Centers

Note: All locations may not service all products. Please contact the nearest Sales & Service Center for

the appropriate facility to handle your service requirements.

Dallas, TX Detroit, MI Houston, TX Lexington, SC

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center 670 Industrial Drive

1470 Post & Paddock 2630 Superior Court 6550 West Sam Houston Lexington, SC 29072

Grand Prairie, TX 75050 Auburn Hills, MI 48326 Parkway North, Suite 200 Tel: 800-845-5629

Tel: 972-641-9563 Tel: 248-391-3700 Houston, TX 77041 Tel: 803-951-7544

Fax: 972-641-9674 Fax: 248-391-7824 Tel: 713-849-2364 Fax: 803-358-7681

Fax: 713-849-2047

Los Angeles, CA Seattle, WA York, PA Canada

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center Sales & Service Center

15503 Blackburn Avenue 2865 152nd Avenue N.E. 3990 East Market Street 5925 McLaughlin Road

Norwalk, CA 90650 Redmond, WA 98052 York, PA 17402 Mississauga, Ont. L5R 1B8

Tel: 562-623-4457 Tel: 425-497-0476 Tel: 717-755-2933 Canada

Fax: 562-802-1718 Fax: 425-497-0496 Fax: 717-757-5063 Tel: 905-501-4785

Fax: 905-501-4786

Germany England France China

Cooper Power Tools Cooper Power Tools Cooper Power Tools SAS Cooper (China) Co., Ltd.

GmbH & Co. OHG GmbH & Co. OHG a company of a company of

a company of a company of Apex Tool Group, LLC Apex Tool Group, LLC

Apex Tool Group, LLC Apex Tool Group, LLC 25 rue Maurice Chevalier 955 Sheng Li Road,

Industriestraße 1 C/O Spline Gauges 77330 Ozoir-La-Ferrière Heqing Pudong, Shanghai

73463 Westhausen Piccadilly, Tamworth France China 201201

Germany Staffordshire B78 2ER Tel: +33 1 6443 2200 Tel: +86-21-28994176

Tel: +49 (0) 73 63 81 0 United Kingdom Fax: +33 1 6443 1717 Fax: +86-21-51118446

Fax: +49 (0) 73 63 81 222 Tel: +44 1827 8741 28

Fax: +44 1827 8741 28

Mexico Brazil Hungary

Cooper Tools Cooper Tools Industrial Ltda. Cooper Tools Hungaria Kft.

de México S.A. de C.V. a company of a company of

a company of Apex Tool Group, LLC Apex Tool Group, LLC

Apex Tool Group, LLC Av. Liberdade, 4055 Berkenyefa sor 7

Vialidad El Pueblito #103 Zona Industrial - Iporanga Pf: 640

Parque Industrial Querétaro 18087-170 Sorocaba 9027 Györ

Querétaro, QRO 76220 SP Brazil Hungary

Mexico Tel: +55 15 2383929 Tel: +36 96 66 1383

Tel: +52 (442) 211-3800 Fax: +55 15 2383260 Fax: +36 96 66 1135

Fax: +52 (442) 103-0443

823126/Printed in USA 04/2011/Copyright © Apex Tool Group, LLC

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: 919-387-0099

Fax: 919-387-2614

www.apextoolgroup.com

Table of contents

Other Cleco Power Screwdriver manuals

Cleco

Cleco 19P Series User manual

Cleco

Cleco 19BPA User manual

Cleco

Cleco 823150PT Installation and operating instructions

Cleco

Cleco 19P Series User manual

Cleco

Cleco BRSAUPT User manual

Cleco

Cleco 19PTA-2343 User manual

Cleco

Cleco 19PTA-2343 User manual

Cleco

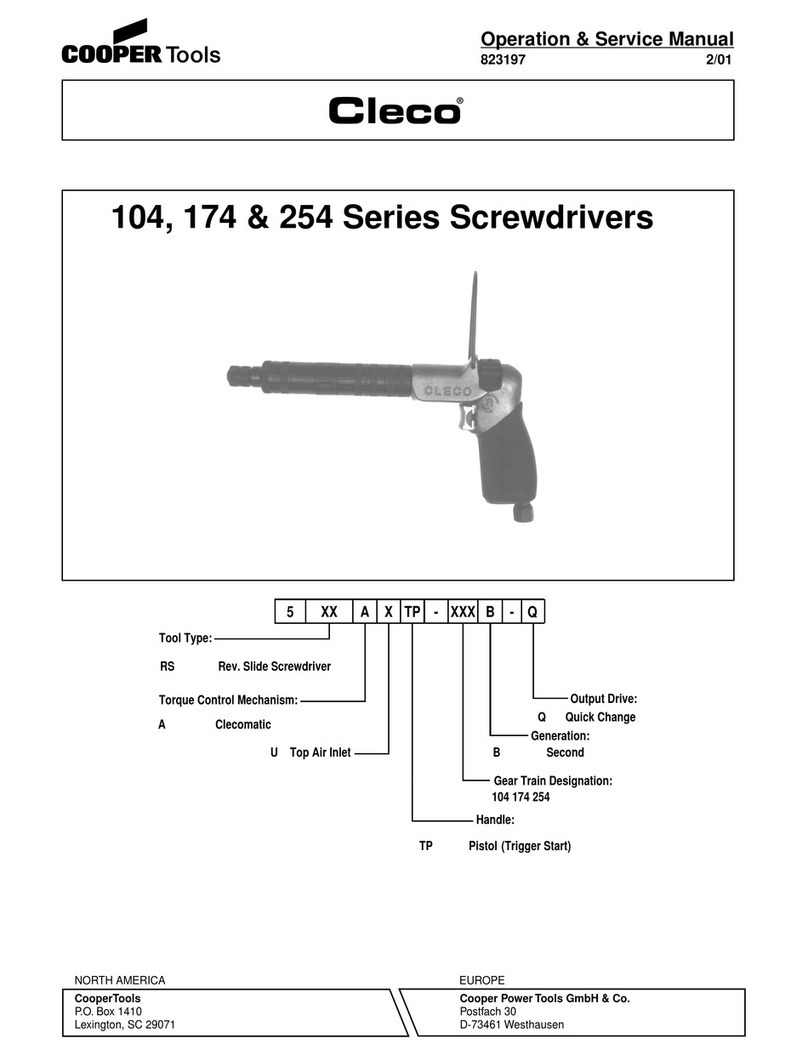

Cleco 104 Series Installation and operating instructions

Popular Power Screwdriver manuals by other brands

Meister

Meister BAS 108 LIO Translation of the original operating instructions

ALDI

ALDI WSD 3.6-2 user manual

Parkside

Parkside PAS 3.6 A1 Operation and safety notes

Metabo

Metabo PowerMaxx Li LC 60 operating instructions

S-BOL

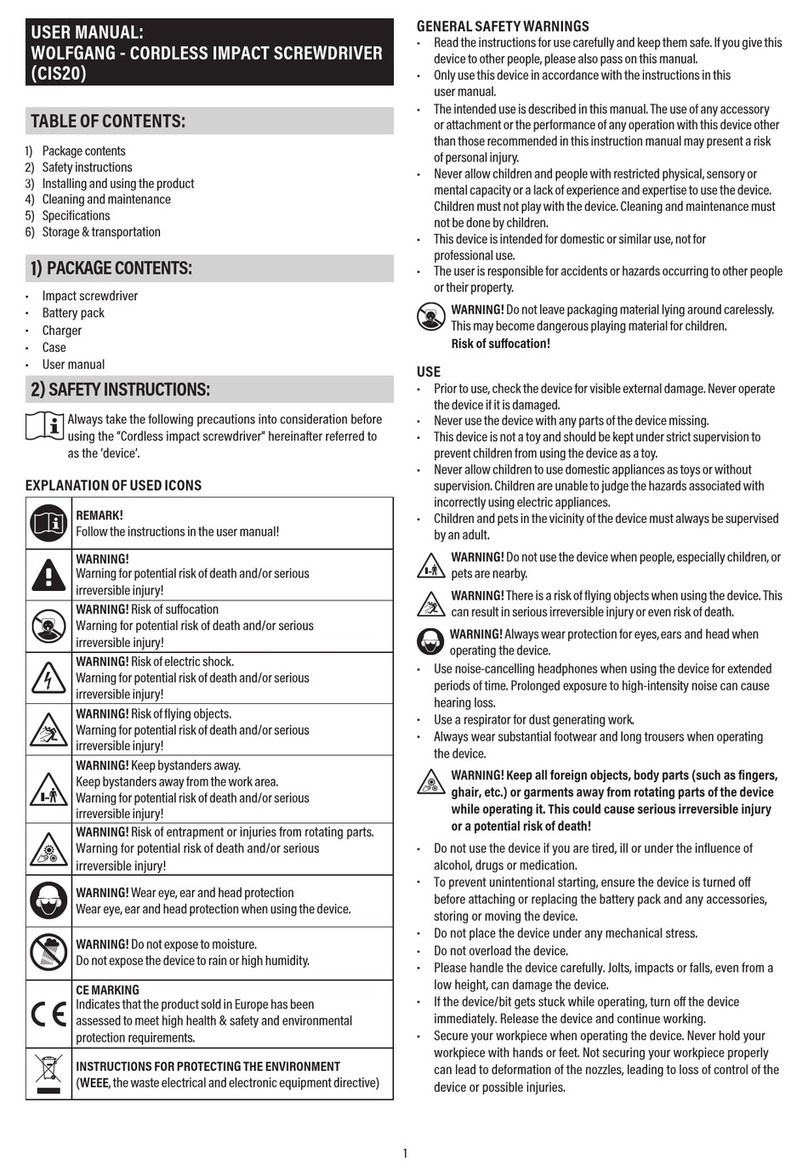

S-BOL WOLFGANG CIS20 user manual

Dexter Laundry

Dexter Laundry 3.6VSD2.5 instruction manual