Revision: 01.2015

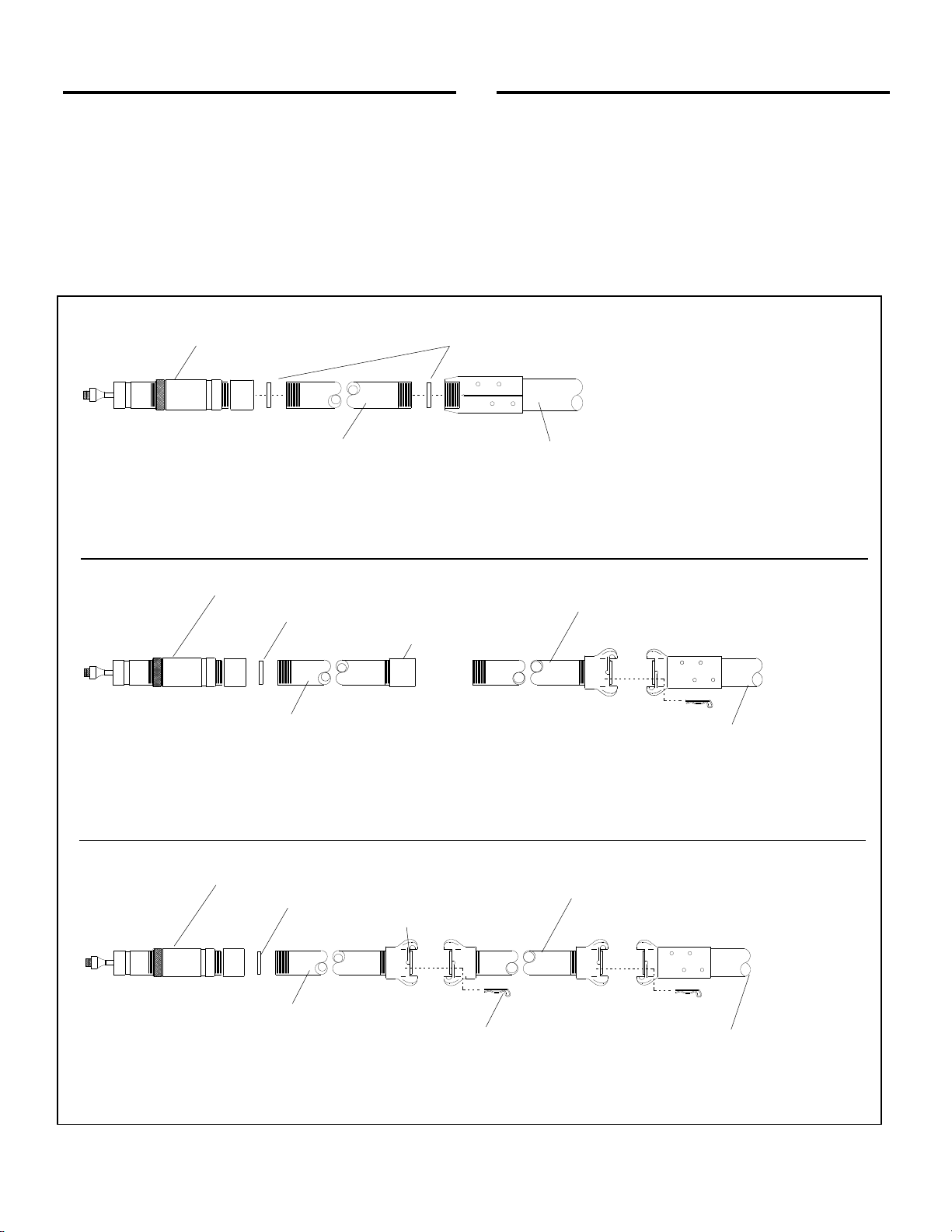

Figure 3-A is the basic setup; it should be used with all lance

setups. Alone it is suitable for blasting short lengths (the

length of the heavy-walled lance) of pipe or cylinders.

Figure 3-B is the basic setup, plus additional standard 1-1/4

pipe lance, attached with threaded pipe couplings. This setup

uses standard threaded pipe couplings to connect the lance

sections together. Using threaded pipe couplings allows it to

fit inside of 3-1/4" diameter and smaller pipe where a quick

coupling will not fit. The threaded couplings require the lance

be screwed on or off when adding or removing sections. The

threads are prone to galling, so the setup in Figure 3-C should

be used whenever possible.

Figure 3-C is the basic setup, plus additional standard 1-1/4

pipe lances, attached with quick couplings. This uses quick

couplings to connect lance sections together. Quick couplings

eliminate the need to rotate the lance when adding or

removing sections. It is limited to use with pipe diameters that

are 3-1/2" diameter and larger that will accommodate the

quick couplings.

2.5 Abrasive

2.5.1 DO NOT USE abrasives containing more than one

percent crystalline (free) silica. Obtain safety data sheets

(SDS) for the blasting abrasive prior to blasting, paying

particular attention the health risks and presence of any

hazardous/toxic substances. Use only abrasives specifically

manufactured for blasting, and that are compatible with the

surface being blasted. Abrasive produced for other

applications may be inconsistent in size and shape, and

contain particles that could jam the abrasive metering valve,

or cause irregular wear. Steel grit is an ideal media to use if

adequate recovery means are available.

2.5.2 Silicon Carbide, Aluminum Oxide, and Garnet:

Aggressive abrasives such as these should be avoided unless

required by job specification. Service life will be reduced

on any components which come in contact with these

abrasives. When an aggressive abrasive must be used,

use a boron carbide or composite deflection tip and

boron sleeves. Boron tips may chip when using large,

aggressive abrasive. Use a composite tip for 36-mesh

and coarser aggressive abrasive.

2.5.3 Abrasive Size

2.5.3.1 The choice of abrasive size depends on the

desiredprofile,cleaningrate,andnozzlesize.Generally,

larger and denser abrasives provide a deeper profile,

whilesmaller abrasivescleanfaster.Withthe 1/2" orifice

nozzle, use 25-mesh and finer; with the 5/8" orifice

nozzle, use 16-mesh and finer.

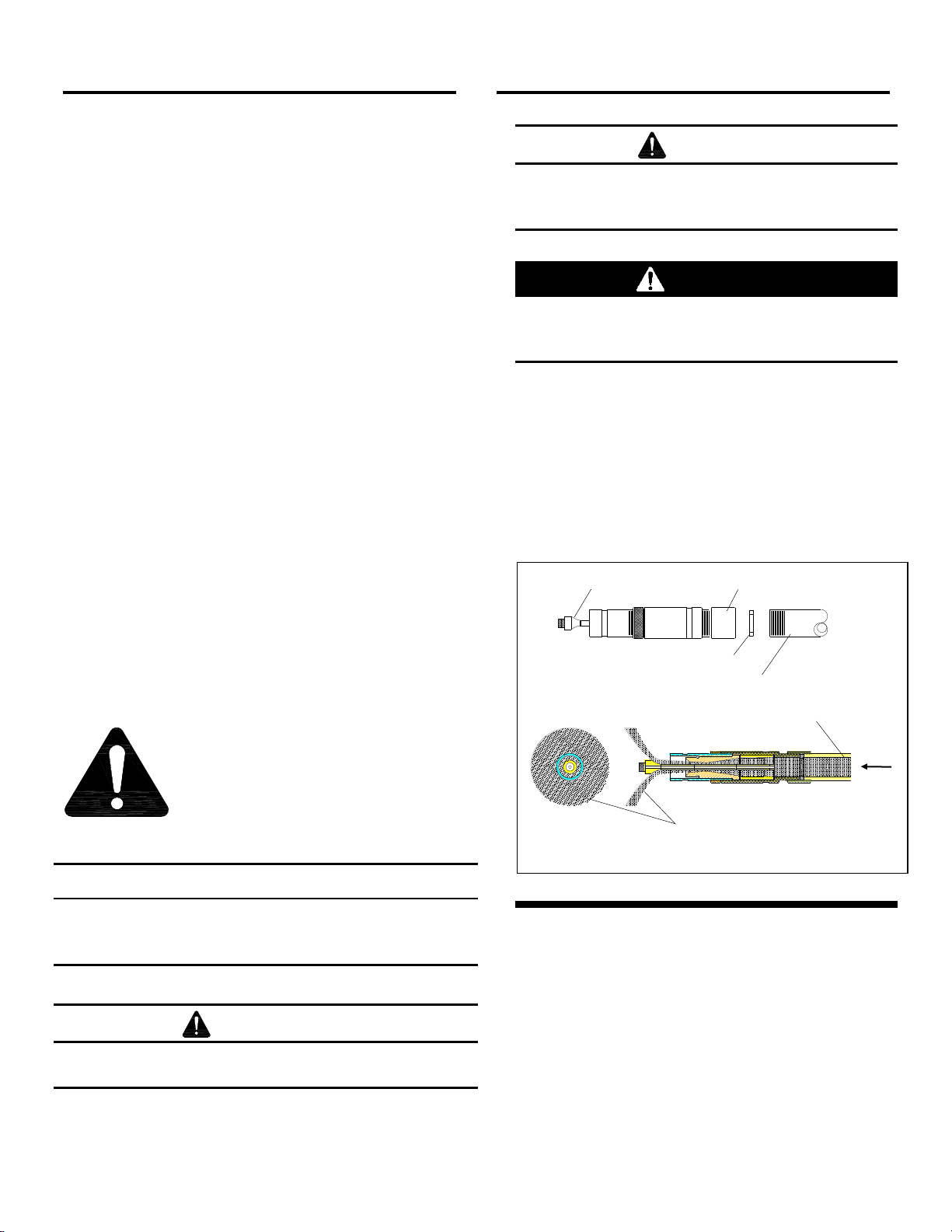

3.0 Attach Centering Device

3.1 Collar and Buttons, 3" to 5", Model HBC-1

Figures 4-A and 4-B

Collars without buttons fit inside 2-3/4" ID pipe, which

must be smooth and without seams or other

protrusions.

3.1.1 The set comes with two collars of different

inside diameters and six each of four different length

buttons to center the tool in 3" to 5" pipe. Refer to the

following steps for assembly. Additional collar and

buttons could be used to support the lance.

1. Slide the front collar over the tip protection sleeve. Align the collar setscrew with the groove in the protection

sleeve. Using the 3/16" hex key provided, tighten the setscrew to secure. Repeat the process to secure the

rear collar to the tool holder.

Figure 4-A

Front Collar has smaller

inside diameter

Rear Collar has larger

inside diameter