INSPECTION

Before unpacking visually inspect the unit for evidence

of damage during shipping.

If damage is noticed, do not unpack the unit, follow

shipping damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later.

2. As soon as damage is discovered or suspected,

notify the carrier that delivered the shipment.

3. Arrange for the carrier's representative to examine

the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

GENERAL

Installation of the kettle must be accomplished by

qualified installation personnel working to all applicable

local and national codes. Improper installation of

product could cause injury or damage.

This equipment is built to comply with applicable

standards for manufacturers. Included among those

approval agencies are: UL, A.G.A., NSF, ASME/N.Bd.,

CSA, CGA, ETL, and others. Many local codes exist,

and it is the responsibility of the owner/installer to

comply with these codes.

Observe all clearance requirements to provide proper

make-up air flow. Do not obstruct the flow of combustion

and ventilation air. Check rating plate to ensure that

kettle has been equipped to operate with the type of

gas available at the installation.

VENTILATION

Gas fired kettles are only to be installed under a

ventilation hood in a room which has provisions for

adequate make up air. Further information can be

obtained by referring to the U.S.A. National Fire

Protection Associations NFPA96 regulations. These

standards have also been adopted by the National

Building Code in Canada.

CLEARANCE REQUIREMENTS

This unit must be installed in accordance with the

clearances shown on the rating label which is adhered

to the unit.

FOR YOUR SAFETY. Keep the appliance area free and

clear of combustible materials.

GAS

ENSURE THE GAS SUPPLY MATCHES THE

KETTLE'S REQUIREMENTS AS STATED ON THE

RATING PLATE.

It is recommended that a sediment trap (drip leg) be

installed in the gas supply line. If the gas pressure

exceeds 14” water column, a pressure regulator must

be installed, to provide a maximum of 14” water column

gas pressure to the gas control valve.

Connect the gas line to the manual valve located at the

rear of the control box.

Installation must be in accordance with local codes

and/or the National Fuel Gas Code ANSI Z223.1 Latest

Edition (USA) or the latest Installation Codes for Gas

Burning Appliances and Equipment CAN/ CGA B149.1

and CAN/ CGA B149.2 (Canada). Use a gas pipe joint

compound which is resistant to L.P. gas. Test all pipe

joints for leaks with soap and water solution. Ensure that

the gas pressure regulator is set for the manifold

pressure indicated on the gas rating plate.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa). The appliance must be

isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.45 kPa).

WATER

The sealed jacket of the gas-fired kettle is precharged

with the correct amount of a water-based formula, and

therefore, no water connection is required to the kettle

jacket. The kettle can be equipped with optional hot and

cold water taps, the taps require 1/2" copper tubing as

supply lines.

CLEANING

After installation the kettle must be thoroughly cleaned

and sanitized prior to cooking.

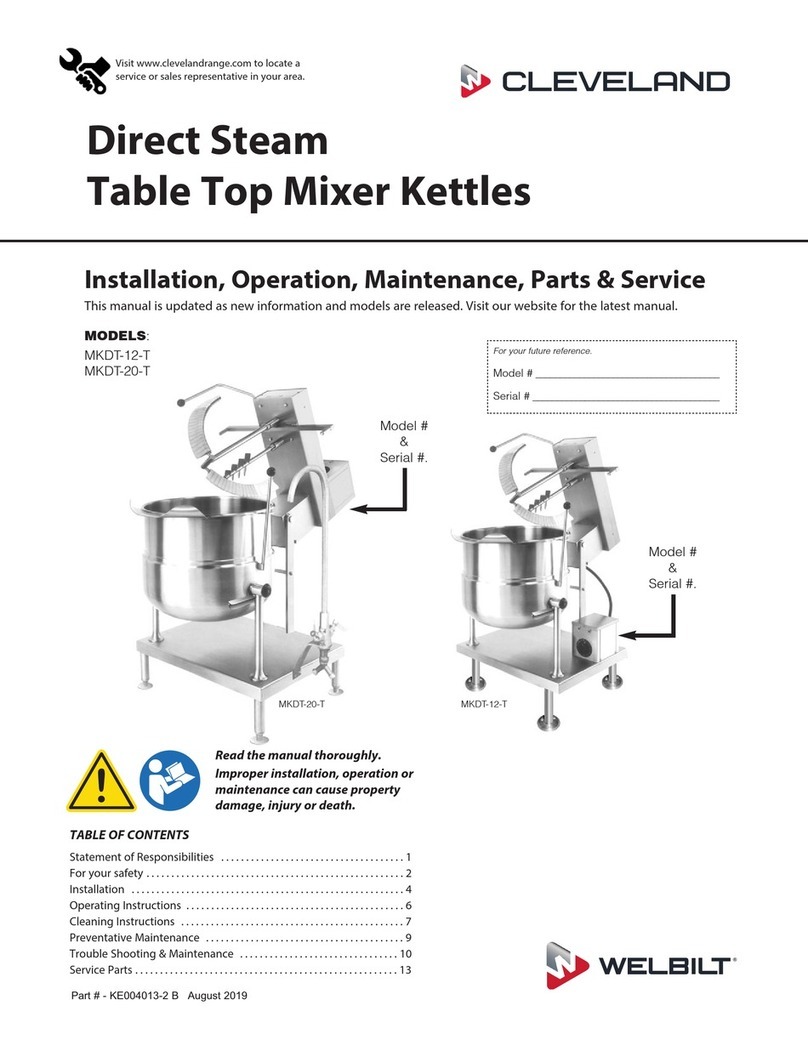

INSTALLATION